United Technologies Carrier XARIOS Series User manual

1UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

INSTALLATION MODULE

XARIOS RANGE

2UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

GENERAL INSTALLATION RECOMMENDATION

CONDENSOR INSTALLATION 3

CONDENSOR: PREPARATION 4

REFRIGERATION HOSES PREPARATION 5

HOSES: MOUNTING 6

BOX: HARNESS & HOSE 7

OIL RETURN FITTING 9

COMPRESSOR INSTALLATION

COMPRESSOR: PREPARATION 10

COMPRESSOR: KLIXON INSTALLATION 11

CHECKS & SETTINGS

PRESSURE CHECK: MANIFOLD GAUGES LOCATION 12

PRESSURE CHECK: MANIFOLD GAUGES CLEANING 13

PRE-LEAK CHECKING 14

UNIT VACUUM 15

REFRIGERANT CHARGE 16

COMMISSIONNING: CPR ADJUSTMENT 17

COMMISSIONNING: SUPERHEAT 19

COMMISSIONNING: OIL CHARGE 20

TABLE OF CONTENT

3UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

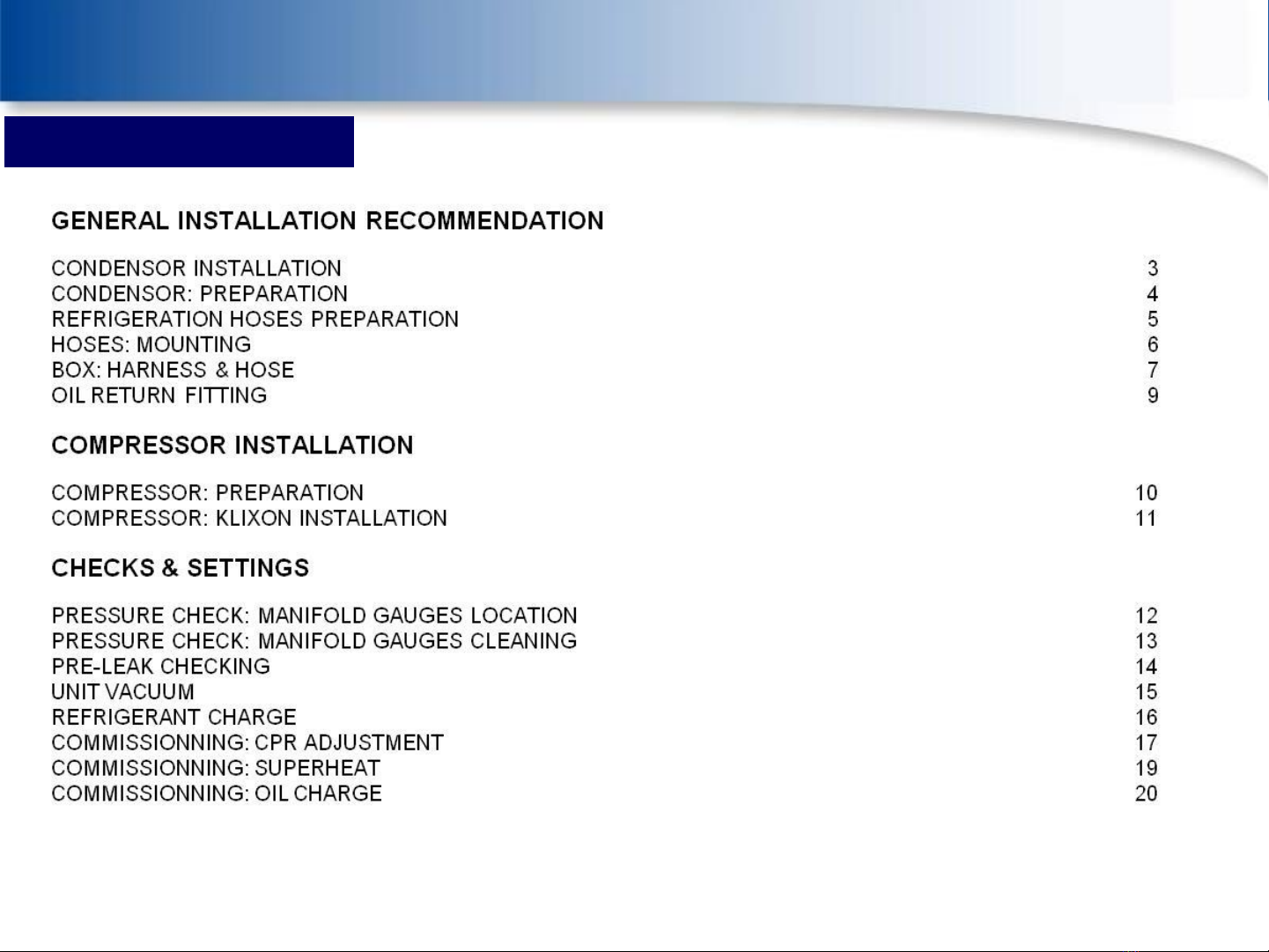

The installation of the deflector on the vehicle

cab should not interfere with the functioning

of the refrigeration equipment

The deflector must not be installed within a

radius of less than 250 mm to 300mm from the

unit

The length between the box and the spoiler

must be at least 480 mm for a Xarios 150 to

515 mm for a Xarios 600

The installation of the deflector must not hinder

accessibility to to the refrigeration unit for

mainenance visits

Access to the power and control boxes must

comply with standard safety conditions

CONDENSOR INSTALLATION

GENERAL INSTALLATION RECOMMENDATION

4UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

Condenser inlet and outlet

1. Oil separator inlet (« Road » H.P

compressor)

2. « Road » compressor oil return

3. Liquid line

4. Hot gas line

5. Hot gas line N°2 (only for MT° unit)

6. Remove the blanks

7. Warning !

Don’t forget to lubricate the ORS joints with

Carrier POE 68 oil and to put them in their

respective groove

CONDENSER: PREPARATION

1

2

3

4

5

6

7

GENERAL INSTALLATION RECOMMENDATION

5UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

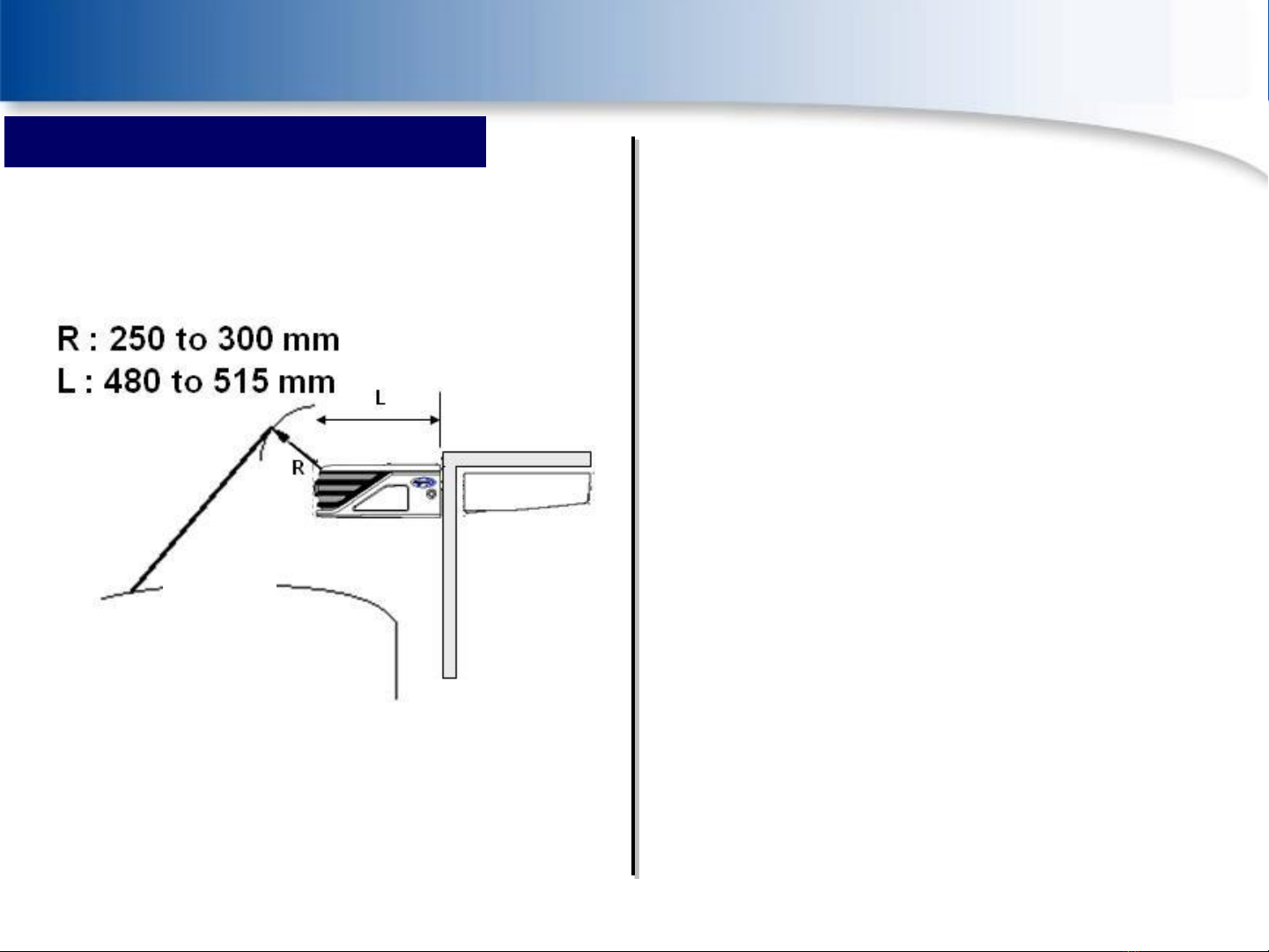

1. Connect the refrigeration hoses

Low and high pressure lines

Liquid line

Hot gas line

Pass the electrical harnesses and the hoses

inside or outside of the body. (Chose one

option depending on the vehicle

configuration)

2. Important :

Don’t forget to mark the liquid line and the

hot gas line

REFRIGERATION HOSES PREPARATION

1

2

GENERAL INSTALLATION RECOMMENDATION

6UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

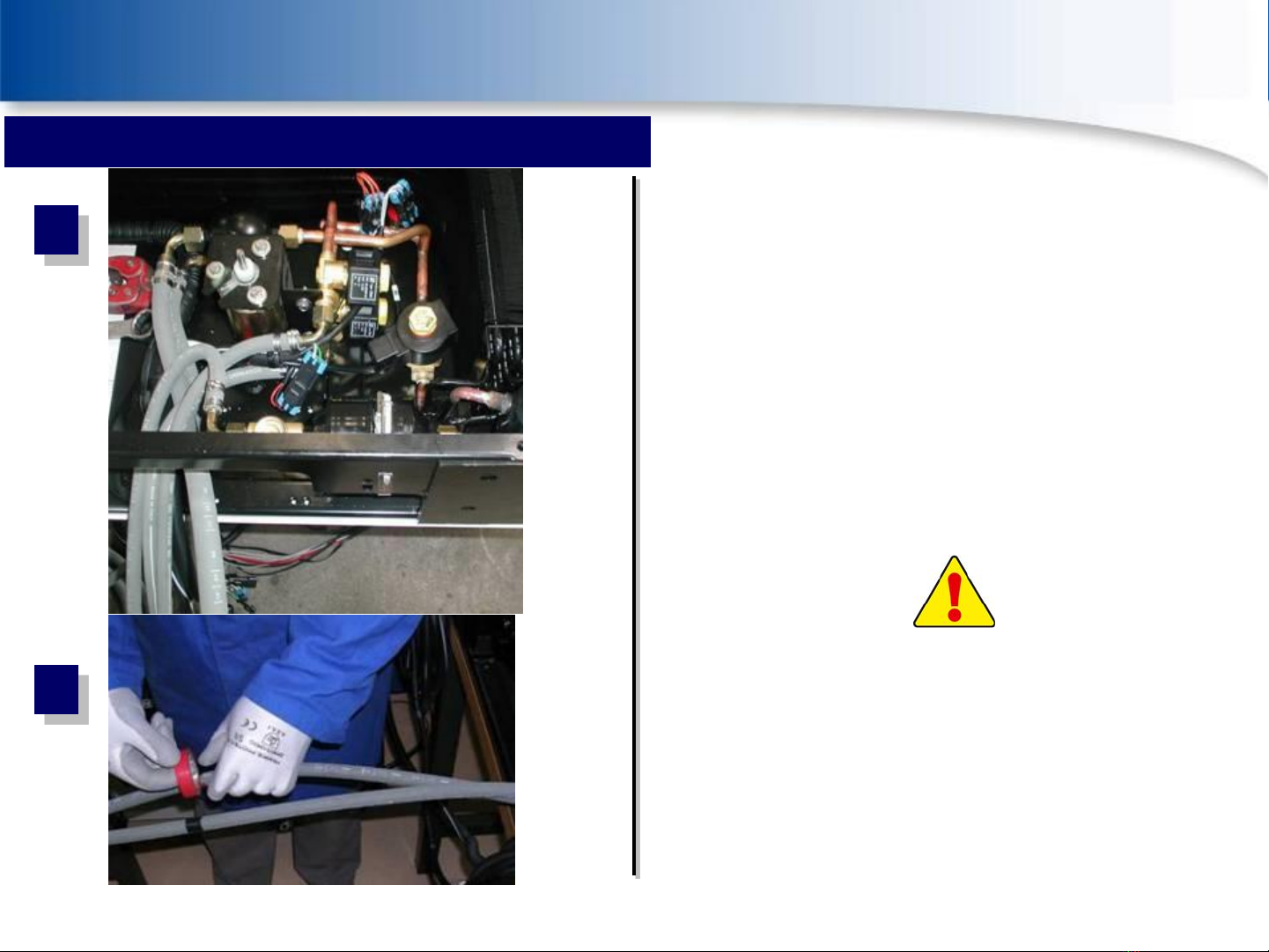

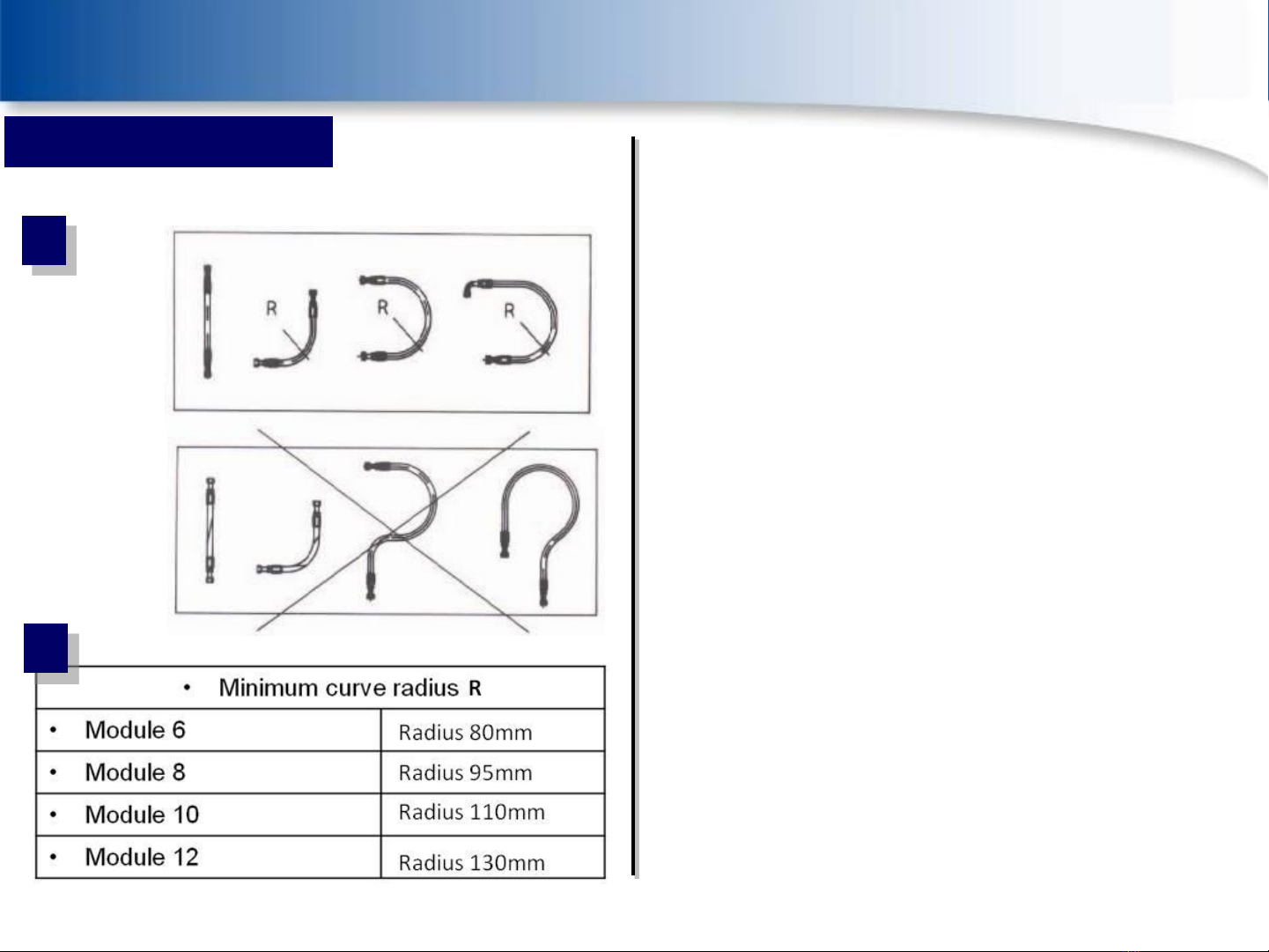

1. Do not twist or curve the hoses.

2. Keep enough length for movement

when the pipes are under pressure.

3. Pipes length can vary between -2% to

+4%.

4. Using elbows and fittings make the

installation easier and increase hose

life.

5. Always insure that minimum radius are

respected. Provide a radius as large as

possible to avoid a restriction in the

hose.

HOSES: MOUNTING

OK

NOT OK

1

5

GENERAL INSTALLATION RECOMMENDATION

7UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

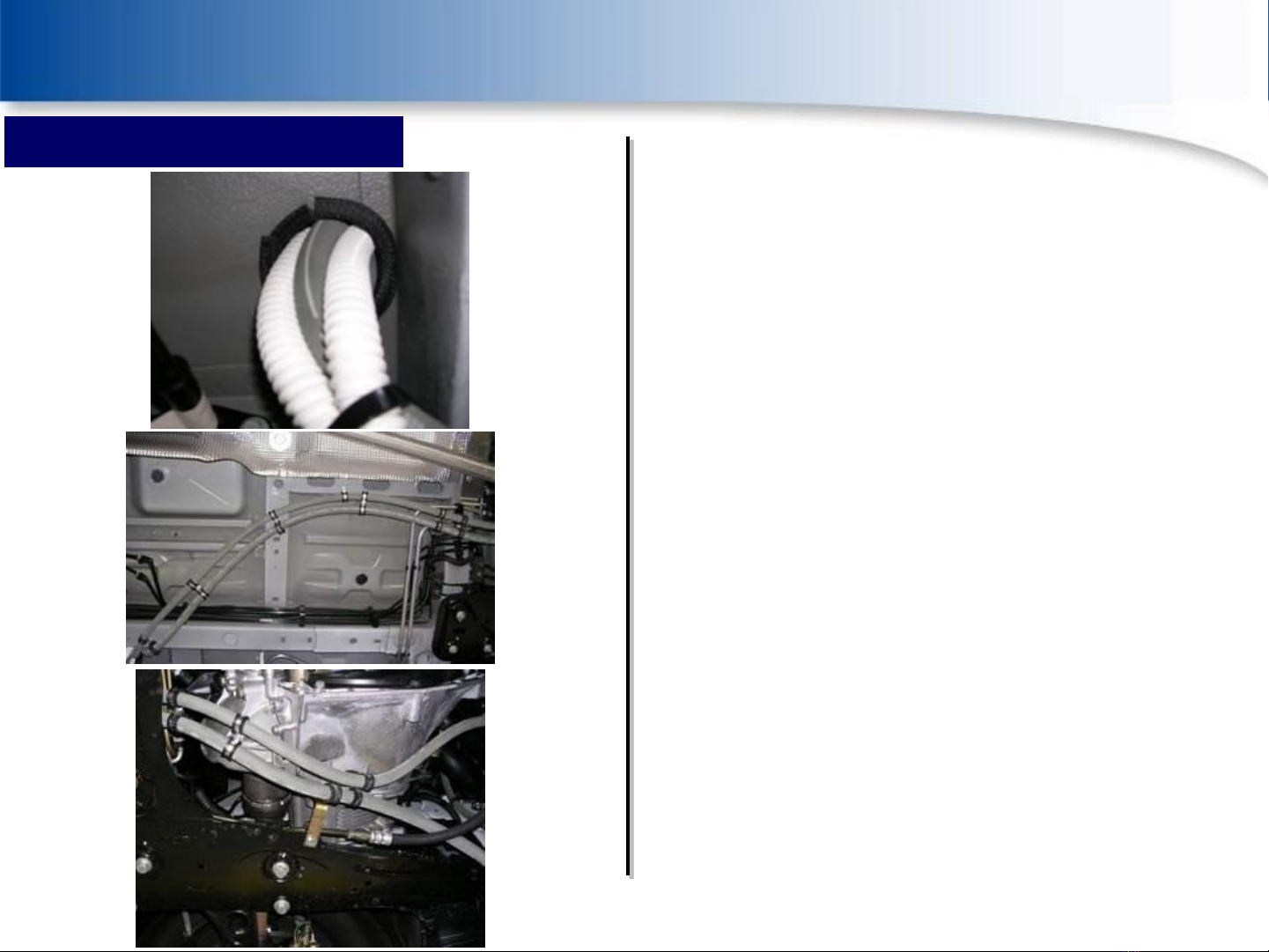

1. Anti thermal bridge method

By migration and fixing of the refrigeration lines,

please avoid when it’s possible the contact

between both H.P and L.P lines (to reduce heat

transfer phenomenom)

2. Fixing and protecting the lines and

harnesses from the inside and the

outside of the partition

To protect the refrigeration lines and the

electrical harnesses, use trunking

Secure the lines with clamps (RSGU)

Secure the trunking with rivnuts, protect the

trunking termination with conduit

BOX: HARNESS & HOSE

1

2

GENERAL INSTALLATION RECOMMENDATION

8UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

Pipes under the vehicle :

Refrigeration lines have to be :

Fixed at regular intervals with rubber clamps

Kept away as far as possible from each other

to prevent heat transfer

Kept away from any heat source

Protected by grommets (Insulation) were

they pass through the vehicle bodywork

BOX: HARNESS & HOSE

GENERAL INSTALLATION RECOMMENDATION

9UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

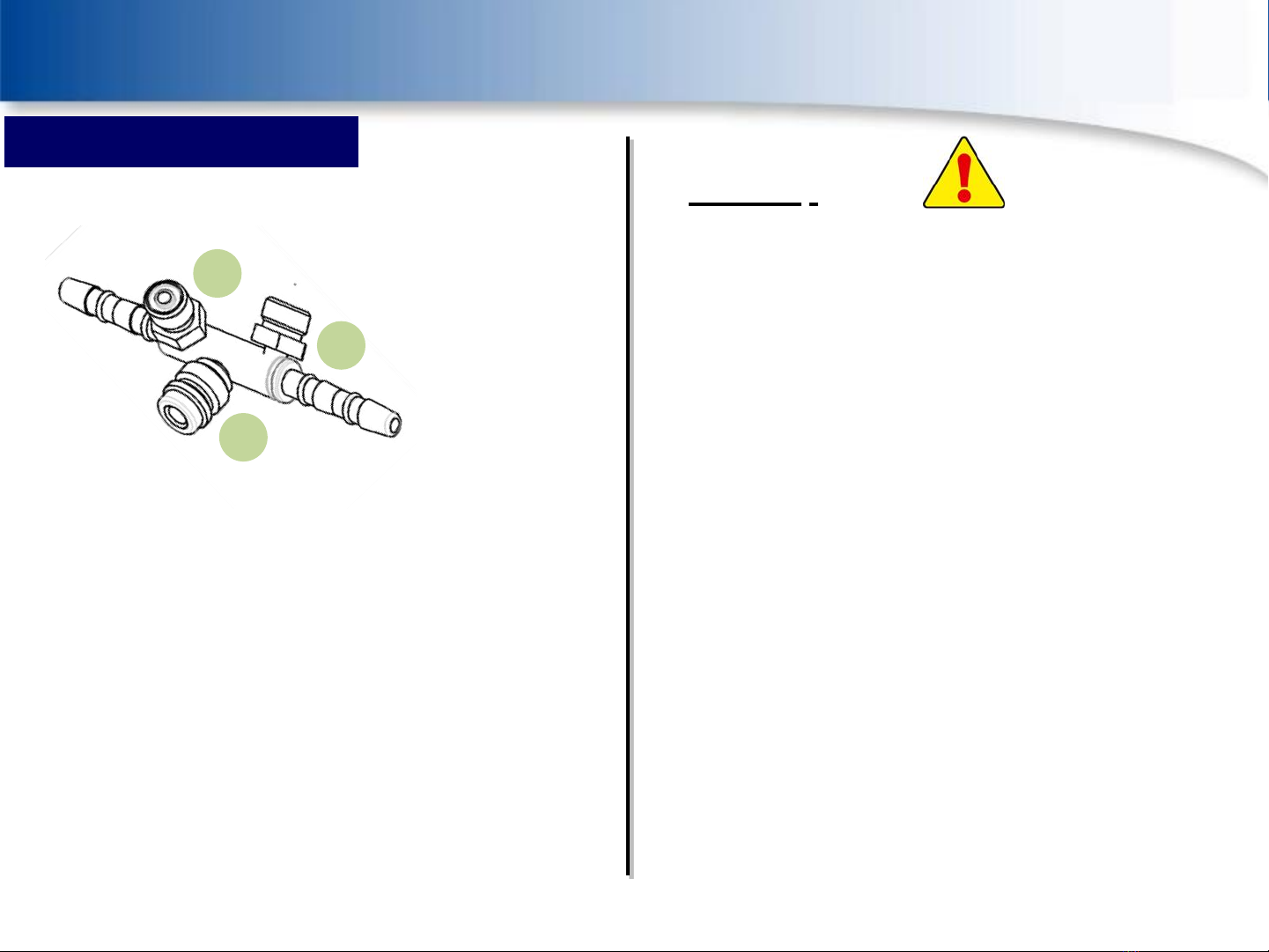

1. Warning !

After the installation of the service valve

connections, please fit service valve caps to avoid

any contamination.

The service valve connections have to be as near

as possible to the road compressor.

2. Road compressor refrigeration

connections

Install the connections on the HP and LP

compressor valves and oil return

OIL RETURN FITTING

3 ways suction fitting

1

2

3

Oil return recommended location (position 1)

Use the 3 ways fitting corresponding to your

installation instead of the usual LP connection fitting:

•40-60291-50 : IDN 16.1

•40-60291-60 : IDN 12.7

There are 3 ways on this fitting:

1. Oil return connexion

2. Schrader valve for LP manifold

3. Not yet used, put a cap + Oring

GENERAL INSTALLATION RECOMMENDATION

10 UTC Climate, Controls & Security

PROPRIETARY 62-61661-00 Rev B

29th maI 2013

1

2

COMPRESSOR: PREPARATION

COMPRESSOR INSTALLATION

Refrigeration oil is very hygroscopic !

The compressor is under a nitrogen

pressure

•Before the compressor mounting, make sure that

the compressor has an adhesive label fitted,

proof that it is charged with Carrier oil type (no oil

change to do)

•Never leave a compressor crankcase opened

If one of these two points is not respected, it is

imperative to do a compressor oil change and to

restore the right level (see the table ) with Carrier

POE 68 oil from a brand new tank.

This manual suits for next models

9

Table of contents