PAGE 7

4.5 ADDITION OF DESICCANT

WARNING

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON

THE DRYER WHILE IT IS UNDER PRESSURE.

DEPRESSURIZE THE DRYER COMPLETELY BEFORE

STARTING INSTALLATION AND/OR MAINTENANCE

PROCEDURES. SERIOUS PERSONAL INJURY MAY

RESULT IF THESE SAFETY RULES ARE NOT FOLLOWED.

DO NOT REMOVE THE HATCH COVER UNTIL ALL AIR

PRESSURE IS OUT OF THE VESSEL. PUSH ON THE

HATCH COVER BY HAND TO FIND OUT IF THE VESSEL

PRESSURE IS REDUCED TO ZERO.

DO NOT TRY TO TIGHTEN THE HATCH COVER IF YOU

HEAR OR FEEL A LEAK. IMMEDIATELY SHUT OFF THE

AIR OR GAS SUPPLY TO THE VESSEL AND REDUCE THE

DRYER PRESSURE TO ZERO.

ALWAYS INSTALL A NEW GASKET EVERY TIME THE

HATCH COVER IS REMOVED, OR AT LEAST ONCE PER

YEAR. REPLACE THE HATCH COVER EVERY FIVE

YEARS REGARDLESS OF CONDITION. USE VAN AIR

AUTHORIZED PARTS ONLY.

DO NOT USE POWER TOOLS OR CHEATER BARS TO

TIGHTEN THE NUT ON THE COVER. TOO MUCH FORCE

CAN DISTORT THE COVER AND/OR THE GASKET. IF

DAMAGED BY OVERTIGHTENING, THE COVER CAN

BLOW OUT AND CAUSE SERIOUS INJURY. (No e:

Tigh en he nu un il i is snug only. When pressure is in

he vessel, he seal will be comple e.)

INSPECT THE COVER AND SEALING SURFACE EVERY

TIME THE COVER IS REMOVED, OR AT LEAST ONCE A

YEAR, FOR DAMAGE SUCH AS CORROSION, CRACKS,

OR DISTORTION. IF THERE IS ANY DAMAGE, INSTALL A

NEW COVER AND GASKET. USE VAN AIR AUTHORIZED

PARTS ONLY.

pen the bypass valve. Close the dryer inlet and outlet isolation

valves. If the bypass and inlet and outlet isolation valves were not

installed, shut down the air system.

pen the drain valve and allow the dryer to depressurize completely.

Loosen the wing nut on the hatch cover. Do not remove the nut, or

the cover will fall into the vessel.

Push on the hatch cover. If the vessel is depressurized, the cover will

unseal. nce the seal is broken, slide the handle so that it is parallel

with the centerline of the long side of the opening. Tilt the hatch cover

and remove it from the dryer.

Add the amount of desiccant tablets required to raise the supply to

the normal operating level or to maximum level (see FIGURE 5); then

level off the tablet bed.

CAUTION

Make sure ha he desiccan does no cover he screen

on he ou le pipe.

Do NOT overfill he vessel. Adequa e space mus be lef

o allow he ha ch cover o be ins alled.

Check the condition of the hatch covet. If is damaged, it must be

replaced. The gasket should be replaced every time.

Check the sealing surface of the opening. If it is contaminated with

dirt or rust, it must be cleaned before installing the hatch cover. A

contaminated surface may prevent the gasket from properly sealing.

Install the filler hatch cover and gasket. Finger tighten the wing nut

on the hatch cover. vertightening will cause damage to the nut. The

cover will seal when the vessel is pressurized.

Start the dryer following the start up procedures in Section 3.1

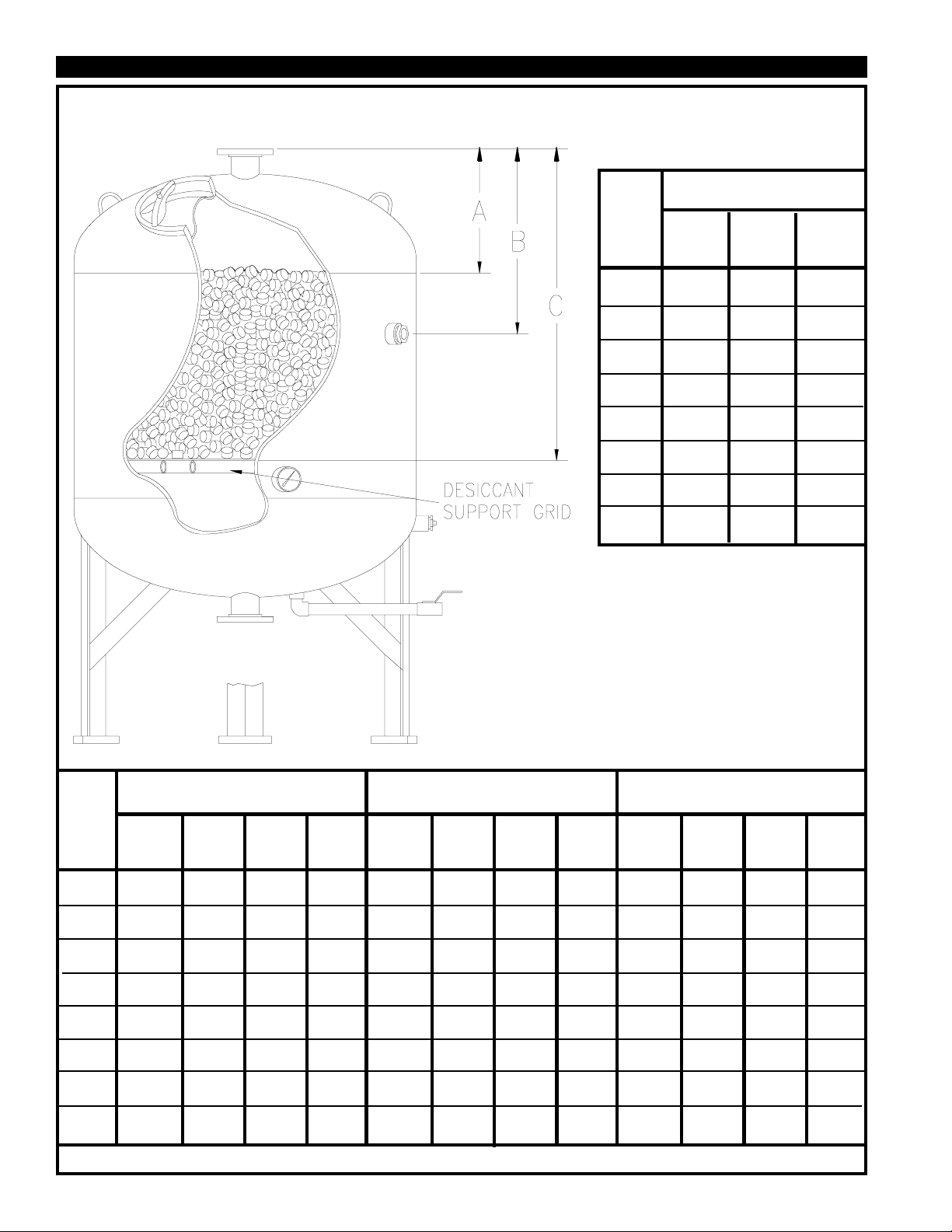

4.5-B DESICCANT USAGE GUIDE

The chemical and physical characteristics of Van Air desiccant

contribute to its effectiveness and economy.

The DESICCANT C NSUMPTI N RATE should be used as a

guide to estimate the usage of desiccant your installation will

require. The formula is based on an annual usage rate of one shift

per day, 5 days per week and 50 weeks per year or 2,000

operating hours per year. The figure is an average and may vary

depending upon your actual conditions (i.e. 24 hour operation,

higher inlet temperature, excessive liquid water content and/or

contaminants.)

DESICCANT CONSUMPTION

(Based upon 1 shift for a one year period @ 100 psig inlet pressure

and 75oF inlet temperature, 100% RH.)

FLOW

SCFM

100

1,000

10,000

DRY-O-LITE

LBS YEAR

132

1,320

13,200

SP

LBS YEAR

665

6,650

66,500

10 BF

LBS YEAR

576

5,760

57,600

To use the chart, first determine the SCFM that is being

processed through the dryer. Locate the nearest flow rate listed

on the chart and interpolate as necessary.

The consumption rate is proportional to the moisture loading.

Each 20oF change in inlet temperature changes the moisture

loading by a factor of nearly 2:1.

The quantity shown in the consumption rate chart is N T the

quantity that must be added to the dryer at one time. The bed

level should be maintained at least to the minimum level at all

times to ensure optimum drying capabilities. The consump ion

ra e is an approxima ion of how much desiccan will be

added over a period of one year.

4.5-A BED LEVEL GUIDE

To determine the supply of desiccant in the dryer, insert a

measuring stick through the filler hatch until it reaches the top

of the desiccant bed; dimensions in FIGURE 5 are calculated

from the filler hatch to levels indicated on the drawing. (N TE:

Dimensions are approximate and are intended as a general

guide only.)

SECTION 4 MAINTENANCE