MC450 Coring Unit. Operator’s Manual

© 2020 Utilicor Technologies Inc.

5

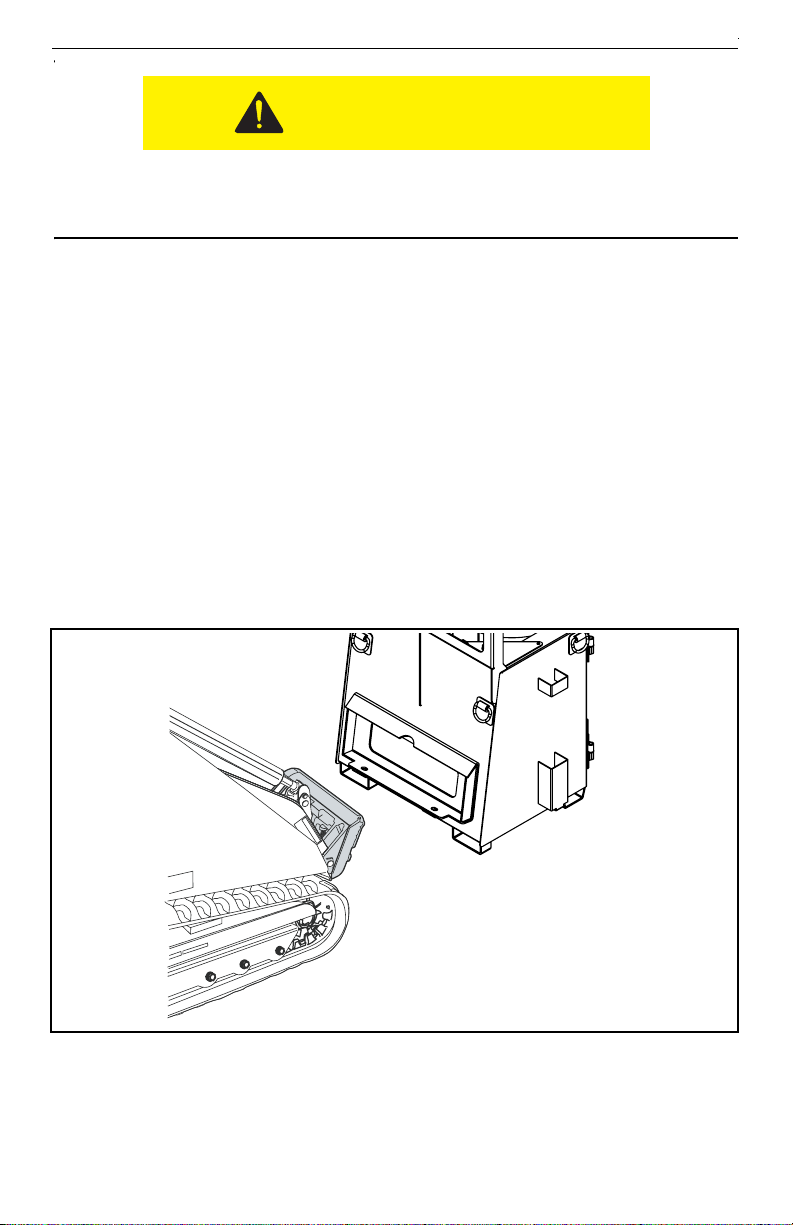

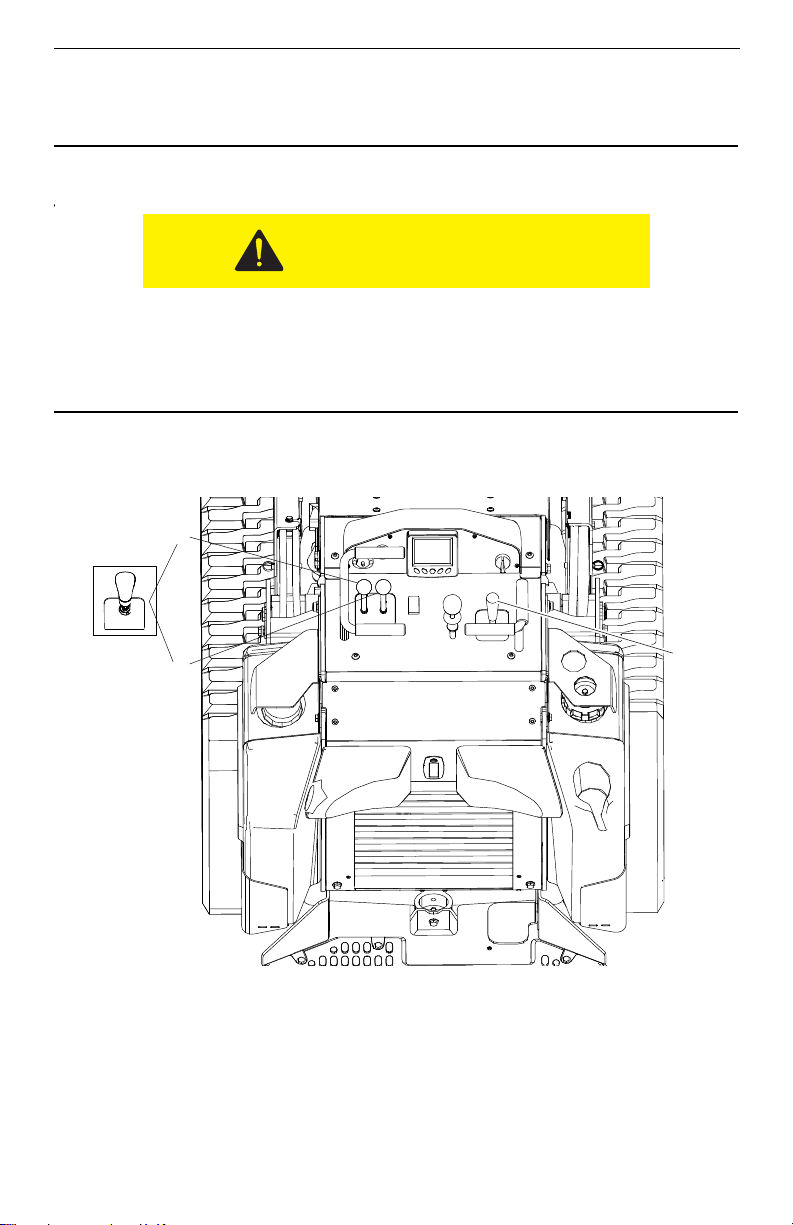

Hydraulic Hoses

1. With key in the ACC position

Cycle mini skid steer directional

flow control to relieve residual

pressure at hydraulic couplers.

2. Remove dirt and debris from

hydraulic couplers.

3. Connect male coupler on attach-

ment to female coupler (3) on unit.

4. Connect female coupler on

attachment to male coupler (1) on

unit.

5. The case drain connection is not

required for this attachment (2).

6. Ensure that connections are secure

by pulling on hoses.

2

1

3

2

1

3

Pressurized fluid or air could pierce skin and cause severe injury. Refer to

operator’s manual for proper use.

To help avoid injury:

• Escaping pressurized fluid can cause injury or pierce skin.

• Before disconnecting a hydraulic line, turn engine off and operate all controls to relieve

pressure. Lower, block, or support any raised component with a hoist. Cover connection

with heavy cloth and loosen connector nut slightly to relieve residual pressure. Catch all

fluid in a container.

• Before using system, check that all connections are tight and all lines are undamaged.

• Use a piece of cardboard or wood, rather than hands, to search for leaks.

• Wear protective clothing, including gloves and eye protection.

• If you are injured, seek immediate medical attention from a doctor familiar with this type of

injury.

Hot parts may cause burns. Do not touch until cool.

To help to avoid injury:

Wear gloves when connecting and disconnecting hydraulic hoses and

wait until unit has cooled before touching hydraulic components.

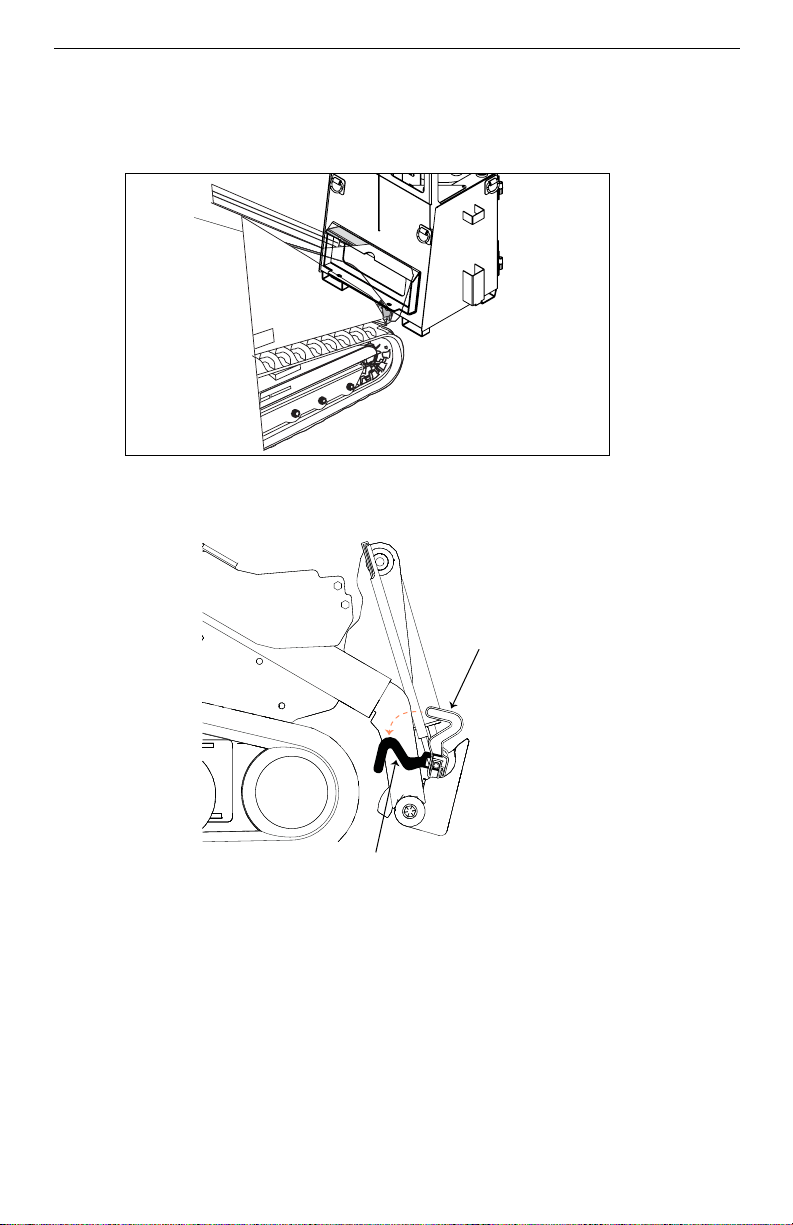

**If you unable to connect the tank line hose you may need to release the pressur in the hose. Lossen the

fitting to allow oil to escape and then re-tighten the fitting. (1¼ wrenches will be needed)

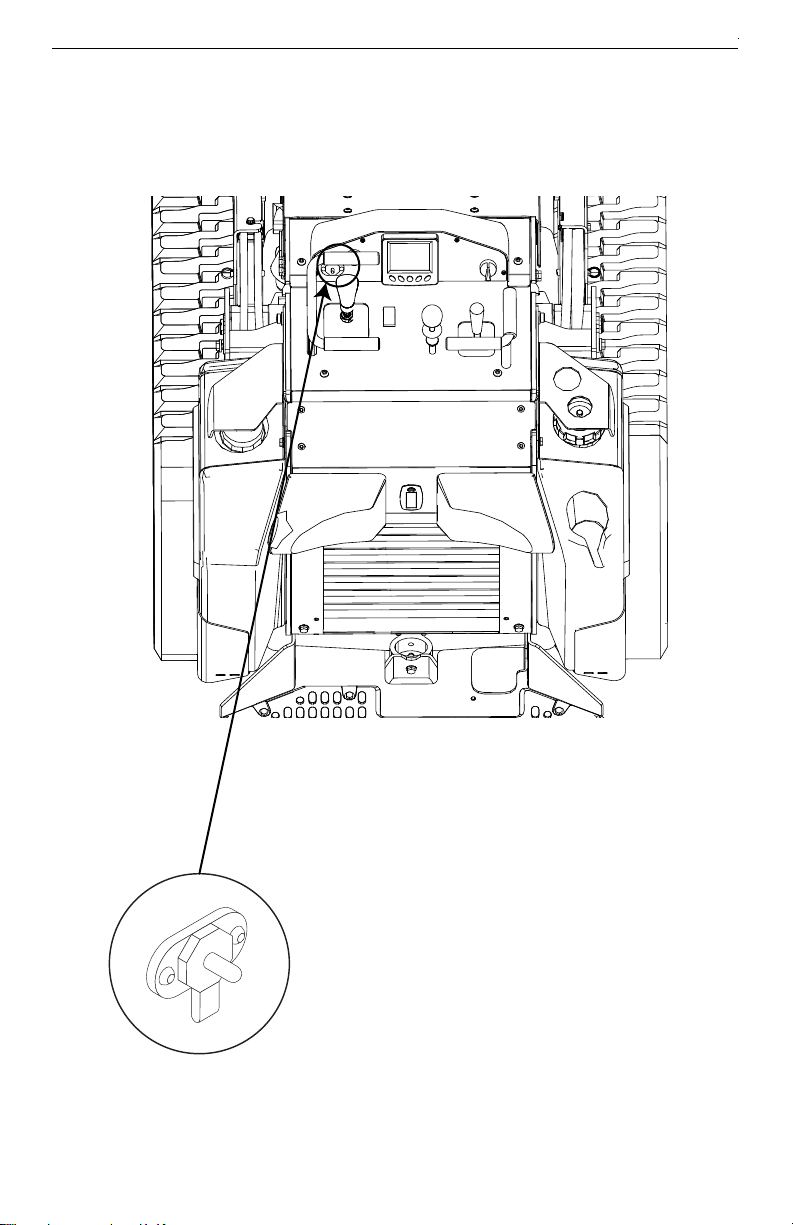

Overview