4

General instructions

•Plastic bags and packaging materials pose danger to small children or animals.

•Make sure you know your machine and you are familiar with its operating procedure. Know the hazards

if not used correctly.

•Person using this machine must know how to safely operate this equipment, must be properly trained and

familiar with hazards and risk that may occur during use of this machine.

•Always pay special attention to safety instructions stated on the labels. Do not remove or damage them.

If the warning label becomes unreadable or damaged please, contact your vendor.

•Keep your working place clean. Disorganized working area may cause accidents.

•Never work in tight working spaces or poorly lit rooms. Make sure the floor is solid and stable and that

you can move around easily. Maintain stable posture during work.

•Observe your work continuously and use all your senses during work. Do not continue to work if you

cannot pay attention.

•Maintain your tools clean.

•Handles must be kept free of grease and dirt.

•Make sure no children, unauthorized persons or animals have access to your workshop.

•Never put your hands or legs inside the working area.

•Never leave your machine unattended during operation.

•Use only for purposes for which it has been designed.

•Use personal protective gear such as safety goggles, ear protection, respirator, safe working shoes etc.

•Do not overreach and use both hands.

•Never work under the influence of alcohol or other drugs.

•Do not use the machine if you feel dizzy or weak.

•Any modifications or improvements to the machine are strictly prohibited. DO NOT USE if you discover

any cracks or damages to the machine.

•Never perform any maintenance during operation.

•If you see any unusual sign or hear any strange sound, switch off your machine and stop working

immediately.

•Do not forget to remove all wrenches and screwdrivers from your machine after use.

•Before use, make sure all screws are tightened securely.

•Perform maintenance regularly. Before use make sure the machine is in good working conditions

and without any damage.

•Use only original spare parts for repairs.

•Using non-original spare parts or other parts not approved by the manufacturer may cause injury to the

operating personnel.

•Use this machine only for work that is capable of handling. Do not overload your machine or accessories.

Do not attempt to use machine with insufficient power to perform heavy duty work.

•Do not overload your machine. Measure the work load in such way, so it could be done with comfortable

speed. Damages due to machine overload are not covered by warranty.

•Do not expose to extremely high temperature or direct sunlight.

•This machine is not designed for use in humid environments or under water.

•if you are not using your machine, store it in a dry and safe place, out of reach of children.

•Before use make sure that all safety elements work correctly and efficiently. Make sure all moving parts

are in good working conditions.

13

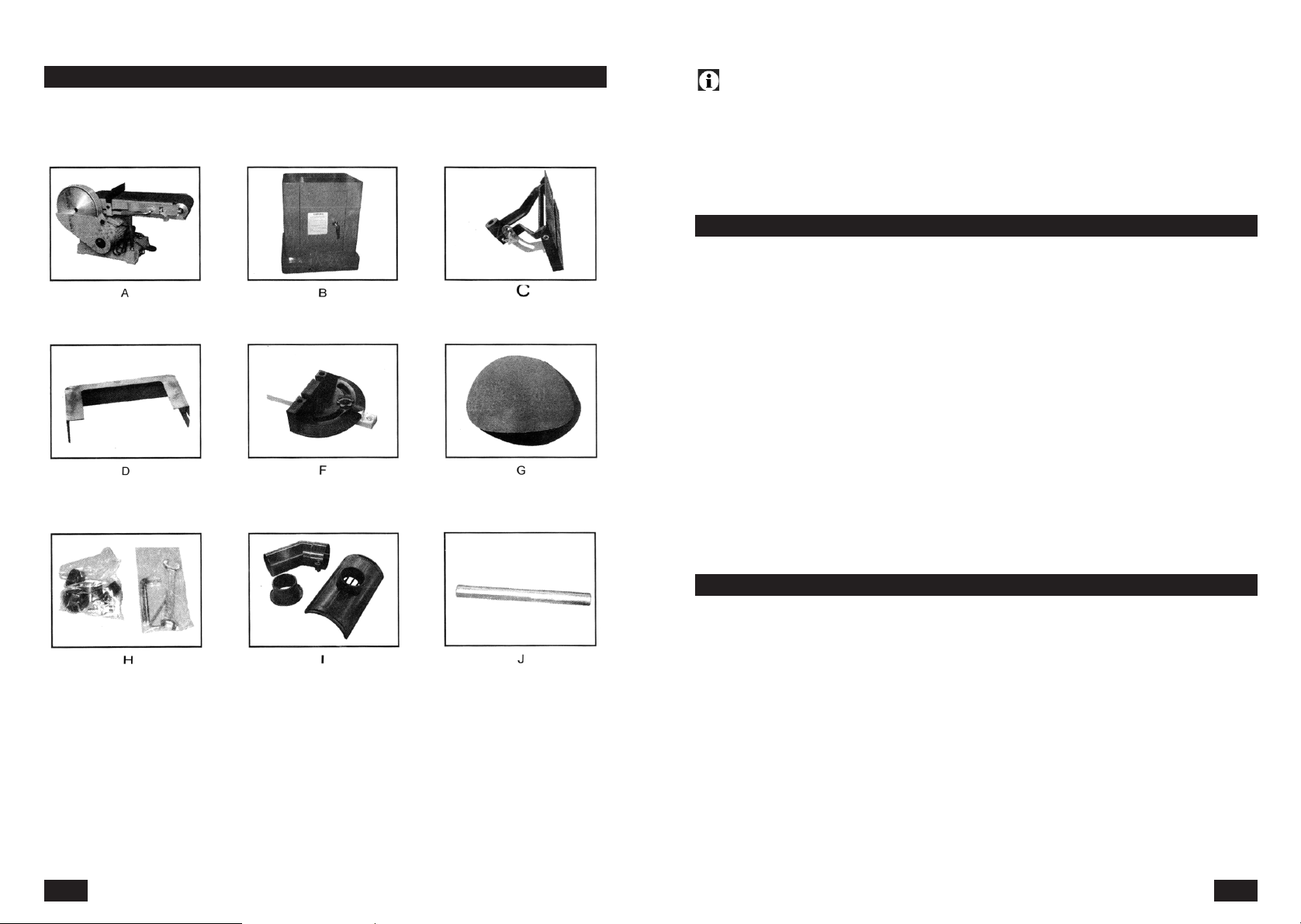

SEZNAM DÍLŮ

No. DESCRIPTION NUMBER

OF PIECES

1 SETTING SCREW M8 x 35 2

2 NUT M8 13

3 WORKTABLE 1

4 GRINDING BELT 1

5 ANGLE RULER 1

6 SCREW M4 × 10 8

7 WASHER 4 3

8 SAWDUST VACUUM ADAPTER 1

9 SAWDUST VACUUM HOUSING 1

10 SETTING SCREW M8 x20 4

11 DRIVING ROLLER 1

12 WASHER 8 13

13 SAFETY WASHER 13

14 TONGUE 5 × 40 1

15 DRIVING SHAFT 1

16 SAFETY RING 9

17 BALL BEARING 3

18 REAR STOPPER 1

19 SCREW WITH HEAD M8×25 2

20 TENSIONING GEAR 2

21 TENSIONING HANDLE 1

22 WORKTABLE 1

23 HANDLE GRIP 1

24 BALL BEARING 1

25 SAFETY RING 35 1

26 SAFETY RING 15 1

27 SCREW WITH HEXAGONAL

HEAD M8 × 30 1

28 SUPPORT BASE 4

29 GRINDING BELT COVER 1

30 SAFETY SCREW M8 1

31 SETTING NUT 4

32 SETTING NUT 5

33 SPRING 5

34 SPRING 5

35 SCREW WITH HEAD M5×16 5

36 TENSIONING PULLEY 15

37 GUIDING PULLEY STUD 1

No. DESCRIPTION NUMBER

OF PIECES

38 SWITCH 1

39 SUPPLY CABLE 1

40 SWITCH 1

41 BASE 1

42 TENSION RELEASING MECHANISM 2

43 SUPPORTING ROD 1

44 HEXAGONAL NUT M16 1

45 SETTING SCREW M8 x 12 4

46 MOTOR 1

47 TONGUE 1

48 GRINDING PAPER 1

49 SCREW M6 × 12 1

50 SAFETY WASHER 1

51 INSERT PIECE 1

52 WHEEL 1

53 V-belt 1

54 SCREW M6 × 20 1

55 MOTOR BELT PULLEY 1

56 HANDLE 1

57 GRINDING BELT COVER 1

58 SAFETY STUD 2

59 SCREW M8 × 12 3

60 SAWDUST VACUUM HOUSING 1

61 SELF-CUTTING SCREW M4 × 10 3

62 HEXAGONAL NUT M6 1

63 TABLE CONSOLE 1

64 SAFETY STUD 1

65 DIAL 1

66 ANGLE GAUGE 1

67 PEDESTAL 1

68 FUSE 1

69 SWITCHBOARD 1

70 RUBBER FOOTING 4

71 COVER 1

72 SCREW WITH HEXAGONAL HEAD

M8 × 16 4

73 RUBBER COVER PLUG 1

74 DESK WITH GRAPHITE SURFACE 1