Unitronics V130-33-TR20 User manual

Other Unitronics Network Router manuals

Unitronics

Unitronics V130-33-TRA22 User manual

Unitronics

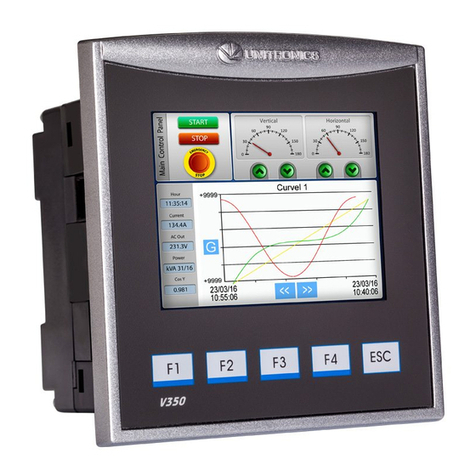

Unitronics Vision OPLC V350-35-R34 User manual

Unitronics

Unitronics Vision OPLC V350-35-T38 User manual

Unitronics

Unitronics V570-57-T20B User manual

Unitronics

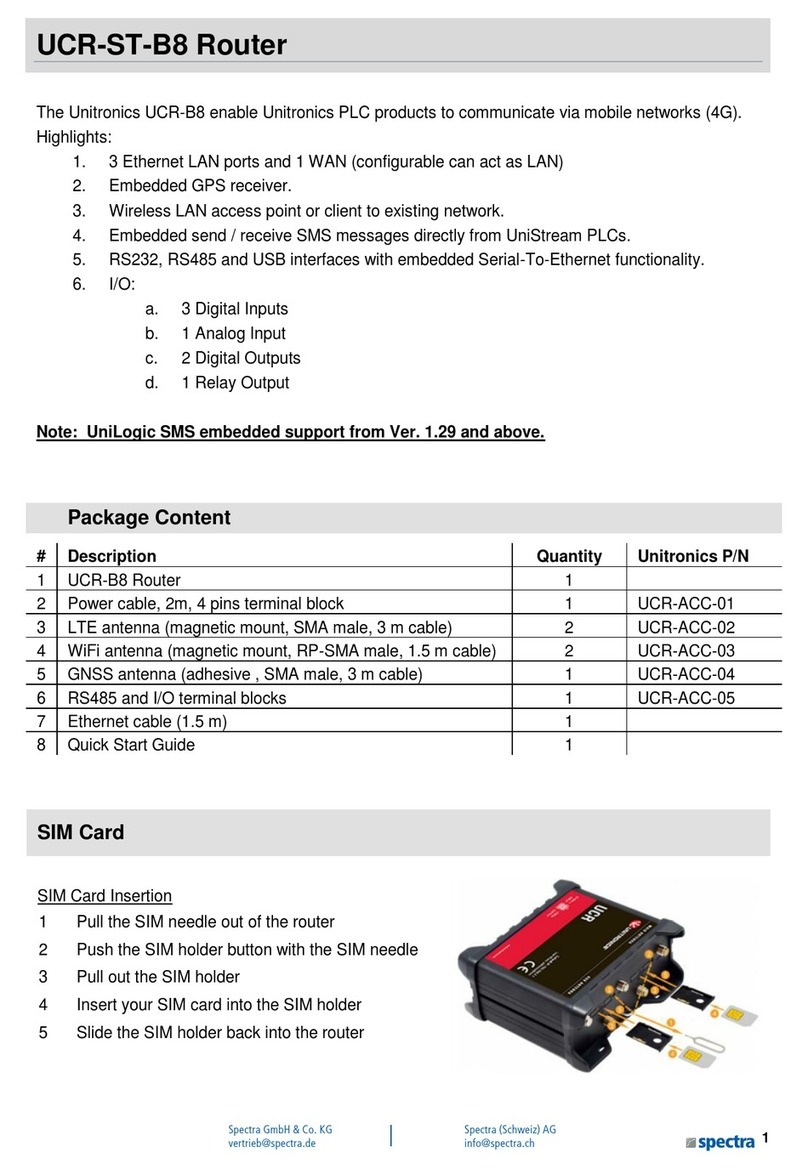

Unitronics UCR-ST-B8 User manual

Unitronics

Unitronics Vision OPLC V130-33-TR34 User manual

Unitronics

Unitronics Vision OPLC V130-33-R6 User manual

Unitronics

Unitronics Vision V130-TR34 User manual

Unitronics

Unitronics V350-35-RA22 User manual

Unitronics

Unitronics Vision OPLC VV570-57-T20B-J User manual

Popular Network Router manuals by other brands

TRENDnet

TRENDnet TEW-435BRM - 54MBPS 802.11G Adsl Firewall M Quick installation guide

Siemens

Siemens SIMOTICS CONNECT 400 manual

Alfa Network

Alfa Network ADS-R02 Specifications

Barracuda Networks

Barracuda Networks Link Balancer quick start guide

ZyXEL Communications

ZyXEL Communications ES-2024PWR Support notes

HPE

HPE FlexNetwork 5510 HI Series Openflow configuration guide