3

Lathe turning operations:

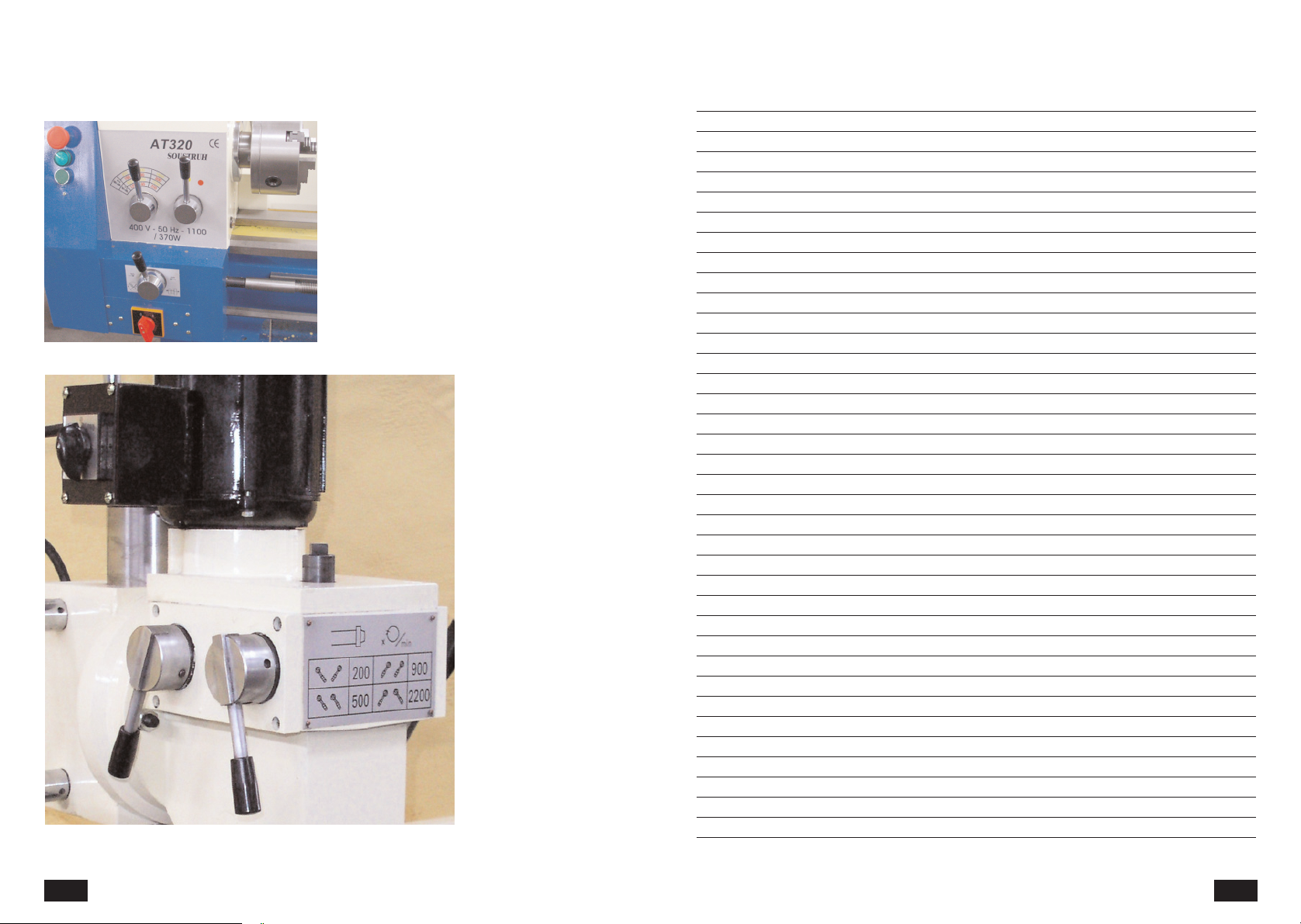

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~400 V / 50 Hz

Power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,100 + 370 W

Maximum cutting diameter above the bed (L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .∅320 mm

Maximum cutting diameter above the support (S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .∅200 mm

Maximum work piece length (X) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .750 mm

Inner chuck diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .∅38 mm

Chuck cone (lathe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Mk

Tailstock cone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Mk

Speed (revolutions) range (lathe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 - 1,600 (12) rpm

M thread pitch (degree) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5 - 4 (17) mm (degree)

W thread pitch (degree) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 - 40 (20) 1/" (degree)

Maximum cutting knife feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 mm

Maximum feed of the cross support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500 mm

Maximum longitudinal feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .750 mm

Automatic longitudinal feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.01 - 1.5 mm/revolution

Automatic cross feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.025 - 0.34 mm/revolution

Continuous setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .NONE

Adjustable longitudinal feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

Adjustable cross feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

Tailstock range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 mm

Number of uni chuck jaws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Fastening diameter of the uni chuck outer/inner (Ui/o) . . . . . . . . . . . . . . . . . . . . . . . . .∅160/200 mm

Speed (revolutions) setting (milling/drilling machine) . . . . . . . . . . . . . . . . .260 - 2,620 (4) rpm (degree)

Head tilt angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Table dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280 × 130 mm

Spindle cone (milling/drilling machine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Mk

Max. drill diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .∅16 mm

Fine spindle feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200/60 mm

Spindle set out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180 mm

Maximum distance between the spindle and the table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265 mm

Overall dimensions (l x w x h), excluding the base . . . . . . . . . . . . . . . . . . . . .1,500 × 625 × 1,200 mm

Gross weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400 kg

TECHNICAL SPECIFICATION

The accuracy of instructions, graphs and information contained herein, depends on the printing date. Due to

continuous product improvement, the manufacturer reserves the right to change technical parameters of the

product, without prior customer notification.