Technical Instruction

INGAL EPS Technical Instruction Floodlight Poles Page 1

Pole Assembly & Installation

For Floodlight Poles

The purpose of this technical instruction is to detail those actions necessary to ensure that Column/Mast sections are joined, assembled

and installed in compliance with the applicable design standards.

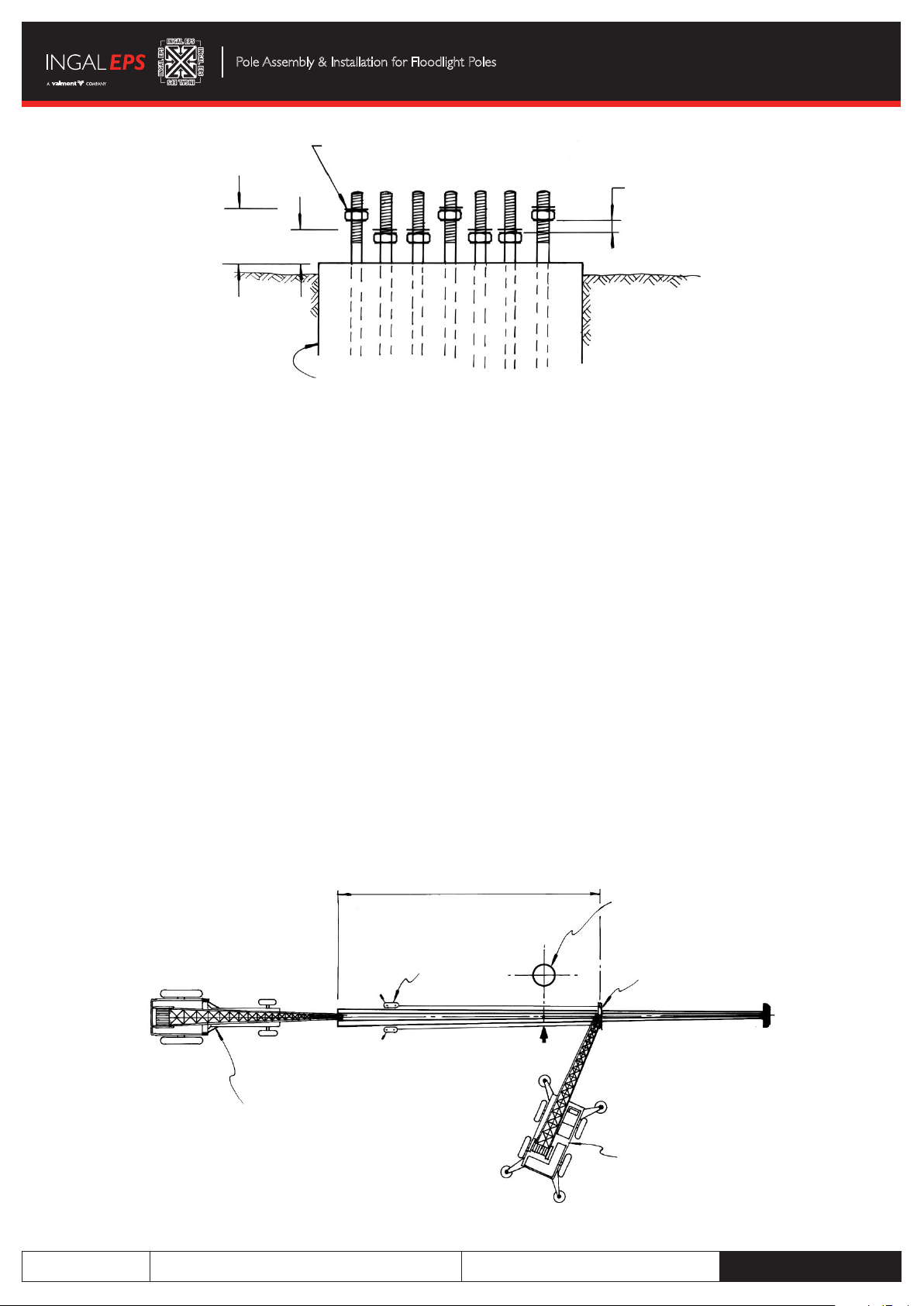

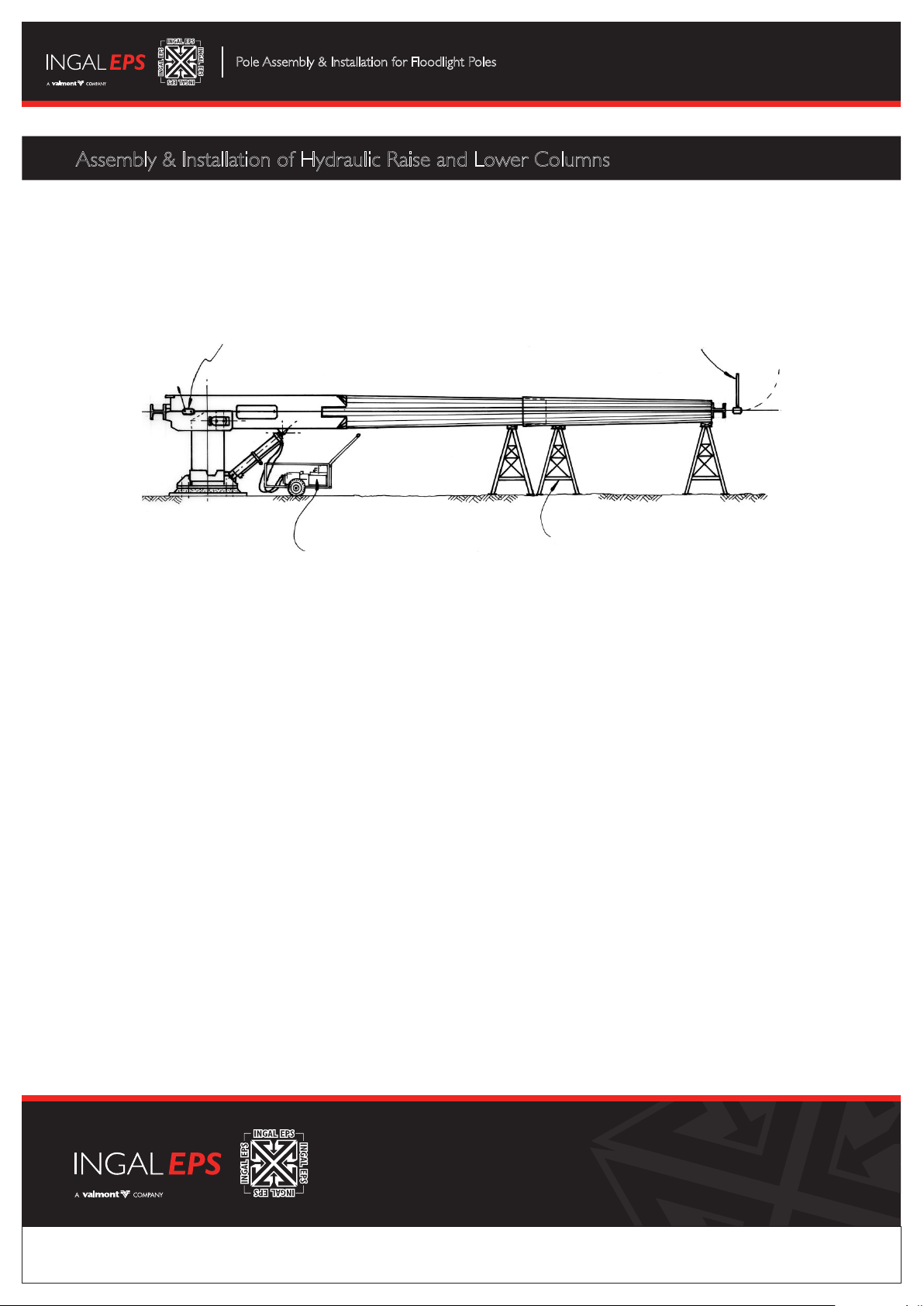

Scope: This procedure applies to the joining/assembly and installation of all column/mast sections, and to the assembly and installation of hydraulic raise

and lower columns.

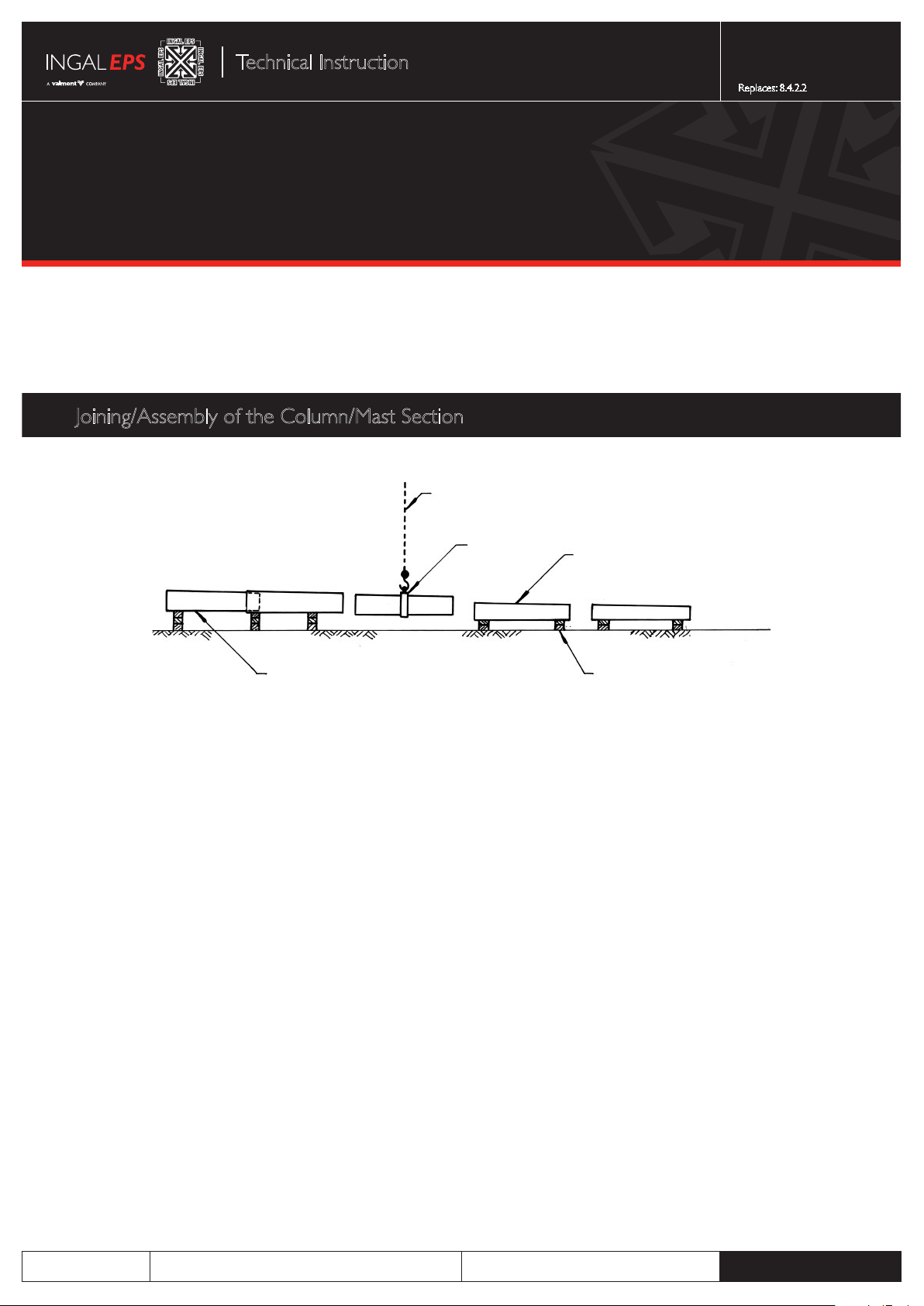

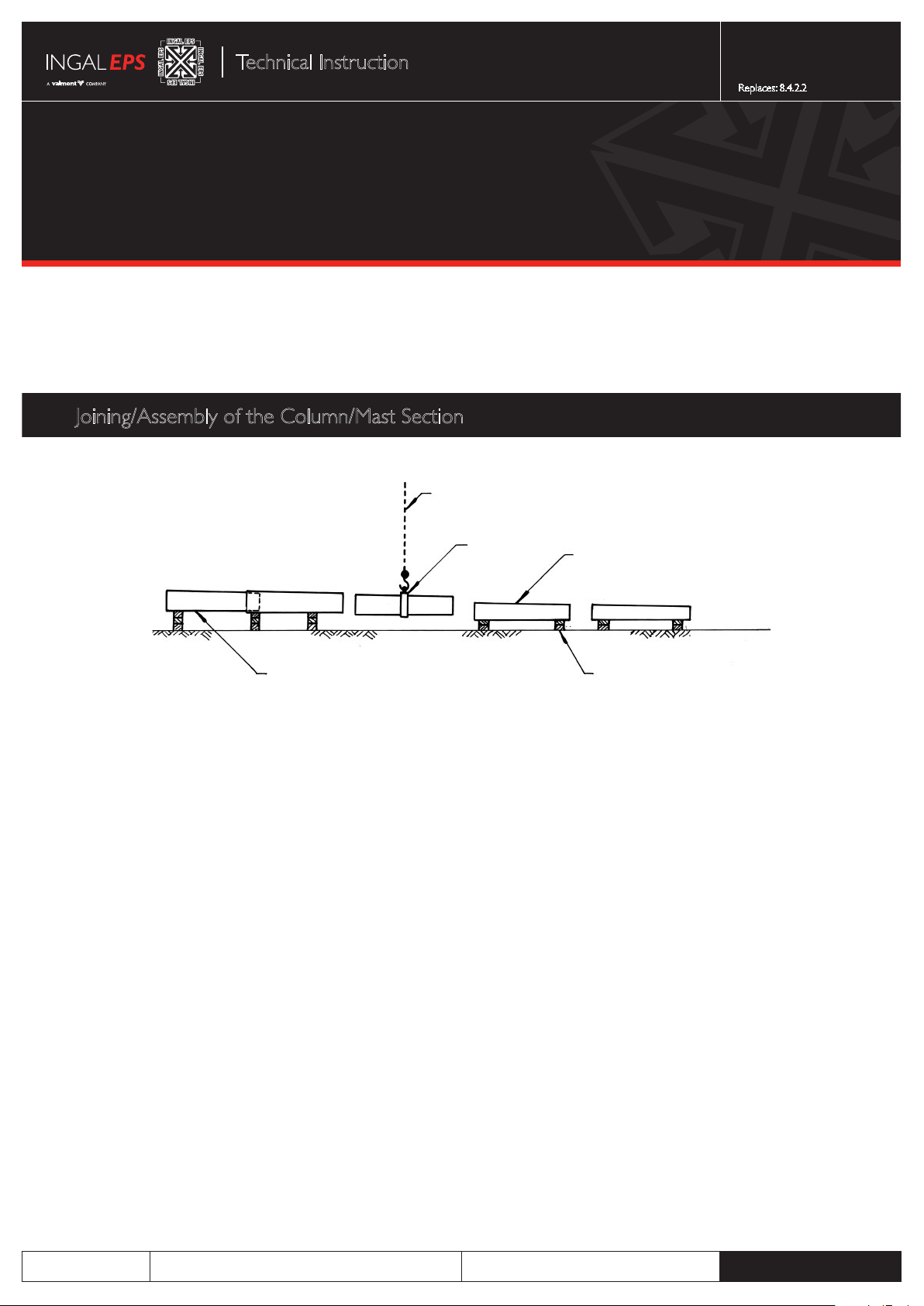

1.0 Joining/Assembly of the Column/Mast Section

1.1 Arrange the base section onto packing with the access opening on the top and levelled so that the underside of the column section will be

horizontal.The height of the packing must be compatible with the base plate and the head frame dimensions so that both will be clear of the

ground when assembled. Seam welds of the column sections and climbing rung clips, if applicable, must be aligned along the length of the column,

(refer to figure 1).

1.2 Make sure that the column base plate is wedged to prevent rotation.

1.3 Check that the packing has a minimum of 300mm clearance of the slip joint length shown on the drawings to allow for any horizontal movement of

the column during assembly.

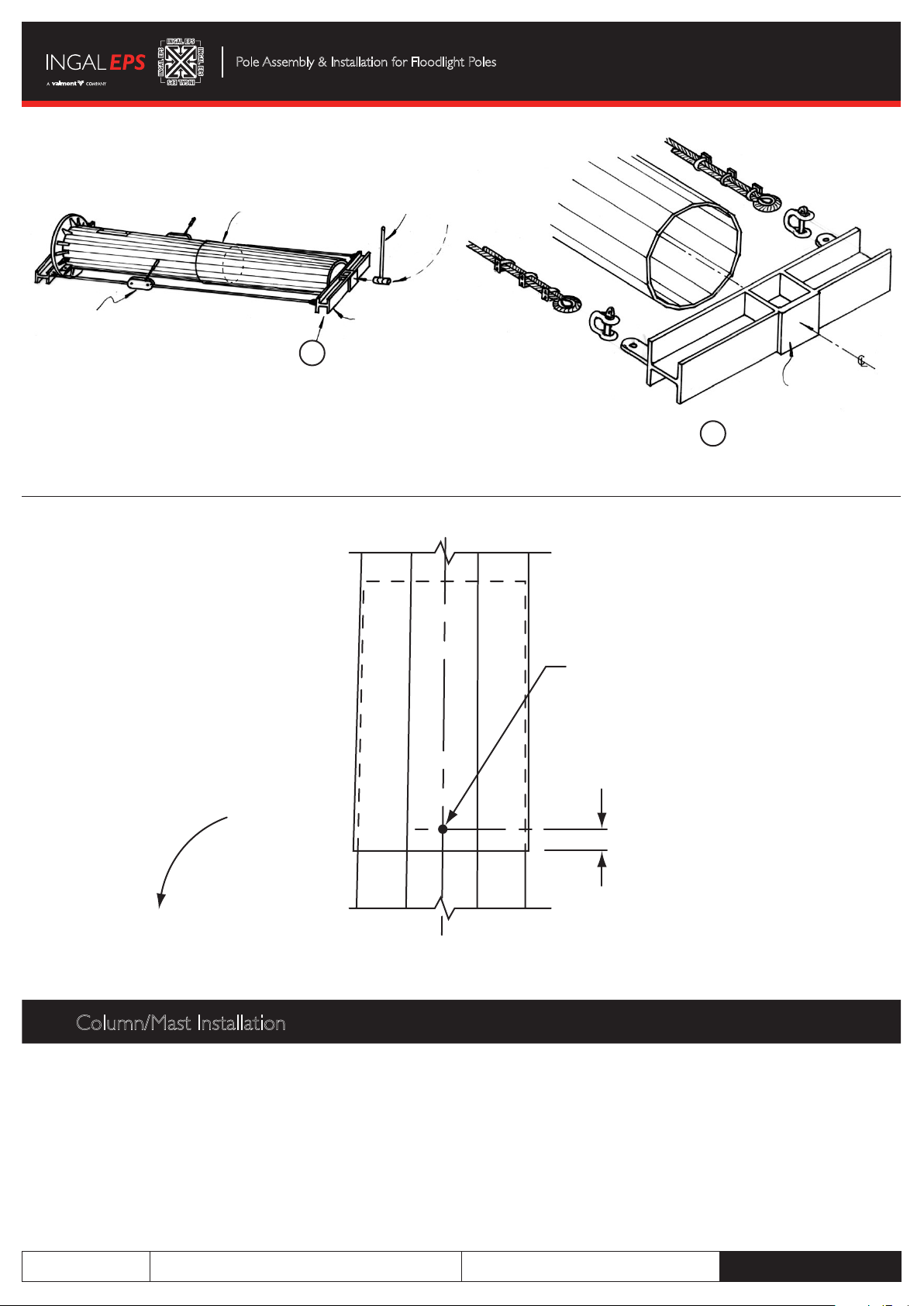

1.4 Sling the section for assembly at its centre of gravity and engage the sections, making sure that perfect alignment is maintained. Only one section at

a time is to be joined starting form the base section.

1.5 Assemble two 3 tonne lift – 5 tonne pull tirfors, one each side of the column, anchoring one end to the base plate or cross beam. At the end of the

column section being assembled a heavy steel section cross beam is arranged, blocked up in the horizontal plane on the column centre line while

the tirfor cables are attached as shown in figure 2. Noting only one section of the pole is assembled at a time starting from the base section.

1.6 Under strict supervision, operate the tirfors in unison to ensure that telescoping of the sections proceeds evenly about the column axis. During

this operation the cross beam can be hammered on the striking plate, (refer to figure 2), and the external surface of the slip joint can also be

hammered via a wooden block to assist in achieving a good joint.

1.7 Misalignment of the sections for any reason may lead to jamming, which will prevent good telescoping of the joint and may be difficult to rectify.

1.8 Check the theoretical slip joint length with respect to the actual slip joint length and continue to apply pressure as described in 1.6 above until no

further movement can be achieved.

1.9 Before removing the crane sling, pack up the newly assembled section to the required level ensuring that the packing is at least 300mm clear of

the next joint to be made. At the same time repack and wedge under the new slip joint before removing the original packing and proceed in this

matter until completion of assembly, keeping a careful check on alignment.

1.10 For Seesaw columns only, slip joints above hinge to be additionally secured with 2 tek screws – refer figure 3.

Figure 1.

Base Plate

Access Door

Crane Rope

Sling Column Sections

Packing

Horizontal or level

with ground line

G.L.

Doc. No: 8.6.02

Revision: 0

Date: 16-4-2013

Replaces: 8.4.2.2