4

VARIANT FACTORY LTD.

GENERAL INSTRUCTIONS

This user manual (method statement)

is aimed at everyone who will be working

with the «VARIANT» product or system it

desupportingribes. It contains information on

how to set up this system, and proper use it.

All persons working with the product

desupportingribed herein must be familiar with

the contents of this manual and with all the

safety instructions it contains.

The customer is to ensure that the informa-

tion materials provided by «VARIANT» are

available to all users, and that they have been

made aware of them and have easy access to

them at the usage location.

Persons who are incapable of reading and

understanding this booklet, or who can do so

only with diculty, must be instructed and

trained by the customer.

Always observe all construction safety

regulations and other safety rules applying

to the application and using of our products

in the country and/or region in which you are

operating.

In the relevant technical documentation

and formwork usage plans, «VARIANT» shows

the workplace safety precautions that are

necessary in order to use the «VARIANT»

products safely in the usage situations shown.

In all cases, users are obliged to ensure

compliance with national laws, Standards and

rules throughout the entire project and to take

appropriate additional or alternative workplace

safety precautions where necessary.

The customer is responsible for drawing up,

documenting, implementing and continually

updating a hazard assessment on every

construction site. This document serves as the

basis for the site-specic hazard assessment,

and for the instructions given to users on how

to prepare and use the system. It does not

substitute for these, however.

This manual can also be used as a generic

method statement or incorporated with a site-

specic method statement.

The equipment/system must be inspected

by the customer before use, to ensure that it

is in suitable condition. Steps must be taken to

rule out the use of any components that are

damaged, deformed, or weakened due to wear,

corrosion or rot.

The customer must ensure that this product

is erected and dismantled, reset and generally

used for its intended purpose under the

direction and supervision of suitably skilled

persons with the authority to issue instructions.

These persons' mental and physical capacity

must not in any way be impaired by alcohol,

medicines or drugs.

The equipment/system must be assembled

and erected in accordance with the applicable

laws, Standards and rules by suitably skilled

personnel of the customer's, having regard to

any and all required safety inspections.

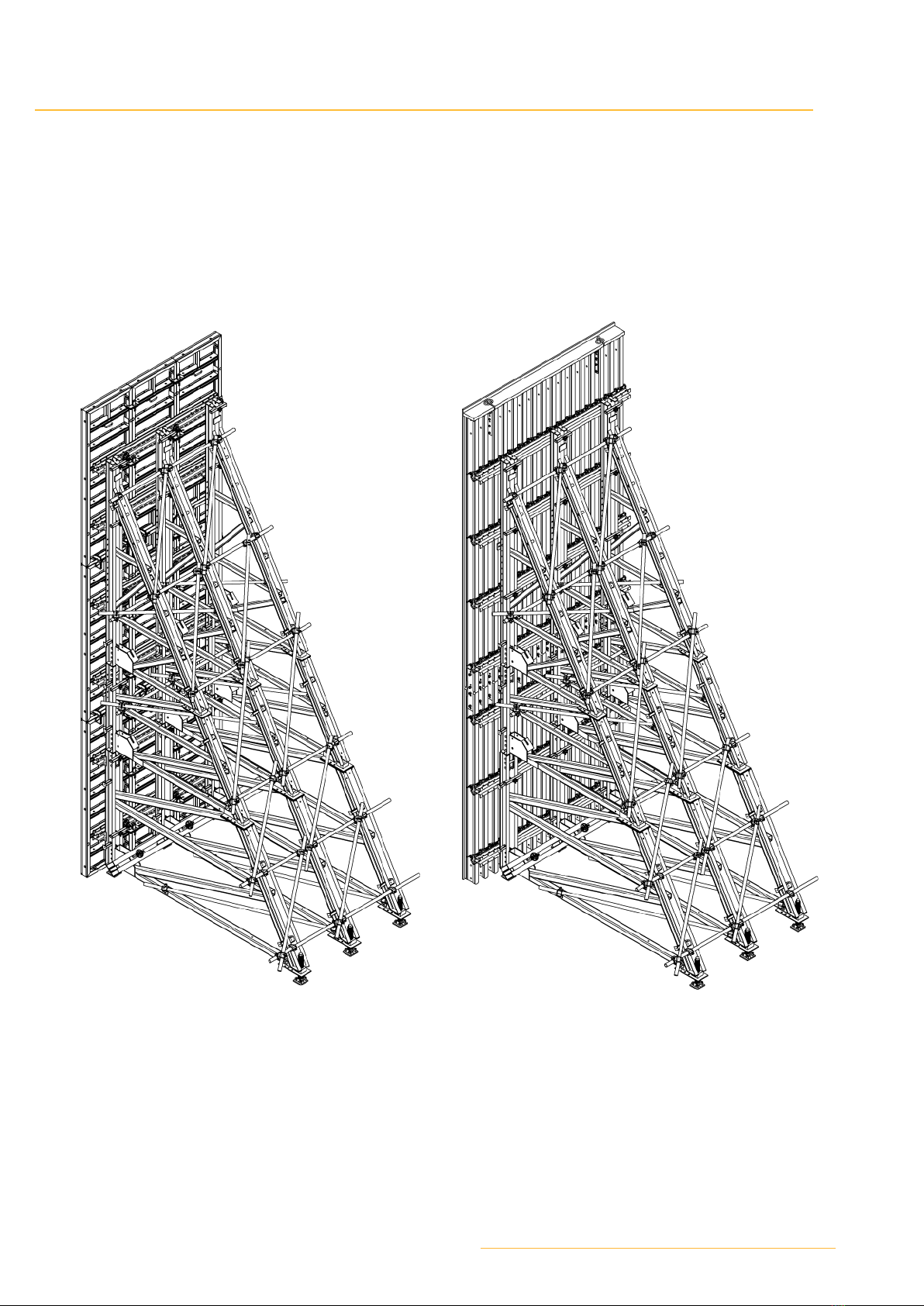

Many of the illustrations in this user manual

show the situation during formwork assembly

and are therefore not always complete from

the safety point of view.

Combining our formwork systems with

those of other manufacturers could be, but

needs to be checked by customer compa-

tibility «VARIANT» product/system with other

independently under its responsibility.

It is not permitted to modify«VARIANT»

products because of a safety risk.

Only original «VARIANT» components

may be used as spare parts. Repairs may only be

carried out by the manufacturer or authorized

facilities.

We reserve the right to make alterations in

the interests of technical progress.