7

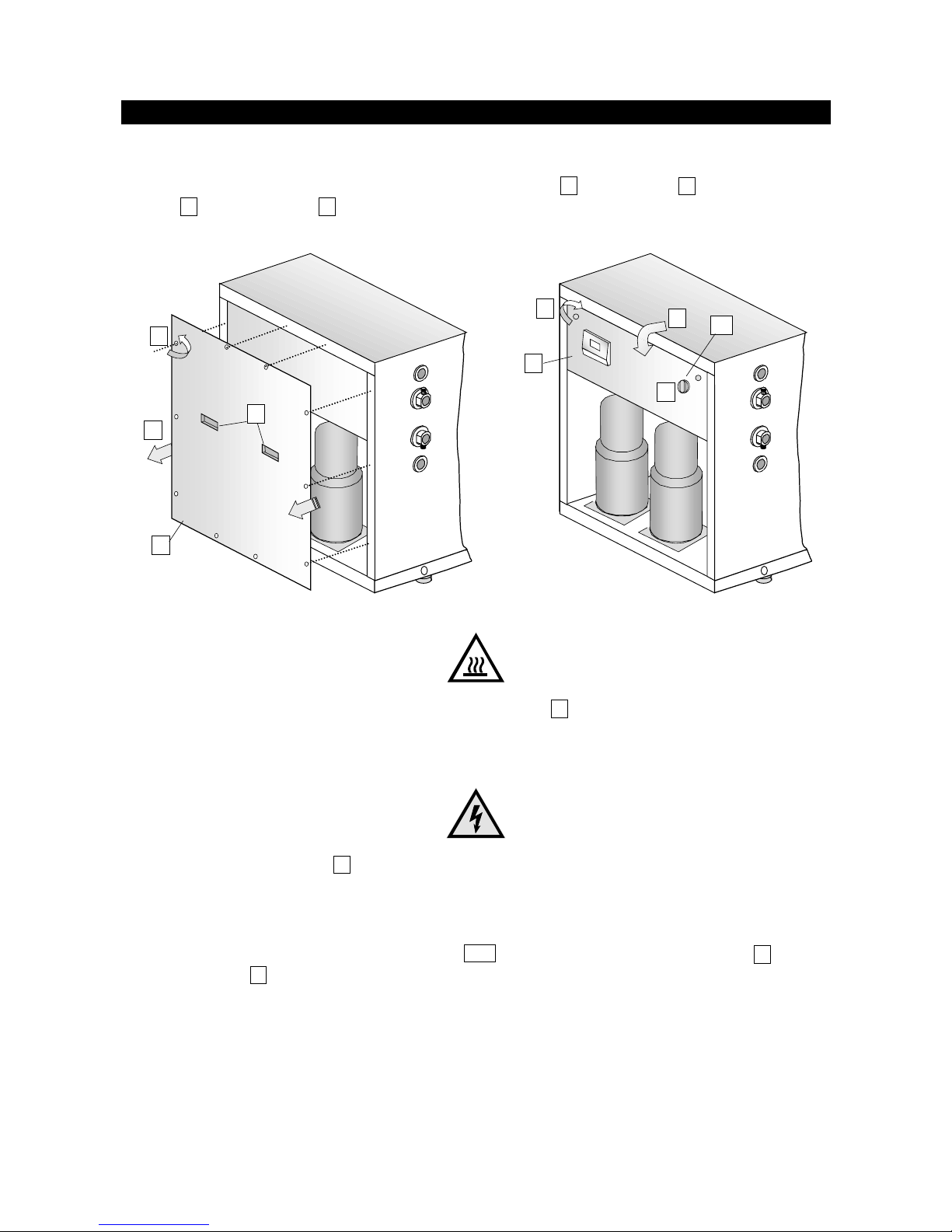

AVAILABLE VERSIONS AND ACCESSORIES

Models ARA00152 (only M versions), ARA00182, ARA00202, ARA00232, ARA00252,

ARA00302, ARA00403 (not supplied for E and M versions), ARA00504 (not

supplied for E and M versions)

Configurations A : Basic version: mechanical cooling with on-off condensation control

D: Basic version with modulating condensation control

L: Ultra low-noise version with modulating condensation control

H: Heat pump with on-off condensation control

P: Heat pump with modulating condensation control

Q: Ultra low-noise heat pump with modulating condensation control

E: Free cooling version with modulating condensation control

M: Ultra low-noise free cooling version with modulating condensation control

Pump group Group with 1 type A pump (0.9 kW)

Group with 2 type A pumps (0.9 kW)

Group with 1 type B pump (1.1 kW)

Group with 2 type B pumps (1.1 kW)

Group with 1 type C pump (1.85 kW)

Group with 2 type C pumps (1.85 kW)

Reservoir tank

(only with pump group)

Tank type “A” (210 litres)

Tank type “B” (300 litres)

Tank type “C” (500 litres)

Heat recovery Partial heat recovery (with modulating condensation control as standard - not supplied

for heat pump versions)

Power supply 400V/3ph+N/50Hz

Electrical accessories Power phase correction capacitors

Control Basic control (not available on free-cooling versions)

Basic control with remote terminal (not available on free-cooling versions)

mP20 control without user terminal (not available on heat pumps)

mP20 control with local user terminal (not available on heat pumps)

mP20 control with remote user terminal (not available on heat pumps)

Serial connections LAN (with mP20 control)

RS485 serial output (with basic control)

RS485 serial output (with mP20 control)

RS422 serial output + LAN (with mP20 control)

RS485 serial output + LAN (with mP20 control)

Refrigerant R22

R407C

R134a

Norms ISPESL (Italian)

TÜV (German)

Refrigerant Accessories Anti-freeze heater on evaporator (not supplied for Free cooling versions)

Anti-freeze heater on pumps (not supplied for Free cooling versions)

Anti-freeze heater on tank (not supplied for Free cooling versions)

High/Low pressure manometers

Pressure sensors Low pressure sensor (with mP20 control only)

High pressure sensor

Options Rubber anti-vibration feet

Coil protection grilles

Metal filters for free cooling coil.