4

OPERATIONS MANUAL Rev. 1.4

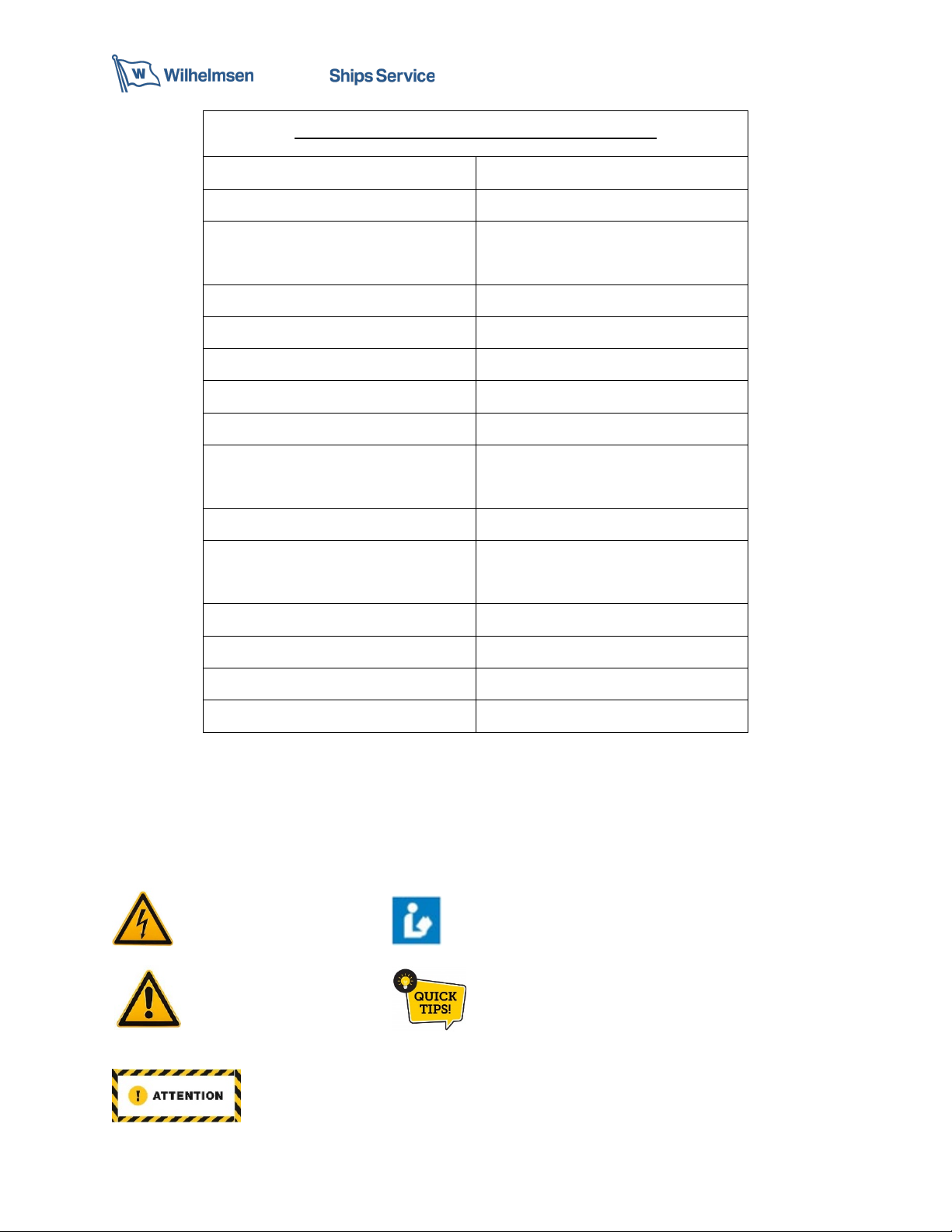

Important Safety Precautions

Before using the machine ensure this operations manual is fully read and

understood. Always keep this manual in a safe place near to the machine.

Never let persons, who are not trained work with the machine

This machine should be operated by qualified personnel only

Τhe operator must always wear appropriate and certified personnel protective

equipment (PPE) for 500 bar.

Persons that are in the immediate proximity of the cleaning area, have to

protect themselves against spurting particles by wearing appropriate personnel

protective equipment (PPE) for 500 bar.

Τhere must be two operators on the machine. Οne at the machine and the other

at the spray handle, both having eye contact on each other.

The machine should be used according to relevant national safety rules.

Never direct the spray jet at yourself, other people or at the machine itself.

Never attempt to clean your clothes or footwear that you or other persons are

wearing with the machine.

Keep bystanders away from the working area.

Increased hazard caused by short spray equipment (less than 750 mm from the

handle to the nozzle)! Never direct the jet against parts of the body! Protect

yourself from any particles splashing back against you!

Ensure you connect the machine to the correct main supply voltage, as specified

by the manufacturer. The machine may only be connected to a correctly

installed plug socket. When connecting extension cables, ensure you are using

cable with proper minimum cross-sections. The machine must not be started if

any electrical component or accessory (cable, plug, switch etc.) is defective.

Only qualified personnel must carry out all electrical repairs.

Use only watertight cable, plugs and sockets. Any electrical installation should

be made only by a qualified electrician.

Τhe machine must be equipped with certified safety equipment at 500 bar.