4. Clean the packing box and blow out any debris

5. Lubricate and install the bottom (male) adaptor

ring over the shaft.

6. Lubricate and install the V-rings with the point of

the “V”pointing toward the actuator.

7. Lubricate and install the top (female) adaptor ring.

8. Push the packing set into the packing box using

the gland until the packing set is fully seated.

9. Install and tighten the gland bolts (12) until they

just touch the gland (11) and then one more full

turn.

10. Reintroduce pressure and check for leaks. If a

leak is noticed, evenly tighten the gland bolts (12)

just until the leak stops. Excess compression will

increase operating torque and shorten the packing

life.

DISASSEMBLY

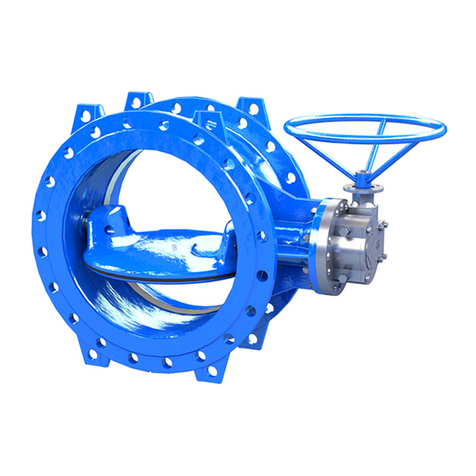

To disassemble/re-assemble the valve the plug shaft must

be vertical. It may be necessary to remove the valve from

the pipeline and rotate so it is sitting on a solid surface.

Before removing the valve, ensure operating equipment is

tagged and locked out and there is no pressure within the

valve. Pressure can be relieved by removing the pipe plug

(13) in the valve cover. Drain or remove the liquid from the

valve.

WARNING

The cover may blow off the top of the valve if

the cover bolts are removed with pressure

inside the valve. Remove ALL pressure before

disassembly

Refer to page 4 for parts identification and location.

A skilled technician should perform all work. No special

tools are required.

1. If disassembling in-line, ensure there is no

pressure within the valve and operating equipment

is locked out. If possible, drain the liquid from the

valve.

2. Close the valve.

3. Scribe or mark the actuator and cover for proper

alignment upon reassembly.

4. Remove the fasteners used to mount the actuator

and lift off the actuator, making sure not to lose the

keys, couplings, etc. for reassembly.

5. Remove the gland bolts (12) and gland (11).

Using a pick, remove the packing set (8)

6. Scribe or mark the cover (5) and body (1) for

proper alignment upon reassembly.

7. Remove the cover bolts (3).

8. Install two eyebolts in opposite holes in the cover’s

actuator mounting flange. Lift the cover straight

up and off the plug shaft. Remove the cover O-

ring (4).

9. Remove the plug (2) by turning and lifting out of

the body.

10. Inspect the upper and lower bearings (7) and

bushings (10) and the upper and lower thrust

bearings/grit excluders (6) for wear. Replace if

needed. It may be necessary to remove the end

plate (15) to extract the lower bearing and

bushing.

11. Inspect the plug’s rubber coating for wear, tears,

and other damage. Replace if necessary.

12. Inspect the welded nickel seating surface in the

body. Minor smooth edged dents and nicks can

be accommodated by the plug’s rubber coating,

but significant sharp edged gouges, dents and

nicks may necessitate replacing the entire valve.

ASSEMBLY

The valve is reassembled by reversing the disassembly

sequence with consideration of the following:

1. Clean and polish all machined bearing and sealing

surfaces. Apply a light coat of lubricant to assist in

the assembly.

2. Install lower bushing (10) in bottom of body and

lower plug bearing (7) on the bottom of the plug.

Place and center the thrust bearing (6) on the

lower bushing (10).

3. Carefully lower plug (2) into body until it enters the

thrust bearing (6) and lower bushing (10). Rotate

the plug until it is nearly closed.

4. Install upper thrust bearing (6) and plug bearing

(7) on the plug shaft and upper bushing (10) in the

cover (5).

5. Lubricate and install the cover O-ring (4) and

carefully lower the cover (5) over the plug shaft so

the marks are aligned.

6. Install cover bolts (3) and tighten in an alternating

manner.

7. Lubricate and install shaft packing (8).

8. Place packing gland (11) over plug shaft and push

packing (8) into the packing box until it is firmly

seated.

9. Install gland bolts (12), tighten until they just touch

the gland (11) and then one more full turn.

10. Align and install actuator.

11. Close valve and (reinstall in line) and introduce

pressure. Check for leaks. If a leak from the shaft

packing is noticed, evenly tighten the gland bolts

(12) just until the leak stops. Excess compression

will increase operating torque and shorten the

packing life.

REPLACEMENT PARTS

Genuine replacement parts are available from your local

VAG/GA Industries representative or from the factory:

VAG USA, LLC

234 Clay Avenue

Mars, PA 16046 USA

Telephone: 724-776-1020

Fax: 724-776-1254

E-mail: quotes-ga@vag-usa.com

Please have the nameplate data available when ordering

parts. Identify needed part(s) by Shop Order (SO) Number,

Figure Number, valve size and individual part number.

All parts ordered individually.

WARRANTY:

The Warranty for GA Industries valves is included in our

Terms and Conditions which can be found here:

https://gaindustries.com/terms