vii

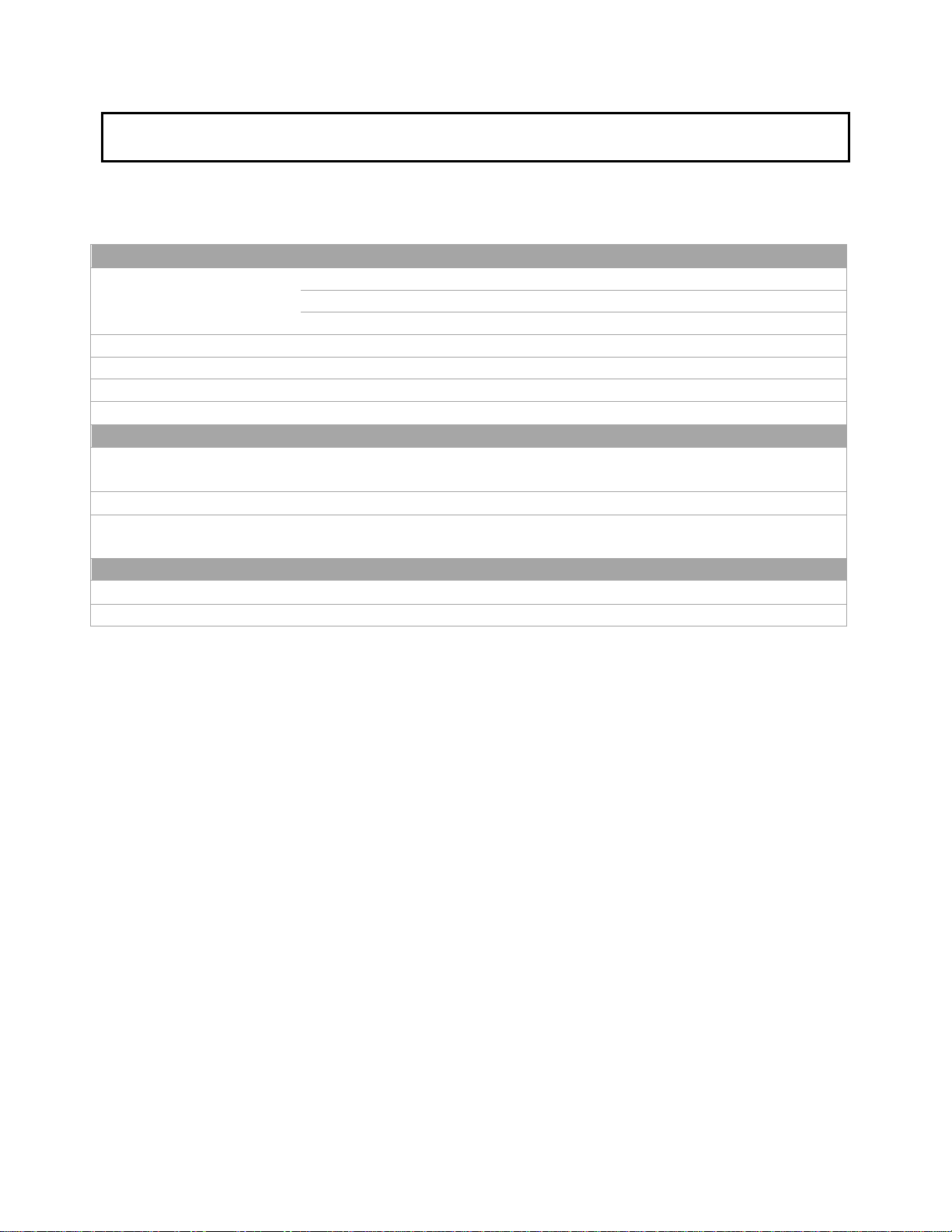

Table of Contents

Introduction..................................................................................................................................... v

Document Scope......................................................................................................................... v

Intended Audience...................................................................................................................... v

Application.................................................................................................................................. v

Exclusions and Limits of Liability.............................................................................................. v

Proprietary Information .............................................................................................................. v

User Alerts................................................................................................................................. vi

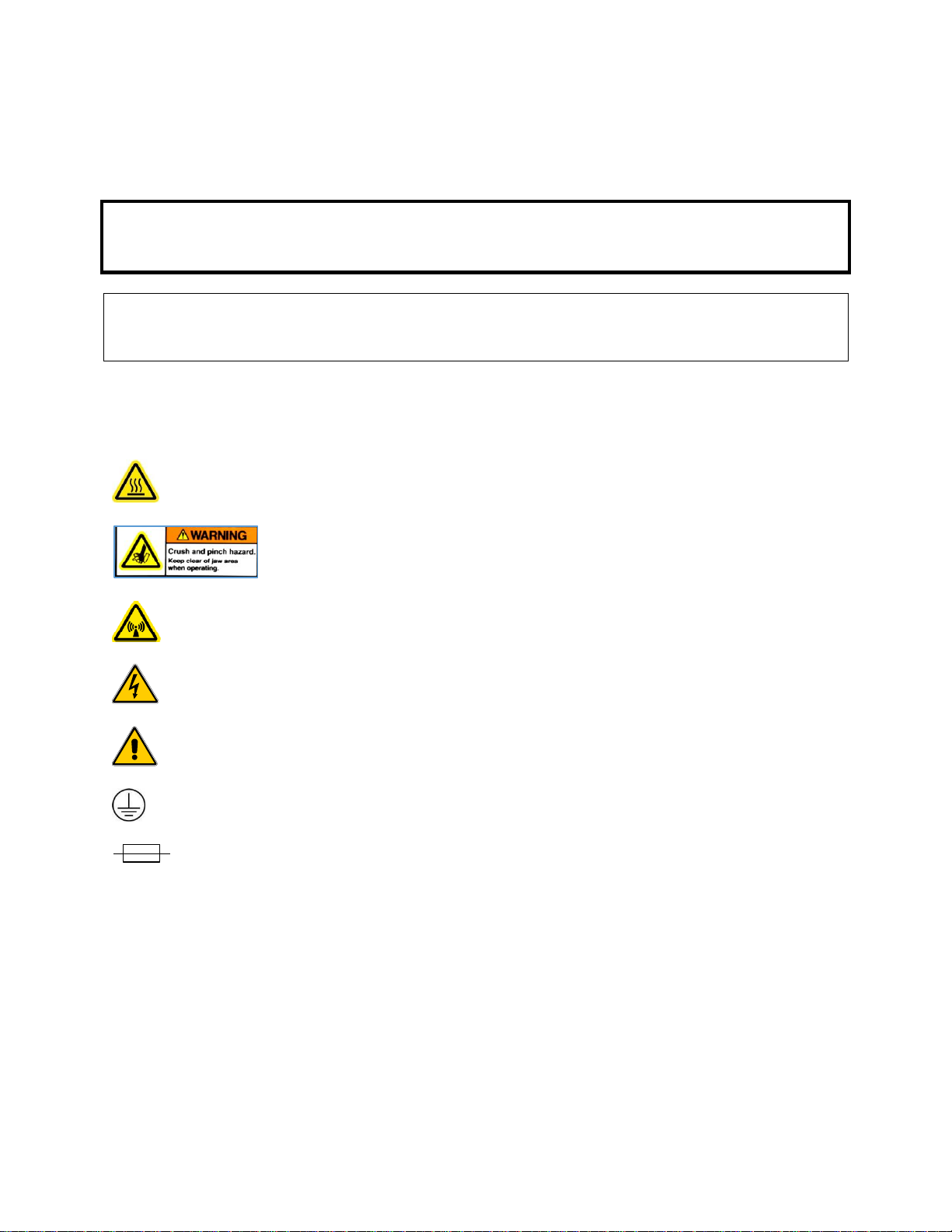

Safety symbols........................................................................................................................... vi

CE Marking Information ........................................................................................................... vi

List of Figures..............................................................................................................................viii

List of Tables ...............................................................................................................................viii

1. Description............................................................................................................................... 1

1.1. The RF Forming/Welding System ................................................................................... 1

1.2. Theory of Operation......................................................................................................... 1

1.3. Operator Safety ................................................................................................................ 1

1.4. Specifications................................................................................................................... 2

2. System Setup ........................................................................................................................... 3

2.1. Diagrams .......................................................................................................................... 3

2.2. Uncrating.......................................................................................................................... 4

2.3. Installation—3806MOD/3807MOD handheld sealer (Sealing Head)............................. 4

2.4. Power On.......................................................................................................................... 5

2.5. Generator Controls........................................................................................................... 6

3. System Operation .................................................................................................................... 7

3.1. Running a Cycle............................................................................................................... 7

3.2. Accessing the Internal Controller..................................................................................... 9

3.3. Programming the Internal Controller............................................................................... 9

3.4. Process Development..................................................................................................... 11

3.5. System Adjustments....................................................................................................... 11

4. Maintenance and Repair........................................................................................................ 13

4.1. Cleaning ......................................................................................................................... 13

4.2. Repair............................................................................................................................. 13

4.3. Returning a Unit for Service .......................................................................................... 13

4.4. Disposal of Equipment................................................................................................... 14

5. Radio Frequency System Safety Considerations................................................................... 15

5.1. Introduction.................................................................................................................... 15

5.2. RF Effects on Human Tissue ......................................................................................... 15

5.3. RF Effects on Pacemakers.............................................................................................. 15

5.4. Electrical Safety ............................................................................................................. 15

5.5. RF Effects on Electronic Equipment.............................................................................. 15

5.6. RF Effects in Potentially Explosive Atmospheres......................................................... 15

Index ............................................................................................................................................. 16