Contents

1 Basic information ...............................................................................................................3

2 Introduction ........................................................................................................................4

2.1 Warning ......................................................................................................................4

3 Operation safety..................................................................................................................5

3.1 Safety regulations .......................................................................................................5

3.2 Safety pictographs ......................................................................................................6

3.3 aximum values of noise and vibrations as measured by AO-206 SZZPLS Prague 7

4 Use, technical specification and technical description of the machine ..............................7

4.1 Use of the machine .....................................................................................................7

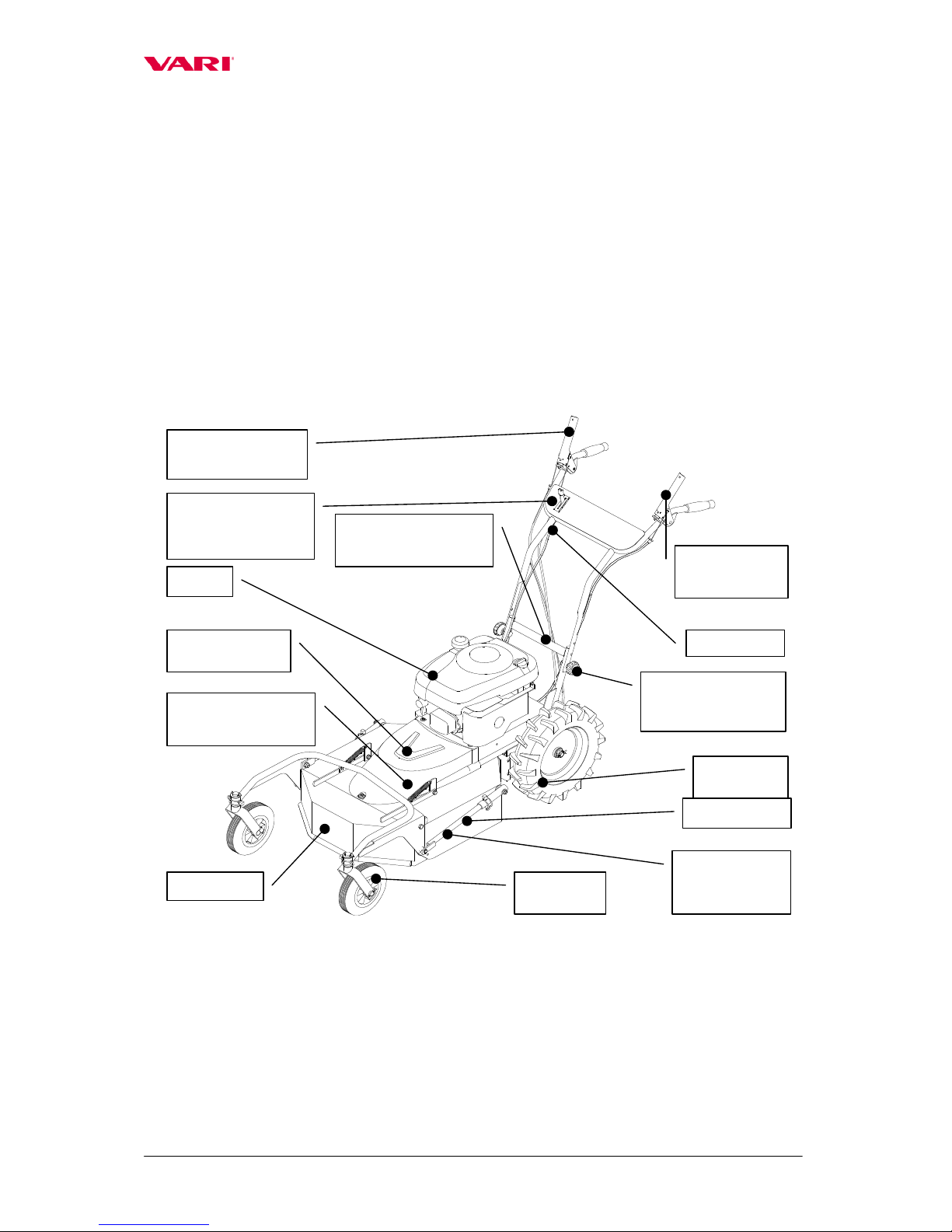

4.2 Technical description of the machine.........................................................................8

5 Instructions for use .............................................................................................................9

5.1 achine assembly ......................................................................................................9

5.2 Putting into operation ...............................................................................................10

5.3 Starting the mowing knife ........................................................................................11

5.4 achine travel ..........................................................................................................11

5.5 achine stop.............................................................................................................13

5.6 Working with the machine........................................................................................13

5.6.1 Adjusting the mowing height ...........................................................................13

5.6.2 owing of grass stands ....................................................................................14

5.6.3 Arrestment of guide wheel suspensions ...........................................................15

5.7 achine accessories .................................................................................................15

5.7.1 Slide shoe and its assembly ..............................................................................15

5.7.2 Swinging and mixing knife complement..........................................................16

6 aintenance, care and storage..........................................................................................16

6.1 Lubrication................................................................................................................16

6.1.1 Gear oil replacement and refilling....................................................................16

6.1.2 Engine oil replacement .....................................................................................18

6.1.3 Table of machine lubrication............................................................................18

6.2 Tightening of bolted connections .............................................................................19

6.3 Replacement and sharpening of working knife ........................................................19

6.4 V-belt replacement and adjustment of tension pulley ..............................................21

6.5 Setting-up litz wires of pulley, brake and machine travel gear clutch......................22

6.6 Diagnostics of driving problems...............................................................................23

6.7 Tyres of driving wheels ............................................................................................23

6.8 Table of service operations.......................................................................................24

6.9 Washing and cleaning of the machine......................................................................24

6.10 Storage......................................................................................................................25

6.11 Liquidation of packaging and machine after service life expiration ........................25

7 Instructions for ordering spare parts.................................................................................26

8 Contact to manufacturer ...................................................................................................26

9 List of components ...........................................................................................................26

9.1 Knife casing and guide wheels .................................................................................27

9.2 owing knife drive ..................................................................................................29

9.3 Handlebars................................................................................................................31

9.4 Wheel drive gear.......................................................................................................33

9.5 Gearbox.....................................................................................................................35

9.6 Swinging and mixing knives, slide shoe ..................................................................37

10 Letter of guarantee............................................................................................................39