9

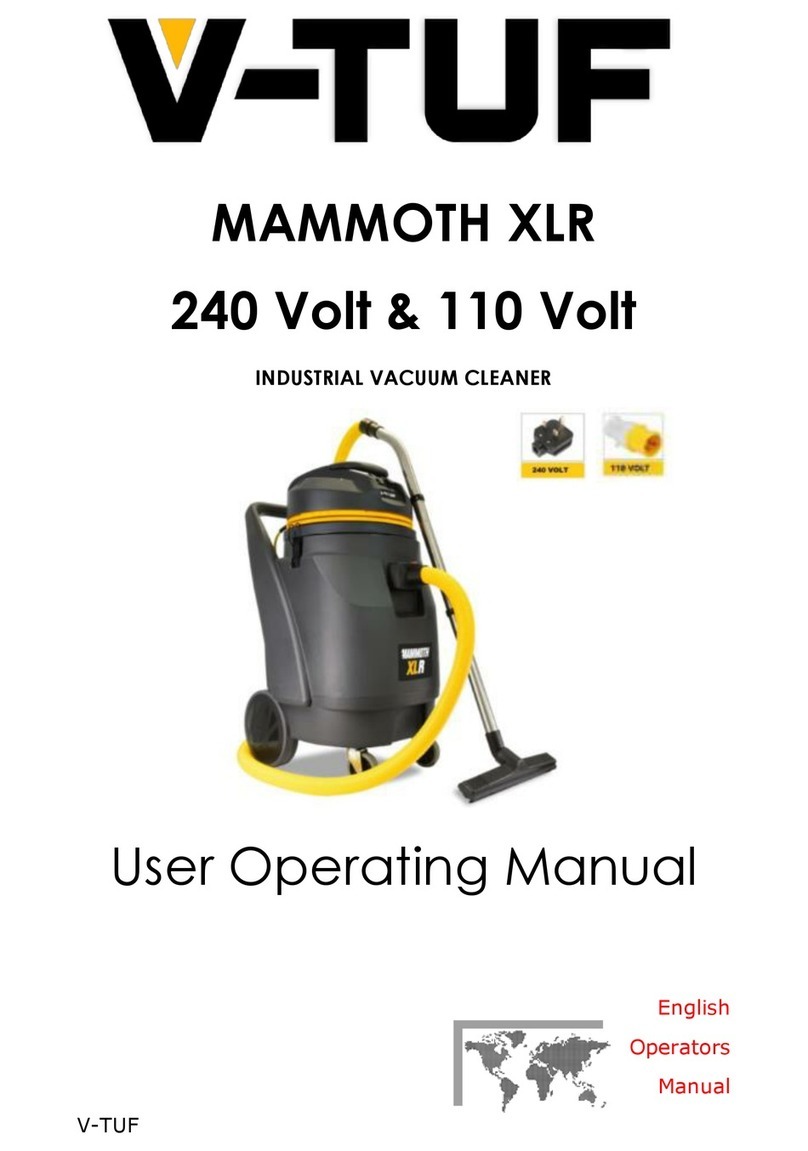

GENERAL INFORMATION

1. This manual has been included as an integral part of the appliance and should be carefully read

through before using the machine.

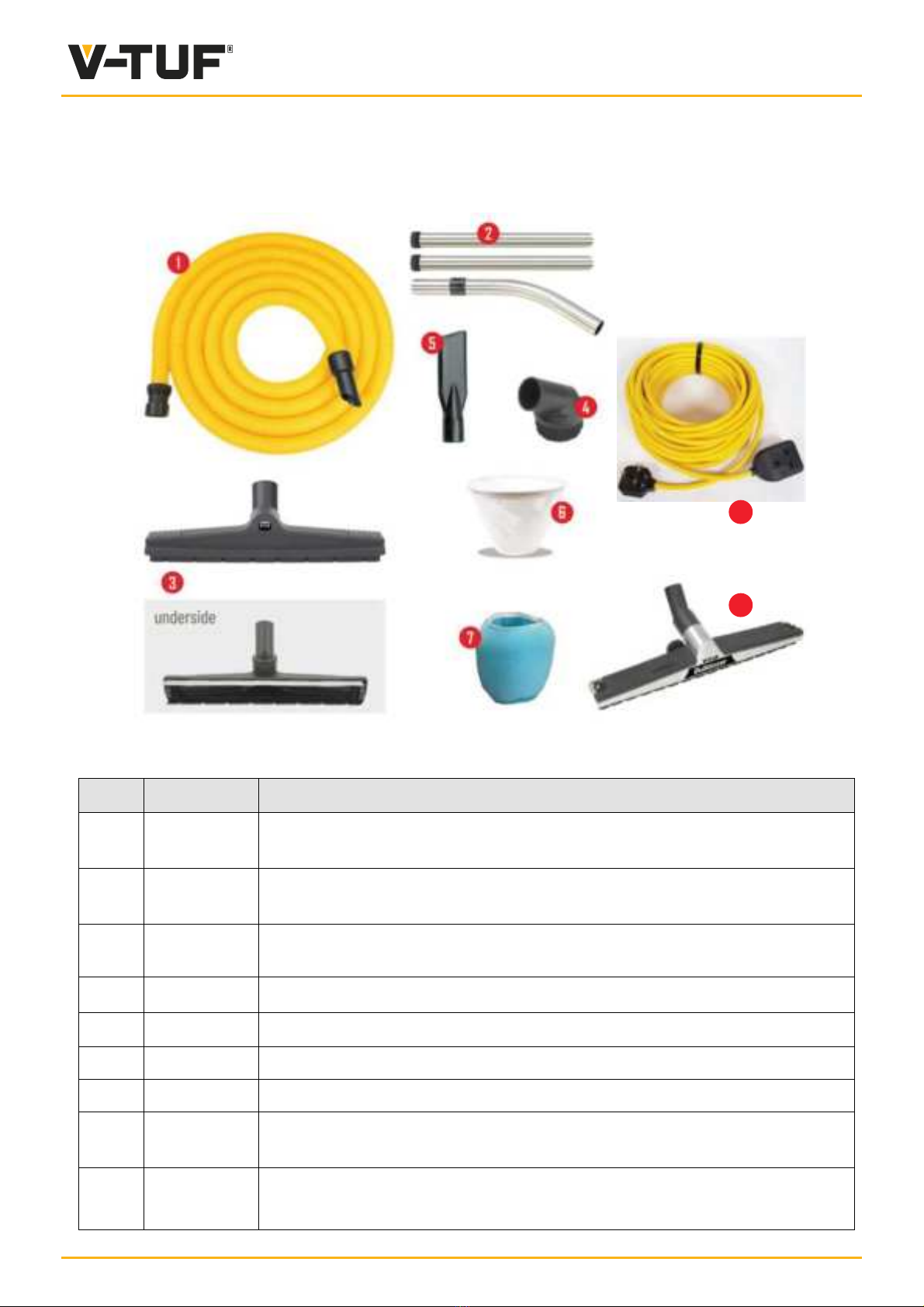

2. Take the appliance out of its packaging and make sure it is in perfect condition, including accessories

and any optional extras you have purchased from the V-TUF range.

3. Make sure that the electrical data of the appliance, shown on the label, corresponds to those of the

mains supply.

4. The appliance must only be used with V-TUF accessories and spare parts as these ensure safe and

perfect operation.

5. The manufacturer disclaims all liability for injury to persons and animals and damage to things due to the

irresponsible use of the appliance and to the use of non-original accessories and spare parts.

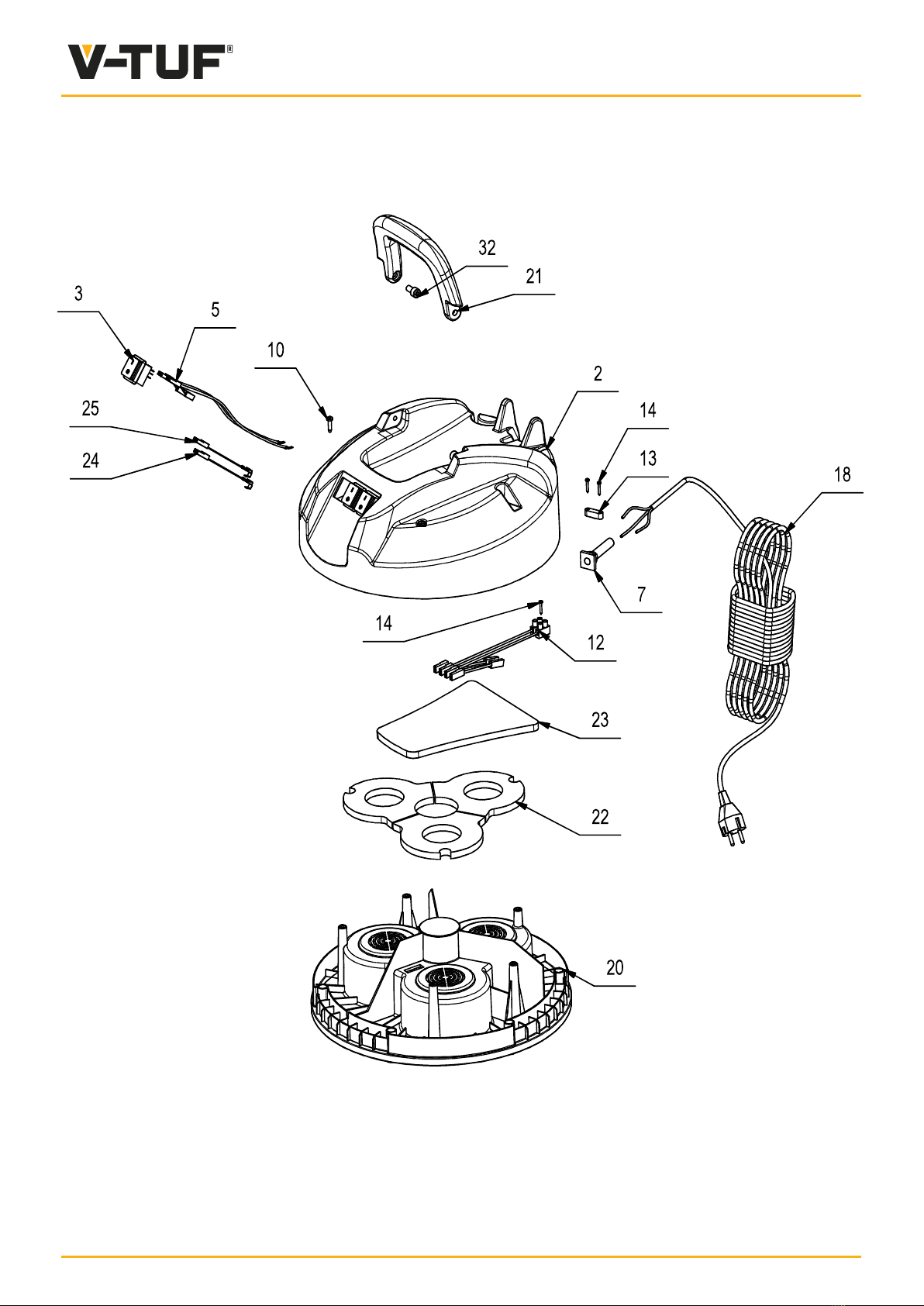

6. The repair and/or replacement of the various component parts, especially electrical parts, must be done

by skilled personnel.

7. The appliance is suitable for use in a range of applications: (hotels, schools, factories, shops, etc...)

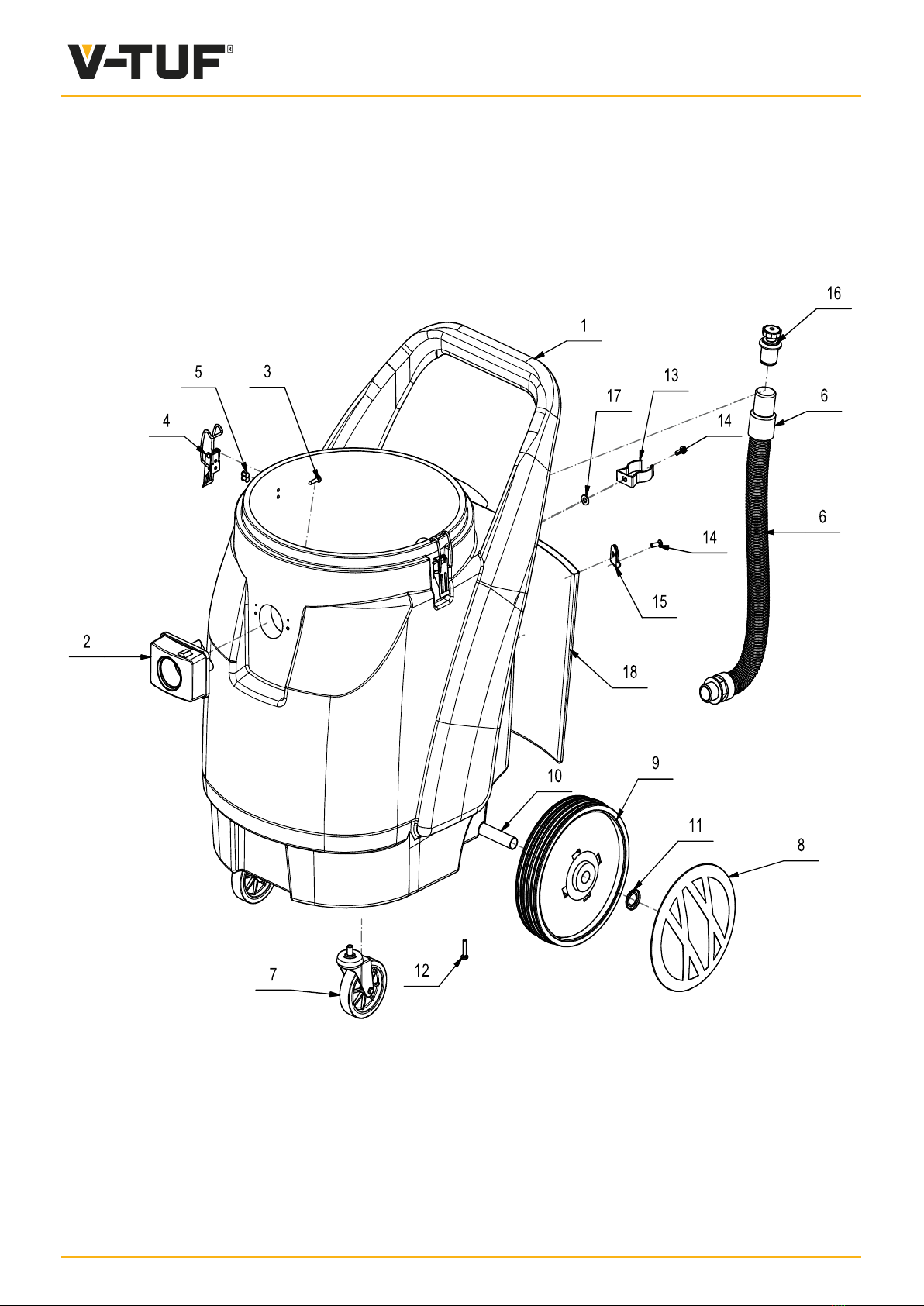

INSTALLATION

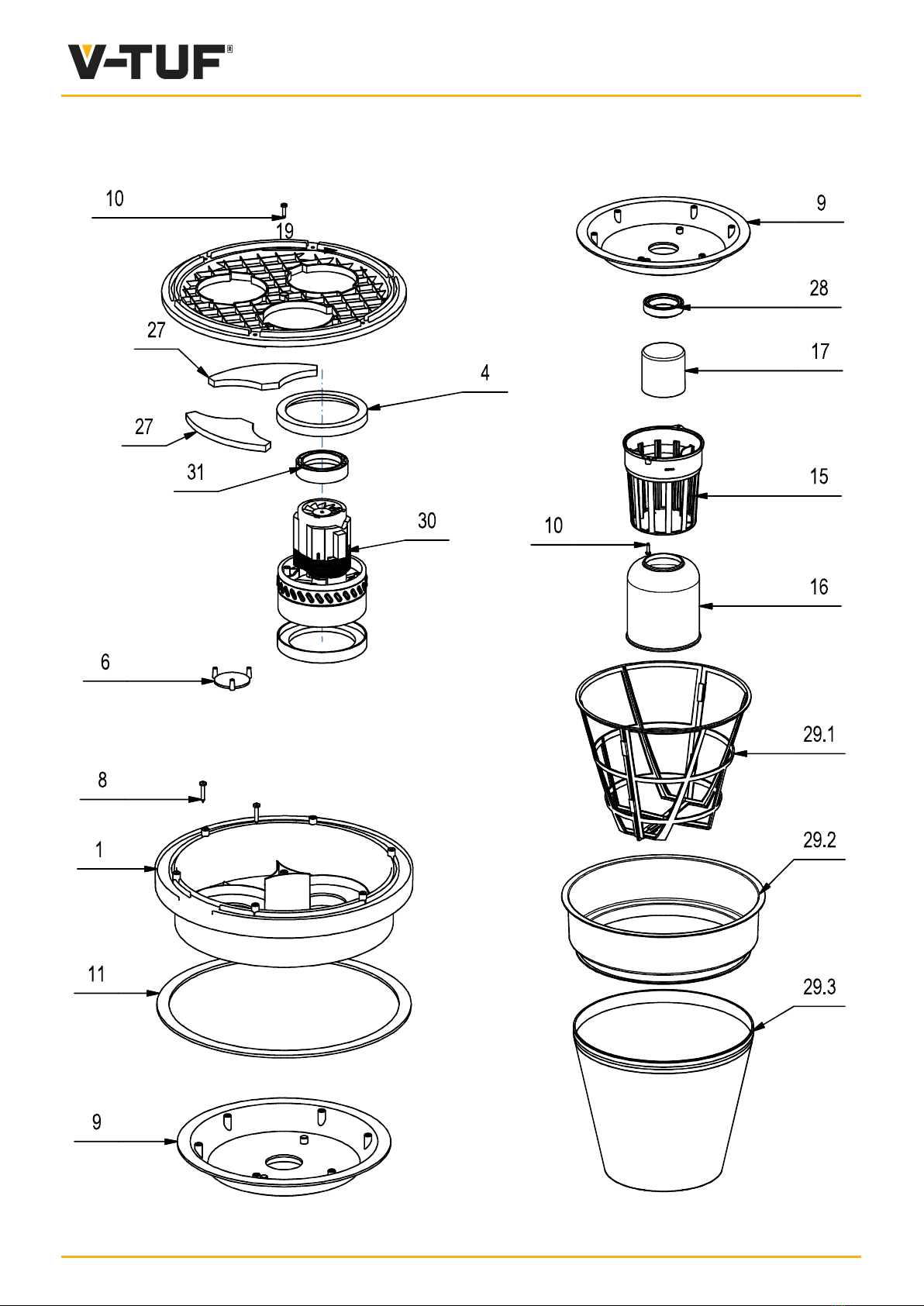

1. Check the position of the filter and the clips that fasten the head to the tank.

Incorrect filter positioning can cause serious damage to the machine.

2. Fit the hose to the vacuum connector; fit the required accessory to the

end of the hose. Inthe case of extractor models fit the pipe on the connector

provided on the head and fit the required accessory to the end of the pipe.

3. Connect the power cable of the appliance to the power socket with switches

on "0" (OFF POSITION).

4.

5. To vacuum liquids, empty the dust from the container, remove the main

Aqua-Dry basket filter and ensure the foam filter is fitted.

(See image 5 on the right)

After the vacuum has been used for wet use ensure the tank and foam filter

is dry before vacuuming dry material.

6.

6. The noise level is below 85 dB(A)

For general DRY material vacuuming and a bit of WET material

vacuuming (typical in auto valeting), ensure the Aqua-dry and

the Foam filter is in place. (See image 4)

Important: If you are vacuuming a lot of fine dust,

we advise you to fit the optional High Efficiency

FILTER - VTVS7026L, fits over the main basket filter, as

shown in the image. This filter must be used for grain

store cleaning on farms or in industry where there is

fine dust or if your notice your machine losing

suction quickly.