10

10. FAULT DIAGNOSIS / FAULT CORRECTION

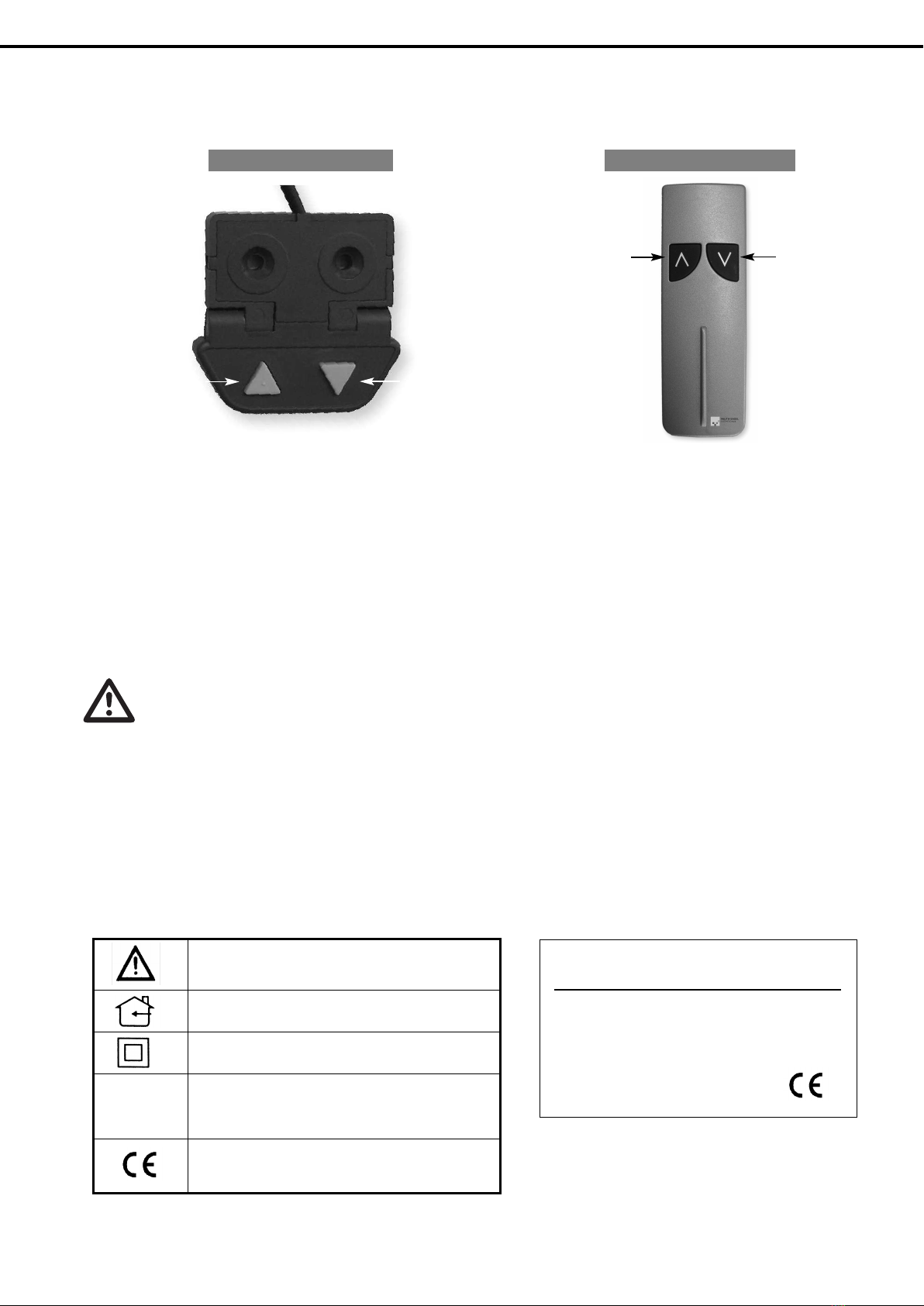

10.1 INITIALISATION

Press the “drive in” button. The telescopic drive drives into the bottom position. Release the button briefly (approx. 2-3 seconds)

and then press the “drive in” button for at least 6 seconds. During initialisation, the system will be lowered approximately 5 mm

and then raised again. This signalises the end of initialisation. Never release the “drive in” button during initialisation.

Fault Possible cause Checks

The system does not drive IIs the mains cable connected to the control

box?

Use a test lamp or similar device to check whether the

operating voltage in the mains connection is OK.

Are all plugs inserted correctly? Check all connections (refer to section 5)

Are any damages to the cables, manual

operating elements, control box, TV switch-

off or the telescopic drive visible

Damaged parts must be exchanged for original repla-

cement parts

The system stops when it is driven

out and can only be driven in

Is the system fully driven out? Once the system has reached the highest position it

can only be driven downwards

Is the system loaded above the maximum

stated load (refer to section 9)

Unload the system and try again

The max. drive out height is set using the

operating element – the system cannot be

driven higher using the remote control

Set to drive out height using the operating element –

refer to section 6

The system only drives downwards

at a low speed although it is not

overloaded.

nitialise the system - refer to section 10.1

The system cannot be driven using

the remote control

The system is driven to the lowest position

using the operating element

Set a different drive out height using the operating

element - refer to section 6

9. TECHNICAL DATA

Electrical

data

Mains voltage 230 V ~ 50-60 Hz

Input power 400 W

Output voltage 18 V

Operating mode nt. max 10 %, max. 2 min/18 min

Remote control frequency 433 MHz

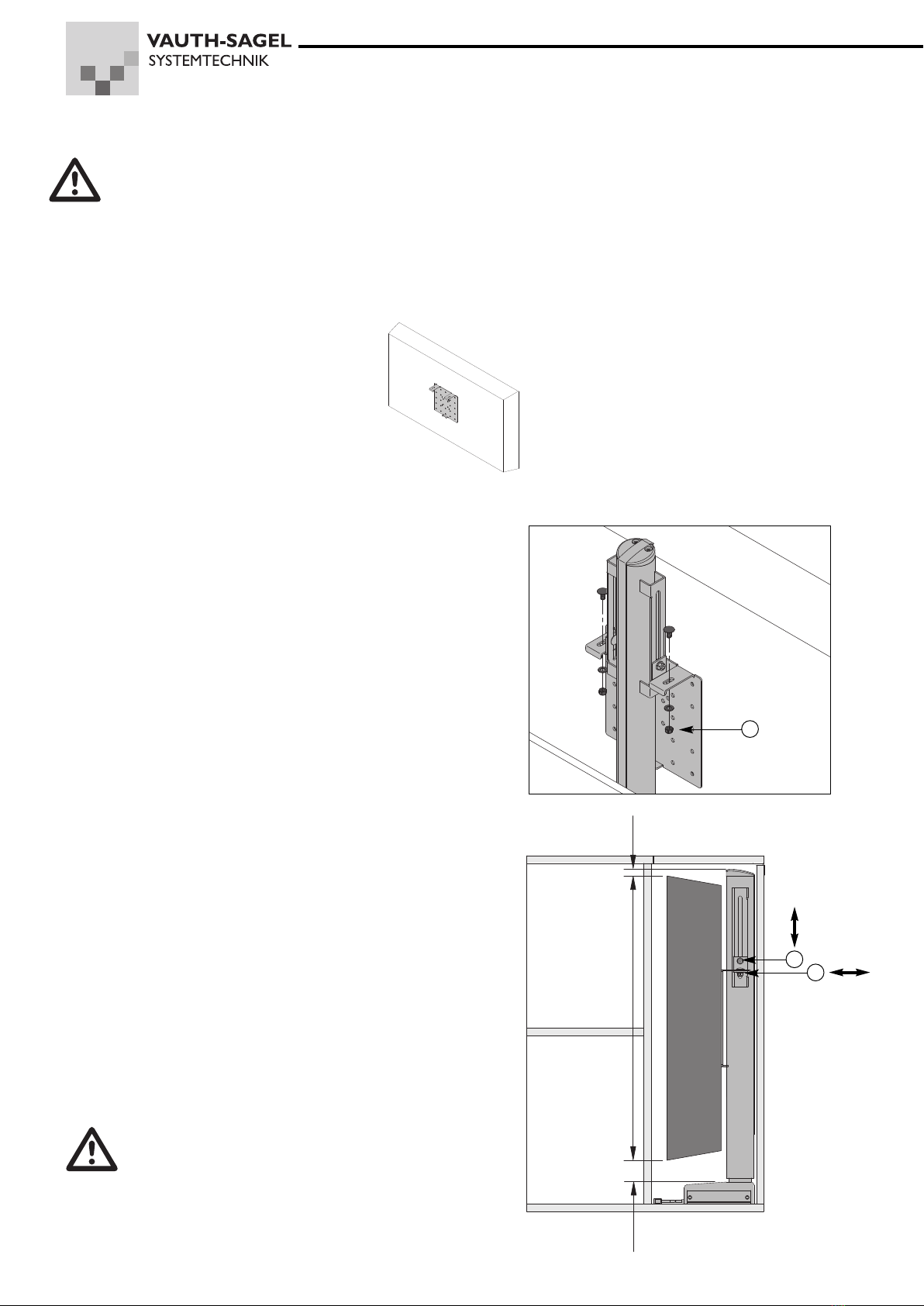

System data Installation height 847mm +5/-2mm (body construction with flap), 833mm +5/-2mm (body construction with

lid) (standard-setting)

Installation depth 195 mm (motor housing)

Width 245mm (retainer plate)

Hub 875 mm

Maximum screen height 765 mm

Maximum load 60 kg

Hub speed 45 mm/s

Environmental temperature +10°C to +40°C

creen fixings VESA 50, 75, 100, 200 mm (VESA = fixing standards for LCD and plasma screens e.g.

for VESA 50 the clearance between the vertical and horizontal fixing holes is 50 mm.