8

INSTALLATION

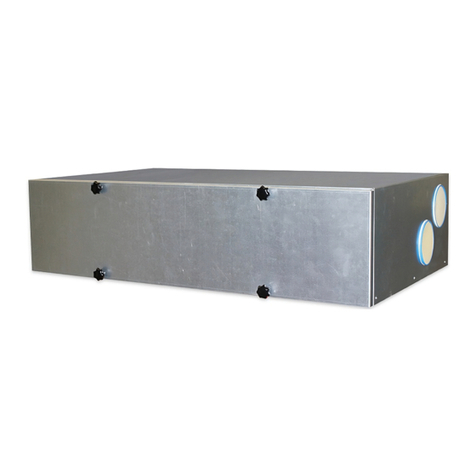

Installing the ventilation unit to the ceiling

mounting plate

1. Install the ceiling mounting plate with M8 thread bars so

that it is horizontally level.

NOTE

The end of the thread bars must be 5 mm or less below

the fastening nut. Do not fasten the ceiling mounting

plate too tight to the ceiling. Ensure that the sliding bars

move and restore to their original position by pulling

from the operating levers (A).

The top edge of the white covering strip of the ceiling

mounting plate can be installed against the ceiling.

Alternatively, a concealed mounting method can be used,

in which case the ceiling can be 30 mm below the top of

the white covering strip.

2. Ensure that the insulation washers are in the outlet collars

below the ceiling mounting plate.

3. Remove the door before installing the ventilation unit to the

ceiling mounting plate.

4. Lift the ventilation unit close to the ceiling mounting plate

and feed the cables and the connection box through the

hole in the ceiling mounting plate on top of the ceiling.

NOTE

Remember to make a service door in the ceiling so that

the cables and the connection box can be accessed.

The distance between the service door and the ceiling

mounting plate must be around 500 mm.

Alternatively, the cables can be fed between the ceiling

mounting plate and the ventilation unit to the rear wall.

When the ventilation unit is lifted against the ceiling

mounting plate, the unit locks in place. Where needed,

guide the mounting hooks on the ceiling mounting plate

(B) to the grooves on the side panels of the ventilation unit.

There are operating levers (A) on the front bottom corners

of the ceiling mounting plate. When the levers have been

restored to the same level with the white covering strip

of the ceiling mounting plate, the unit has been locked in

place.

5. Where required, the unit can be detached from the ceiling

mounting plate. Remove the door of the unit. Lift the

unit slightly upwards and pull simultaneously from both

operating levers (A) of the ceiling mounting plate to detach

the unit from the ceiling mounting plate.

Attic floor penetration plate

The attic floor penetration plate (D) is optional. When an attic

floor penetration plate is used, the tightness of the vapour

barrier has to be ensured.

The attic floor penetration plate can be fastened on the

finished rear wall. The minimum distance of the attic floor

penetration plate from the finished side walls is 15 mm.

1

3

4

5

2

B

B

A

A

D