9100 SERIES REFLOW SOLDERING SYSTEM

990-606 v

CONTENTS

CHAPTER 1: System Description....................................................................................................... 1-1

Section I: Features ...................................................................................................................... 1-1

Features............................................................................................................................ 1-1

Section II: System Components.................................................................................................. 1-2

Major Components........................................................................................................... 1-2

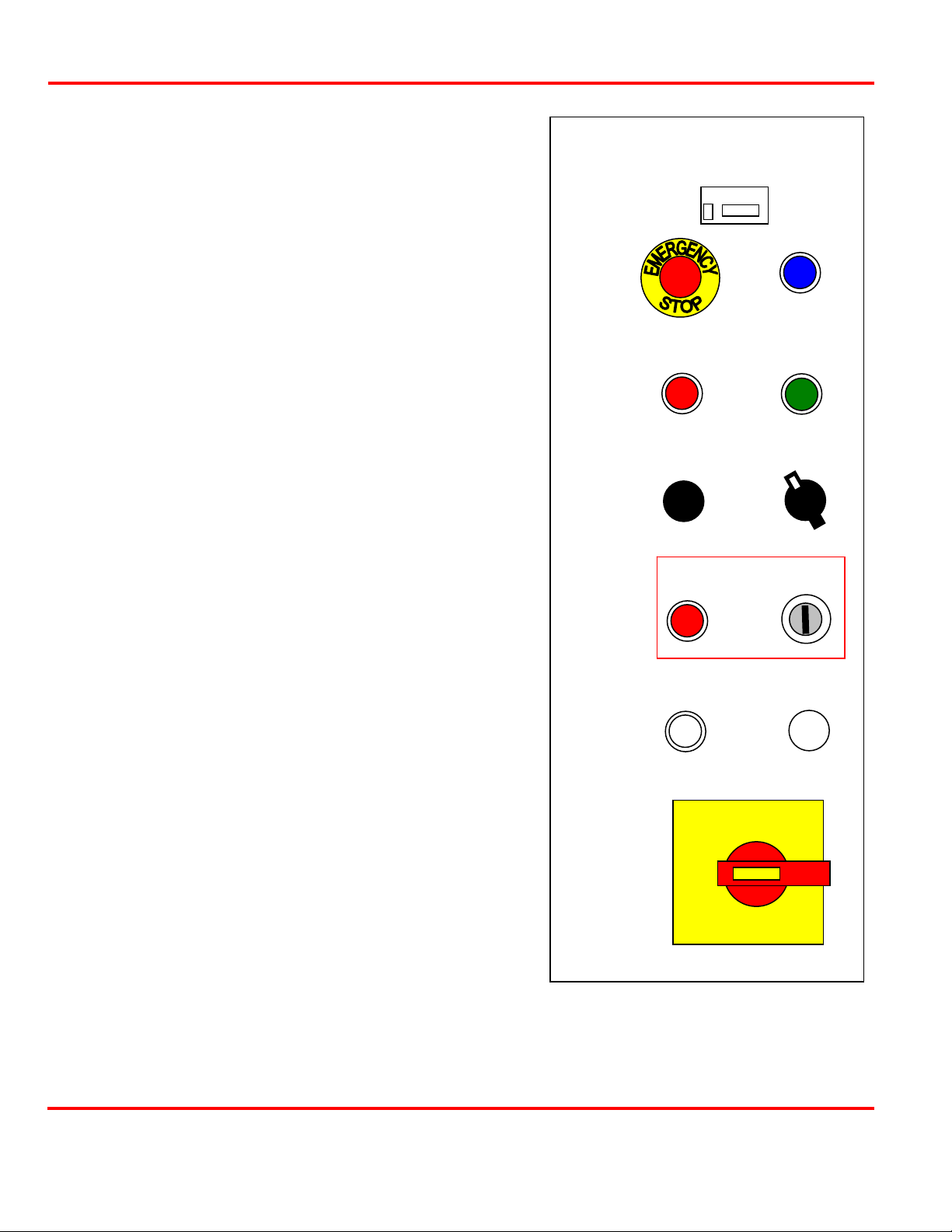

Controls and Indicators.................................................................................................... 1-4

Control Panel ....................................................................................................... 1-4

Tabletop Controls ................................................................................................ 1-5

Access Doors ................................................................................................................... 1-6

Electrical Connectors....................................................................................................... 1-6

CHAPTER 2: Getting Started............................................................................................................. 2-1

Section I: Planning for Installation............................................................................................. 2-1

Space Requirements......................................................................................................... 2-1

Power Requirements........................................................................................................ 2-1

Compressed Air Requirements........................................................................................ 2-1

User Manufactured Jigs, Mounting Hole Requirements ................................................. 2-1

CHAPTER 3: Operating Instructions ................................................................................................ 3-1

Section I: Operating Precautions ................................................................................................ 3-1

General Operator Safety .................................................................................................. 3-1

Set-Up Safety................................................................................................................... 3-1

Section II: Preparing for Operation ............................................................................................ 3-1

Pre-Operational Checks................................................................................................... 3-1

Turning the Equipment On .............................................................................................. 3-2

Section III: Operation ................................................................................................................ 3-2

Set-Up.............................................................................................................................. 3-2

Installing the Jigs................................................................................................. 3-2

Aligning the Bonding Head................................................................................. 3-3

Establishing the Reflow Schedule ....................................................................... 3-5

Operation ......................................................................................................................... 3-5

Section IV: Shutdown................................................................................................................. 3-6

Emergency Shutdown...................................................................................................... 3-6

Normal Shutdown............................................................................................................ 3-6