Page | 3

4.3.13 Operating Tips ...................................................................................................................................................13

4.4 Auto Operation using the CPC Interface............................................................................................................14

4.4.1 Store or Update Process...................................................................................................................................15

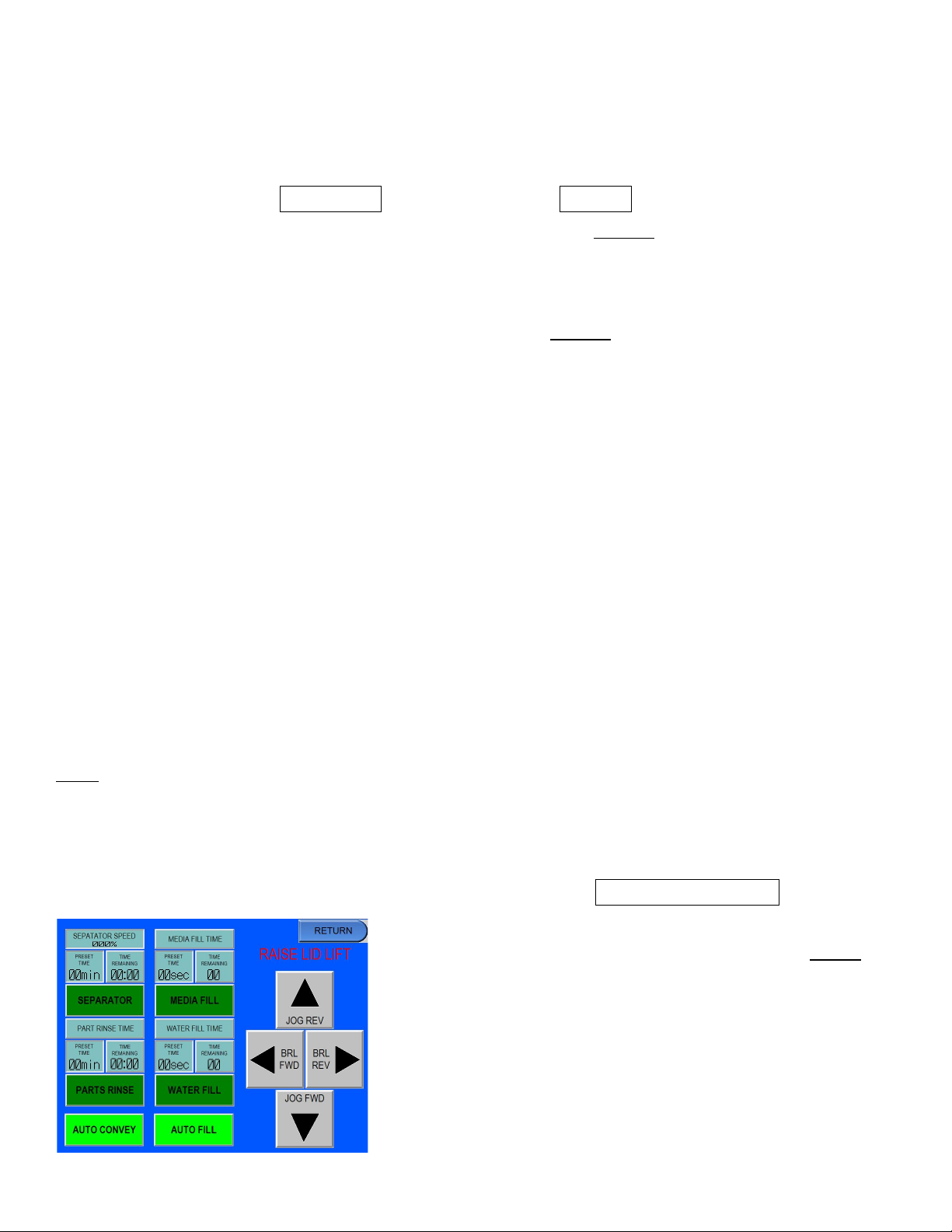

4.4.2 Separator Controls..............................................................................................................................................19

4.4.3 Rinse Timer............................................................................................................................................................20

4.4.4 Auto-Reverse ........................................................................................................................................................21

4.4.5 Run a Preset Process..........................................................................................................................................21

5.0 Maintenance......................................................................................................................................................................24

5.1 Maintenance in CPC Interface ................................................................................................................................24

5.1.1 System Information............................................................................................................................................24

5.1.2 System Tools Password.....................................................................................................................................25

5.1.3 System Tools.........................................................................................................................................................25

5.1.4 Password Reset....................................................................................................................................................25

5.1.5 I/O Meter................................................................................................................................................................25

5.1.6 Help Menu.............................................................................................................................................................26

5.2 Maintenance and Repair ..........................................................................................................................................27

5.2.1 Preventative Maintenance Schedule............................................................................................................28

5.2.2 Turret Drive Assembly .......................................................................................................................................28

5.3.3 Adjusting Main Drive Belt ................................................................................................................................29

5.3.4 Replacing Main Drive Belt................................................................................................................................29

5.3.5 Barrel Drive Assembly........................................................................................................................................30

5.3.6 Inspection ..............................................................................................................................................................30

5.3.7 Drive Component Removal .............................................................................................................................31

5.3.8 Adjusting Barrel Chain.......................................................................................................................................32

5.3.9 Bearings..................................................................................................................................................................34

5.3.10 Barrels ...................................................................................................................................................................38

6.0 Troubleshooting...............................................................................................................................................................40

6.1 Interface Not Functioning........................................................................................................................................40

6.2 Will Not Begin Cycle ..................................................................................................................................................41

6.3 Premature System Halt .............................................................................................................................................42