VAG Operating and maintenance instructions • 3

1 General

1.1 Safety

These operating and maintenance instructions must

be observed at all times and used jointly with the VAG

Installation and Operating Instructions for Valves. The

user must not change or modify this product or the

mounting parts / fittings supplied with it. VAG does not assume

any warranty or liability for consequential damage arising from the

non-compliance with these instructions. For the use of this valve,

the generally accepted technical rules (e.g. DIN standards, DVGW

standards - German association for gas and water , directives VDI

- German association for engineers, directives VDMA - German

association for engineering and installation etc.). The valves must

only be installed by qualified, specially trained staff. For further

specifications and information such as dimensions, materials and

fields of application, please refer to the related documentation

(KAT 2014-A).

Valves produced by VAG are designed and manufactured in ac-

cordance with international design and engineering standards.

Therefore they are principally operation safe. However, all valves

can represent a source of danger if they are used inappropriately

or for other purposes than the ones which they have been de-

signed for.

In the operator‘s company, each person associated with the in-

stallation, dismantling, operation or maintenance of the valves has

to read and understand the whole operation instructions (German

directives for accident prevention UVV, VBG1 § 14 and the fol-

lowing).

Before removing any protection device and/or beginning to work

on the valves, the concerned pipeline section has to be isolated.

As far as is possible all risk should be removed. Any unauthorised,

mistaken or sudden operation of the valve must be prevented;

care should also be taken to ensure any stored energy (pressu-

rised air or water) is removed.

When working on installations requiring supervision, the respec-

tive laws and directives (e.g. industrial codes of practice, direc-

tives for accident prevention, technical directives for steam boil-

ers, AD directives) have to be observed. Additionally, the local

directives for accident prevention and health and safety have also

to be observed.

If a valve at the end of a pressurised pipeline has to be opened,

it has to be done in such a way that the emerging fluid does not

cause any injury or damage. Caution must be taken when closing

and end of pipeline valve: Any human interference between the

body and closing piston may result in severe injury.

If a valve has to be dismantled from the pipeline, some fluid may

leak out from the pipeline or from the valve. The pipeline has to

be completely emptied before dismantling the valve. Take care of

later coming residues!

1.2 Proper use

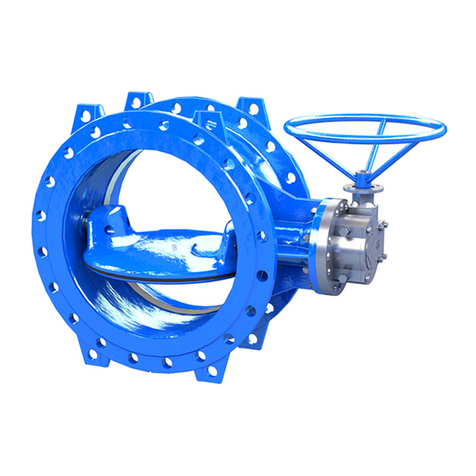

The VAG RIKO®Plunger valve is a valve designed for installation

in pipelines. Plunger Valves are designed to fulfil special control

functions in water supply systems. The technical application limits

(e.g. working pressure, medium, temperature etc.) are described

in the product related documentation (KAT 2014-A). Solids in the

medium can lead to increased wear of the valve. Depending on

the type, load and particle size, these must be taken into account

when selecting the valve and planning the system. For any devi-

ating operating conditions and applications the user must obtain

the manufacturer‘s prior written approval.

1.3 Marking

According to DIN EN 19, every valve is marked with the nominal

width (DN), the nominal pressure (PN), the body material and the

manufacturer. The name plate on the body provides the following

information:

VAG Name of the manufacturer

DN Nominal width of the valve

PN Nominal pressure of the valve

Controlling equipment

Material of the body

Date of manufacturing

2 Transportation and Storage

2.1 Transportation

To transport the valve to its installation site, it must be

packed in a stable, properly sized container. The con-

tainer also needs to ensure that the valve is protected

against weather influences and damage. When the valve

is transported long distance (e.g. overseas) and exposed

to special climatic conditions, it needs to be protected

by sealing it in plastic wrapping and adding a desiccant.

The RIKO®Plunger Valve needs to be transported with

the feets on the floor (cf. Pictures 1). The factory-applied

corrosion protection coating and mountings (e.g. gear-

box or electric actuator) need to be specially protected.

Picture 1: Preferred transport position

2.2 Storage

The RIKO®Plunger Valve is to be stored horizontally on its feet (cf.

Pictures 1). The valves should be stored in a dry, well-ventilated

area. The direct exposure of the valves to radiation heat emitted

by radiators should be avoided. The assemblies and components

relevant for proper function of the valve, such as plunger must

be protected against dust and other kinds of dirt by appropriate

covers.

The valves have to be stored in a dry location, protected from

dirt and accidental damage. Protection caps and wrapping mate-

rial around the connection parts have to be removed immediately

before installation. Lifting gear such as ropes and belts must be

attached only to the body or the eye-bolts of the valve, not to the

actuator or gearbox.

3 Product and function description

3.1 Features and function description

Plunger valves are designed to fulfill regulating functions in the

water supply. Unlike butterfly or gate valves assuming