SEA USA User 1 24V DG R1B User manual

USER 1 - 24V DG R1B

24V ELECTRONIC CONTROL UNIT FOR SLIDING GATES AND BARRIERS

67411535 REV 10 - 02/2018

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172 USA

Tel. - :++1-305.594.1151 ++1-305.594.7325

Toll free: 800.689.4716

web site: www.sea-usa.com

e-mail: [email protected]

International registered trademark n. 2.777.971

IMPORTANT SAFETY INFORMATION

All the above described operations must be made exclusively by an authorized installer

Clean and grease parts in movement (wheels,

counter-connecting rod, release, etc.)

Check for corroded parts and replace if

necessary

Check if the screws and all mounting

hardwares are properly tighten

Annual

Annual

Annual

Check the conditions of wear and tear of the

devices in movement

Check the correct drain of the rainwater

Check the integrity of the connection cables

Annual

Annual

Annual

Inspect the track for any signs of cracking or

separation

Ensure that the gate moves freely

Annual

Annual

Check and confirm the proper operation of all

safety devices (photocells, edge sensors etc)

Check and confirm the operation of all

installed accessories

Check and confirm the operation of the

manual release

Annual

Annual

Annual

TURNING ON THE POWER

Check the battery conditions and be sure that

connections are free of corrosion

Verify the functionally of the battery backup,

or power failure option

BY MAIN POWER SOURCE TURNED OFF

Annual

TURNING OFF THE POWER

CCCC

GENERAL SAFETY PRECAUTIONS

The following precautions are an integral and essential part of the product and must be supplied to the user Read

them carefully as they contain important indications for the safe installation, use and maintenance.

1. These instruction must be kept and forwarded to all possible future users of the system.

2. This product must be used only for that which it has been expressly designed.

3. Any other use is to be considered improper and therefore dangerous.

4. The manufacturer cannot be held responsible for possible damage caused by improper, erroneous or

unreasonable use.

5. Avoid operating in the proximity of the hinges or moving mechanical parts.

6. Do not enter the path of the moving gate while in motion.

7. Do not obstruct the motion of the gate as this may cause a situation of danger.

8. Do not allow children to play or stay within the path of the moving gate.

9. Keep remote control or any other control devices out of the reach of children, in order to avoid possible involuntary

activation of the gate operator.

10. In case of break down or malfunctioning of the product, disconnect from the main power source.

Do not attempt to repair or intervene directly, contact only qualified personnel for repair.

11. Failure to comply with the above may create a situation of danger.

12. All cleaning, maintenance or repair work must be carried out by qualified personnel.

13. In order to guarantee that the system works efficiently and correctly it is important to have the manufacturer's

instructions on maintenance of the gate and operator carried out by qualified personnel.

14. In particular, regular checks are recommended in order to verify that the safety devices are operating correctly.

All installation, maintenance and repair work must be documented and made available to the user.

IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4.Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object

activates the non-contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to

adjust and retest the gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service person make

repairs to gate hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. Every gate operator installation MUST have secondary protection devices agains entrapments, such as edge

sensors and photo beams more in particulary in places where the risk of entrapments is more likely to occur

9. SAVE THESE INSTRUCTIONS

!

PERIODICAL MAINTENANCE

GENERAL SAFETY INFORMATION

An appliance shall be provided with an instruction manual. The instruction manual shall give instructions for the

installation, operation, and user maintenance of the appliance.

The installation instructions shall specify the need for a grounding-type receptacle for connection to the supply and

shall stress the importance of proper grounding.

The installation instructions shall inform the installer that permanent wiring is to be employed as required by local

codes, and instructions for conversion to permanent wiring shall be supplied.

Information shall be supplied with a gate operator for:

a) The required installation and adjustment of all devices and systems to effect the primary and secondary protection

against entrapment (where included with the operator).

b) The intended connections for all devices and systems to effect the primary and secondary protection against

entrapment. The information shall be supplied in the instruction manual, wiring diagrams, separate instructions, or the

equivalent.

Vehicular gate operators (or systems)

A vehicular gate operator shall be provided with the information in the instruction manual that defines the different

vehicular gate operator Class categories and give examples of each usage. The manual shall also indicate the use for

which the particular unit is intended as defined in Glossary, Section 3. The installation instructions for vehicular gate

operators shall include information on the Types of gate for which the gate operator is intended.

A gate operator shall be provided with the specific instructions describing all user adjustments required for proper

operation of the gate. Detailed instructions shall be provided regarding user adjustment of any clutch or pressure relief

adjustments provided. The instructions shall also indicate the need for periodic checking and adjustment by a qualified

technician of the control mechanism for force, speed, and sensitivity.

Instructions for the installation, adjustment, and wiring of external controls and devices serving as required protection

against entrapment shall be provided with the operator when such controls are shipped with the operator.

Instructions regarding intended installation of the gate operator shall be supplied as part of the installation instructions

or as a separate document. The following instructions or the equivalent shall be supplied where applicable:

IMPORTANT INSTALLATION INSTRUCTIONS

a) Install the gate operator only when:

1) The operator is appropriate for the construction of the gate and the usage Class of the gate,

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4 feet

(1.22 m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the openings

anywhere in the gate, and in that portion of the adjacent fence that the gate covers in the open position,

3) All exposed pinch points are eliminated or guarded, and

4) Guarding is supplied for exposed rollers.

b) The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a

separate access opening. The partial access opening shall be designed to promote pedestrian usage. Locate the gate

such that persons will not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

c) The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent

structures when opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access

areas.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do

not over-tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

e) The gate operator controls must be placed so that the user has full view of the gate area when the gate is moving and

AWAY FROM THE GATE PATH PERIMETER.

f) Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and

where the user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or

easily accessible controls shall have a security feature to prevent unauthorized use.

g) The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not

cause the operator to start.

h) A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible

International registered trademark n. 2.777.971

i) For gate operators utilizing a non-contact sensor:

1) See instructions on the placement of non-contact sensors for each Type of application

2) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the

gate is still moving

3) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier

j) For a gate operator utilizing a contact sensor:

1) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the

leading edge, trailing edge, and postmounted both inside and outside of a vehicular horizontal slide gate.

2) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4) A hardwired contact sensor shall be located and its wiring arranged so that the communication between the

sensor and the gate operator is not subjected to mechanical damage.

5) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for

entrapment protection functions shall be located where the transmission of the signals are not obstructed or

impeded by building structures, natural landscaping or similar obstruction. A wireless contact sensor shall

function under the intended end-use conditions.

6) One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally,

if the bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of

travel, one or more contact sensors shall be located on the bottom edge.

7) One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

Instruction regarding intended operation of the gate operator shall be provided as part of the user instructions or as a

separate document. The following instructions or the equivalent shall be provided

NOTICE

As for misunderstandings that may arise refer to your area distributor or call our help desk. These instructions are part

of the device and must be kept in a well known place. The installer shall follow the provided instructions thoroughly.

SEA products must only be used to automate doors, gates and wings. Any initiative taken without SEA USA Inc. explicit

authorization will preserve the manufacturer from whatsoever responsibility. The installer shall provide warning notices

on not assessable further risks. SEA USA Inc. in its relentless aim to improve the products, is allowed to make

whatsoever adjustment without giving notice. This doesn’t oblige SEA to up-grade the past production. SEA USA Inc.

can not be deemed responsible for any damage or accident caused by product breaking, being damages or accidents

due to a failure to comply with the instructions herein. The guarantee will be void and the manufacturer responsibility

will be nullified if SEA USA Inc. original spare parts are not being used. The electrical installation shall be carried out by

a professional technician who will release documentation as requested by the laws in force. Packaging materials such

as plastic bags, foam polystyrene, nails etc must be kept out of children’s reach as dangers may arise.

To respect the norms in force it is recommended to use the ENCODER SYSTEM together with the electronic

control units

International registered trademark n. 2.777.971

Starting on Jan. 12, 2016, new UL 325 changes take effect, bringing a series of new mandates for the gate operator

industry. Here’s a quick guide to the key modifications.

1. Entrapment-Protection Devices. Gate operators are required to have a minimum of two independent means of

entrapment protection where the risk of entrapment or obstruction exists. A manufacturer can use two inherent-type

systems, two external-type systems, or an inherent and an external system to meet the requirement. However, the

same type of device cannot be used for both means of protection.

2. Monitoring Required. An external non-contact sensor or contact sensor may be used as a means of entrapment

protection. However, the sensor must be monitored once every cycle for (1) the correct connection to the operator and

(2) the correct operation of the sensor.

If the device is not present, not functioning, or is shorted, then the gate operator can only be operated by constant

pressure on the control device. Portable wireless controls will not function in this case.

3. Entrapment Risk Identification. As in the past, it’s up to the installer to examine the installation and determine

where a risk of entrapment or obstruction exists. Manufacturers are required to provide instructions for the placement

of external devices, but they give only examples of suggested entrapment protection in their installation manuals. If the

installer identifies a risk of entrapment or obstruction, at least two independent means of entrapment protection are

required.

4.Terminology Change. The terms “primary” and “secondary” have been removed in the description of entrapment

protection devices. This was done to emphasize that all entrapment protection devices are equally important.

Changes to UL 325 ED. 6th for Gate Operators

5. The End of Type E. Type E (audible alarm) devices can no longer be used for entrapment protection. This change

was made because the Type E device is really a warning device, not an entrapment-protection device. Also, all gate

operator classes are now required to have an audio alarm that sounds when two successive obstructions are

encountered via a contact-type system.

6. Access Control Location for Emergency Use. An exception has been added in the manufacturer’s instructional

requirements for the location of controls that operate the gate.

The instructional requirements state that these controls must be at least 6' away from any moving part of the gate. In the

new exception, “Emergency access controls only accessible by authorized personnel (e.g., fire, police, EMS) may be

placed at any location in the line-of-sight of the gate.”

7. Barrier-Arm Operator Exception. An exception has changed for barrier-arm gate operators requiring entrapment

protection. The previous exception stated that a barrier-arm operator did not require entrapment protection if the arm

did not move toward a rigid object closer than 2'. The distance has been reduced to 16" so it more closely aligns with the

industry-defined entrapment protection provisions in ASTM F2200.

8. Gate Operator Class II and Class III Definitions. The definitions for installation classes for gate operators were

modified. Class II now includes commercial locations accessible to the general public. Class III was refined to specify

industrial locations not accessible to the general public. These changes, while seemingly minor, may affect which gate

operator is suitable for a particular installation location.

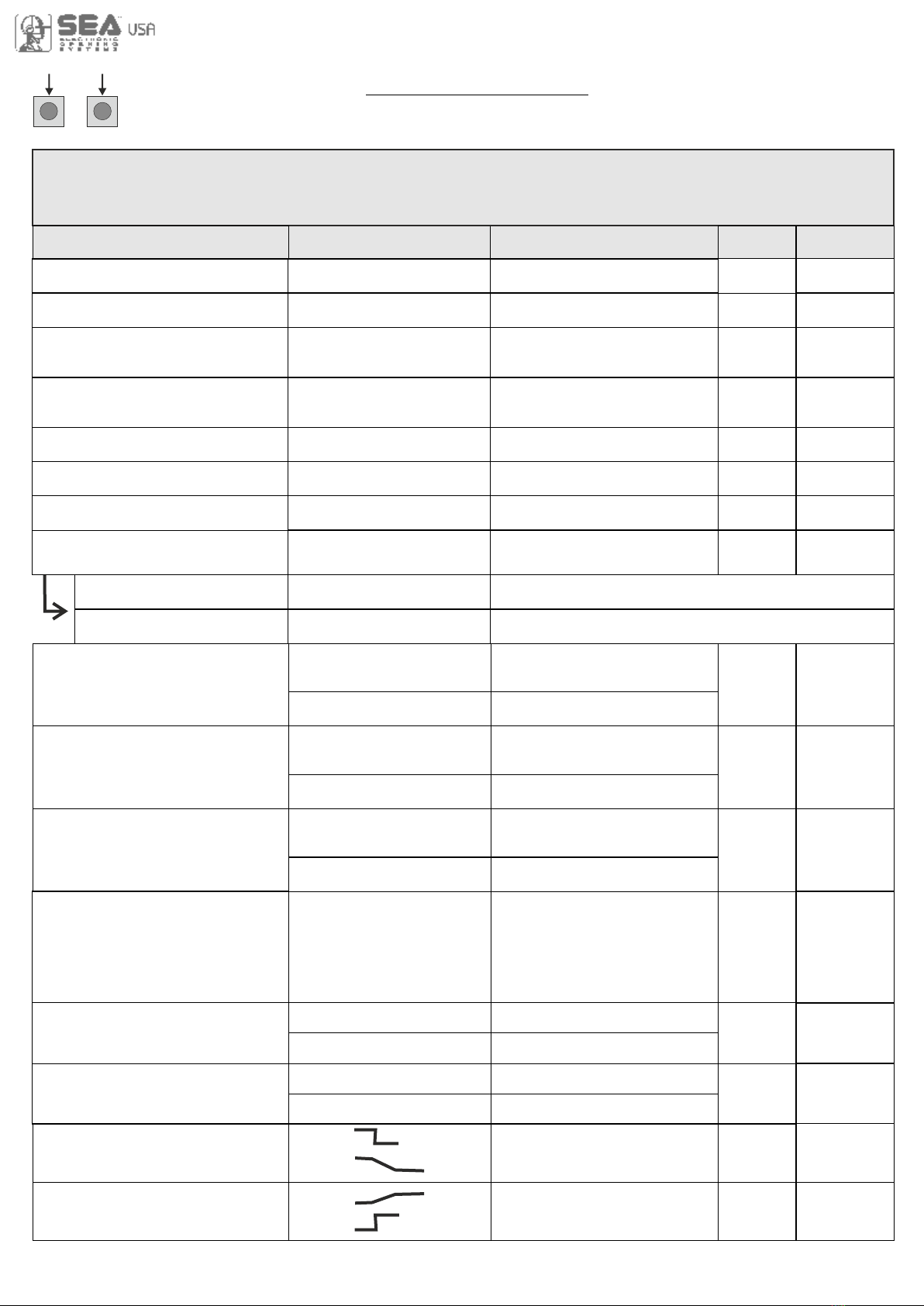

UL 325 ED. 6th ENTRAPMENT PROTECTION REQUIREMENTS

This vehicular gate operator must be installed with at least two independent entrapment protection

means as specified in the table below.

International registered trademark n. 2.777.971

VERITICAL BARRIER NOTE:

Barrier gate operators (arm) that is not intended to move toward a rigid objact closer than 16 inches (406mm)

are not required to be provided with a means of entrapment protection

* B1 and B2 means of entrapment protection MUST be MONITORED

HORIZONTAL SLIDE

VERTICAL LIFT - VERTICAL PIVOT

ENTRAPMENT

PROTECTION

TYPES

TYPE A

TYPE B1

TYPE B2

TYPE C

Inherent entrapment protection system

Non-contact sensors such as photoelectric sensors or equivalents

Contact sensors such as edge sensors or equivalent devices

Inherent force limiting, inherent adjustable clutch or inherent pressure relief device

The same type of device shall not be used for both entrapment protection means. Use of a single device to cover both

the opening and closing directions is in accordance with the requirement; however, a single device is not required to

cover both directions. Tice installer is required to install entrapment protection devices in each entrapment zone

TYPE D Actuating device requiring constant pressure to maintain opening or closing motion of the gate

SWING

VERTICAL BARRIER (ARM)

A , B1*, B2* or D A , B1*, B2*, C or D

GATE OPERATOR CATEGORY

Effective January, 12 2016

VEHICULAR GATE OPERATOR CLASSES

Residential Vehicular Gate Operator-Class I: A vehicular gate operator (or system) intended for use in garages or

parking areas associated with a residence of one-to-four single families

Commercial/General Access Vehicular Gate Operator-Class II: A vehicular gate operator (or system) intended for

use in a commercial location or building such as a multi-family housing unit (five or more single family units), hotel,

garages, retail store, or other buildings accessible by or servicing the general public

Industrial/Limited Access Vehicular Gate Operator–Class III: A vehicular gate operator (or system) intended for

use in an industrial location or building such as a factory or loading dock area or other locations not accessible by or

intended to service the general public

Restricted Access Vehicular Gate Operator–Class IV: A vehicular gate operator (or system) intended for use in an

industrial location or building such as a factory or loading dock area or other locations not accessible by or intended to

service the general public

6

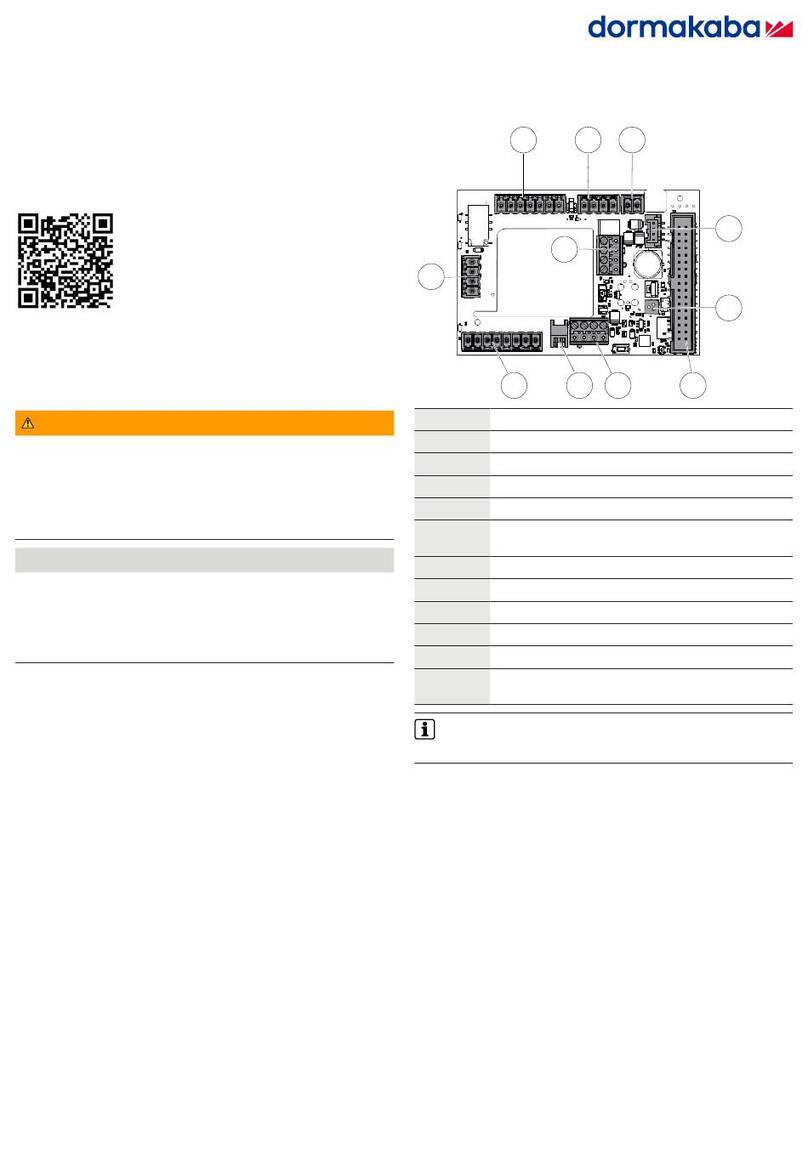

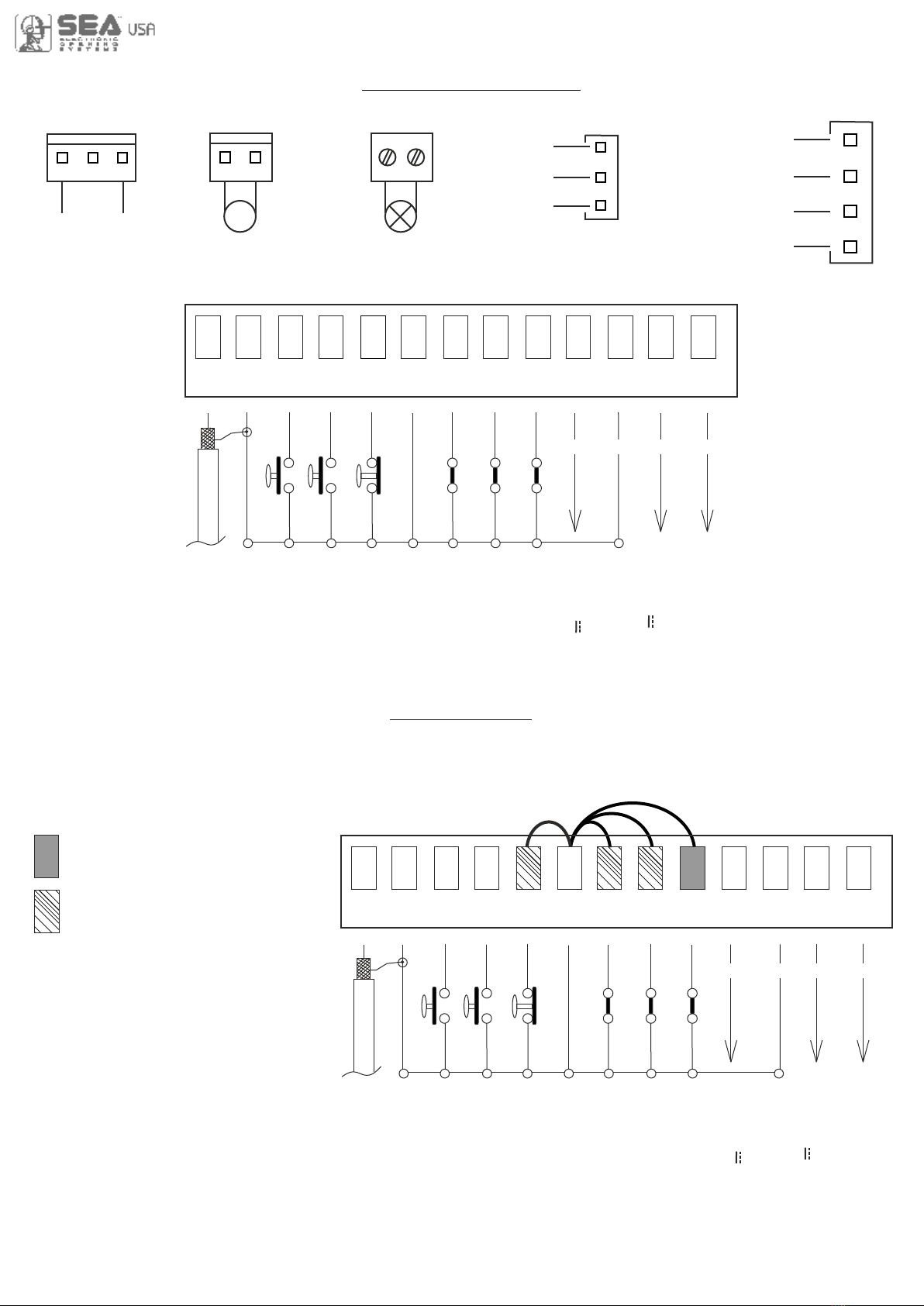

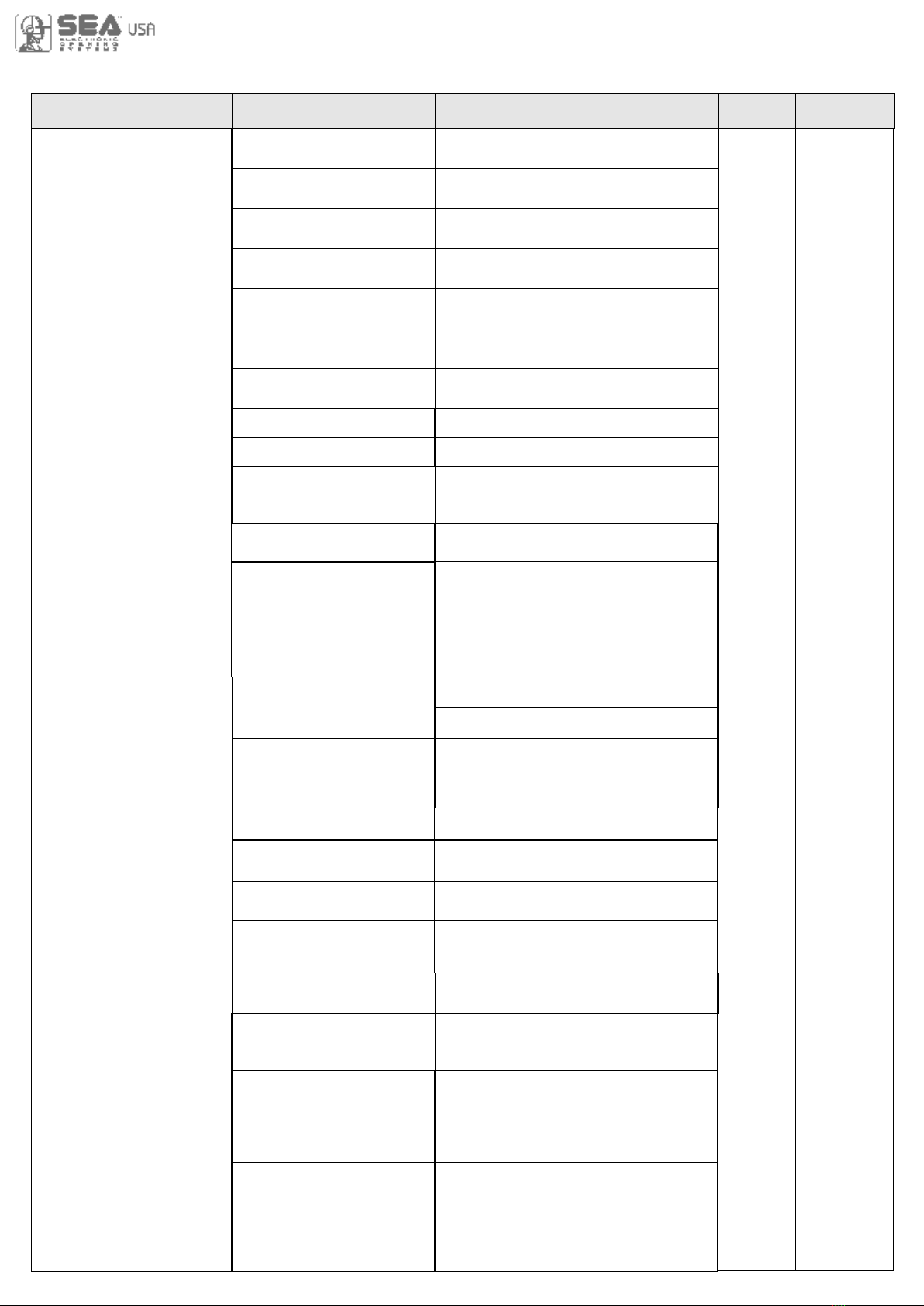

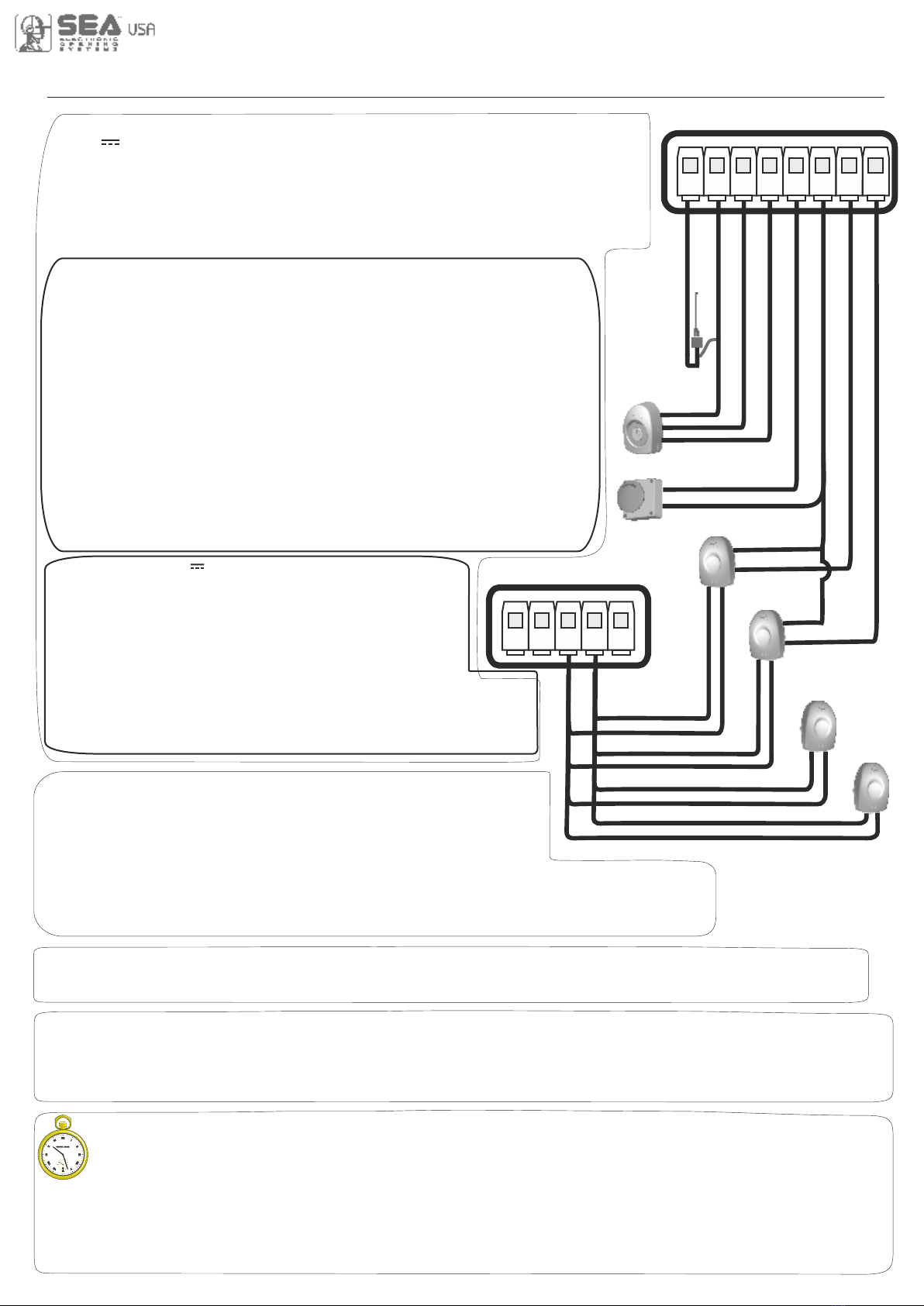

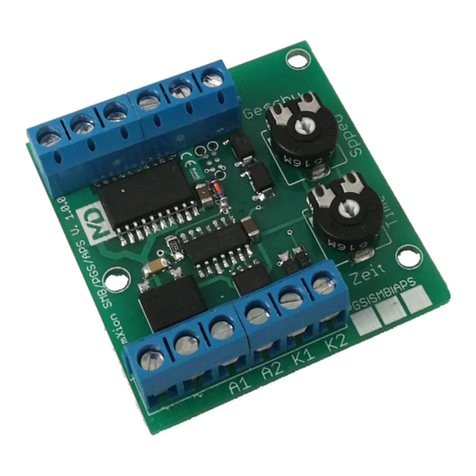

DESCRIPTION OF THE COMPONENTS

TECHNICAL SPECIFICATIONS

Control unit power supply: 24 V~

Absorption in stand by: 30 mA

Environment temperature: -20°C +50°C

Specifications of external enclosure: 305 x 225 x 125 mm - Ip55

JOLLY 3

CN8 F1

CN1

CNA

CN3

CN5

CNP

CN6

RL2

RL1

CN2

CN4

CN7

UP DOWN OK

RD3

RD1

PR1

DISPLAY

1 2 3 4 5 6 7 8 9 10 11 12 13

1

EXP

POWER FUSE BATTERY MOTOR LIGHT

MASTER/SLAVE

PROG

RADIO MODULE

JOLLY

LIMIT SWITCH

156 mm

100 mm

RICEVENTE RX

CNE

ENCODER

1COURTESY LIGHT

Cn1 = Input/Output connector

CN2 = Limit switch connector

CN3 = JOLLY 3 connector

CN4 = Master/slave connector

CN5 = Courtesy light output plug

CN6 = Motors connector

CN7 = Batteries connector - Quick connection

CN8 = Power connector

CNA = RX Receiver connector

CNE = Encoder connector

CNP = Programming connector

EXP = External module connector

OK = Programming button

DOWN = Programming button

UP = Programming button

RD1 =Motors piloting Mosfet

RD3 = Motors piloting Mosfet

R1 = Motors command relay

R2 = Motors command relay

PR1 = Rectifier jumper

F1 = Fuse 10 AT

7

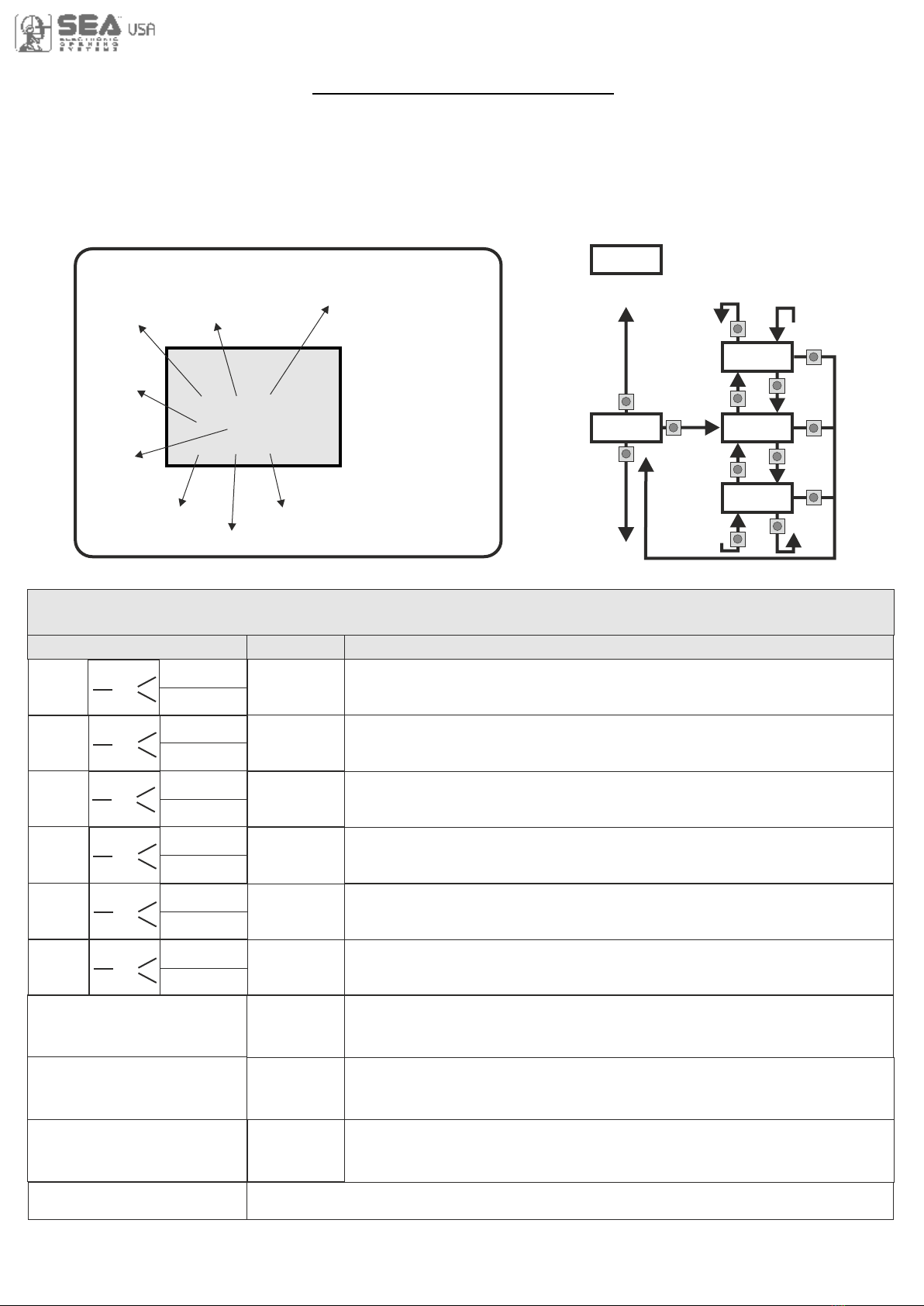

CONNECTIONS

The herein reported functions are available starting from revision 02.00 compatible with JOLLY 3

Start

Stop

Common

Antenna

START Ped.

Common

Photocell 1

Common

AUX

(24V 200 mA max)

24V 750 mA max

(Accessories)

Safety edge

Flash (-)

Photocell 2

WARNING: The control unit is designed with the automatic detection of not used N.C. inputs (photocells, Stop and Limit

switch) except the SAFETY EDGE input. The exclude inputs in self-programming can be restored in the “Check inputs”

menu without need to repeat the programming

Obligatory jumper

without

accessory connection

Limit switch Cl.1 (Yellow)

24V (Red)

Common (White)

Limit switch Op.1 (Green)

LIGHT (CN5)

Max 100mA

POWER (CN8)

24V~

MOTOR (CN6)

M

Max 200W

JUMPERS

123 4 5 6 7 8 910 11 12 13

CN1

ANT COM START

PEDST

STOP COM PH1 PH2

EDGE

AUX

COM 24V (FL)-

123 4 5 6 7 8 910 11 12 13

CN1

ANT COM START

PEDST

STOP COM PH1 PH2

EDGE

AUX

COM 24V (FL)-

Optional

+ +

- -

+ +

- -

LIMIT SWITCH (CN2)

1

ENCODER (CNE)

1

Brown

White

Green

Start

Stop

Common

Antenna

START Ped.

Common

Photocell 1

Common

AUX

(24V 200 mA max)

24V 750 mA max

(Accessories)

Safety edge

Flash (-)

Photocell 2

8

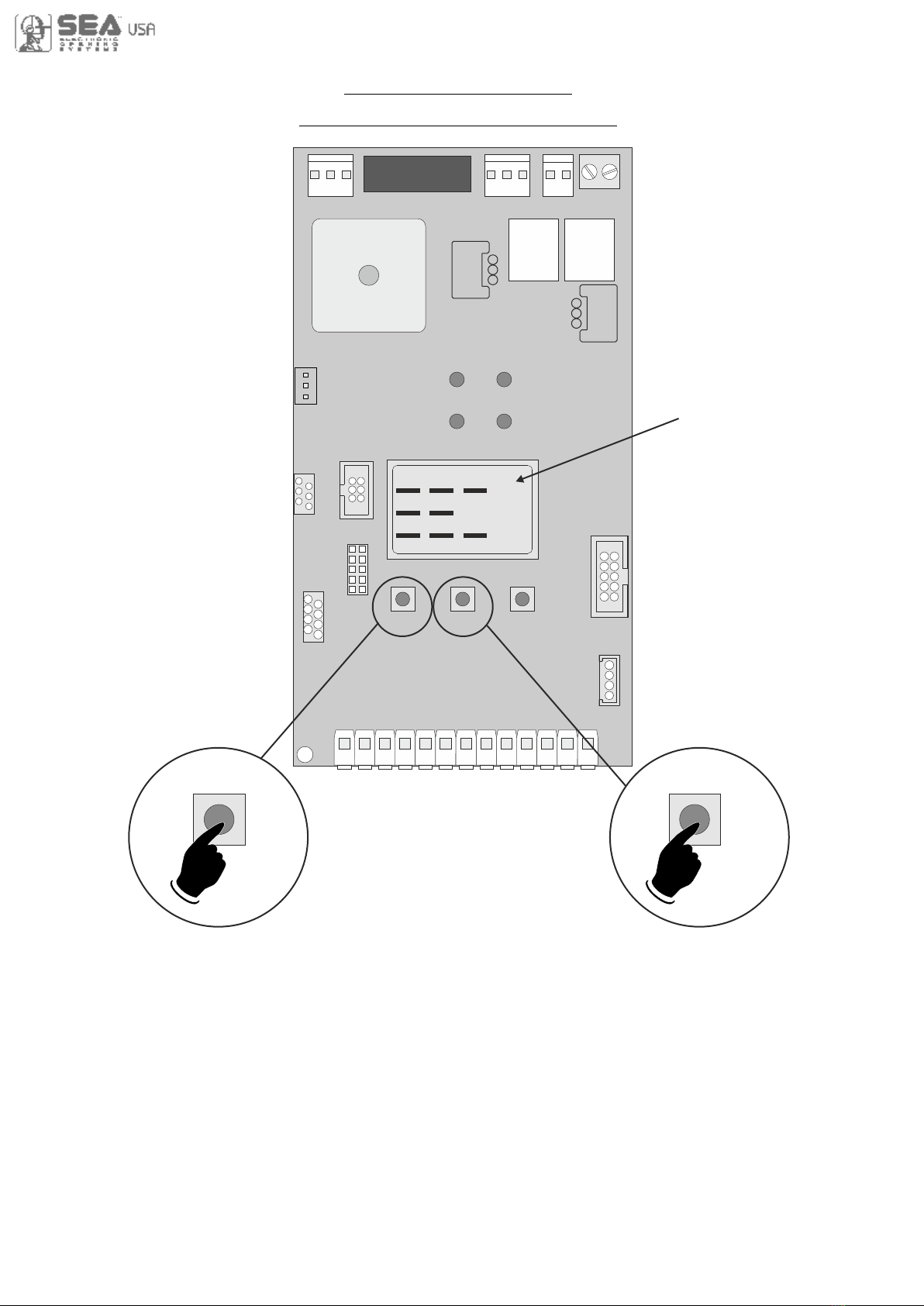

UP DOWN

5 s 5 s

UP DOWN OK

DISPLAY

1 2 3 4 5 6 7 8 9 10 11 12 13

PROGRAMMING

FAST SELF-LEARNING

Start quick programming

You can start the quick programming by

holding UP for 5 s in the “Input check

menu", until the motor starts.

“Input check

menu"

Fast self-learning START command by

radio control

You can store the START button of the

remote control while pressing DOWN for 5 s

in the “Input check menu".

Once the writing "Press button" appears,

press the button of the transmitter, which

you want to store for the START command.

By pressing OK, you can exit the menu,

otherwise it will be left automatically after 5

seconds.

9

PROGRAMMING

BUTTONS

OK to exit

Menu or press

the button of

the next TX to

be stored

RECEIVER

MISSING

Skip this step if you do not want to program a transmitter

Choose the type of

motor with

UP or DOWN

To confirm and

return

to main menu

Choose "ON" with UP or

DOWN button only if in

programming the motor starts

in opening

With UP or DOWN

choose

the desired logic

With UP or DOWN

choose a delay for

automatic closing

With UP or DOWN

Choose ON

With UP or DOWN choose ON

to start times learning

At the end of the selflearning

the control unit returns automatically

to the main menu

With

UP or DOWN Choose

ON to start test

Skip this step if a TX has already been stored

ALL OTHER PARAMETERS HAVE DEFAULT SETTINGS WHICH ARE USEFUL FOR THE 90% OF THE APPLICATIONS

BUT CAN BE HOWEVER SET THROUGH THE SPECIAL MENU. FOR ENTERING INTO THE SPECIAL MENU MOVE

ON ONE OF THE MENU AND PRESS THE UP AND DOWN BUTTONS AT THE SAME TIME FOR 5 S

If on the display

appears the item:

Check if a receiver

has been connceted

The gate will execute a CLOSING-OPENING-CLOSING CYCLE

PROGRAMMING

QUICK START

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

OK

1

2

3

5

6

7

8

9

OK

OK

OK OK

OK OK

OK OK

OK OK

OK OK

UP

UP

UP

UP

UP

UP

UP

OKOK

START

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

OK

UP

LANGUAGE ITALIANO

UP

MENU

SEA

SET

MENU

SEA

SET

OK

END

15

MENU

SEA

SET

OK

SPECIAL

MENU

16

UP

UP

10

OK

DOWNUP

OK

Go back to menu

9-PROGRAMMING,

replace the gate halfway

and repeat the timing

programming

TRANSMITTERS

MOTOR

REVERSE

MOTOR

LOGIC

PAUSE

TIME

START IN

PAUSE

PROGRAM-

MING

TEST

START

If the motor has

magnetic limit switches,

select "Magnetic"

in the special menu:

104 - SELECT LIMIT SWITCH

PRESS

BUTTON STORED

Skip this step

if you want to work

in half-automatic

logic

To confirm and

return

to main menu

To confirm and

return

to main menu

To confirm and

return

to main menu

To confirm and

return

to main menu

To confirm and return

to main menu

Press OK to return to the

display of the inputs state

Press OK to enter the special menu

Press the

button of the

TX to be

stored

10

BASIC MENU

MENU SET

1 - LANGUAGE Español

English

Français

Italiano

Start

Dutch

Italiano

Stop

Unloch

External module

Partial opening Start

Clear memory

Delete a transmitter

End

2 - TRANSMITTERS

3 - MOTOR

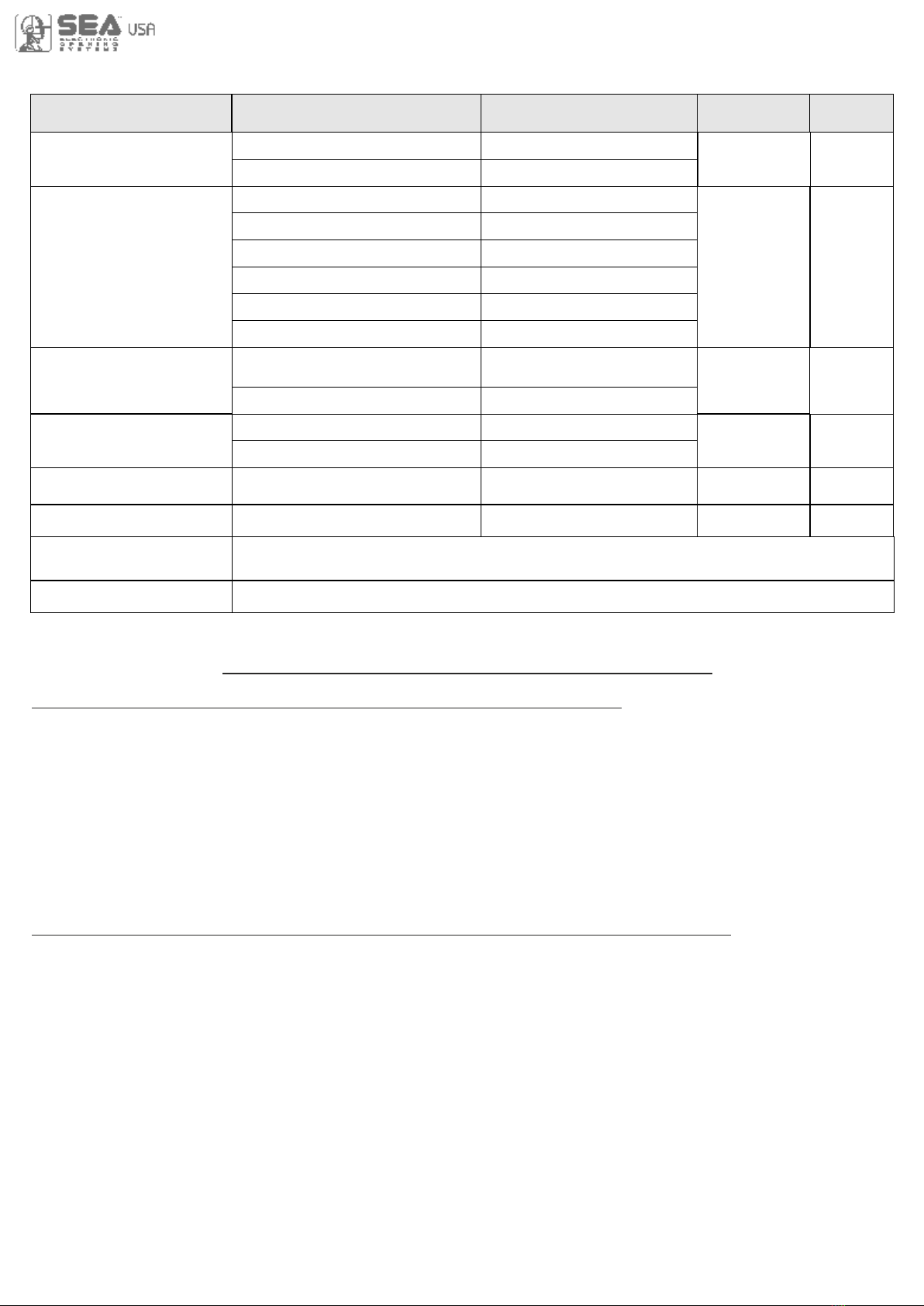

MENU FUNCTIONS TABLE USER1 24V DG R1B

Start

Stop

Storing of a command

for unlocking an electric

brake

Italian

English

French

Spanish

External module

Partial opening Start

Delete single transmitter

Delete transmitter memory

Dutch

“Transmitters” menu output

Start

Partial

Opening

Start

Default

Description Set value

Sliding

Joint

Sprint 3 metres

Saturn

Mercury 800

VergL.5 metres

Erg Maxi

Erg

Verg

Sprint 4 metres

Sprint 5 metres

Storm 5 metres

Storm 6 metres

Storm 7,5 metres

VergL.4 metres

VergL.3 metres

Reversible sliding motors

Mercury Fast

Saturn 1500

Erg Maxi Double

Orion No LS

Taurus No LS

B-224 B-800 No LS

B-200 sliding and B-500

Joint

Sprint 3 metres

Saturn

Mercury 800

VergL.5 metres

Erg Maxi

Erg

Verg

Sprint 4 metres

Sprint 5 metres

Storm 5 metres

Storm 6 metres

Storm 7,5 metres

VergL.4 metres

VergL.3 metres

C-500 and Puma

Mercury Fast

Saturn Fast

Saturn Super Fast

Saturn 1500

Erg Maxi Double

Orion (without limit-switch)

Taurus (without limit-switch)

B-224 e B-800

(without limit-switch)

Saturn Fast

Saturn Super Fast

Sliding

Bistable Stop

Pressed once, it stops the

gate; pressed twice, it re-

active the Start command

11

WORKING TIMES SELF-LEARNING

1 240

Off Off

Off

On Off

Off

On

Off On

Off

Off

Off On Off

Automatic

2 buttons

Safety

Dead man

Open-stop-close-stop-open

Open-stop-close-open

Press OK to return to the display of the firmware version

and to the one of inputs state

Press OK to enter the special menu

8 - START IN PAUSE

6 - LOGIC

7 - PAUSE TIME

5 - REVERSE MOTOR

9 - PROGRAMMING

10 - TEST START

15 - END

16 - SPECIAL MENU

Synchronized right motor

Automatic

Step by step type 1

Step by step type 2

Two buttons

Safety

Dead man

Setting from 1s to 4min.

OFF

(semi-automatic logics)

In pause start is not acceped

In pause start is accepted

Start command

Times learning start

Synchronized left motor

Open-stop-

close-open

MENU SET

Default

Description Set value

WORKING TIME SELF-LEARNING ON MOTORS WITH LIMIT-SWITCH

PRELIMINARY NOTE: When using magnetic limit switches (such as on B-200 model), make sure that

the control unit is set on «magnetic limit switch» before learning:

MENU 104 - SELECT LIMIT SWITCH - “Magnetic”

1) Turn off the power supply, release the motor and place the door (or the barrier) manually at its mid run

2) Reset the mechanical lock

3) Select 9 - PROGRAMMING on the display, press OK and then one of the UP or DOWN buttons.

Now the gate will automatically execute a CLOSING-OPENING-CLOSING cycle

4) The self-learning is done

WORKING TIME SELF-LEARNING ON MOTORS WITHOUT LIMIT-SWITCH (NO LS)

PRELIMINARY NOTE: motors without limit-switch must have MECHANICAL STOPS IN OPENING AND

CLOSING set on the desired point of stop as in opening as in closing

Follow the points from 1 to 4 above shown as in the procedure for limit-switch motors

ATTENTION: If the motor starts in opening, remove and re-put power supply, select on the display

5-REVERSE MOTOR and through the UP and DOWN buttons select ON; if you have the Jolly3 programmer,

activate the motor exchange function and, only if present, limit-switch exchange function. If the motor starts

in closing and stops, remove the power supply and reverse the motor cables, then repeat the programming

procedure

ATTENTION: This procedure is potentially dangerous and should only be performed by qualified

personnel in safety conditions

The control unit is pre-set with DEFAULT settings. To start the control unit with the DEFAULT settings

just keep pressed the UP and DOWN buttons at the same time power supplying the control unit

till the display shows the message «INIT». The DEFAULT settings are shown in the Menues table

12

FUNCTION LOGIC

AUTOMATIC LOGIC

A start impulse opens the gate. A second impluse during the opening will not be accepted.

A start impulse during closing reverses the movement.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

SECURITY LOGIC

A start impulse opens the gate. A second impulse during opening reverses the movement.

A start impulse during closing reverses the movement.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

STEP BY STEP TYPE 1 LOGIC

The start impulse follows the OPEN-STOP-CLOSE-STOP-OPEN logic.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

STEP BY STEP TYPE 2 LOGIC

The start impulse follows the OPEN-STOP-CLOSE -OPEN logic.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

DEAD MAN LOGIC

The gate opens as long as the START button of opening is pressed; releasing it the gate stops. The gate

closes as long as the button connected to the PARTIAL OPENING START is pressed; releasing it the gate

stops. To execute complete opening and/or closing cycles the related pushbuttons must be constantly

pressed.

2 PUSHBUTTONS LOGIC

One start opens, one partial opening start closes. In opening the closing will not be accepted. In closing a

start command reopens, a partial opening start command (closes) will be ignored.

PASSWORD ENTERING MANAGEMENT

With a new control unit all menus can be displayed and set and the password will be disabled.

Selecting one of the Menus and keeping UP and DOWN pressed at the same time for 5 seconds, you will

access the SP Menu containing the 34-PASSWORD Menu. Pressing OK in the 34-PASSWORD Menu, you

will proceed with the entering of the numeric code of the 4-digit password. Use UP and DOWN to increase or

decrease the number, press OK to confirm it and you will pass automatically to the entering of the next

number. Pressing OK after the last entered number the word “Sure?” appears, confirm the activation of the

password and the message OK appears, pressing UP or DOWN instead you can cancel the operation and

“No operation” will appear on the display. Once entered the password, it will be definitively activated, once

the display switch off timeout has expired, or by turning off and on again the control unit. Once the password

has been activated, the menus of the display can be only displayed but not set. To unlock them you must

enter the correct password in the 34-PASSWORD menu, if the password is wrong the message “Error” will

appear. At this point, if the password has been entered correctly, the menus will be unlocked and it will be

possible to change the parameters of the control unit again. If the control unit has been unlocked through 34-

PASSWORD Menu, it is possible to enter a new and different password, using the same entering process as

for the first one; at this point, the old password will no longer be valid. If the password has been forgotten, the

only way to unlock the control unit is to contact the SEA technical assistance, which will assess whether to

provide the procedure to unlock the control unit or not.

Note: The password cannot be set through the Jolly 3 terminal.

13

UPDOWN

PRESS AT THE SAME TIME FOR 5 S TO ENTER OR TO EXIT THE SPECIAL MENU

SPECIAL MENU

MENU SP Default

SET

SPECIAL MENU FUNCTIONS TABLE USER 1 24V DG R1B

For entering into the special menu move on one of the menu and press the UP and DOWN

buttons at the same time for 5 s. For exiting the special menu press END or move on one of the

menu and press the UP and DOWN buttons at the same time for 5 s.

Description Set Value

30 100

30 100

30 100

30 100

30 100

10 100

10 100

10% (Fast intervention)

99% (Slow intervention)

Off (Intervention excluded)

10% (Fast intervention)

99% (Slow intervention)

Off (Intervention excluded)

- - - - -

Off

5 100

Off

5 100

17 - OPENING SPEED 1 *

18 - CLOSING SPEED 1 *

21 - OPENING SLOWDOWN

SPEED 1 *

22 - CLOSING SLOWDOWN

SPEED 1 *

25 - LEARNING SPEED *

28 - OPENING TORQ 1 *

29 - CLOSING TORQ 1 *

33 - OPENING SENSITIVITY

MOTOR1 *

34 - CLOSING SENSITIVITY

MOTOR1 *

57 - WORKING CURRENT

59 - OPENING

SLOWDOWN 1 *

60 - CLOSING

SLOWDOWN 1 *

10% (Fast intervention)

99% (Slow intervention)

Off (Intervention excluded)

37 - SLOWDOWN

SENSITIVITY

xxx.

xxx.

47 - ENCODER PAR.1 *

48 - ENCODER TOT.1 *

0 %

100%

63 - DECELERATION *

Setting from 30 to 100

Setting from 30 to 100

Setting from 30 to 100

Setting from 30 to 100

Setting from 30 to 100

Opening torq

Closing torq

Adjusts the intervention time

of the Encoder in opening

Disabled

Adjusts the intervention time

of the Encoder in closing

Disabled

Disabled

Adjusts the aperometric

sensitivity during slowdown

Shows the absorbed current

by the motor during the mo-

vement. The letter H at the

left of the current value indi-

cates the exceeding of the

set inversion threshold

Disabled

Setting from 5 to 100

Disabled

Setting from 5 to 100

Encoder impulses during operation

Encoder impulses stored

Adjusts the passage

between normal speed

and slowdown speed

30

30

* 50

* 50

* 80

* 80

* 40

* 40

* 50

* 60

* 60

30

On

32 - ENCODER

If ON it allows the

Encoder reading Off

0 %

100%

64 - ACCELERATION *

Acceleration ramp

Adjusts the motor start

Note: Menus 47 and 48 are present only if the encoder is ON

* 70%

* 50%

14

73 - CLOSING TOLERANCE

MOTOR1

0 100

82 - MOTOR RELEASE

1 100

Off

Disabled

Setting from 1 to 100

Off

Adjusts the tolerance

between stop and obstacle

closing

0

MENU SP Default

SET Description Set Value

0 15 6 %

0 15 6 %

70 - OPENING POSITION

RECOVERY

71 - CLOSING POSITION

RECOVERY

Retrieves the inertia of the

motor in opening after Stop

or reversing

Retrieves the inertia of the

motor in closing after Stop

or reversing

0 100

Adjust the tolerance between

stop and obstacle opening

72 - OPENING TOLERANCE

MOTOR1 0

Off

Off

79 - ANTI INTRUSION Only closing

Only opening

Opening and closing

If you force the gate

manually, the control

unit starts the motor to

restore the state of the

gate before forcing

85 - PREFLASHING

86 - FLASHING LIGHT

87 - FLASHING LIGHT

AND TIMER

88 - COURTESY LIGHT

89 - TRAFFIC LIGHT

RESERVATION

90 - PARTIAL OPENING

91 - PARTIAL OPENING

PAUSE

92 - TIMER

0.0 5.0

Only closing

Buzzer

Normal

Light

Always

Off

On

In cycle

1 240

Off

Off on

20 100

= Start

Off

Off

On photo2

On pedestrian entry

1 240

Pre-flashing only

active before closing

Pre-flashing time

Normal

Control lamp

Always ON

Buzzer

The flashing light remains

OFF with the active timer

and open gate

The flashing light remains

ON with active timer and

open gate

Disabled

Courtesy light setting

from 1s to 4 min

Courtesy light in cycle

Off

Normal

Off

Off

Off

30

= Start

Off

When setting this function

the partial opening input

will be activated to work on

the auxiliary board SEM

(traffic light management)

Setting from 20 to 100

Pause in partial opening

same as in total opening

Disabled

Setting from 1s to 4 min.

Transforms the selected

input in an input on

which to connect an

external clock

15

MENU SP Default

SET Description Set Value

Negative brake management

Negative Electrobrake

1 flash per sec. in opening

2 flashes per sec. in closing

Steady lit in Stop or Open

Gate open warning

light

Always AUX output always

power supplied

94 - 24V AUX

In cycle

In pause

Opening

Closing

AUX output power sup-

plied only during opening

AUX output power sup-

plied only during closing

AUX output power sup-

plied only during pause

AUX output active

only during cycle

Always

Fototest

In cycle and fototest

AUX output only during cycle

with fototest function active

AUX output for connection

of photocell TX to autotest

Positive brake management

Positive Electrobrake

95 - FOTOTEST

Photo1

Photo2

Photo1-2

Auto-test active only on Photo1

Auto-test active only on Photo2

Auto-test active on

Photo1 and Photo2

Photo1-2

97 - PHOTO1

Opening and closing

Closing

Stop and close

Close

Pause reload

Active in opening and closing

Photocell active in closing

The photocell gives a command

to close during opening, pause

and closing

The photocell charging

t h e p a us i n g t i m e

The photocell stops in closing

and closes when released

Closing

Delay pause time

If the photocell is occupied

during opening, pause or

closing, the gate reopens

completely and closes without

observing the pause time

Shadow loop

Until occupied with open gate,

it prevent reclosing. The loop

function is OFF during closing

Shadow loop RP

Until occupied with open gate,

it prevent reclosing. Once

released, the gate repeats the

pause timebefore closing.

The loop function is OFF during

closing

Stop

The photocell is active

also before opening

Start 3s

Barrier Led Light

the output will be activated at

each Start impulse for 3 seconds

The 24Vaux output will pilot the

lights on the barrier so that, with

the beam closed the light is on,

with the beam opened the light is

switched off and with the moving

beam the light is blinking

16

MENU SP Default

SET Description Set Value

98 - PHOTO2

Opening

Opening and closing

Closing

Stop and close

Close

Pause reload

Active in opening and closing

Photocell active in closing

The photocell gives a command

to close during opening, pause

and closing

The photocell charging

t h e p a us i n g t i m e

The photocell stops in closing

and closes when released

Delay pause time

If the photocell is occupied

during opening, pause or

closing, the gate reopens

completely and closes without

observing the pause time

Shadow loop

Until occupied with open gate,

it prevent reclosing. The loop

function is OFF during closing

Shadow loop RP

Until occupied with open gate,

it prevent reclosing. Once

released, the gate repeats the

pause timebefore closing.

The loop function is OFF during

closing

Stop

The photocell is active

also before opening

Stop N.O.

(only for VERG barrier)

It modifies the PHOTO2 input

into a Normally Open stop button

100 - EDGE1

8K2

Edge is active and pro-

tected by a 8K2 resistor

Normal

99 - PHOTO OFF

IN CLOSING 0 50 0

Setting from 0 to 50

Normal N.C. contact

Normal

8K2 Double

Photo 1 10K

Photo 1 10K Double

Allows to connect two

edges protected by a 8K2

resistor

Edge works as a photocell

protected by a 10K resistor

Allows to connect two

photocells protected by a

10K resistor

104 - SELECT

LIMIT SWITCH *

Mechanical limit switch

Magnetic limit switch

Mechanical

Magnetic

Mechanical

102 - EDGE

DIRECTION

Opening and closing

Only in Closing

Only in Opening

Active in opening and closing

Active only in Closing

Active only in Opening

Opening

and

closing

Stop and Open

If the photocell is activated during

opening, the gate stops and con-

tinues to open when released.

The photocell is ignored in

closure

17

1 10

Shows last event

(See alarms table)

106 - DIAGNOSTICS

0 240000 0

100 240000 100000

107 - MAINTENANCE

CYCLES

108 - PERFORMED

CYCLES

Setting from 100 to

240000

See Note 3 below

Reports the executed

cycles. Keep pressed

OK to reset the cycles

112 - PASSWORD - - - -

Allows the entering of a

password blocking the

control unit parameters

modification

- - - -

When ON, if no mains

power and batteries

connected, the gate

will open fully and will

remain open until the

power returns. At this

point it will perform an

automatic reclosing

113 - EMERGENCY Off On

Off

Press OK to exit the special menu.

The special menu switches off automatically after 20 minutes

120 - BASIC MENU

MENU SP Default

SET Description Set Value

From 30% to 100% 80%

119 - DISPLAY WRITING

SPEED

Note 1: The * indicates that the default value or the menu may change depending on the selected motor

type.

Note 2: After initialization the parameters "motor type" and "limit switch type" remain son the value chosen in

the setup program.

Note 3: Display writing speed set on 30% keeps writing slow; Display writing speed set on 100% keeps

writing fast. Please note that speed does not change on JOLLY 3 display.

105 - MASTER-SLAVE

Master

Slave

Off

Off

For applications with two

motors in master-slave,

you can set the control

unit as slave

For applications with two

motors in master-slave, it

allows to set the control

unit as master

Disabled

18

Initial system

Software Version

Programming example

DISPLAY INPUT STATUS

W h e n t h e

segment is ON

d u r i n g s e l f -

le arn in g, the

input status is

closed or OFF

Partial Opening

Start

Photocell 1

Photocell 2

Edge 1

MENU

SEA

SET

- - -

- -

- - -

Start

Stop

Limit

Switch

opening

motor 1

Limit

Switch

closing

motor 1

VERG

UP

OK

UP

UP

UP

DOWN

DOWN

DOWN

OK

OK

OK

DOWN

SCOR

JOINT

UP

U.001

MOTOR

LIMIT SWITCH

CLOSING

LIMIT SWITCH

OPENING

MENU

START

Description Description

EDGE

PHOTO1

PHOTO2

END

Start test

Safety edge

test

Photocell 1

test

Photocell 2

test

Opening

limit switch

test

Closing

limit switch

test

The contact must be a N.O. Contact . When activating the related

command on the display SET lights up, the input works.

If SET is always on, check the wirings.

The contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

The contact must be a N.O. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, check the wirings.

The contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

Ithe contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

The contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

Exit menu

OK

OK

MENU FUNCTION TABLE CHECK USER 1 24V DG R1B INPUTS

To access the Menu for input check keep pressed OK for about 5 seconds.

OK

0.0V

Batteries

Voltage

Level

Note: If the Stop, Photocell 1 and Photocell 2, Edge 1 contacts are not bridged in self-learning,

they will be deactivated and can be reactivated through this menu, without repeating times self-learning

The contact must be a N.C. Contact. When activating the related command on

the display SET lights up, the input works. If SET is always on, make sure that

the contact is a N.C. Contact. Menu active only on version with limit switches

Enabled

Enabled

Blocked

Blocked

Enabled

Blocked

Enabled

Blocked

Partial

opening

Start test

STOP OK

OK

START

PARTIAL

OPENING

OK

Enabled

Blocked

Enabled

Blocked

Stop test

Batteries charge level indicator

The contact must be a N.C. Contact. When activating the related command on

the display SET lights up, the input works. If SET is always on, make sure that

the contact is a N.C. Contact. Menu active only on version with limit switches

INPUT CHECK MENU

The settings of the control unit are made through the UP, DOWN and OK buttons. The UP and DOWN

buttons to scroll through the MENUS and SUBMENUS. By pressing OK you enter from MENU into

SUBMENU and confirm the choice. Moving in the 1-LANGUAGE menu pressing the UP and DOWN buttons

at the same time you access the SP MENU for special settings. Moving in the 1-LANGUAGE menu pressing

the OK button for 5 seconds, you enter the CHECK MENU, where you can check the operating status of all

inputs.

19

RADIO TRANSMITTER SELF LEARNING

WITH RECEIVER ON BOARD OF CONTROL UNIT

!

WARNING: Make the radio transmitters programming before you connect the antenna and insert

the receiver into the special CMR connector (if available) with turned off control unit. With RF UNI

and RF UNI PG module it will be possible to use both Coccinella Roll Plus transmitters and radio

transmitters with fixed code. The first memorized radio transmitter will determine the type of the

remaining radio transmitters. If the receiver is a Rolling Code, press twice the button of the radio

transmitter that you want to program to memorize the first TX. In the case of transmitters with fix code it is

necessary to press 1 time the button of the transmitter you want to program to store the first remote control

Notes:

- Enter radio transmitters learning only when the working cycle stops and the gate is closed.

- You can store max. 2 of the available 4 functions. If the control unit receives a code which was already

associated to another function it will be updated with the new function.

TABLE EXAMPLE

Transmitter

button

Memory

location

Serial

number Customer

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

SET

START

PARTIAL

OPENING

START

EXTERNAL

MODULE

STOP

DELETE A

TRANSMITTER

0OK? OK

CLEAR

MEMORY OK

PRESS

BUTTON STORED

STORED

STORED

STORED

PRESS

BUTTON

PRESS

BUTTON

PRESS

BUTTON

If you want to program the

partial opening start as

second channel

If you want to delete

a single transmitter

If you want to delete

the whole memory

If you want to program the

activation of the LIGHT

output as second channel

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Select with

UP or DOWN

the memory

location

to be deleted

and press OK

Press the

button of the

transmitter

to be stored

If you do not want to execute the

cancellation, press UP or DOWN to

return to the 2-TRANSMITTER menu

Confirm the cancellation

If you want to program the

UNLOCH as second channel

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

UNLOCH STORED

PRESS

BUTTON

Press the

button of the

transmitter

to be stored

If you want to program the

STOP as second channel

OK

for 10 s.

MENU

SEA

SET

OK

TRANSMITTERS

OK

MENU

SEA

SET

If you want to exit the

2-TRANSMITTERS menu

END

MENU

SEA

SET

OK

UP

OK

OK

OK

OK

OK

OK

OK

Menu output

RF UNI 16 USERS Whitout memory

800 USERS With additional memory MEM

RF UNI PG 100 USERS Fixed code

800 USERS Roll Plus

RF UNI PG 800 UTENTI Fixed code

800 UTENTI Roll Plus

New model

Old Model

12 3 4

0

1

2

3

20

START - STOP - PARTIAL OPENING - ANTENNA - PHOTOCELL

START (N.O.) The START is connected between the clamps 2 and 3 of the CN 1 terminal.

An impulse given to this contact opens and closes the automation depending onthe selected logic it can be given by a key switch,

a keypad, etc. To connect the other devices refer to the related instructions leaflets. (ie. loop detectors and proximity switches).

Note1: In DEAD MAN logic it is necessary to keep pressed the Start for the opening of the automation.

Note2: In 2 BUTTONS logic this button performs the opening.

STOP (N.C.) The STOP is connected between the clamps 2 and 5 of the CN1 terminal .

The pressure on this button immediately stops the motor in any condition/position. A start command is needed to

re-start the movement. After a stop the motor always re-starts in closing.

Can be activated through on-board display or through the Jolly programmer. In both cases it’s a N.O. contact

which provoques the opening of the automation keeping it open until it is activated. When it’s released, the gate

attends the set pausing time and executes the reclosing. The TIMER command can be activated on the inputs

FOTO2, PARTIAL OPENING.

Note1: When activated on the pedestrian entry, the partial opening will be disabled also on the radio transmitter.

Note2: In case of intervention of a security device during the timer (Stop, Ammeter, Edge), to restore the movement it will be

necessary to give a start impulse.

Note3: In case of no power supply with open gate and active Timer the control unit will restore its use, otherwise if during restore

of the power supply the TIMER is not activated it will be necessary to give a start impulse for the reclosing.

TIMER

PARTIAL OPENING (N.O.) The partial opening can be connected

between the clamps 2 and 4 of the CN1 terminal .

This input allows a partial opening the opening space can be set through the

on-board display or through the JOLLY device.

Note1: The contact for partial opening is a N.O. Contact (Normally open).

Note2:In 2 BUTTONS logic it is necessary to keep pressed the Start Ped. to re-close the automation.

Note3: In dead man logic this button executes the re-closing if you keep it pressed.

Note4: When closed during pause, the gate will reclose only after this input has been reopened.

TIMER activation: This input can be transformed into TIMER (See TIMER).

Photocell 1 and Photocell 2 Connections

+ = 24V (Accessories) max 750mA COM = 0V PH1 = Photocell contact 1

PH2 = Photocell contact 2

Note: Self-test: connect the TX to the AUX clamp and activate the Autotest function. The

photocell 1 default setting is FOTO CLOSE and the photocell 2 one is FOTO OPEN. The

photocell 2 can be set also as TIMER (see TIMER function).

Note3: On the 26-FOTOTEST menu you can also activate the self-test even on the single

photocell.

OPTIONS ON FOTO1 and FOTO2 adjustable on on- board display or with

JOLLY terminal.

FOTO CLOSE activation (“Closing”): if occupied, reverses the movement in closing,

during pause it prevent the closing.

Activation repeat pause (“Pause reload”): If occupied, during pause it recharges the

timer of pause. In closing it reverses the movement.

FOTO OPEN AND CLOSE activation (“Opening and closing”): If activated the photocell

blocks the movement as long as it’s busy, when released the opening continues.

FOTO PARK activation (“Stop and close”) : in opening it is not active; in pause are

activated it commands the closing when released, otherwise it’s not active; in closing it stops

the movement as long as it is busy, when released the closing continues.

FOTO STOP activation (“Stop”): When activated before the opening the photocell blocks

the automation as long as it is busy, during the opening it will be ignored. In closing the

intervention of the photocell causes the reopening.

Activation PHOTO CLOSE IMMEDIATELY (“Close”): The photocell stops the gate as

long as it is occupied in both opening and closing, when released it gives a closing command

(Closing one second after release of the photocell ).

“Delay pause time”activation: If the photocell is occupied during opening, pause

or closing, the gate reopens completely and closes without observing the pause time.

Antenna

Common

Start

Start ped.

Stop

Common

Photocell 1

CN1

1 2 3 4 5 6 7 8

Photocell 2

RX1

RX2

TX1

TX2

CN1

9 10 11 12 13

Common

24V (Accessories)

Options AUX 24V max 200mA can be set with

on-board Display or with Jolly device.

Through the Jolly programmer it is possible to chose when

having tension on the AUX output. The options are: “Always”,

“In cycle”, “Opening”, “Closing”, “In pause”, “Fototest” and

“In cycle and fototest”. When using control units with batteries

and/or solar panels, we recommend connecting the accesso-

ries which are not used when operator stands still (e.g. photocells) to a

AUX output, setting the option “In cycle”. With this setting you can save

energy by lowering power consumption in stand-by, increasing the

autonomy of the system.

Table of contents

Other SEA USA Control Unit manuals

Popular Control Unit manuals by other brands

Gemu

Gemu 9650100Z 26T1-C Installation, Operating and Maintenance Instruction

Festo

Festo CPV-D102 Elektronics manual

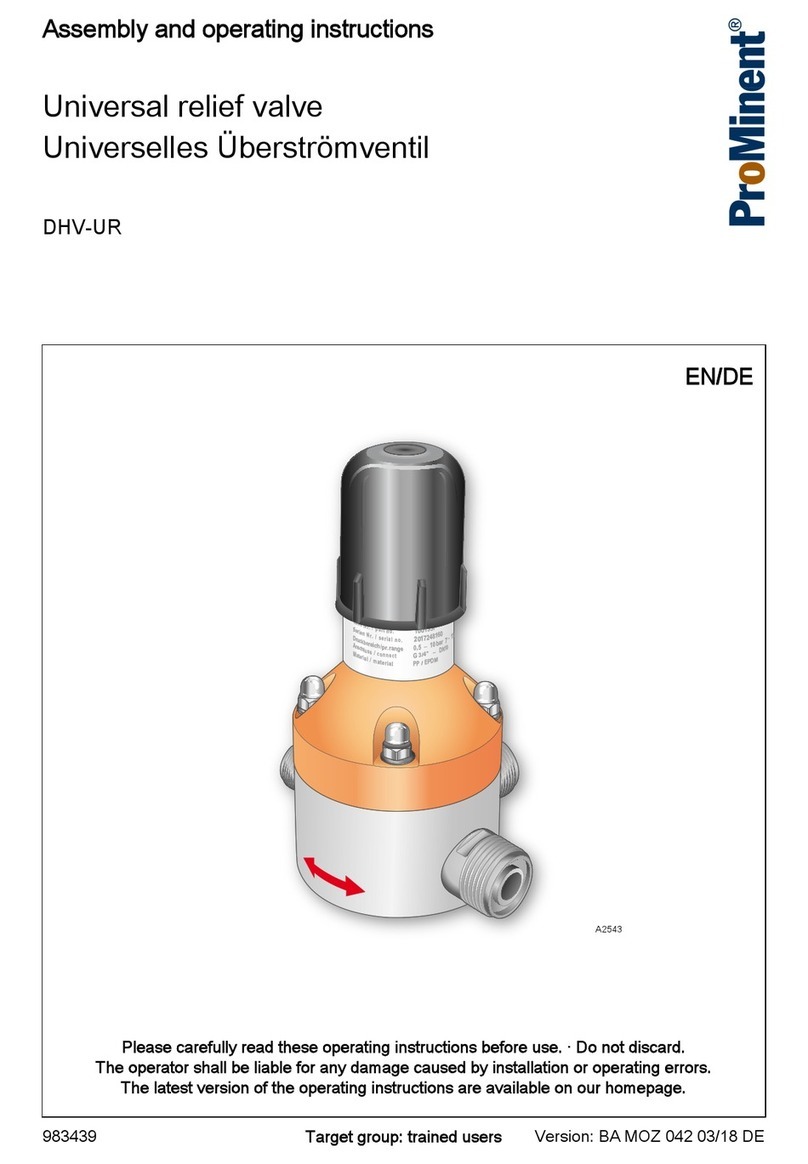

ProMinent

ProMinent DHV-UR Assembly and operating instructions

Viessmann

Viessmann Vivotronic 050 HK1S Installation and service instructions

Flann Microwave

Flann Microwave 624 Instrument manual

Toshiba

Toshiba MD911 instruction manual

Danfoss

Danfoss Colibri ETS 12C installation guide

Circutor

Circutor line-EDS-PS instruction manual

MD

MD mXion APS user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series user manual

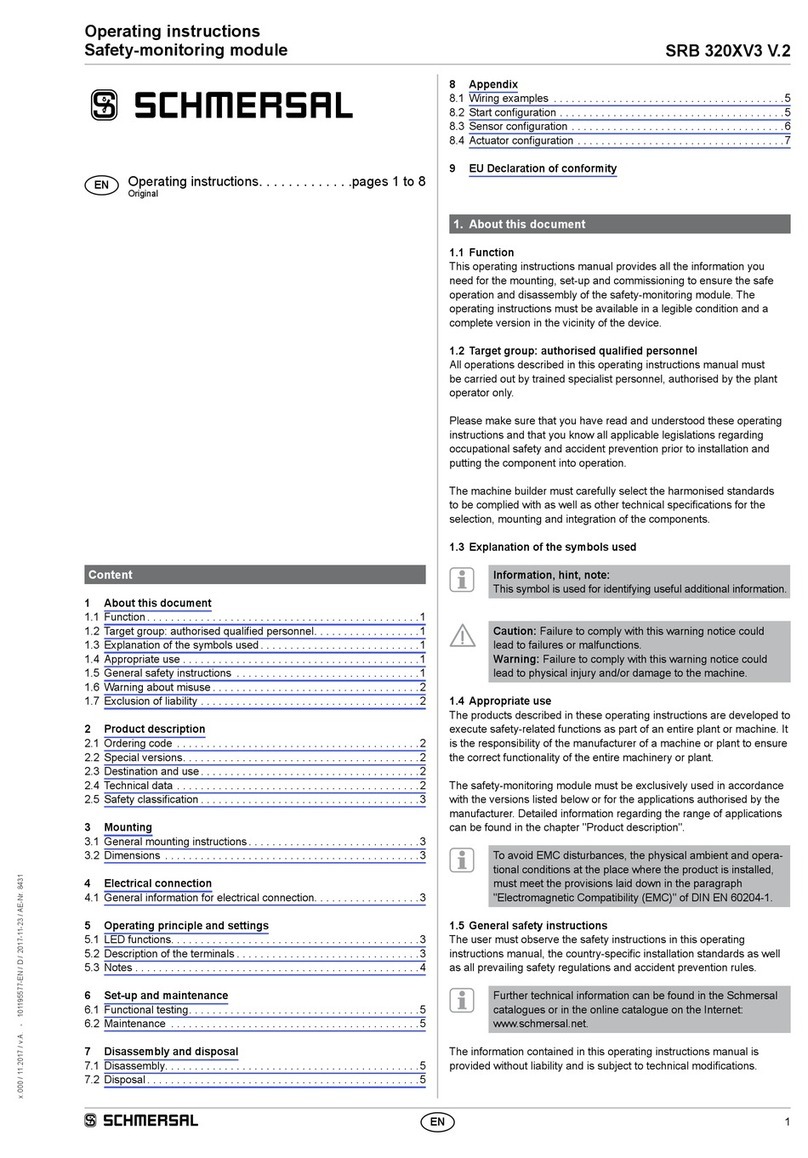

schmersal

schmersal SRB 320XV3 V.2 operating instructions

Resol

Resol EM Extension module Mounting, connection, operation