Heavy Duty Assisted Lift Trunnion Operation and Maintenance Manual Form Reference C64.65546

Issue 5.00

1 of 39 Issue Date May 2021

Table of Contents

Document Control ....................................................................................................................... 2

Introduction ................................................................................................................................ 4

Product Labelling ........................................................................................................................ 5

Safety .......................................................................................................................................... 6

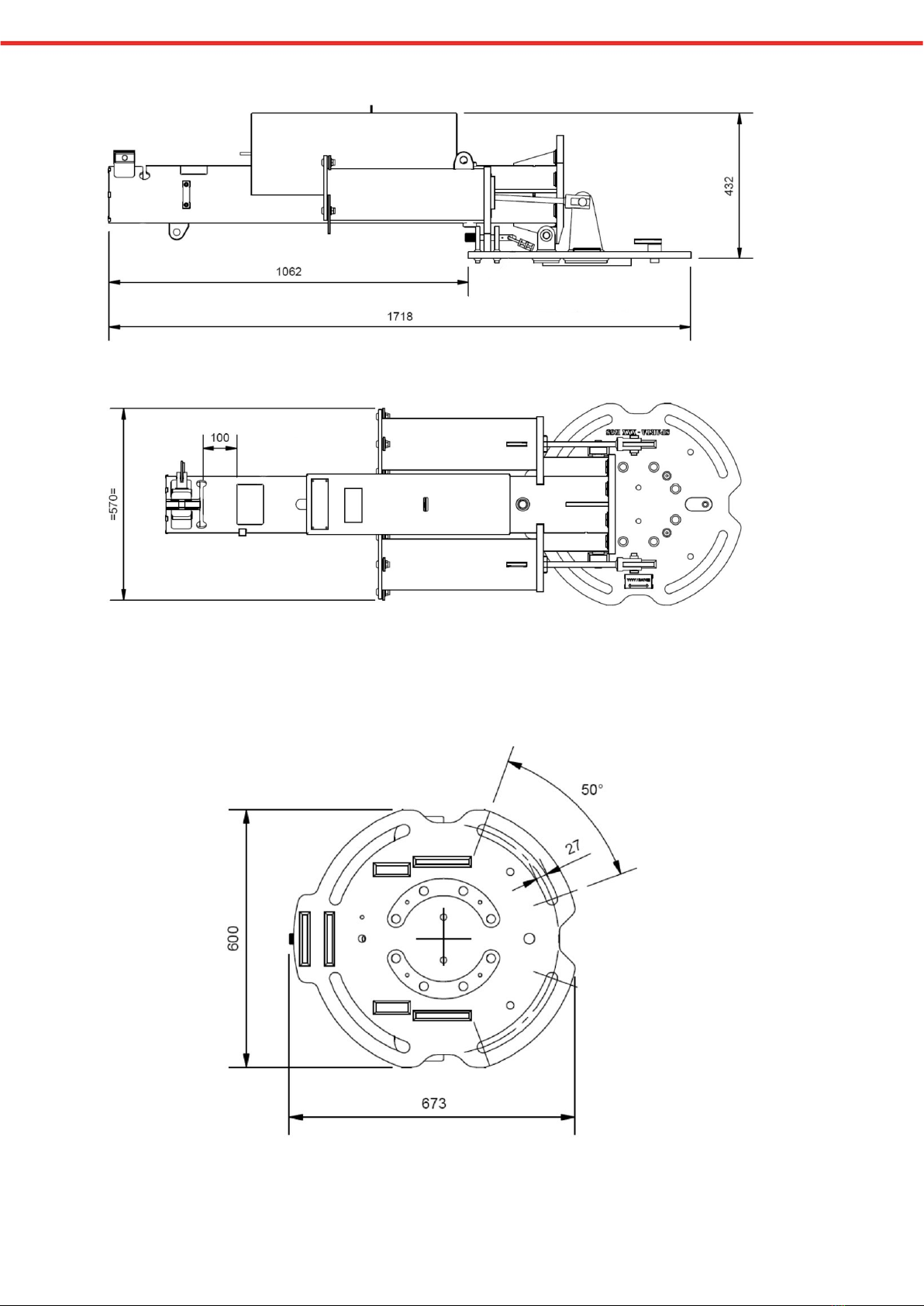

Dimensions .................................................................................................................................. 8

Description ................................................................................................................................ 10

Signal Configuration and Lifting Data ...................................................................................... 10

Storage and Movement ............................................................................................................. 12

Tooling ....................................................................................................................................... 13

Torque Loadings ........................................................................................................................ 13

Foundation and Site Checks ..................................................................................................... 14

Pre Installation Checks ............................................................................................................. 15

Installation ................................................................................................................................ 16

Raising &Lowering the HD ALT ................................................................................................ 17

Inserting the Post and Erecting the Signal .............................................................................. 18

Electrical Connection ................................................................................................................ 21

Signal Alignment ....................................................................................................................... 22

Post Installation Checks ........................................................................................................... 27

Module Replacement (CLS Module) ......................................................................................... 27

Module Replacement (Other Signal Modules) ......................................................................... 29

Additional Visors ....................................................................................................................... 30

Wedge Inserts ........................................................................................................................... 33

Blanking Plates ......................................................................................................................... 33

Maintenance Activity ................................................................................................................ 34

Signal Husbandry ...................................................................................................................... 34

Service and Repair .................................................................................................................... 35

End of Life Disposal ................................................................................................................... 35

Product Support ........................................................................................................................ 35

Appendix A - HD ALT/Signal Lifting Force Data ...................................................................... 35