FPMAN-1-190214 Page 2

TABLE OF CONTENTS

PROPRIETARY NOTICE............................................................................................................. 3

NAMEPLATE EXAMPLE............................................................................................................ 4

ELECTRICAL SAFETY LABEL ................................................................................................. 4

GENERAL SPECIFICATIONS .................................................................................................... 5

ELECTRICAL SPECIFICATIONS............................................................................................... 5

OPERATION................................................................................................................................. 6

APPLICATIONS ........................................................................................................................... 6

Using FlowStream at Varying Temperatures............................................................................. 6

Reference Conditions for Mass Flow Measurement.................................................................. 7

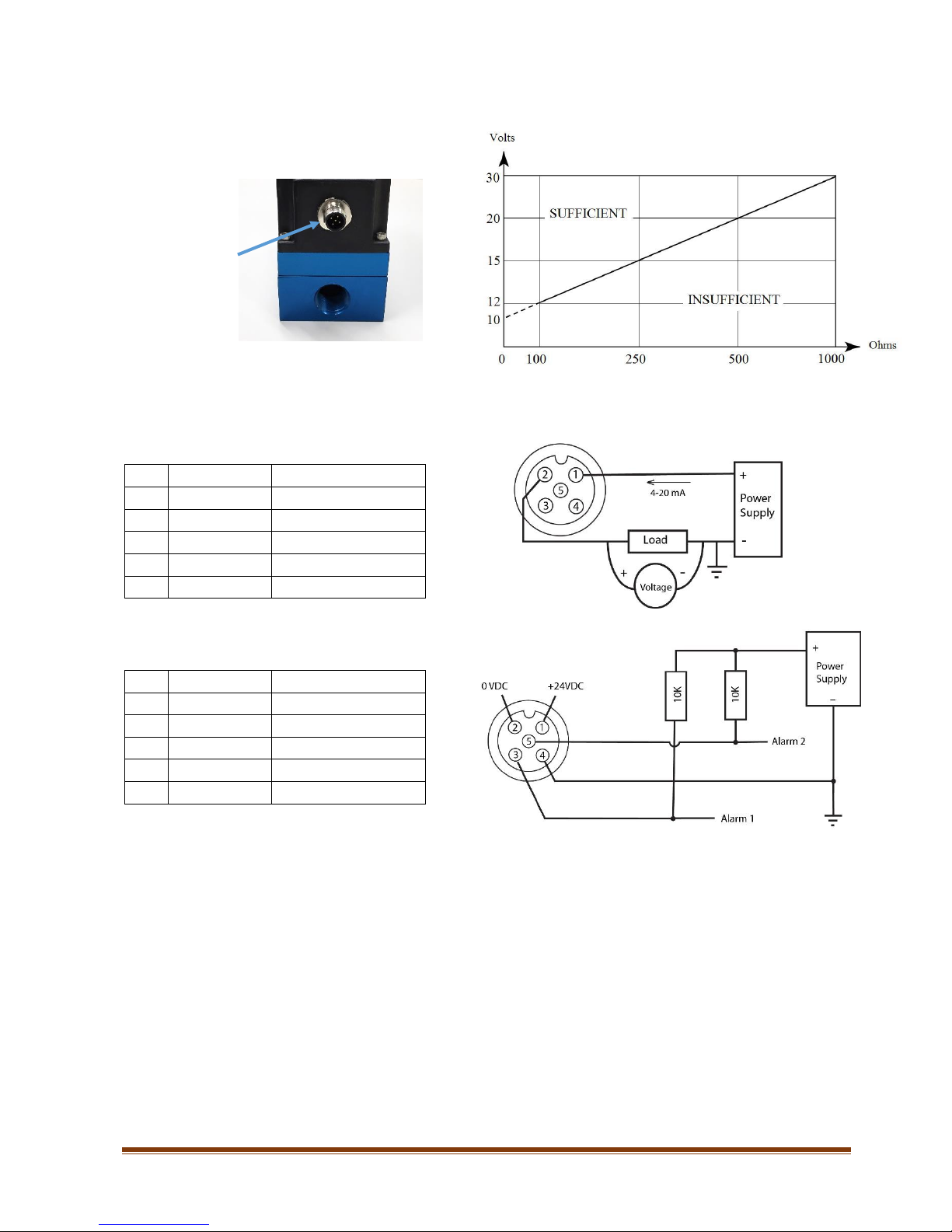

WIRING DIAGRAMS................................................................................................................... 8

KEYPAD OPTIONS...................................................................................................................... 9

USER MENU............................................................................................................................... 10

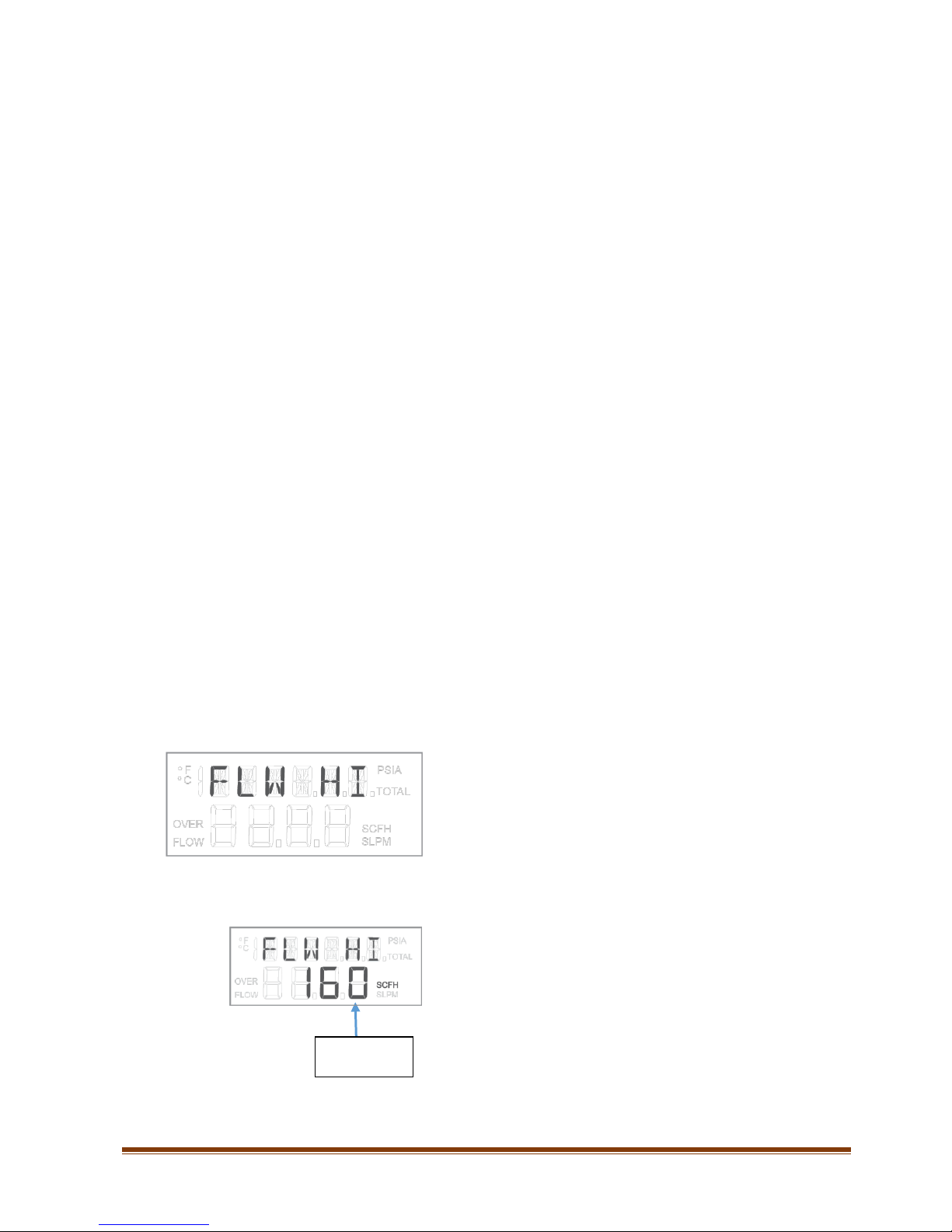

FLOW HI ................................................................................................................................. 10

FLOW LO................................................................................................................................ 11

OUTPUT SPAN....................................................................................................................... 11

THRESH .................................................................................................................................. 11

AVG......................................................................................................................................... 12

GAS.......................................................................................................................................... 12

USER FACTOR....................................................................................................................... 12

RESET...................................................................................................................................... 13

EXIT......................................................................................................................................... 13

AVAILABLE FLOW SIZES....................................................................................................... 14

ORDERING INFORMATION.................................................................................................... 15

DIMENSIONS

............................................................................................................................. 17

RETURN MATERIAL

AUTHORIZATION

............................................................................... 18

WARRANTY INFORMATION.................................................................................................. 20