Installation instructions

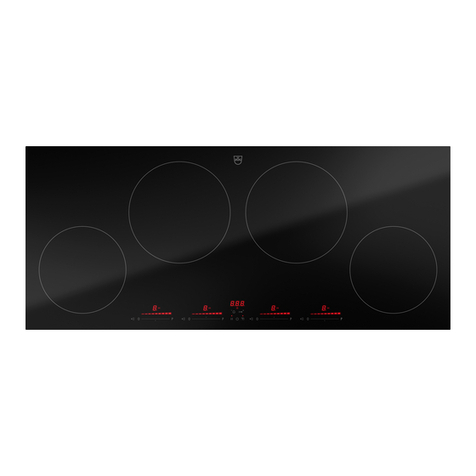

Induction hob

CookTop Teppan Yaki I40

1097806-04

27/07/2023

2

Designation Art. no.

Anthracite silicone FA880 (310ml) B11556

White silicone FA880 (310ml) 1031313

Stone grey silicone FA880 (310ml) 1031314

Marble smoothing agent AA320 (1000ml) B11557

Fugenboy (silicone finishing tool) B75158

Electrical connection

Electrical connections must be carried out by qualified personnel in accordance with the guidelines and standards

for low-voltage installations and the specifications of the local electricity supply companies.

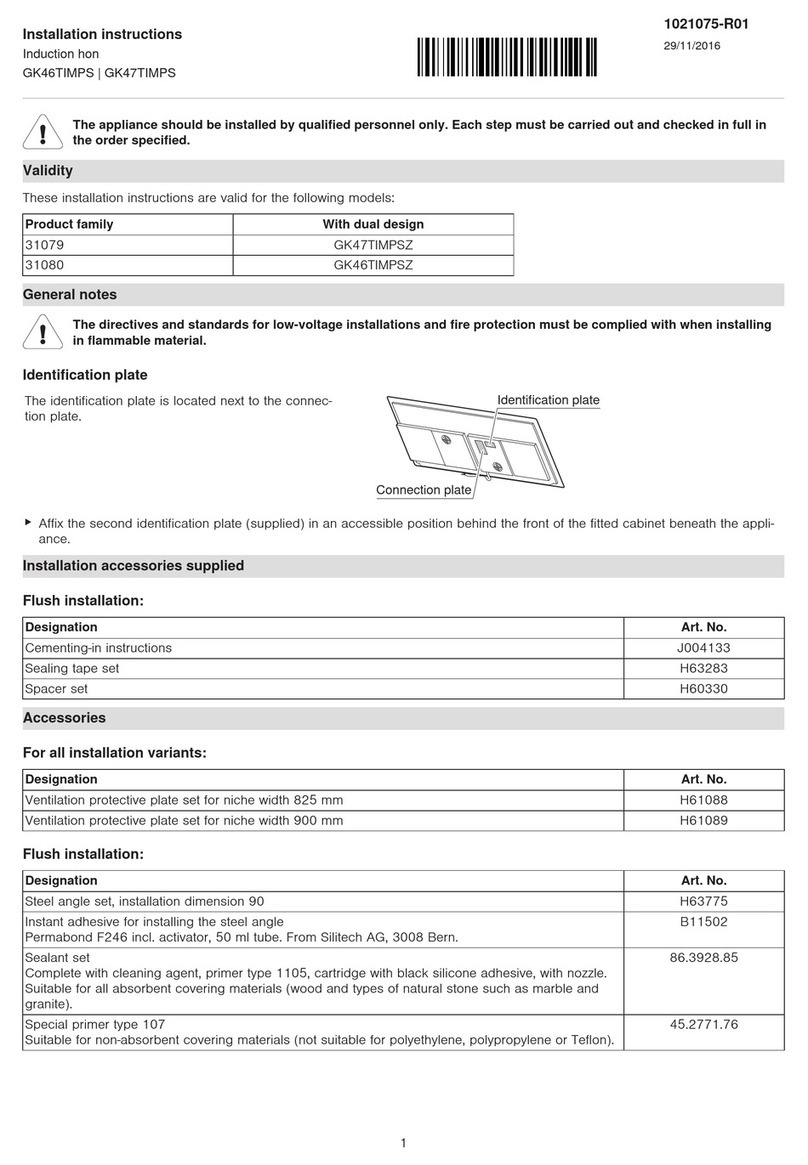

Refer to the identification plate for information on the required mains voltage and current type.

A plug-in appliance may only be connected to a socket outlet with earthing contact, installed according to specifications. An

all-pole mains isolating device with 3 mm contact opening should be provided in the house wiring system. Switches, plug and

socket devices, circuit breakers and fusible cut-outs which are accessible after installation and which have all-poles switching

are permissible as isolating devices. Effective earthing and separately installed neutral and earth conductors ensure safe and

fault-free operation. After installation, live parts and cables with basic insulation must not be accessible. Check old installa-

tions.

▸If the hobs are used at an altitude of over 2,000metres,a reduced performance must be expected.

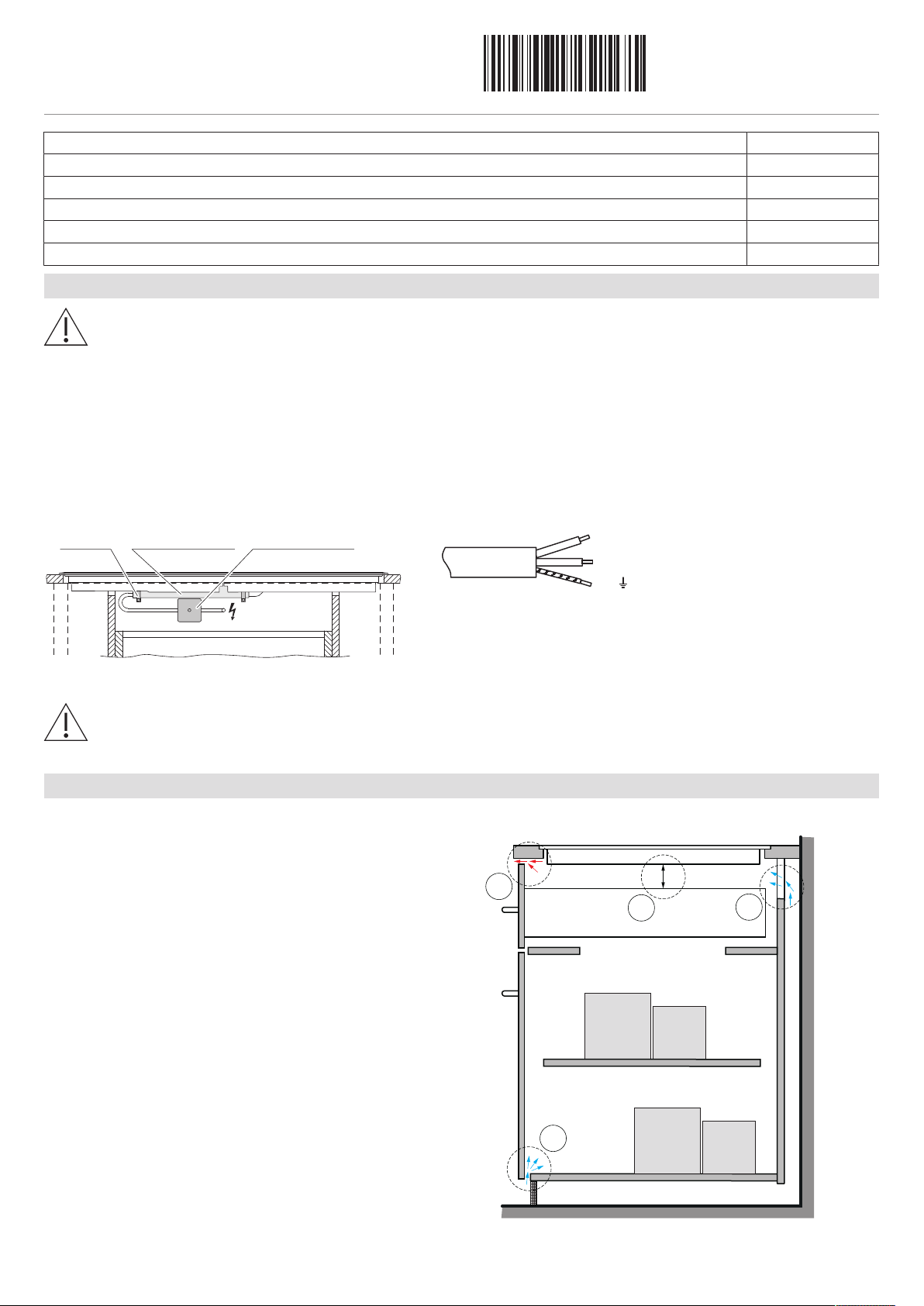

The appliance is equipped with a connection cable which must be connected to an on-site junction box.

Installation pipe Distribution boxClamp

black

black

yellow/green

N

L1

PE/

220–240 V~

1 1 1 1 1 1 1 1

2 2 2 2 2 2 2 2

Error message U400

Faulty connection:

A pole conductor has been connected to the connection terminal for neutral conductors.

Quickly disconnect the appliance from the mains!

Ventilation

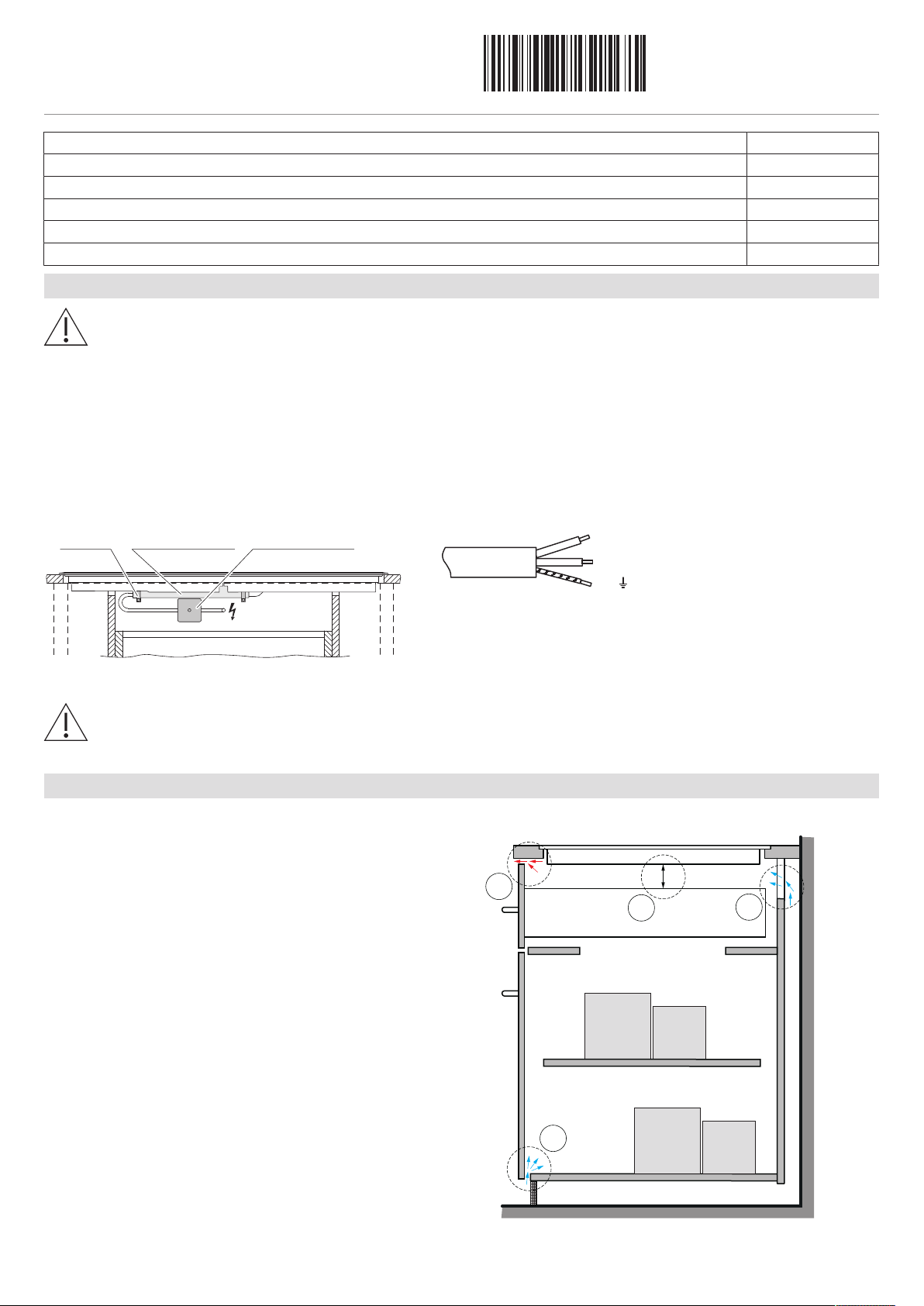

For installation of a V-ZUG induction hob, the following minimum requirements apply:

1. The hot air exhaust should be provided by a ventilation slit

of ≥2mm at the front.

2. A space of ≥10mm in height is required beneath the appli-

ance.

3. Not only exhaust air but also replacement air in the cabinet

should be taken into account. There are different ways to

do this, including:

a) The rear panel of the base unit must be open around

the work surface cut-out to guarantee continuous air circu-

lation through the ventilation slits. The air must be drawn in

from outside the cabinet and be able to circulate freely

from inside the cabinet to the hob. The lower plinth must

not be hermetically sealed. This can be achieved through a

shadow gap at the plinth panel or through the use of a

ventilation grille.

b) Alternatively, a concealed fresh air supply can ensure

air circulation inside the cabinet. In order that enough cold

air can be drawn in, there must be a continuous circulation

of fresh air that extends outside the cabinet. The lower

drawer panel should therefore not hermetically seal the

cabinet.