UniqueTek Inc. 540 W. Iron Ave., Suite 118 web: www.uniquetek.com

Phone: 480-507-0866 Mesa, AZ 85210 e-mail: info@uniquetek.com

Fax: 480-507-0867 - 1 - Rev. 20 04/15

Micrometer Powder Bar Kit™

For the Dillon Auto Powder Measure *

Thank you for buying the UniqueTek Micrometer

Powder Bar Kit™for your Dillon Precision Auto Powder

Measure. This kit includes everything you need to

convert your Powder Bar to a Micrometer Powder Bar.

This conversion kit is compatible with all Dillon Powder

Bars (Extra Small, Small, Large, Magnum, Belted

Magnum* plus the SL 900 Shot Bar*).

* The Belted Magnum powder bar and SL900 Shot Bar require minor

modification. See Note in Step 4 of instructions.

Before beginning installation, it is recommended that

you read these instructions completely at least twice. It

is also recommended that you review the factory

instructions and exploded parts diagram for your Dillon

Precision Auto Powder Measure. If you do not have

the instruction manual for your press, manuals are

available for download at the Dillon Precision web site.

(www.dillonprecision.com)

* Dillon Precision does not authorize the Micrometer Powder Bar Kit™

for use on any of its reloading presses and its use may void

manufacturer or dealer warrantees.

If you have any questions about installation, operation or experience any problem with your micrometer, please call

me first. I can often resolve the problem over the phone (480-216-2041 cell). – Lee

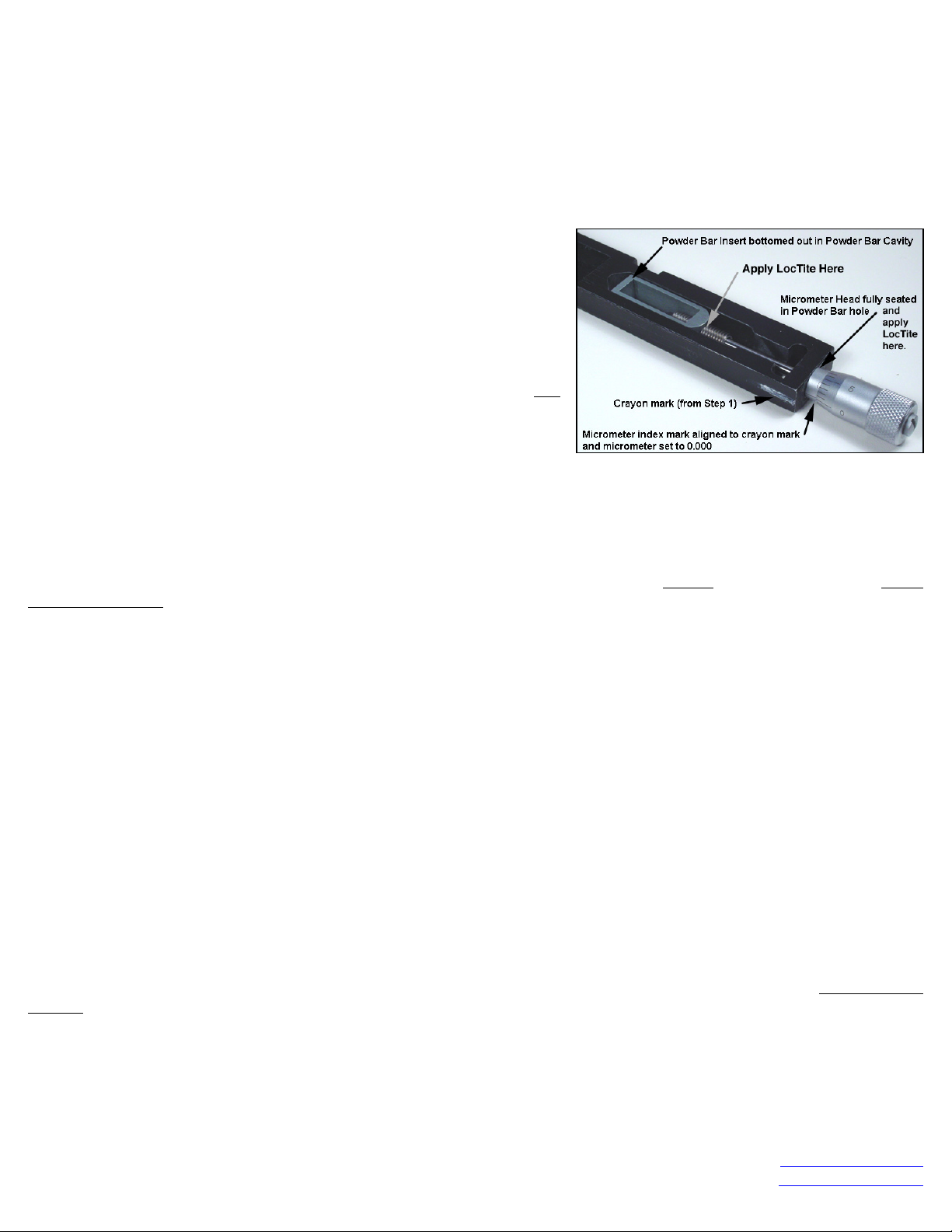

Step 1: Place an Index Mark on Powder Bar

The Auto Powder Measure is oriented differently on each Dillon press. Before

removing the powder bar, decide from which side you will want to view the

micrometer when adjusting the powder charge. As you are facing the press, you will

typically adjust the micrometer from the side shown below.

• Square Deal B – Left Side • XL 650 – Left Side • Super 1050 – Left Side

• RL 550B – Right Side • SL 900 – Right Side • AT 500 – Right Side

Mark a line on that side of the powder bar, near the adjustment screw, with a pencil,

white crayon or other marker that is easily visible but removable. This line will be

used later to orient the micrometer index mark for easy reading. On the XL 650 and

Square Deal B you will notice that the micrometer numbers will be upside-down. But

this orientation will be much easier to see during adjustment than if it was oriented

on the opposite side of the powder bar as with the other presses.

Step 2: Remove Powder Bar

Remove the Powder Bar from the Powder Measure. (Refer to Auto Powder Measure instruction manual for details.)

Step 3: Disassemble the Powder Bar

NOTE: Before disassembly, look closely at the Powder Bar and note that Powder Bar Inserts (Ex-Small, Small and

Large) and some Powder Bars (Small and Large) have a flat side and a side with a cavity. The cavities must always

be on the bottom side of the Powder Bar.

a. Remove the Powder Bar Post. Press the bolt head against a

hard surface to compress the spring washer while pulling out

the Powder Bar Post. The Belted Magnum powder bar and

SL900 Shot Bar have a 3/8” set screw instead of a powder bar

post. Remove the set screw using a 3/16” hex key.

b. Remove the Powder Bar Adjustment Screw.

c. Set aside the Powder Bar Adjustment Screw, spring washer

and flat washer. They will no longer be used.

Step 4: Prepare the Powder Bar for Installation **

The Teflon coating must be completely removed from the hole in the end of the powder bar where the adjustment

screw was removed. Use a round file or rolled up sandpaper to scrape away the Teflon coating, leaving a fresh bare

metal surface for the LocTite to achieve a good bond. Clean the hole with rubbing alcohol to remove any residue.

Note: If you happen to have a 7mm thread tap, it does a quick job of cutting through the Teflon coating and exposing clean bare metal for the

Loctite to achieve a solid bond. Only a 7mm tap is the correct size. Do not substitute any other size metric or SAE tap.

** The Belted Magnum powder bar and SL900 Shot Bar adjustment screw hole is smaller than on the other powder bars and must be

enlarged using a 17/64” drill bit before installing the micrometer. Some older Small and Large powder bars may also require enlarging.