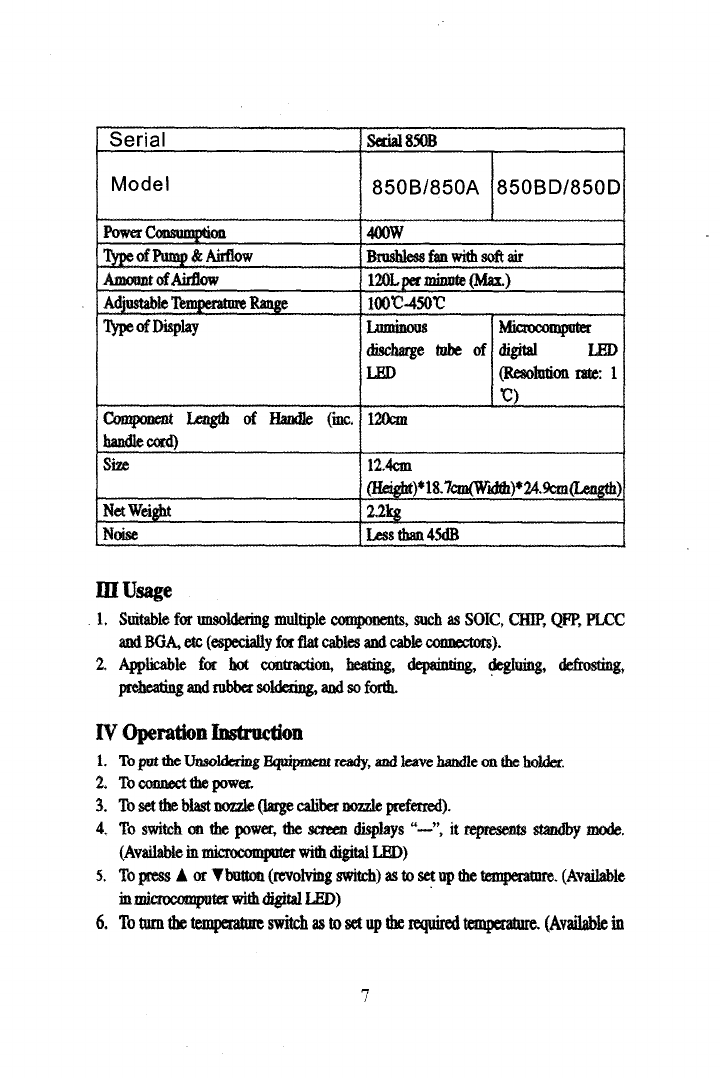

Serial

Serial

850B

Model

850B/850A

850BD/850D

Power

Cansum~ion

400W

Type

of

Pump

&

Airflow

Bnrsbless

fan

with

soft

air

Amount

of

Airflow

121N

per

minute

(Max.)

100O.450t

AdjastabkT~p..ratt.ieRange

Ty

pe

of

Display

Luminous

discharge

tube

of

LED

Mii

.0

owputct

digital

LED

(Resolution

rate:

1

G)

Component

Length

of

Handle

(mc.

handle

card)

12m

Site

12.4cm

(FIeig)nt)~18.7cm(Width)'249cm(Length)

Net

Weight

2.2kg

Noise

Less

than

45dB

II

I

Usage

1.

Suitable

for

isoldering

multiple

components,

such

as

SOIC,

CHIP,

QFP,

PLCC

and

BGA,

etc

(especially

for

flat

cables

and

cable

connectors).

2.

Applicable

fot

hot

contraction,

heating,

depainting,

degluing,

defrosting,

preheating

and

rubber

soldering,

and

so

forth.

IV

Operation

Instruction

1.

lb

put

the

Unsoldering

Bquiprnent

ready,

and

leave

handle

on

the

holder.

2.

l

connect

the

power.

3.

To

set

the

blast

nozzle

(large

caliber

nozzle

preferred).

4.

To

switch

on

the

power,

the

screen

displays

"—"

it

represents

standby

mode.

(Available

in

microcomputer

with

digital

L®)

5.

To

press

A

or

♦button

(revolving

switch)

as

to

set

up

the

temperature.

(Available

in

microcomputer

with

digital

LED)

6.

To

turn

the

temperature

switch

as

to

set

up

the

required

temperature.

(Available

in