page 5 of 27

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. 25/11/2013 // 999281

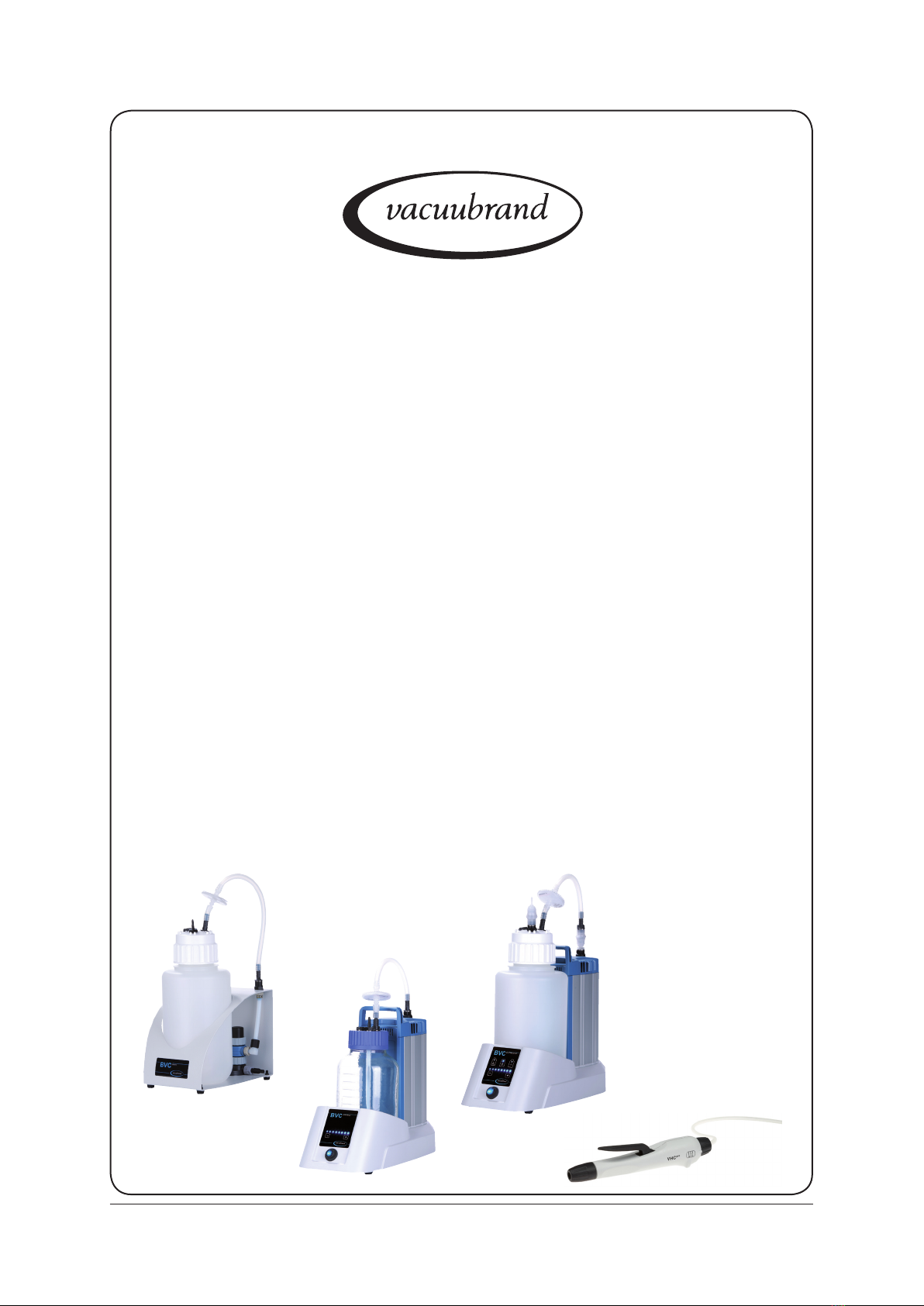

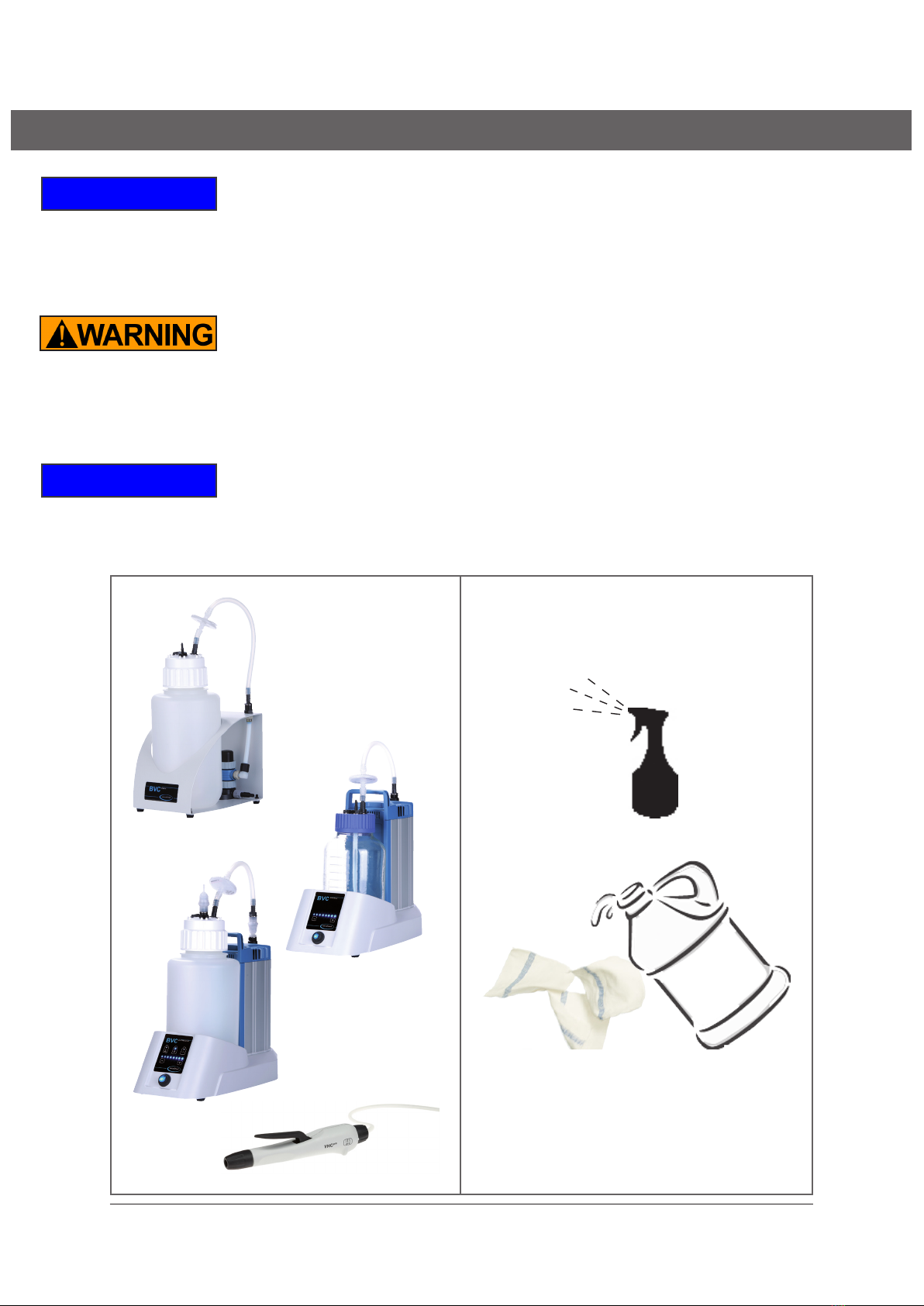

ThismanualdescribespossibilitiestodecontaminatetheaspirationsystemsBVC

andthehandleVHCpro.

Priortodecontaminationcleanwithadampclothifnecessary.Usewateroramild

detergent as cleaning agent.

Prior to sending the devices to the factory the devices have to be decontami-

anted completely.

The applicability of the decontamination method and the selection of the ap-

propriate disinfectants have to be ensured by the user.

Ensure that repair is done only by an appropriately trained and supervised tech-

nician.Obeylocalandnationalsafetyrequirements.Ensurethatthetechnicianis

familiar with the safety procedures which relate to the products processed by the

pumpingsystem.Ensure that the pumpis decontaminated before repair andthat

youtakeadequateprecautionstoprotectpeoplefromtheeffectsofhazardoussub-

stances if contamination has occurred.

+Take adequate precautions to protect people from the effects of dangerous sub-

stances. Wear appropriate safety-clothing, do not inhale and avoid contact with

skin.

Prior to decontamination from outside and / or disassembling the device isolate

equipment from mains. Allowsufcientcooling.

Ensure that the device cannot be operated accidentally. Never operate the de-

vice if covers or other parts are disassembled. Never operate a defective or

damaged device.

Wait 5 seconds before starting work to allow the capacitors to discharge.

Beforestartingcheckthattherequiredparts(e.g.tools,disinfectnats)areavailable

and of the correct type.

Checktheoperatingsequencementallyusingexplodedviewdrawings,spareparts

lists and circuit diagram on feasibility, safety requirements and consequences on

safetyandfunctionoftheequipment.

Obeyregulationswhendisposingofsolventsandchemicals.

Inorder tocomplywithlaw(occupational,healthandsafetyregulations,safetyat

worklawandregulationsforenvironmentalprotection)vacuumpumps,components

and measuring instruments returned to the manufacturer can be repaired only when

certainprocedures(seesection”Notes on return to the factory”)arefollowed.

Scrapping and waste disposal

Dispose of the pump and any components removed from it safely in accordance with

alllocalandnationalsafetyandenvironmentalrequirements.

Safety information!

NOTICE

NOTICE