3. MAINTENANCE, REPAIR AND INSTALLATION

3.1 MAINTENANCE AND REPAIR

No routine maintenance of Eclipse units is required when installed in environments for which they are designed. Repair of Eclipse units must be

done by the manufacturer or by qualied personnel that are knowledgeable about the installation of electromechanical equipment in hazardous

areas. All parts needed for repair must be purchased through an authorized distributer for Stonel products to maintain warranty and to ensure the

safety and compliance of the equipment.

3.2 INSTALLATION

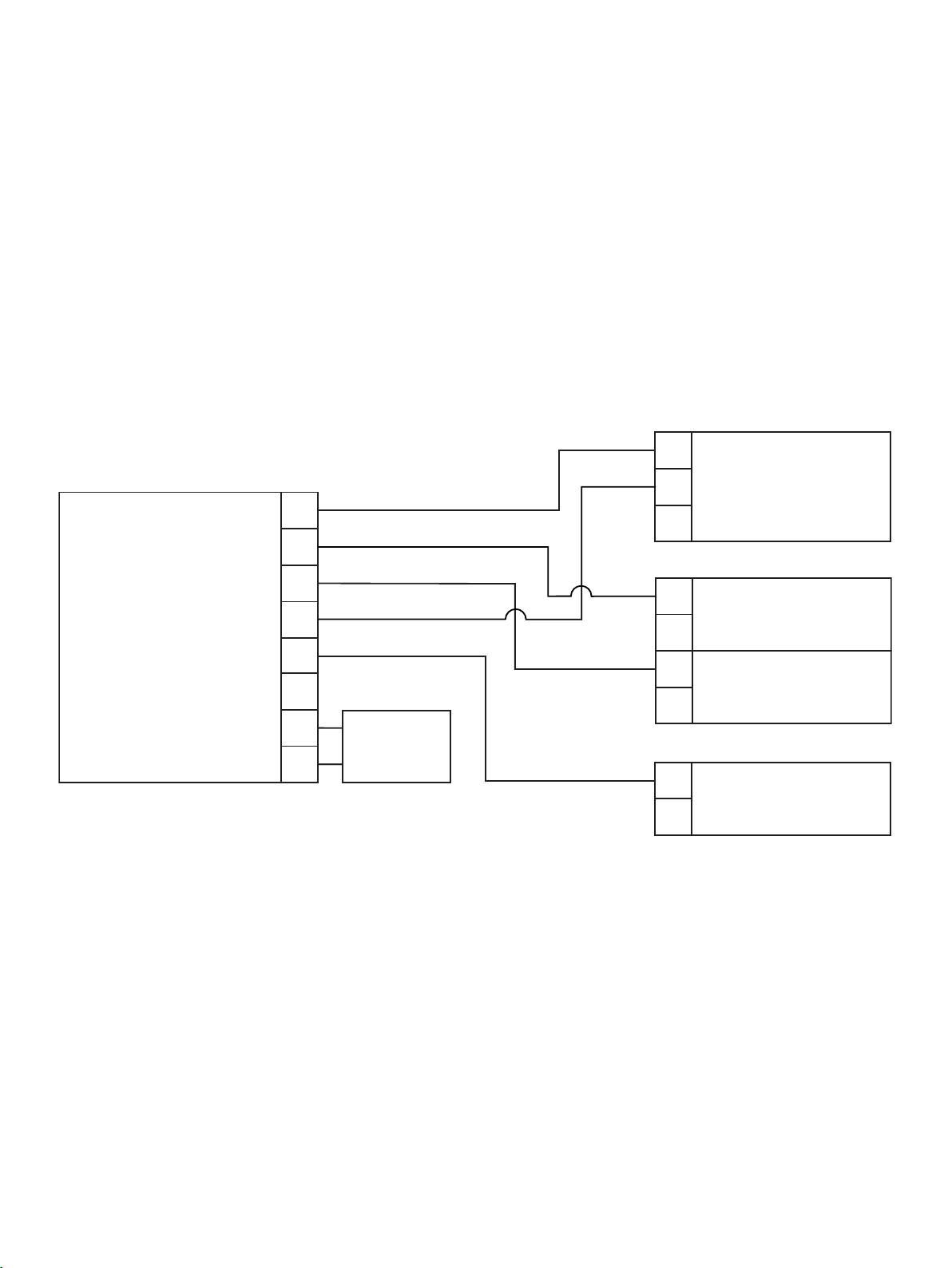

ATTENTION: IF REQUIRED, THE ECLIPSE HOUSING

CAN BE GROUNDED TO EARTH POTENTIAL BY

THE INTERNAL GROUND LUG. (SEE ASSEMBLY

DRAWING 1.6 ITEM 3 ON PAGE 4)

ATTENTION: IN ORDER TO MAINTAIN ENCLOSURE

TYPE AND IP RATINGS, COVER SHALL BE

TIGHTENED BY HAND UNTIL COVER MAKES

CONTACT WITH THE HOUSING. DO NOT USE ANY

TOOL TO TIGHTEN THE COVER.

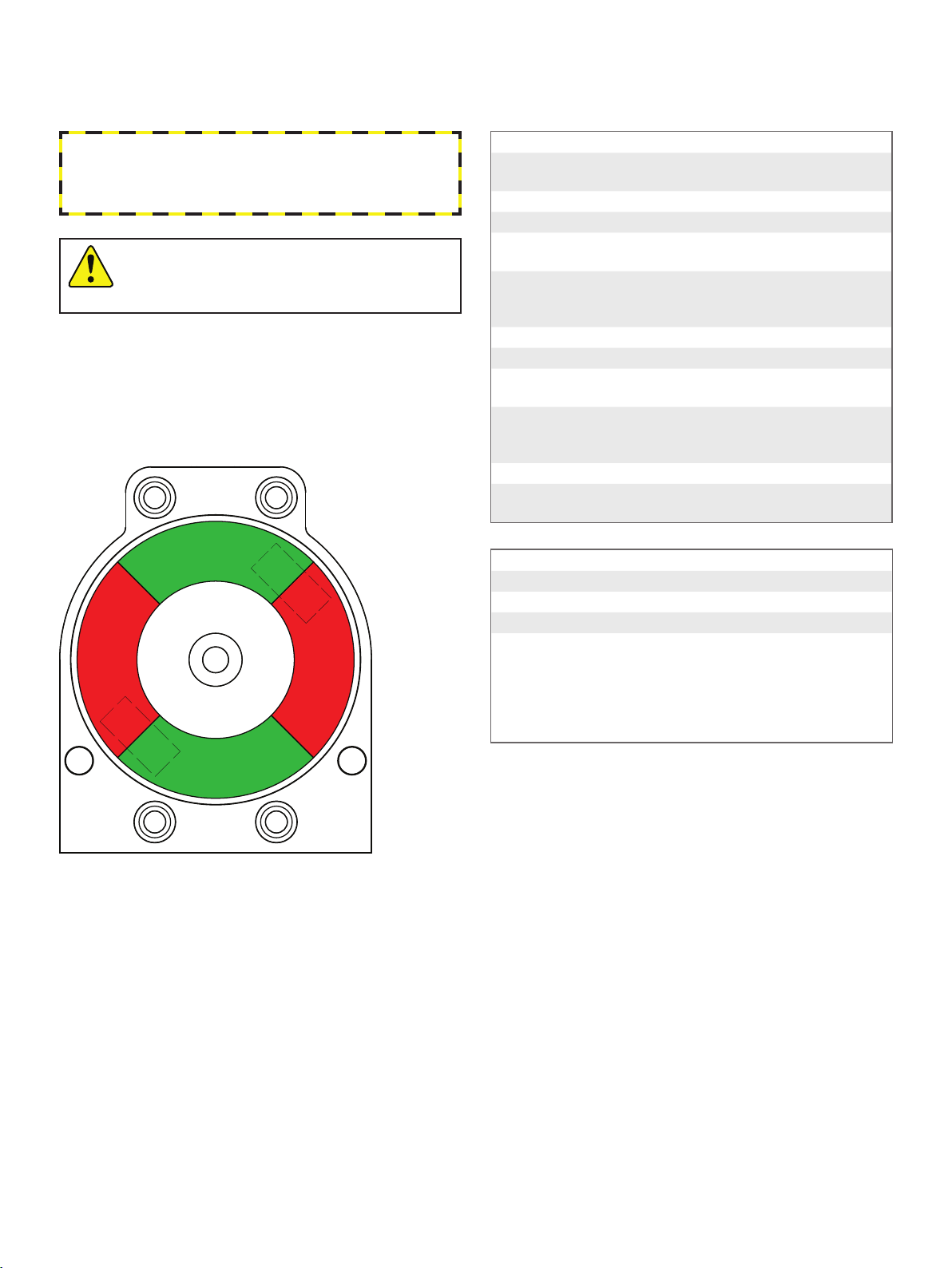

WARNING

Solenoid power supplied must be limited with a

fuse or circuit breaker rated to 2 Amps maximum.

ATTENTION: IF THE UNIT IS USED IN A MANNER

NOT SPECIFIED BY STONEL, THE PROTECTION

PROVIDED BY IT MAY BE IMPAIRED.

CAUTION: TO MAINTAIN SAFETY, ONLY POWER

SUPPLIES THAT PROVIDE DOUBLE/REINFORCED

INSULATION, SUCH AS THOSE WITH PELV/SELV

OUTPUTS, SHALL BE USED. (AS APPLICABLE)

Field wiring

• This product comes shipped with conduit covers in an eort to

protect the internal components from debris during shipment and

handling. It is the responsibility of the receiving and/or installing

personnel to provide appropriate permanent sealing devices

to prevent the intrusion of debris or moisture when stored or

installed outdoors.

• Use eld wiring rated at least 10 K (+10° C) above ambient

temperature.

All models

WARNING

EXPLOSION HAZARD. DO NOT CONNECT OR DISCONNECT

WHEN ENERGIZED UNLESS THE AREA IS FREE OF

IGNITABLE CONCENTRATIONS.

Models with receptacles

WARNING

THE UNIT IS RATED FOR INGRESS PROTECTION WHEN

THE MATING CORDSET IS ATTACHED. THE MATING

CORDSET SHALL REMAIN CONNECTED DURING

OPERATION AND SHALL ONLY BE DISCONNECTED /

RECONNECTED BY TRAINED SERVICE PERSONNEL. IF

THE MATING CORD SET IS DISCONNECTED, IT IS THE

RESPONSIBILITY OF THE SERVICE PERSONNEL TO

INSTALL AN APPROPRIATELY RATED CAP (NOT SUPPLIED)

OVER THE RECEPTACLE TO MAINTAIN THE RATED

INGRESS PROTECTION OF THE UNIT.

When installed in Division 2 areas in the United States and Canada, a

Division 2 FM approved Turck eurofast® or minifast® cordset and the

use of a tool-secured Turck lokfast® guard is required.

Because the unit is rated for Ingress Protection with the mating cordset

attached, care must be taken when selecting the cordset to ensure it is

rated by the manufacturer with equivalent Ingress Protection ratings to

the unit.

The Turck lokfast® guard renders the cordset not “normally arcing”

and maintains ingress protection rating by making the connection tool

secured. Refer to the lokfast® guard’s documentation for details on

releasing the locking mechanism.

The cordsets, as specied above, are available with cable rated

for various wiring methods, such as ITC, PLTC, MC, etc. It is the

responsibility of the installer, or end user, to install this product

in accordance with the wiring method(s) specied by the cordset

manufacturer.

It is the responsibility of the installer, or end user, to install this product

in accordance with the National Electrical Code (NFPA 70) for the US,

CE Code, Part I for Canada, or any other national or regional code

dening proper practices.

7EC70EN - 6/2022 | Stonel product publication 105509revA