9

To reduce the risk of serious injury from burns, never attempt to refuel the unit until it has

been completely removed from the operator.

Check for fuel leakage while refuelling and during operation. If fuel or oil leakage is found, do

not start or run the engine until leak is xed and spilled fuel has been wiped away. Take care

not to get fuel on your clothing. If this happens, change your clothing immediately.

Unit vibrations can cause an improperly tightened fuel cap to loosen or come o and spill

quantities of fuel. In order to reduce risk of fuel spillage and re, tighten fuel cap by hand with

as much force as possible.

Your mistblower is a one-person machine. To reduce the risk of eye or other injury from

thrown objects, insure that bystanders are at least 50 feet (15m) away during use. Stop the

engine immediately if you are approached. The assistance of another person may be needed

in placing the unit on your back after starting. In order to reduce the risk of injury to the

assistant from thrown objects or from contact with fumes, the engine should be kept at idle

speed during this brief period, and your assistant should not stand in the area of the outlet

nozzle or exhaust. Otherwise, the unit should be started and operated without assistance. For

specic starting instructions, see the appropriate section of your owner‘s manual. Place the

machine on rm ground or other solid surface in an open area. Maintain good balance and

secure footing.

When you pull the starter grip, don‘t wrap the starter rope around your hand. Do not allow

the grip to snap back, but guide the starter rope slowly back to permit the rope to rewind

properly. Failure to follow this procedure may result in injury to hand or ngers and may

damage the starter echanism.

Never operate your machine if it is damaged, improperly adjusted or not completely and

securely assembled.

Your mistblower produces poisonous exhaust fumes as soon as the combustible engine is

running. These gases (e.g. carbon monoxide) may be colorless and odorless. To reduce the

risk of serious or fatal injury from breathing toxic fumes, never run the mistblower indoors or

in poorly ventilated locations. Ensure proper ventilation when working in trenches or other

conned areas. Keep the space behind the engine clear at all times to allow for the escape

of hot and toxic exhaust fumes. Operate your machine under good visibility and daylight

conditions only. Work carefully.

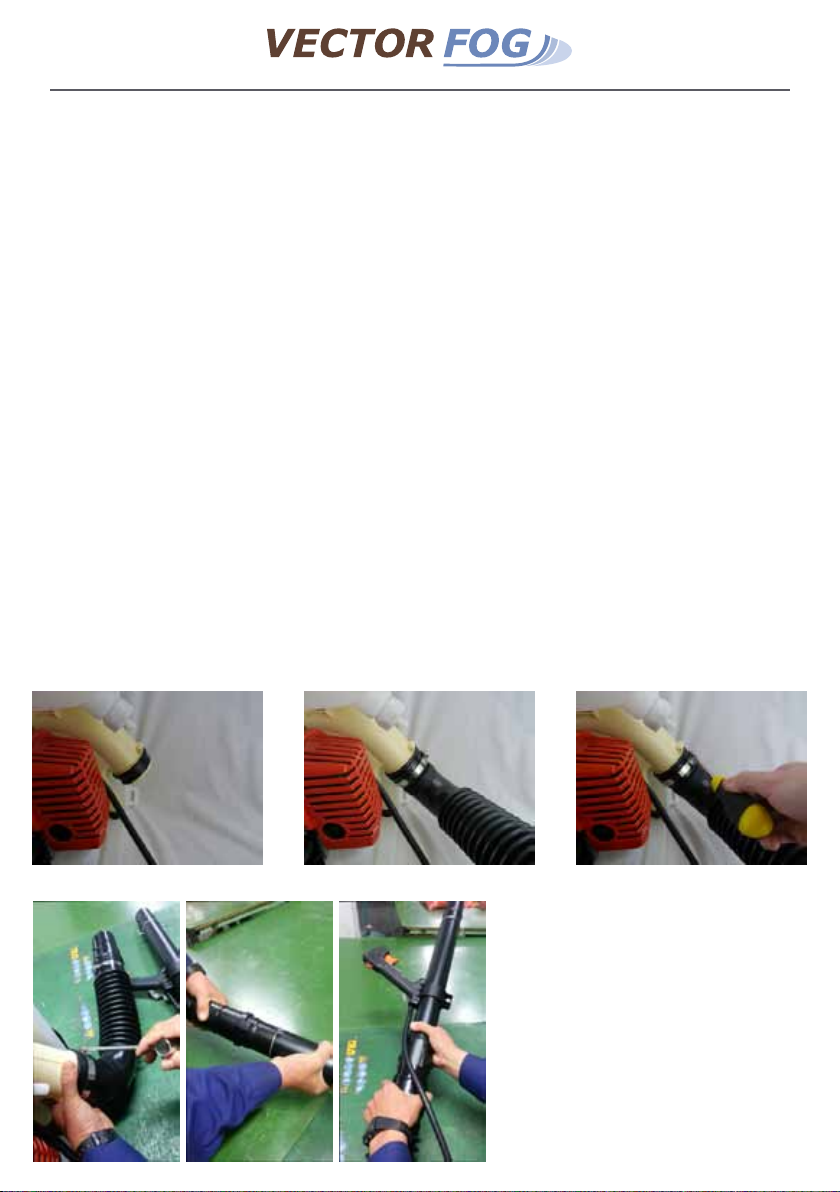

When working with the mistblower, always wear it on your back using the carrying harness.

Wrap your ngers tightly around the handle, keeping the control handle cradled between

your thumb and forenger. Keep your hand in this position to have your machine under

control at all times.