31

1968 FORDF-100 ASCENDER, BND

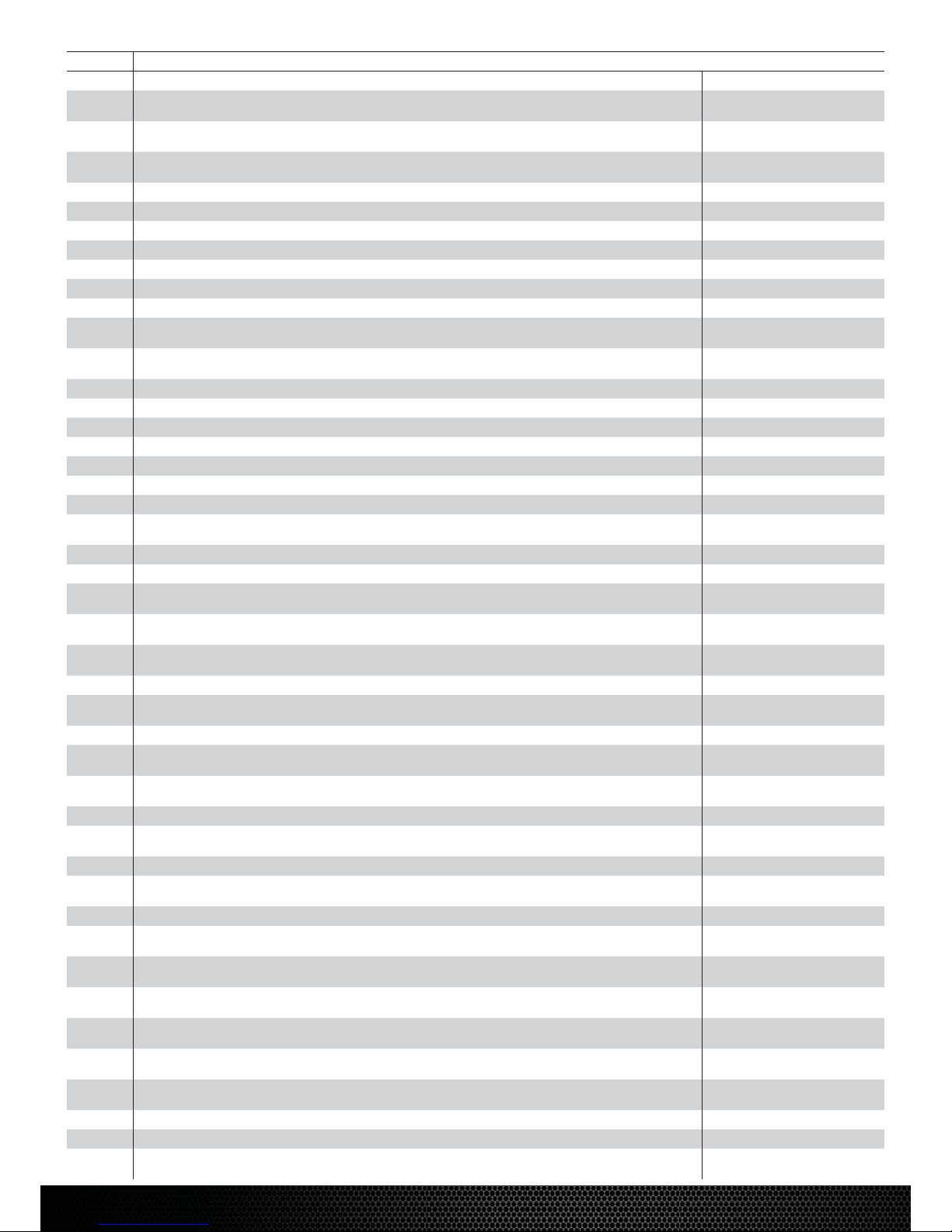

Replacement Parts List • Teileliste • Liste des pièces de rechange • Elenco dei ricambi

Part # English Deutsch Français Italiano

LOS4114 48 Pitch Pinion Gear, 14T 48 Pitch Ritzel, 14T Pignon moteur 48DP, 14T 48 Pitch pignone, 14T

DYNS2210 Waterproof 60A Forward/Reverse

Brushed ESC

Wasserdicht 60A Vorwärts / Rückwärts

gebürstet ESC

Étanche à l'eau 60A avant / inversé ESC

brossé

Impermeabile 60A ESC spazzolato in

avanti / invertito

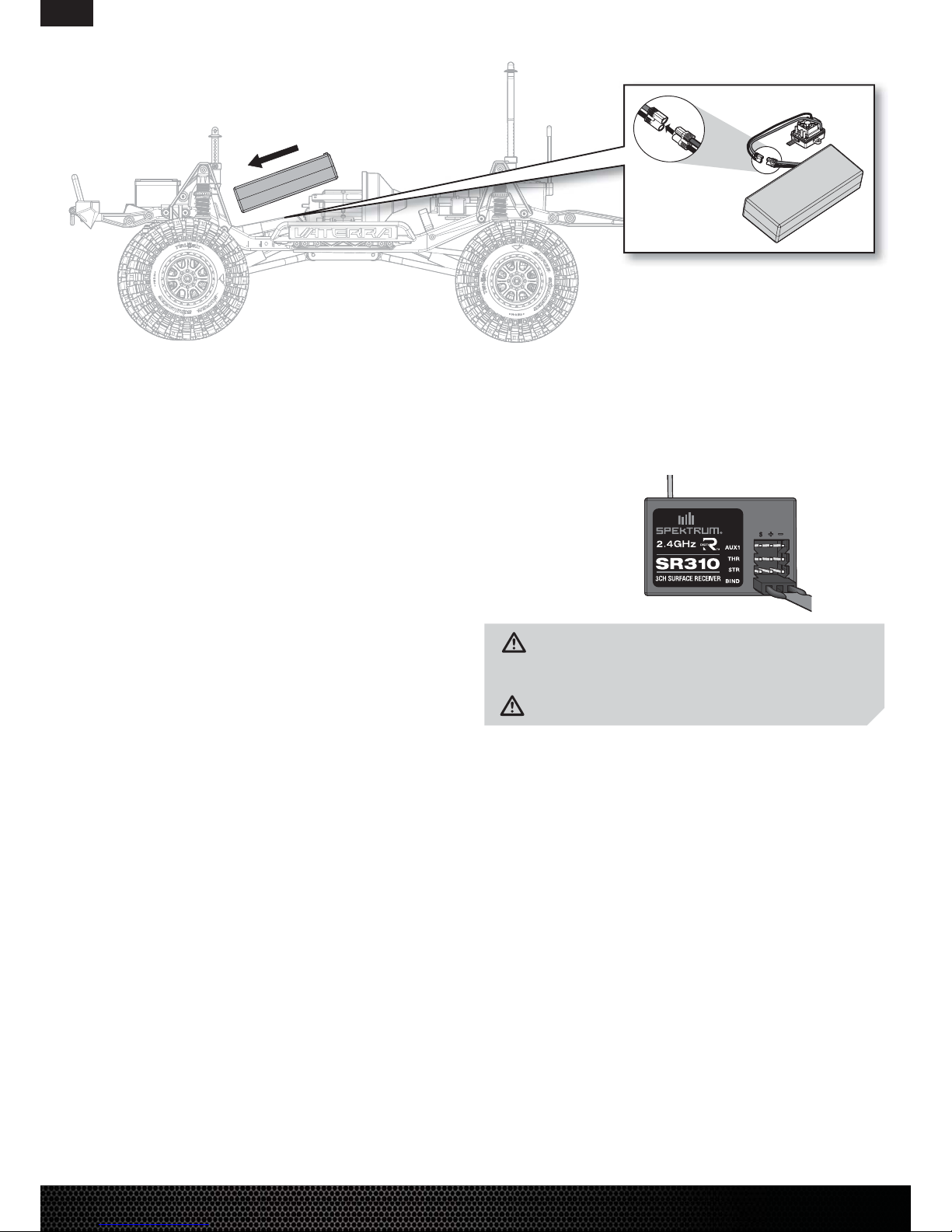

SPMSR310 SR310 DSMR 3 Channel Sport

Receiver SR310 DSMR 3 Kanal Sportempfänger Récepteur sport SR310 DSMR à 3 canaux Ricevitore sportivo SR310 DSMR 3

canali

SPMS605 9KG Servo, Waterproof, Metal Gear,

23T

9KG Servo, wasserdicht, Metallgetriebe,

23T

9KG Servo, imperméable à l'eau, équipement

métallique, 23T

Servo 9KG, impermeabile, ingranaggio

del metallo, 23T

TLR255002 Button Head Screws, M2.5x10mm (10) Halbrundschrauben, M2,5x10mm (10) Vis à tête bombée, M2,5x10mm (10) Viti a testa tonda, M2.5x10mm (10)

TLR255006 Button Head Screws, M4x10mm (10) Halbrundschrauben, M4x10mm (10) Vis à tête bombée, M4x10mm (10) Viti a testa tonda, M4x10mm (10)

TLR5903 Button Head Screws, M3 x 10mm (10) Halbrundschrauben, M3x10mm (10) Vis à tête bombée, M3x10mm (10) Viti a testa tonda, M3 x 10mm (10)

TLR5904 Button Head Screws, M3 x 12mm (10) Halbrundschrauben, M3x12mm (10) Vis à tête bombée, M3x12mm (10) Viti a testa tonda, M3 x 12mm (10)

TLR5909 Button Head Screws, M3 x 16mm (10) Halbrundschrauben, M3x16mm (10) Vis à tête bombée, M3x16mm (10) Viti a testa tonda, M3 x 16mm (10)

TLR5962 Flathead Screws, M3 x 10mm (10) Flachkopfschrauben, M3 x 10mm (10) Vis à tête plate, M3x10mm (10) Viti a testa piatta, M3 x 10mm (10)

TLR5964 Flathead Screw, M3 x 16mm (10) Flachkopfschrauben, M3 x 16mm (10) Vis à tête plate, M3x16mm (10) Viti a testa piatta, M3 x 16mm (10)

VTR230055 Ascender Roll Cage Set w/Alum

panels (290mm)

Ascender Roll Cage Set mit Alu-Verkleid-

ung (290mm)

Arceau cage Ascender avec panneaux alu

(290mm)

Set gabbia antiribaltamento Ascender

Set c/pannelli allum. (290mm)

VTR230057 1968 Ford F-100 Pickup Cab Set Clear:

ASN

1968 Ford F-100 Pickup Cab Set

transparent: ASN

ASN - Carrosserie transparente 1968

Ford F-100 Pickup

Set cabina trasparente 1968 Ford F-100

Pickup: ASN

VTR231033 Chassis Frame Rail Set: ASN Baugruppe Chassisrahmenschiene: ASN ASN - Set de longerons de châssis Set rotaie telaio: ASN

VTR231034 Chassis Brace Set: ASN Chassisstrebe Set: ASN ASN - Set de renforts de châssis Set supporto telaio: ASN

VTR231035 Shock Tower Set FR/RR: ASN Stoßdämpferbrücke Set v/h: ASN ASN - Support d'amortisseur Av/Arr Set torre ammort: ASN

VTR231036 Bumper Set FR/RR: ASN Stoßstangenset v/h: ASN ASN - Set de parechoc Av/Arr Set paraurti FR/RR: ASN

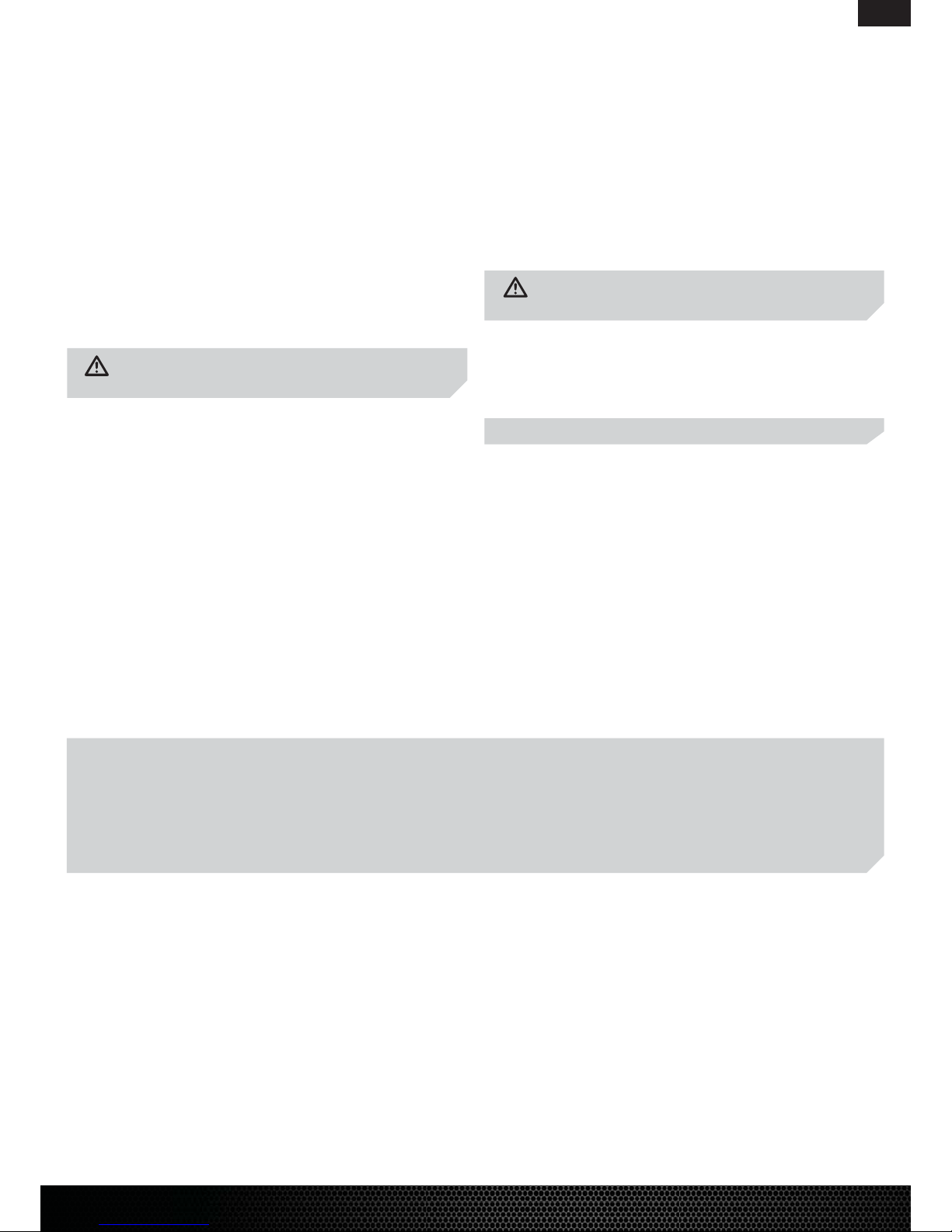

VTR231037 Receiver Box & ESC Tray: ASN Empfängerbox & Reglerhalter: ASN ASN - Boite de récepteur et platine de contrôleur Sede scatola ricevente ed ESC: ASN

VTR231038 Battery Tray, Mounts & Strap: ASN Batterieeinschub, -träger & -lasche: ASN ASN - Support de batterie, fixations et sangles Sede batteria, supporti e cinghia: ASN

VTR232001 Transmission Case: Twin Hammers Getriebegehäuse: Twin Hammers Twin Hammers - Boitier de transmission Scatola trasmissione: Twin Hammers

VTR232013 Drive Shaft Yoke, Cup & Hardware (1):

Twin Hammers

Antriebswellenmitnehmer und Zubehör

(1): Twin Hammers

Twin Hammers - Coupelle de cardan avec

croisillon et visserie (1)

Giogo albero trasm., coppa e viteria (1):

Twin Hammers

VTR232017 Transmission Shaft Set: Twin Hammers Antriebswellenset: Twin Hammers Twin Hammers - Set d'arbres de transmission Set albero trasmissione: Twin Hammers

VTR232024 Slipper Pads (2): Twin Hammers Slipper Pads (2): Twin Hammers Twin Hammers - Garnitures de slipper (2) Pastiglie slipper (2): Twin Hammers

VTR232026 Slipper Spring, Cup, Spacer & Washer Slipperfeder, Außenring, Distanzscheibe

& Unterlegscheibe: TH ASN

Rondelle, entretoise, ressort et coupelle de

slipper

Molla, coppa, distanziale e rondelle

slipper

VTR232067 Motor Plate, Gear Cover & Hdw: ASN Motorplatte, Getriebeabdeckung & Hdw:

ASN

ASN - Support moteur, carter de transmission

et visserie

Piastra motore, copertura ingran. e

viteria: ASN

VTR232068 Center Transmission Gear Set &

Spacers: ASN

Zentralgetriebe Set & Distanzscheiben:

ASN

ASN - Set de pignons de transmission

centrale et entretoises

Set albero trasmissione centrale e

distanziali: ASN

VTR232069 Spur Gear, 86T, 48P (2) Hauptzahnrad, 87T, 48P (2) Couronne 82T, 48p (2) Corona, 86T, 48P (2)

VTR232072 Input Drive Shaft Yoke, Cup & Hdw

(1): ASN

Antriebswellengabel, Außenring, Distan-

zscheibe & Hdw (1): ASN ASN - Tête de cardan, coupelle et accessoires Giogo albero ingresso, coppa e viteria:

ASN

VTR232073 Spool 24T & Pinion Gear 13T: ASN Spule 24T & Zahngetriebe 13T: ASN ASN - Spool 24T et pignon 13T Rocchetto 24T e pignone 13T: ASN

VTR232074 Axle Housing & Link Mount Set FR/

RR: ASN

Set Achsgehäuse & Befestigungspunkte

v/h: ASN ASN - Corps de pont et fixations Av/Arr Sede albero e set supporto link: ASN

VTR232075 Di Cover & Di Skid Plate Set FR/

RR: ASN

Set Dierentialabdeckung & Dieren-

tialgleitplatte FR/RR: ASN

ASN - Couvercle de diérentiel et plaque de

protection Av/Arr

Copertura di. e set piastra pattino

di.: ASN

VTR232076 Front CV Shaft Set: ASN CV Antriebswellenset vorne: ASN ASN - Set de cardans CV avant Set albero CV anteriore: ASN

VTR232077 Wheel Hex, Pins & Serrated Lock Nut:

ASN (4)

Radmuttern, Stifte und Stoppmuttern

(4): ASN

ASN - Goupilles, hexagones et écrous de

roues (4)

Esagoni ruote, perni e dado autob-

loccante dentellato: ASN (4)

VTR232078 Axle Shafts Rear (2): ASN Achswellen Heck (2): ASN ASN - Axe de roue Arr (2) Asse albero posteriore: ASN

VTR232079 HD Molded Center Dsft Set Short/

Long: ASN HD Antriebswelle Mitte, kurz/lang: ASN Ascender - Cardan central moulé renforcé

Court/Long

Set HD centrale stampato corto/lungo:

Ascender

VTR232080 HD Pinion Drive Gear 13T (2) Antriebsritzel HD 13T (2) Pignon renforcé 13T (2) Pignone HD 13T (2)

VTR233026 Shock Shaft & Piston Set (4): ASN Set Kolbenstange & Kolben (4): ASN ASN - Set de tige d'amortisseur et de piston

(4) Set pistone e albero ammort. (4): ASN

VTR233027 Shock Body, Adj Collar, Upper & Lower

Cap (4): ASN

Gehäuse, Einstellmanschette, obere &

untere Kappe (4): ASN

ASN - Corps d'amortisseur, bague de réglage

et bouchons inf. et sup. (4)

Corpo ammort., collare regol., copertura

infer./super. (4): ASN

VTR233028 Shock End,Cup,Rubber Stop & Mid

Collar (4): ASN

Stoßdämpferende, Außenring, Anschlag-

gummi & Mittelmanschette (4): ASN

ASN - Chape d'amortisseur, coupelle, butée

caoutchouc, bouchon inf. et sup. (4)

Terminale ammort., coppa, fermo in

gomma e collare medio (4): ASN

VTR233029 Upper Shock Spring Set Soft, Med,

Hard (2ea.): ASN

Set obere Stoßdämpferfeder weich,

medium, hart (2ea.): ASN

ASN - Set de ressorts supérieurs, souple,

moyen, dur (2 de chaque)

Set molla super. ammort. morbida,

media, dura: ASN

VTR233030 Lower Shock Spring Set Soft, Med,

Hard (2ea.): ASN

Set untere Stoßdämpferfeder weich,

medium, hart (2es.): ASN

ASN - Set de ressorts inférieurs, souple,

moyen, dur (2 de chaque)

Set molla infer. ammort. morbida,

media, dura: ASN

VTR234025 Steering Spindle & Hub Set FR/RR:

ASN Set Lenkspindel & Träger (v/h): ASN ASN - Set de fusées et étriers Av/Arr Set fuso sterzo e mozzo: ASN

VTR234026 Steering Linkage Set: ASN Set Lenkgestänge: ASN ASN - Tringlerie de direction Set comandi sterzo: ASN

VTR234027 Suspension Rod Ends: ASN Kugelpfannenaufhängung: ASN ASN - Chapes de suspension Estremità asta sospensione: ASN

VTR234028 3mm Threaded Alum. Link, 61mm (4) 3mm Aluminiumgewinde, 61mm (4) Biellette aluminium M3, 61mm (4) Collegamento filettato allum. 3mm,

61mm (4)