5. Cleaning and maintenance

Remove the plug from the socket before any cleaning, maintenance process!

Use warm water and glass cleaner for cleaning the glass surfaces (only the side and top panel

are from glass).

For cleaning the lift self-service doors use warm water and very fine cloth to avoid scratching.

The display chase is made of stainless steel specially designed for contact with food products;

therefore it does not require extra maintenance. Do not use abrasive and corrosive cleaning

agents.

Never clean the cabinet using a water hose and similar. This may cause short-

circuiting.

Use a brush and vacuum cleaner for the cleaning process –the best method is to blow the

condenser with compressed air. Do not use hard or sharp objects which might damage or

destroy the condenser or the display case during cleaning. Apply the cleaning in regular

intervals (minimally once per month). The manufacturer/seller will not be responsible for any

damage resulting from unqualified handling. The manufacturer/seller is also not responsible

for any damage resulting from using the equipment for other purposes than it is

manufactured and intended for.

6. Service and troubleshooting

Replacing the light –dismount the lamp by pulling lengthwise from the holder. Mount the

new one lamp in reverse order.

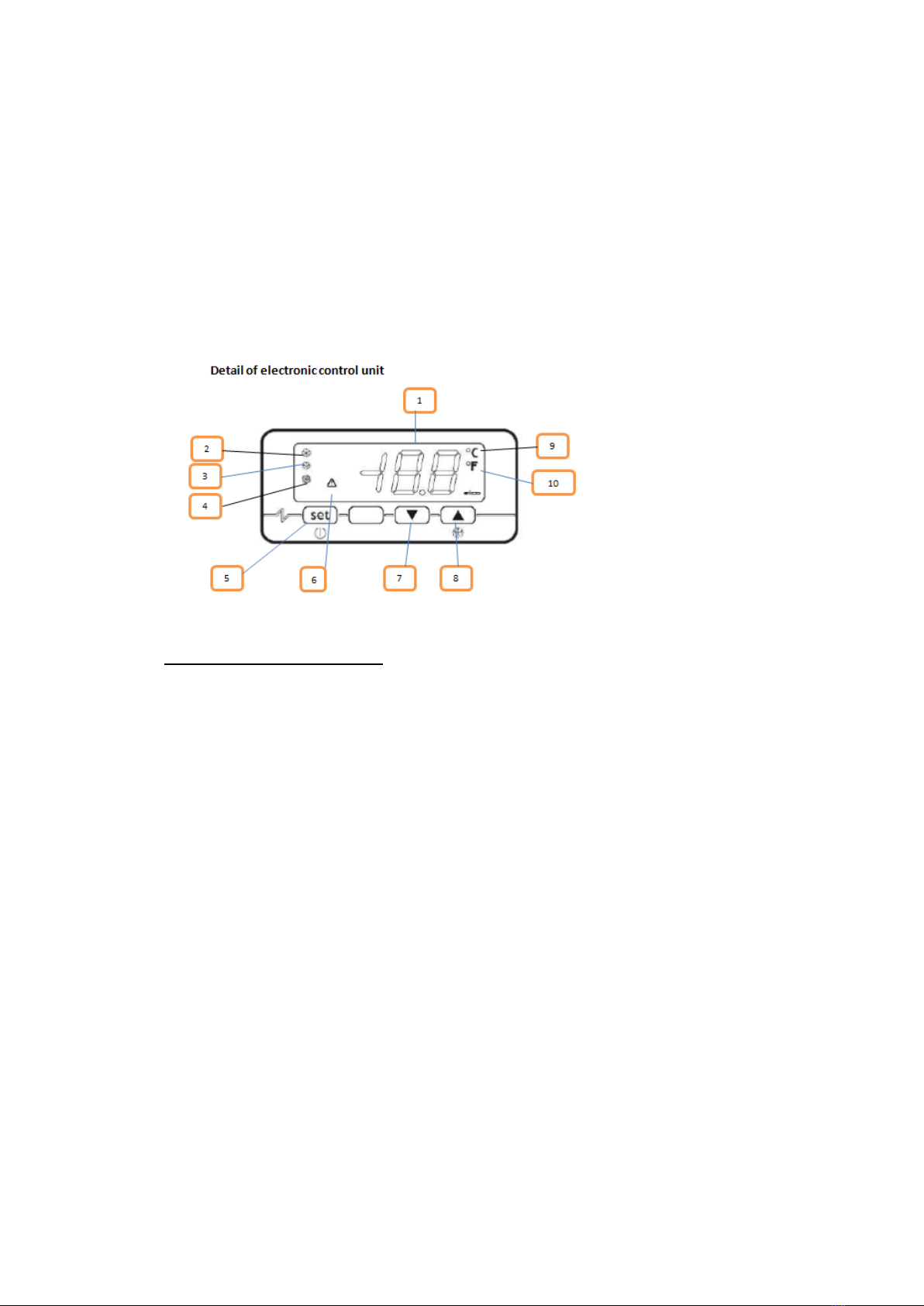

If the counter doesn’t work properly please check:

-Is the counter connected to the main power?

-Is the power supply on? (please check fuses)

-Is the main on/off switch in correct position?

-Is the evaporator free of ice?

-Did you correctly load the counter with food?

In case of other malfunctions please contact your supplier and provide him the serial number

of the counter.