Page 7 of 35

2. INSTALLATION

2.1 IMPORTANT - READ BEFORE UNPACKING

Warning: Take care when lifting the unit that the weight and position do not exceed comfortable

limits. When installing the device make sure that it is adequately supported at all times.

Warning: Do not operate any of the controls until the XY shipping pin and all transit items have been

removed. Failure to do so may result in serious damage to both the translator and vacuum system.

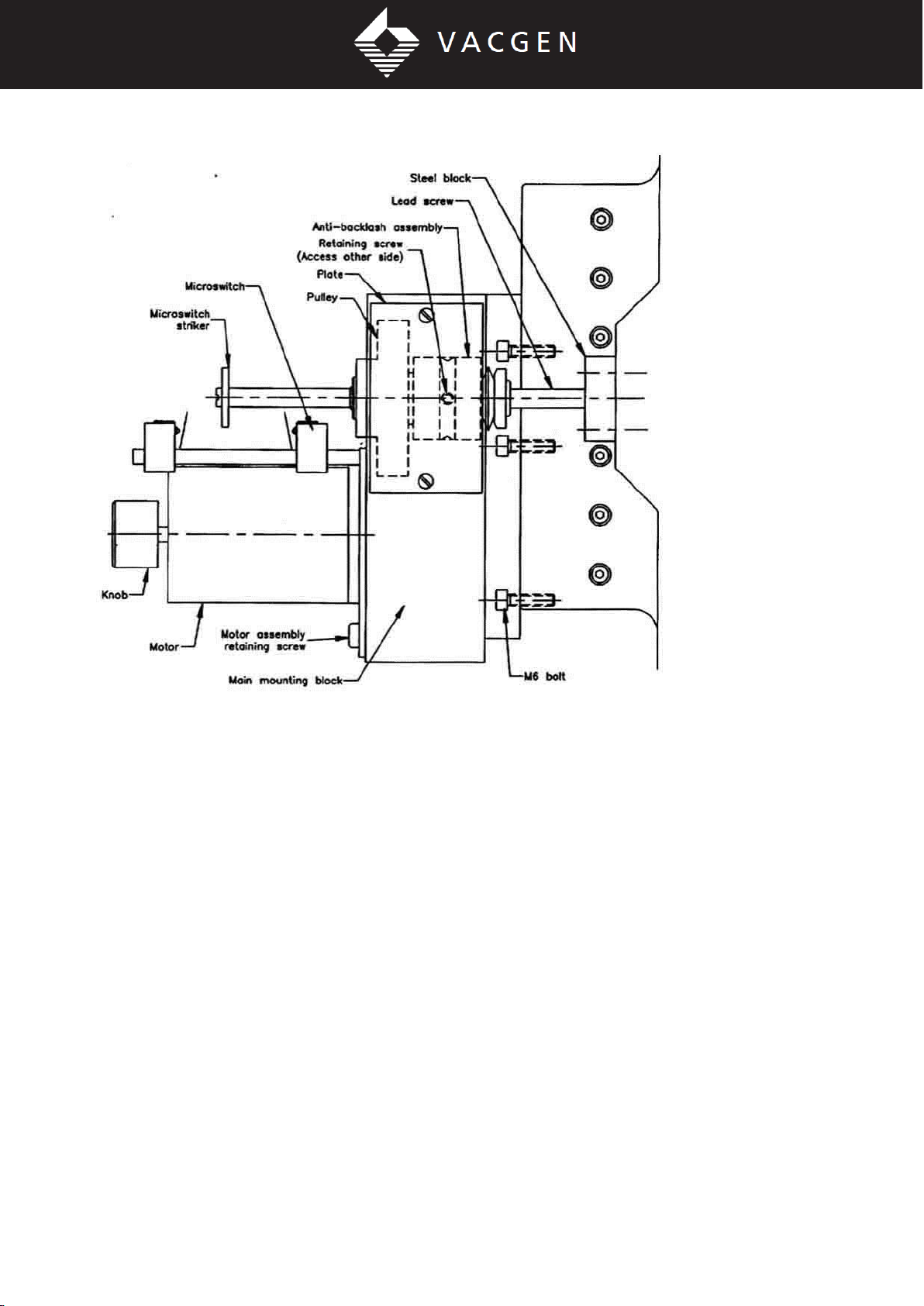

a. With two or more persons, lift out the translator using the lifting handles. DO NOT use bellows,

drives or instrumentation as lifting points. Take care not to hit or damage any protruding parts of the

translator. Lie the translator on its back or stand vertically on the attached frame.

b. Carefully inspect the translator for visual signs of damage. The packaging is designed to with

stand shock and vibration but some of the fixing screws may become loose, more especially with air

freight shipment. All parts should be secure and there should be no 'play' in any of the movements. All

screws should be securely fastened but not excessively tight.

c. Any damage in transit should be, reported to the carrier and to VACGEN at Hastings, or your local

agent, within three days. Retain the packaging.

d. Remove the shipping pin and all transit items before operating any of the controls.

2.2 INSTALLATION GUIDELINES

Warning: This equipment must be installed by qualified personnel.

Warning: It is the responsibility of the user to consider the safety requirements of hazardous

materials used with this equipment and the consequence of any leakage, however caused. Consider

possible reactions with materials of construction. Any equipment returned to VACGEN must have the

correct Declaration of Contamination securely Fastened to the outside of the packaging.

Warning: Lubricants used in this assembly may cause irritation to sensitive skin. Wear protective

clothing.

Warning: It is the responsibility of the user to fit emergency stops to automated equipment.

Warning: Equipment must be fully earthed to prevent dangerous electrostatic charge buildup.

a. The OMNIAX will operate when mounted in any orientation. However, because of the weight of the

translator, very careful consideration must be given to ensuring that the level of stress exerted onto

the chamber and within the translator itself is as low as possible. Where practical the translator should

be vertically mounted. For horizontally mounted units, special mounting arrangements are required.

See Appendix A.

b. It is not possible to generalize on mounting arrangements for other orientations. Any supporting

cradle must allow for X & Y motions as well as supporting the weight of the frame. Also the centre of

gravity will vary as the Z motion is used. Normally this is not significant but must be considered where

very long Z travels (800mm and greater) are used or where heavy equipment is being moved on the Z

slide.

c. Bolt to the system flange using the correct size bolts and gaskets as indicated in the table below.

For tapped flanges use a thread lubricant, such as VACGEN ZTL on the bolt threads. Use washers

under bolt heads or nuts.