SAVE THIS MANUAL FOR FUTURE REFERENCE

SAFETY INFORMATION Garage Gator Motorized Storage Unit

3

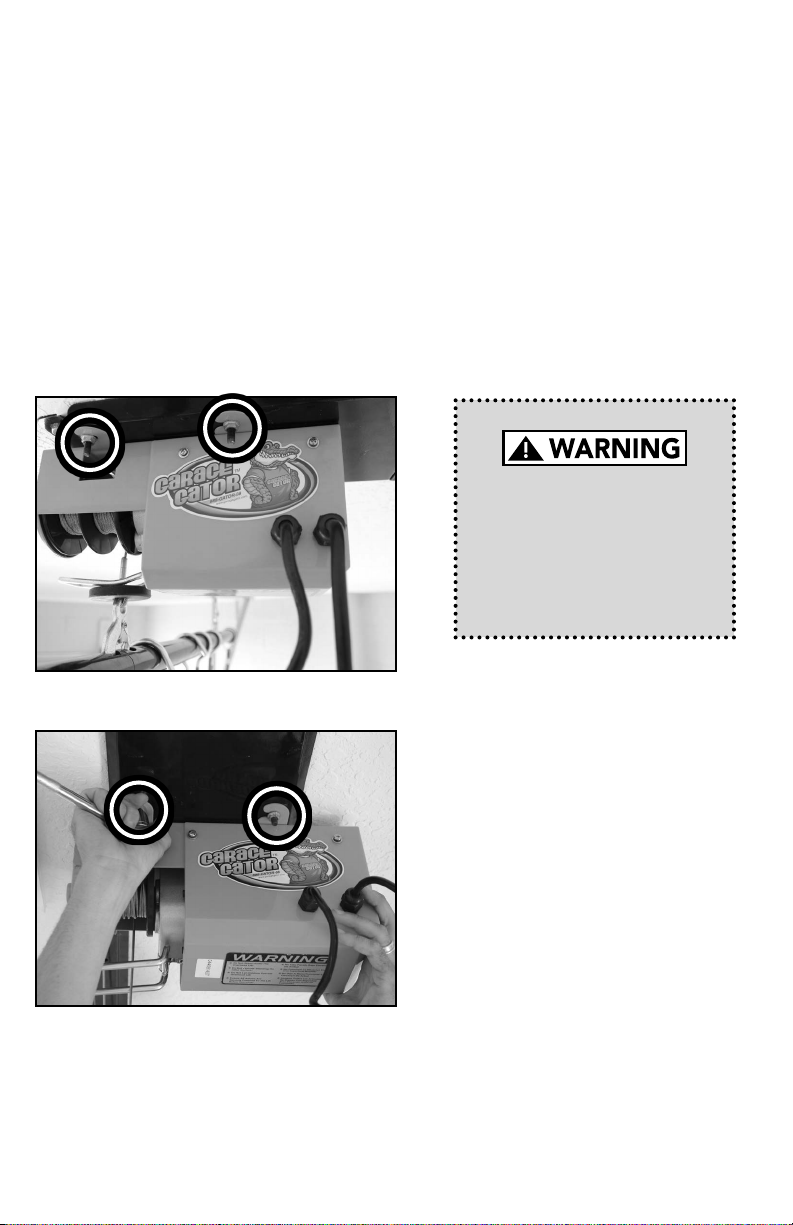

When you see the WARNING safety symbol on the following pages this will

alert you of the possibility of serious injuries or death if you do not comply

with the corresponding instructions. The hazard may come from something

mechanical or from electric shock. Read the instructions carefully!

To reduce the risk of

severe injury or death:

1. READ AND FOLLOW ALL SAFETY, INSTALLATION AND OPERATION

INSTRUCTIONS. If you have any questions or do not understand an

instruction contact V-Bro Products.

2. Do not use to lift people or animals.

3. Do not use to support a load over people or animals.

4. Never operate while hand(s) are near moving parts.

5. Do not stand under lift.

6. Let unit cool down for 5 minutes after every cycle.

7. Install on a at level ceiling, or open rafters. Will not operate correctly if

installed on an angle.

8. Visually inspect trusses for damage before installing your GGR220.

WARNING: THIS IS A DO IT YOURSELF (DIY) PROJECT. DO NOT ATTEMPT THIS INSTALLATION

WITHOUT A BASIC UNDERSTANDING OF THE CONTENTS IN THESE ASSEMBLY

INSTRUCTIONS. IF YOU ARE NOT CONFIDENT WITH LOCATING AND ANCHORING THE

GARAGE GATOR TO THE CEILING JOISTS, DO NOT ATTEMPT THIS INSTALLATION WITHOUT

SOMEONE WHO IS.

WARNING: DO NOT EXCEED THE WEIGHT LIMITS (Based on model used)

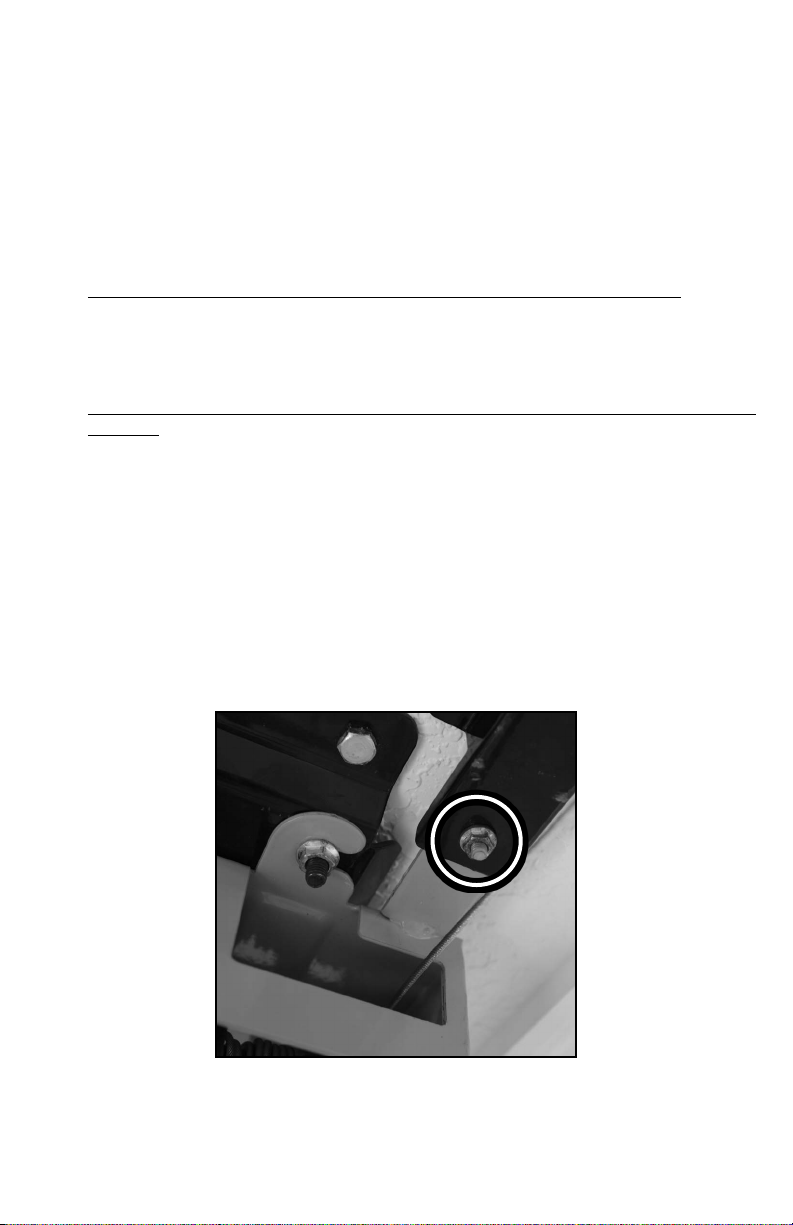

WARNING: This weight limit is based on all lag bolts being secured in the CENTER of the joists a

wood framed garage. The joists must have a minimum 2” x 6” (standard lumber) cross section, 24”

(or less) apart, with at least 2” of penetration from each lag screw used. For truss framed garage

ceiling structures, joists with a 2” x 4” (bottom truss cord) cross section is acceptable.

Do not climb on or (if you have a platform) do NOT hang from.

BOTTOM LINE...BE CAREFUL, THESE INSTRUCTIONS, WARNINGS AND NOTES DO NOT

REPLACE YOUR SOUND JUDGMENT AND DECISION MAKING. IF, FOR ANY REASON, YOU

FEEL THE QUALITY OF YOUR CEILING STRUCTURE IS IN QUESTION, DISCONTINUE THE

INSTALLATION PROCESS IMMEDIATELY. USE THE GARAGE GATOR WISELY AND ENJOY

RECLAIMING YOUR GARAGE!