Front Matter Sageon II, 24V Bulk Product Manual

PM990-5201-24, Rev. 6 v

TABLE OF CONTENTS

1. GENERAL WARNING ...............................................................................................................................................1-1

2. CONFIGURATION .....................................................................................................................................................2-1

2.1 GENERAL DESCRIPTION..................................................................................................................................2-1

2.2 SYSTEM DESCRIPTION.....................................................................................................................................2-1

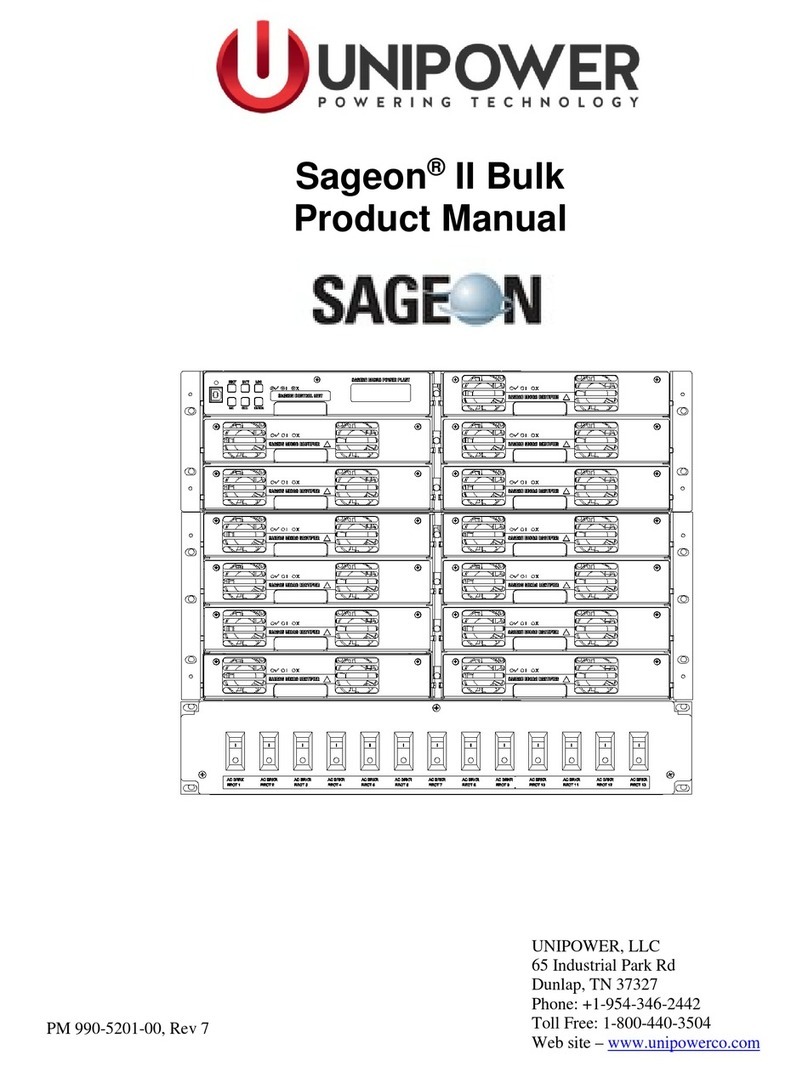

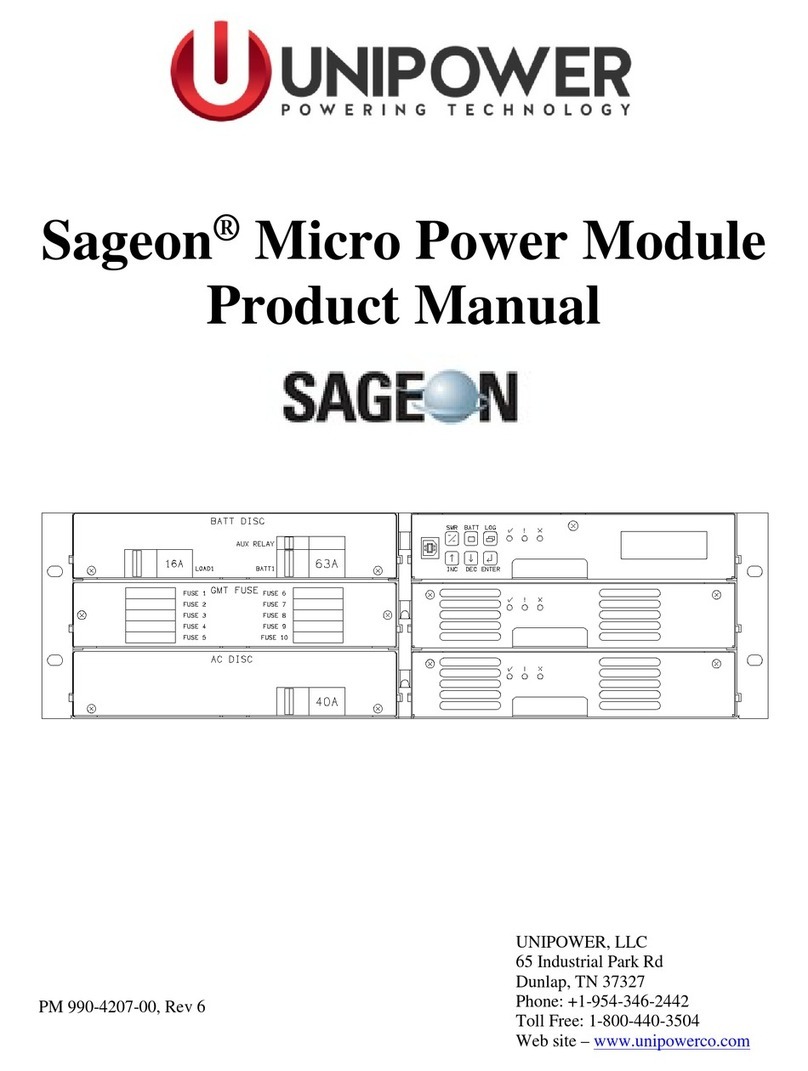

2.2.1Front View........................................................................................................................................................2-1

2.2.2 Rear View.........................................................................................................................................................2-3

3. INSTALLATION..........................................................................................................................................................3-1

3.1 MOUNTING THE POWER MODULE................................................................................................................3-1

3.1.1 Tools Required for Installation .........................................................................................................................3-1

3.1.2 Gaining Access to Rear Wiring ........................................................................................................................3-1

3.2 OVERVIEW OF EXTERNAL WIRING CONNECTIONS.................................................................................3-1

3.3 MAINS CONNECTIONS .....................................................................................................................................3-2

3.3.1 Factory Supplied Configurations ......................................................................................................................3-2

3.3.2 Single phase – individual protected external feeds...........................................................................................3-2

3.3.3 Surge protection requirements ..........................................................................................................................3-3

3.4 BULK LOAD CONNECTIONS ...........................................................................................................................3-4

3.5 BATTERY CONNECTIONS................................................................................................................................3-4

3.6 TEMPERATURE SENSORS................................................................................................................................3-4

3.7 AUXILIARY RELAY CONNECTIONS..............................................................................................................3-5

3.8 CONTROLLER POWER CONNECTIONS.........................................................................................................3-6

3.9 FRONT PANEL USB COMMUNICATIONS CONNECTION...........................................................................3-6

3.10 REMOTE COMMUNICATION CONNECTION ................................................................................................3-6

3.10.1 TCP/IP and Sageview Interfaces..................................................................................................................3-6

3.11 AC OPTION BOX (LIST 41 & 61).......................................................................................................................3-7

3.12 ADDING AUXILIARY EXPANSION MODULES.............................................................................................3-8

4. COMMISSIONING......................................................................................................................................................4-1

5. OPERATION................................................................................................................................................................5-1

5.1 CONTROLLER COMPONENTS.........................................................................................................................5-1

5.1.1 Alpha-numeric Display.....................................................................................................................................5-1

5.1.2 Front Panel Pushbuttons ...................................................................................................................................5-1

5.1.3 Status Indicating LEDs (Controller) .................................................................................................................5-2

5.2 CONTROLLER SECURITY & ALARMS...........................................................................................................5-2

5.2.1 Password security..............................................................................................................................................5-2

5.2.1.1 Entering a password to gain access to parameters change.....................................................................5-2

5.2.2 When an alarm condition exists........................................................................................................................5-3

5.2.3 Controller Alarms .............................................................................................................................................5-3

5.2.4 User programmable relay functions..................................................................................................................5-4

5.3 NAVIGATING CONTROLLER FUNCTIONS ...................................................................................................5-5

5.3.1 Base Menu (System Level Functions) ..............................................................................................................5-5

5.3.2 RECTIFIER Menu (Rectifier Specific Functions)............................................................................................5-8

5.3.3 Alarm Log.........................................................................................................................................................5-8

5.3.4 Battery Menu (Battery Specific Functions) ......................................................................................................5-9

6. TROUBLESHOOTING...............................................................................................................................................6-1

6.1 TO REMOVE A RECTIFIER MODULE OR A CONTROLLER........................................................................6-4

6.2 TO INSERT A RECTIFIER MODULE OR A CONTROLLER ..........................................................................6-4

7. APPENDIX A – SETTING UP NETWORK INTERFACES ...................................................................................7-1

7.1 PROGRAMMING IP ADDRESSES USING DEVICE INSTALLER SOFTWARE...........................................7-1

7.1.1 Preparations for local address set up.................................................................................................................7-1

7.1.2 Local IP address set up procedure.....................................................................................................................7-1

7.1.3 Preparations for gateway address set up ...........................................................................................................7-1