10

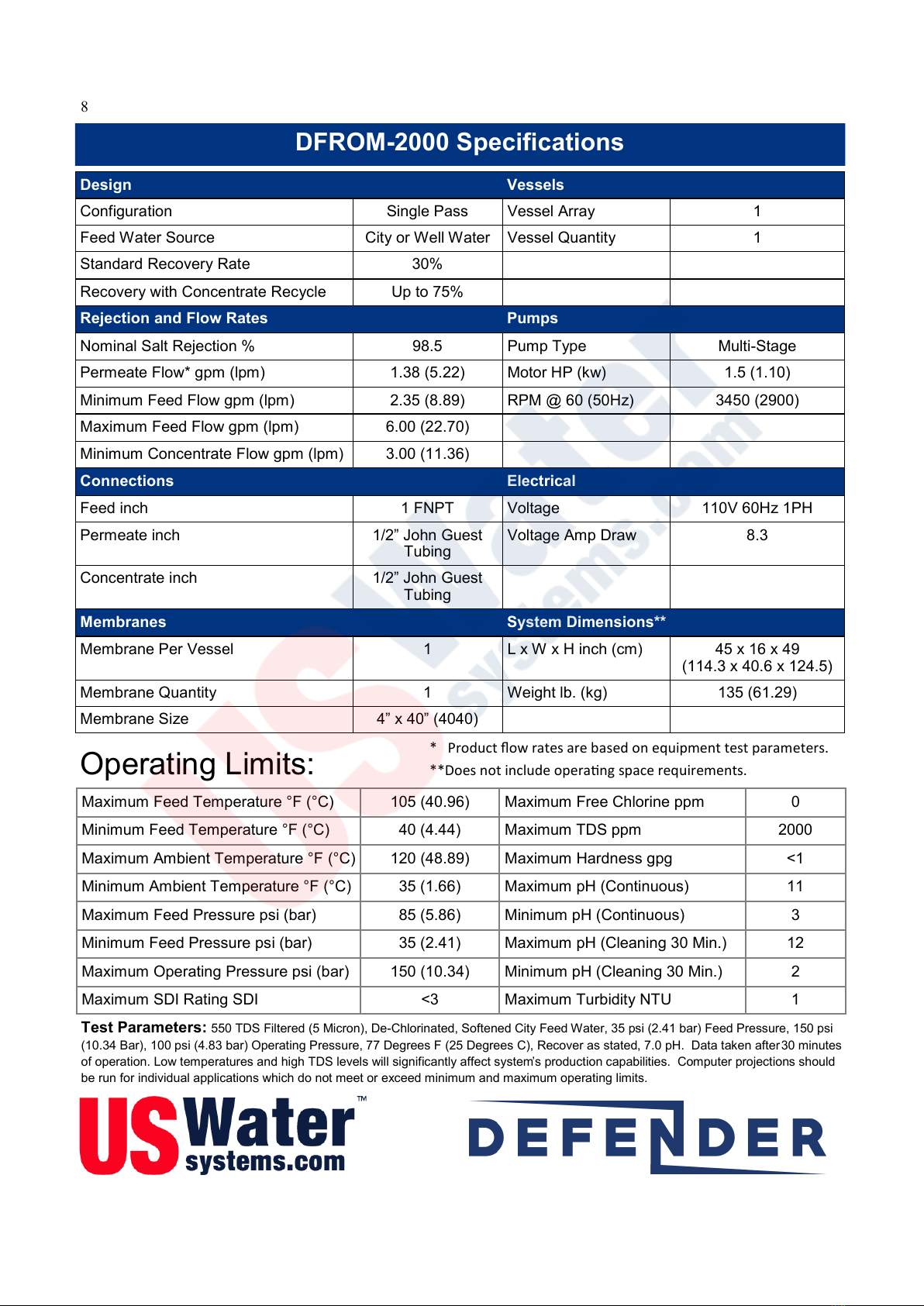

DFROM-6000 Specifications

Design Vessels

Configuration Single Pass Vessel Array 1:1:1

Feed Water Source City or Well Water Vessel Quantity 3

Standard Recovery Rate 53%

Recovery with Concentrate Recycle Up to 75%

Rejection and Flow Rates Pumps

Nominal Salt Rejection % 98.5 Pump Type Multi-Stage

Permeate Flow* gpm (lpm) 4.16 (15.80) Motor HP (kw) 1.5 (1.12)

Minimum Feed Flow gpm (lpm) 7.16 (27.20) RPM @ 60 (50Hz) 3450 (2900)

Maximum Feed Flow gpm (lpm) 14.00 (53.00)

Minimum Concentrate Flow gpm (lpm) 3.00 (11.36)

Connections Electrical

Feed inch 1 FNPT Voltage 220V 60Hz 1PH

Permeate inch 1/2” John Guest

Tubing

Voltage Amp Draw 8.3

Concentrate inch 1/2” John Guest

Tubing

Membranes System Dimensions**

Membrane Per Vessel 1L x W x H inch (cm) 30 x 38 x 47

(76 x 96 x 119)

Membrane Quantity 3Weight lb. (kg) 250 (61.29)

Membrane Size 4” x 40” (4040)

* Product ow rates are based on equipment test parameters.

**Does not include operang space requirements.

Operating Limits:

Maximum Feed Temperature °F (°C) 85 (29.00) Maximum Free Chlorine ppm 0

Minimum Feed Temperature °F (°C) 40 (4.44) Maximum TDS ppm 2000

Maximum Ambient Temperature °F (°C) 120 (48.89) Maximum Hardness gpg <1

Minimum Ambient Temperature °F (°C) 40 (4.44) Maximum pH (Continuous) 11

Maximum Feed Pressure psi (bar) 85 (5.86) Minimum pH (Continuous) 5

Minimum Feed Pressure psi (bar) 35 (2.41) Maximum pH (Cleaning 30 Min.) 12

Maximum Operating Pressure psi (bar) 150 (10.34) Minimum pH (Cleaning 30 Min.) 2

Maximum SDI Rating SDI <3 Maximum Turbidity NTU 1

Test Parameters: 550 TDS Filtered (5 Micron), De-Chlorinated, Softened City Feed Water, 35 psi (2.41 bar) Feed Pressure, 150 psi

(10.34 Bar), 100 psi (4.83 bar) Operating Pressure, 77 Degrees F (25 Degrees C), Recover as stated, 7.0 pH. Data taken after 30 minutes

of operation. Low temperatures and high TDS levels will significantly affect system’s production capabilities. Computer projections should

be run for individual applications which do not meet or exceed minimum and maximum operating limits.