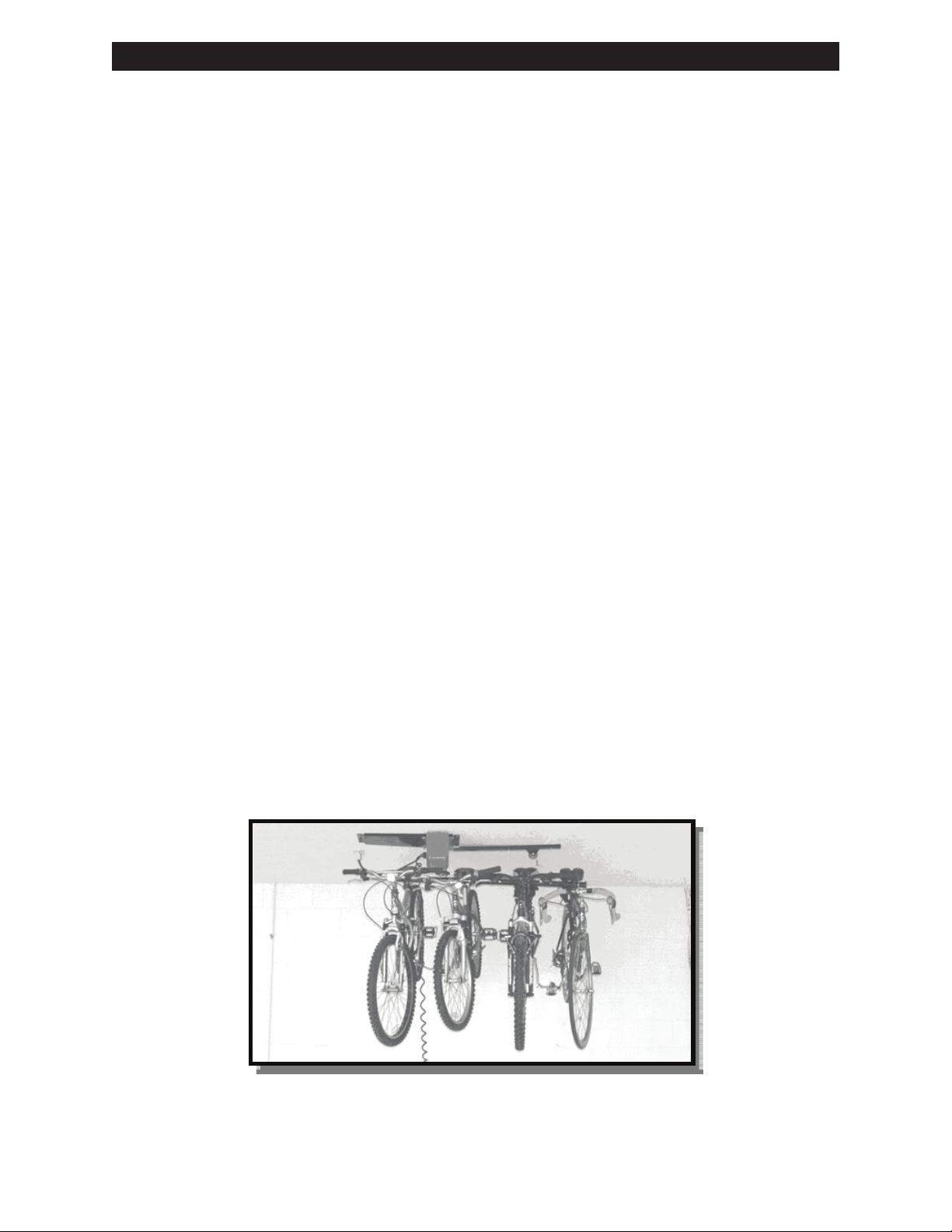

Carefully inspect your new motorized storage unit for any possible damage and/or

shortage of parts. Separate all major components and parts as detailed below and on

the next page. Do not attempt installation if parts are damaged or missing. If parts of your

GGR125 are missing or appear damaged call V-Bro customer service at 1-888-GATOR-

08, Monday - Friday, 8:00 AM to 5:00 PM Eastern Time. Before calling carefully check the

carton as parts may be in the packing material.

5

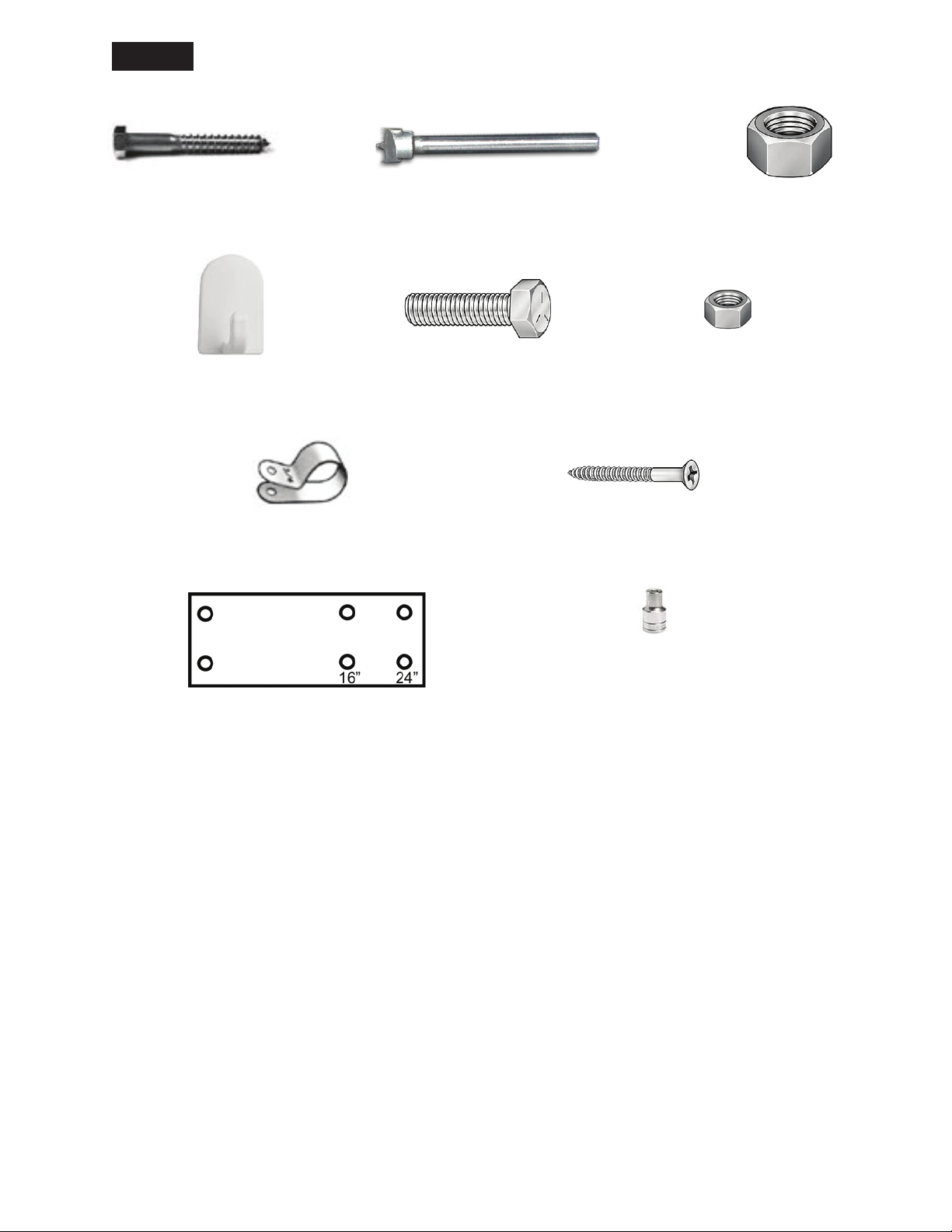

CARTON INVENTORY tinUegarotSdezirotoMrotaGegaraG

(A) Motor Mounting Plate

MAJOR COMPONENTS

5

parts of your GG125 are missing or appear damaged call V-Bro customer service at

1-800-954-6745, Monday – Friday, 8:00 AM to 5:00 PM Eastern Time. Before calling

carefully check the carton as parts may be in the packing material.

MAJOR COMPONENTS

Motor Mounting Plate (A)

Motor Hoist (B)

Spacer Channel Bar (C) Spacer Channel Pulley Bar (D)

Hook Bar Connector x2 (F)

Hook Bar End x2 (G)

Hooks x4 (H) Bike Cables x2 (I) Bonus Storage Net (J)

IMPORTANT NOTE

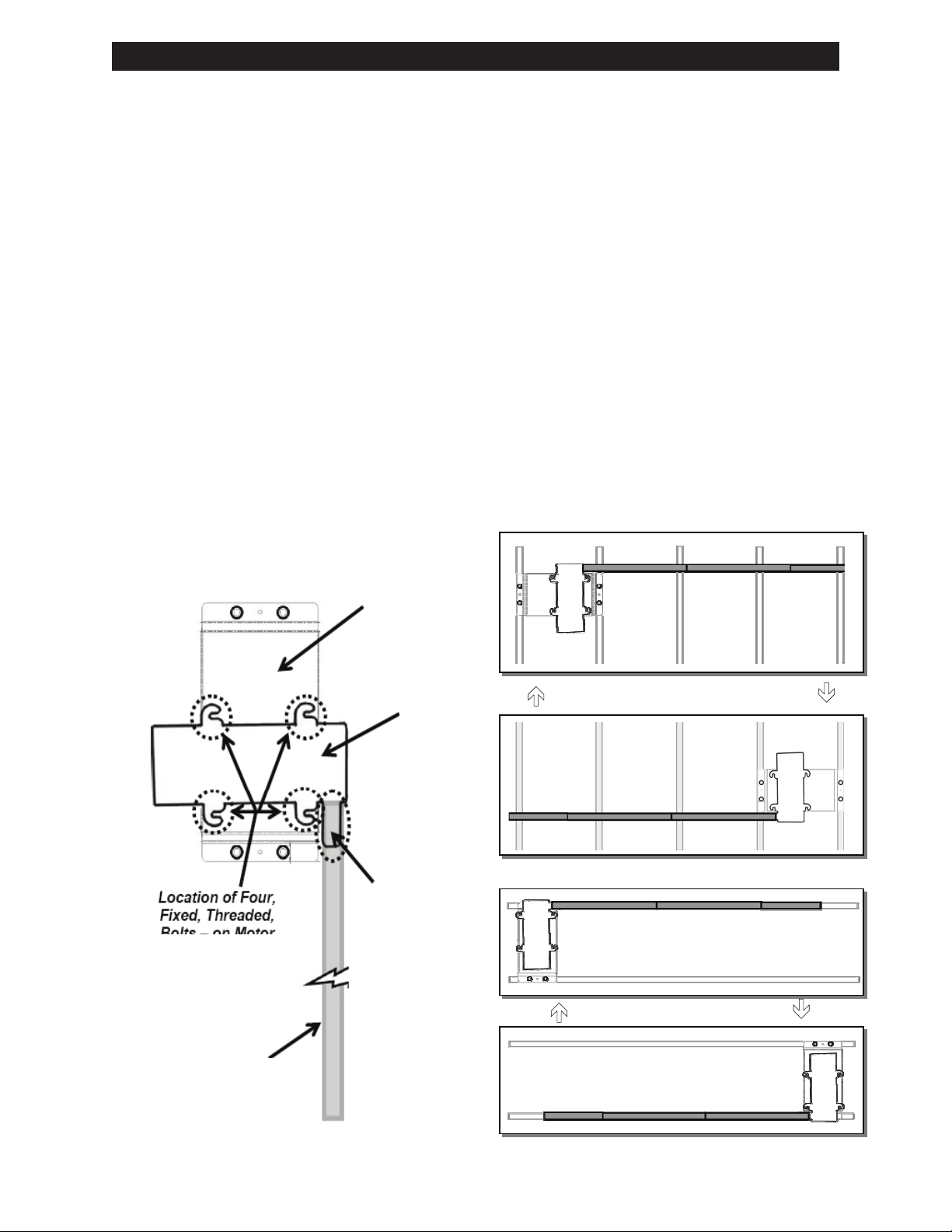

The motor mounting plate (A)

and motor hoist (B) are bolted

together when shipped. IT IS

NECESSARY to remove the

motor hoist from the motor

mounting plate by loosening (it

is not necessary to remove) the

nuts from the fixed, threaded

bolts on the motor mounting

plate. Once loosened, the

motor hoist can easily be slid off

the motor mounting plate.

(B) Motor Hoist

(C) Spacer Channel Bar (D) Spacer Channel Pulley Bar

(F) Hook Bar Connector x2

(H) Hooks x4 (I) Bike Cables x2

IMPORTANT NOTE

The motor mounting plate (A)

and motor hoist (B) are bolted

together when shipped. IT IS

NECESSARY to remove the

motor hoist from the motor

mounting plate by loosening (it

is not necessary to remove) the

bolts on the motor mounting

plate. Once loosened, the motor

hoist can easily be slid off the

motor mounting plate.

5

parts of your GG125 are missing or appear damaged call V-Bro customer service at

1-800-954-6745, Monday – Friday, 8:00 AM to 5:00 PM Eastern Time. Before calling

carefully check the carton as parts may be in the packing material.

MAJOR COMPONENTS

Motor Mounting Plate (A)

Motor Hoist (B)

Spacer Channel Bar (C) Spacer Channel Pulley Bar (D)

Hook Bar Connector x2 (F) Hook Bar End x2 (G)

Hooks x4 (H) Bike Cables x2 (I) Bonus Storage Net (J)

IMPORTANT NOTE

The motor mounting plate (A)

and motor hoist (B) are bolted

together when shipped. IT IS

NECESSARY to remove the

motor hoist from the motor

mounting plate by loosening (it

is not necessary to remove) the

nuts from the fixed, threaded

bolts on the motor mounting

plate. Once loosened, the

motor hoist can easily be slid off

the motor mounting plate.

5

parts of your GG125 are missing or appear damaged call V-Bro customer service at

1-800-954-6745, Monday – Friday, 8:00 AM to 5:00 PM Eastern Time. Before calling

carefully check the carton as parts may be in the packing material.

MAJOR COMPONENTS

Motor Mounting Plate (A)

Motor Hoist (B)

Spacer Channel Bar (C) Spacer Channel Pulley Bar (D)

Hook Bar Connector x2 (F)

Hook Bar End x2 (G)

Hooks x4 (H) Bike Cables x2 (I) Bonus Storage Net (J)

IMPORTANT NOTE

The motor mounting plate (A)

and motor hoist (B) are bolted

together when shipped. IT IS

NECESSARY to remove the

motor hoist from the motor

mounting plate by loosening (it

is not necessary to remove) the

nuts from the fixed, threaded

bolts on the motor mounting

plate. Once loosened, the

motor hoist can easily be slid off

the motor mounting plate.

5

parts of your GG125 are missing or appear damaged call V-Bro customer service at

1-800-954-6745, Monday – Friday, 8:00 AM to 5:00 PM Eastern Time. Before calling

carefully check the carton as parts may be in the packing material.

MAJOR COMPONENTS

Motor Mounting Plate (A)

Motor Hoist (B)

Spacer Channel Bar (C) Spacer Channel Pulley Bar (D)

Hook Bar Connector x2 (F) Hook Bar End x2 (G)

Hooks x4 (H) Bike Cables x2 (I) Bonus Storage Net (J)

IMPORTANT NOTE

The motor mounting plate (A)

and motor hoist (B) are bolted

together when shipped. IT IS

NECESSARY to remove the

motor hoist from the motor

mounting plate by loosening (it

is not necessary to remove) the

nuts from the fixed, threaded

bolts on the motor mounting

plate. Once loosened, the

motor hoist can easily be slid off

the motor mounting plate.

5

parts of your GG125 are missing or appear damaged call V-Bro customer service at

1-800-954-6745, Monday – Friday, 8:00 AM to 5:00 PM Eastern Time. Before calling

carefully check the carton as parts may be in the packing material.

MAJOR COMPONENTS

Motor Mounting Plate (A)

Motor Hoist (B)

Spacer Channel Bar (C) Spacer Channel Pulley Bar (D)

Hook Bar Connector x2 (F) Hook Bar End x2 (G)

Hooks x4 (H) Bike Cables x2 (I) Bonus Storage Net (J)

IMPORTANT NOTE

The motor mounting plate (A)

and motor hoist (B) are bolted

together when shipped. IT IS

NECESSARY to remove the

motor hoist from the motor

mounting plate by loosening (it

is not necessary to remove) the

nuts from the fixed, threaded

bolts on the motor mounting

plate. Once loosened, the

motor hoist can easily be slid off

the motor mounting plate.

(G) Hook Bar End x2

(J) Bonus Storage Net

Mounting plate is attached together

by using 3 of (P) bolts.