INSTRUCTIONS FOR

SPRAY GUNS, GRAVITY FEED 1.8MM, 2.2MM

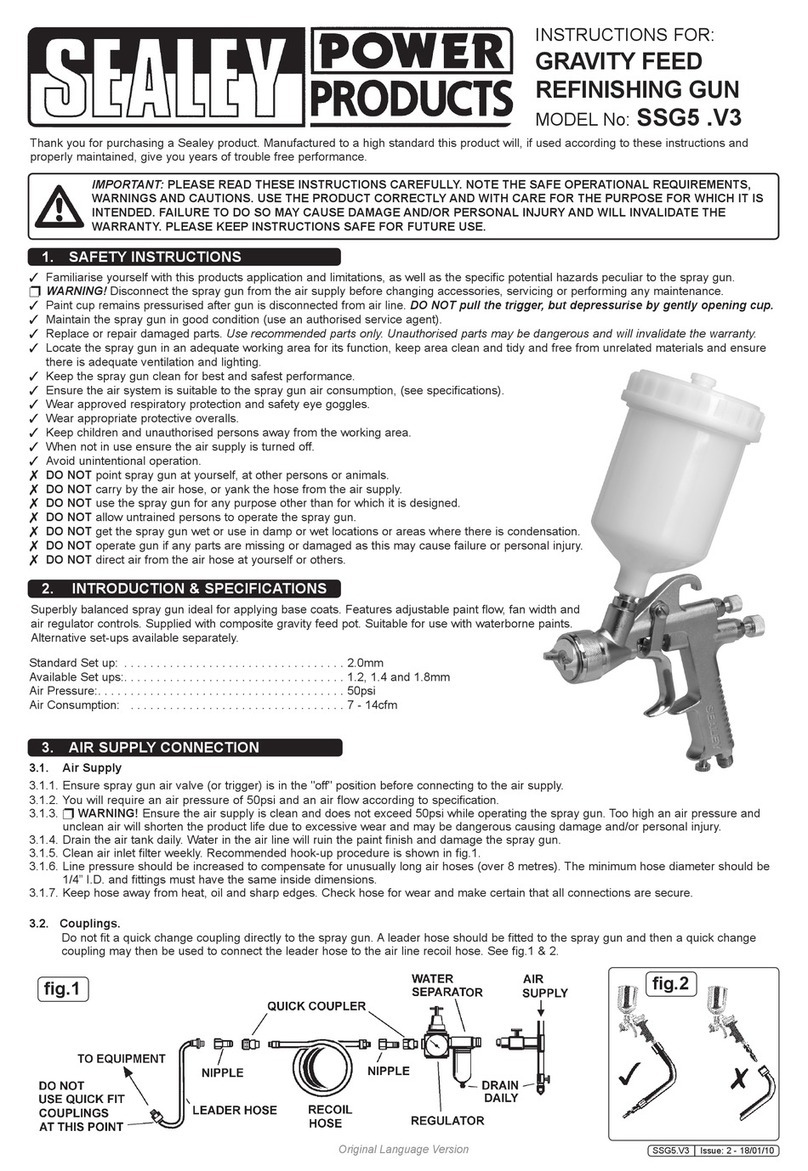

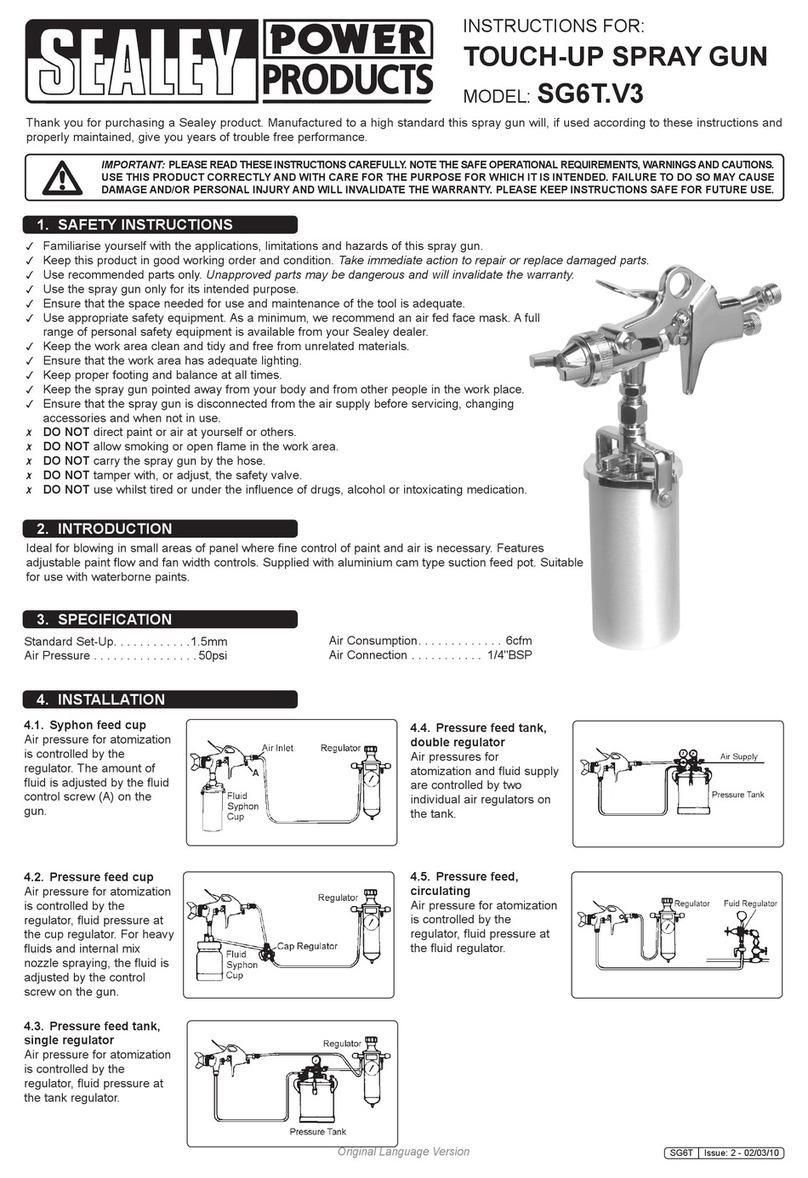

SET UP

MODEL NO: SSG501.V4, SSG502.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Disconnect the spray gun from the air supply before changing accessories, servicing or performing any maintenance.

9Paint cup remains pressurised after gun is disconnected from air line. DO NOT pull the trigger, but depressurise by gently opening cup.

9Maintain the spray gun in good condition (use an authorised service agent).

9Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Locate the spray gun in an adequate working area for its function, keep area clean and tidy and free from unrelated materials and

ensure there is adequate ventilation and lighting.

9Keep the spray gun clean for best and safest performance.

9Ensure the air system is suitable to the spray gun air consumption, (see specifications).

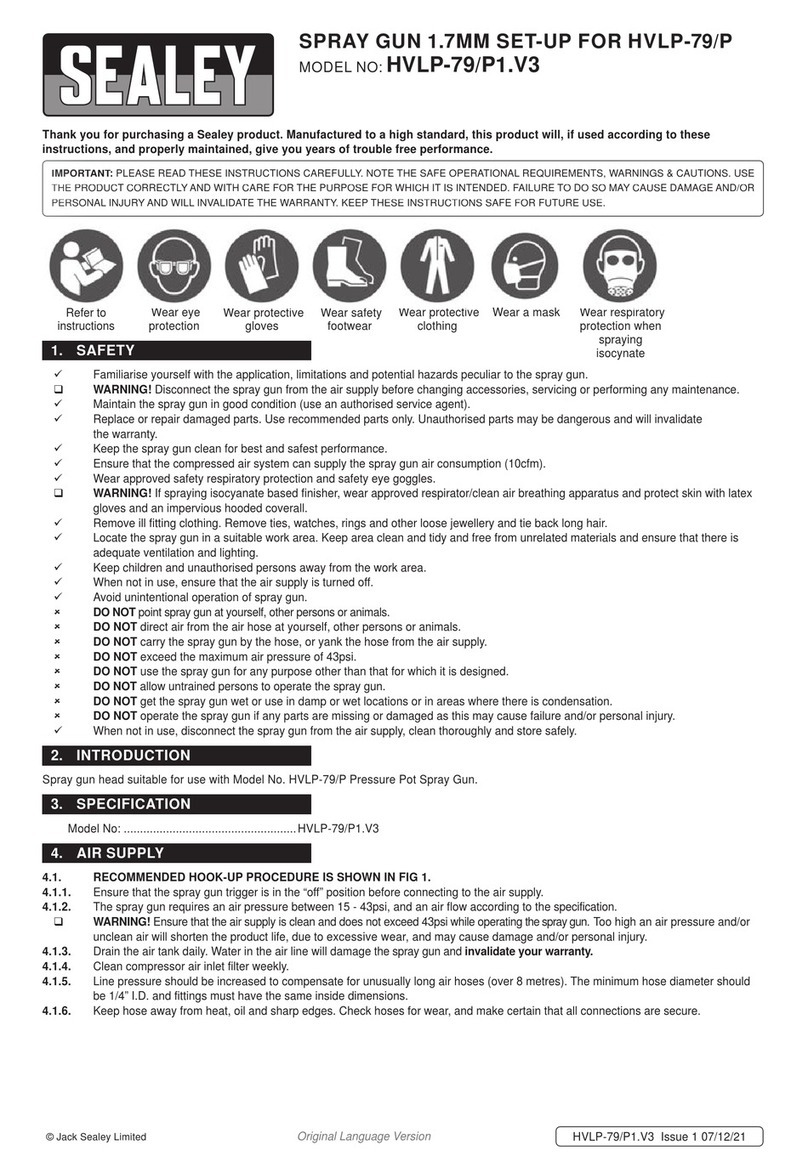

9Wear approved respiratory protection and safety eye goggles.

9Wear appropriate protective overalls, gloves and boots.

9Keep children and unauthorised persons away from the working area.

9When not in use ensure the air supply is turned off.

9Avoid unintentional operation.

8DO NOT point spray gun at yourself, at other persons or animals.

8DO NOT carry by the air hose, or yank the hose from the air supply.

8DO NOT use the spray gun for any purpose other than for which it is designed.

8DO NOT allow untrained persons to operate the spray gun.

8DO NOT get the spray gun wet or use in damp or wet locations or areas where there is

condensation.

8DO NOT operate gun if any parts are missing or damaged as this may cause failure

or personal injury.

8DO NOT direct air from the air hose at yourself or others.

2. INTRODUCTION

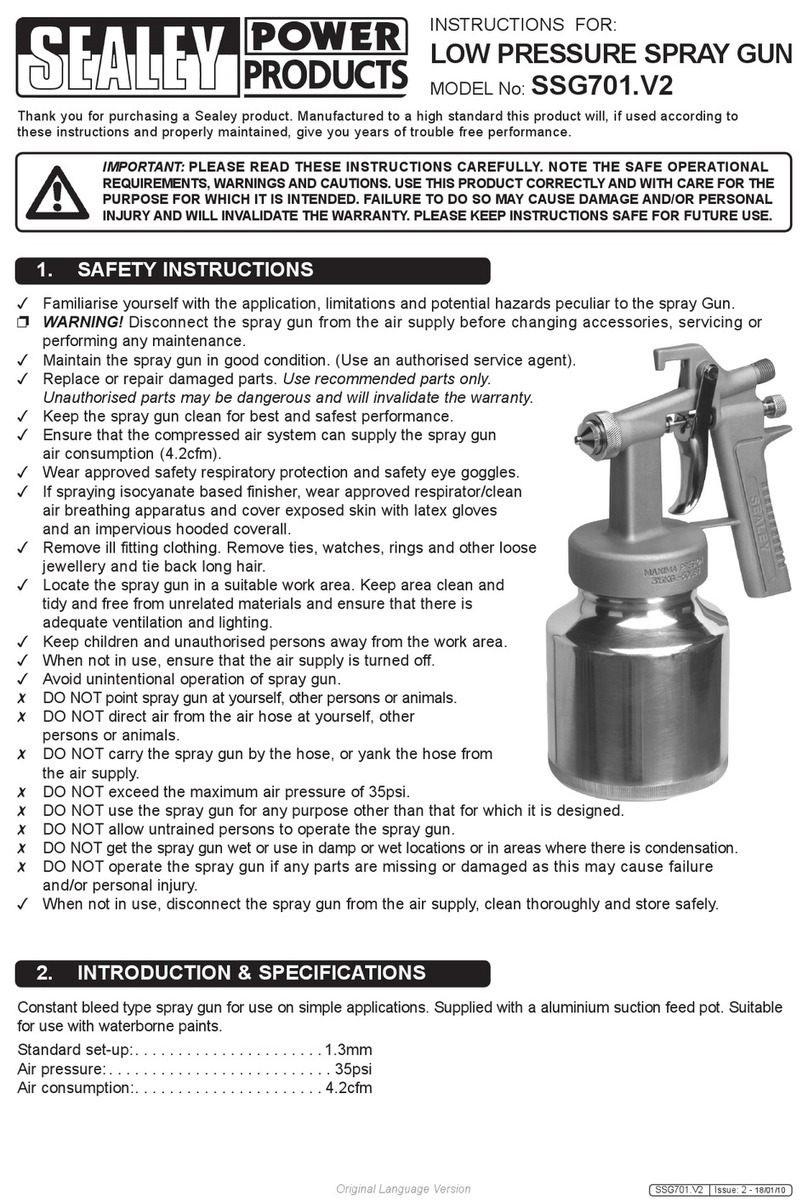

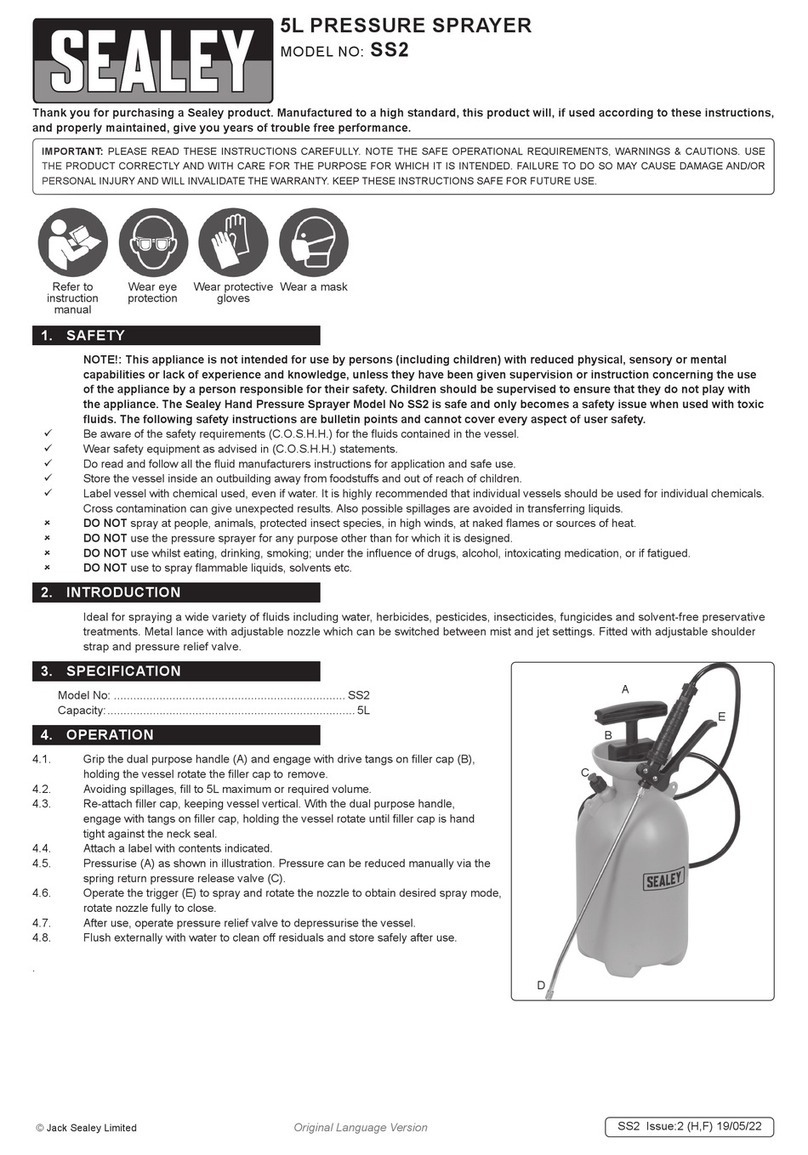

Ideal for applying undercoats, primers and adhesives. Features adjustable paint flow and fan width controls. Supplied with composite gravity

feed pot. Suitable for use with water based paints. Alternative set-ups available separately.

3. SPECIFICATION

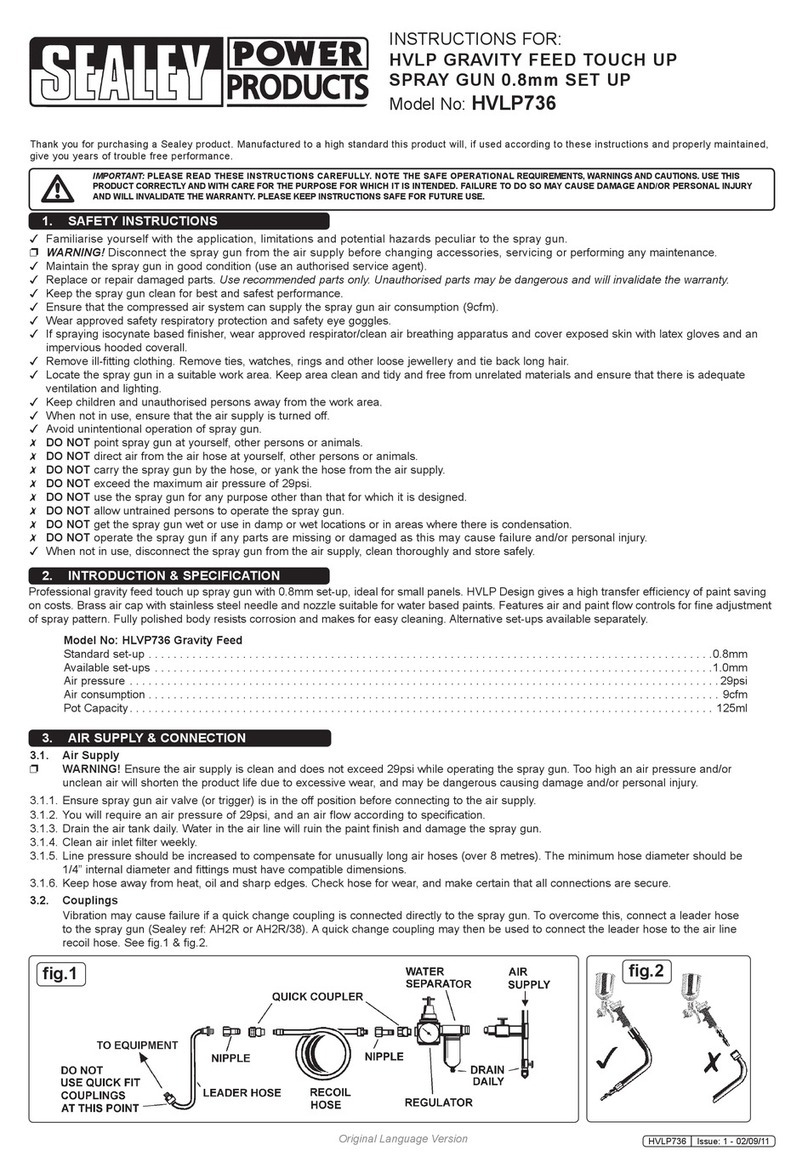

4. AIR SUPPLY CONNECTION

4.1. AIR SUPPLY

4.1.1. Ensure spray gun air valve (or trigger) is in the “off” position before connecting to the air supply.

4.1.2. You will require an air pressure of 50psi and an air flow according to specification.

WARNING! Ensure the air supply is clean and does not exceed 50psi while operating the spray gun. Too high an air pressure and

unclean air will shorten the product life due to excessive wear and may be dangerous causing damage and/or personal injury.

Drain the air tank daily. Water in the air line will ruin the paint finish and damage the spray gun.

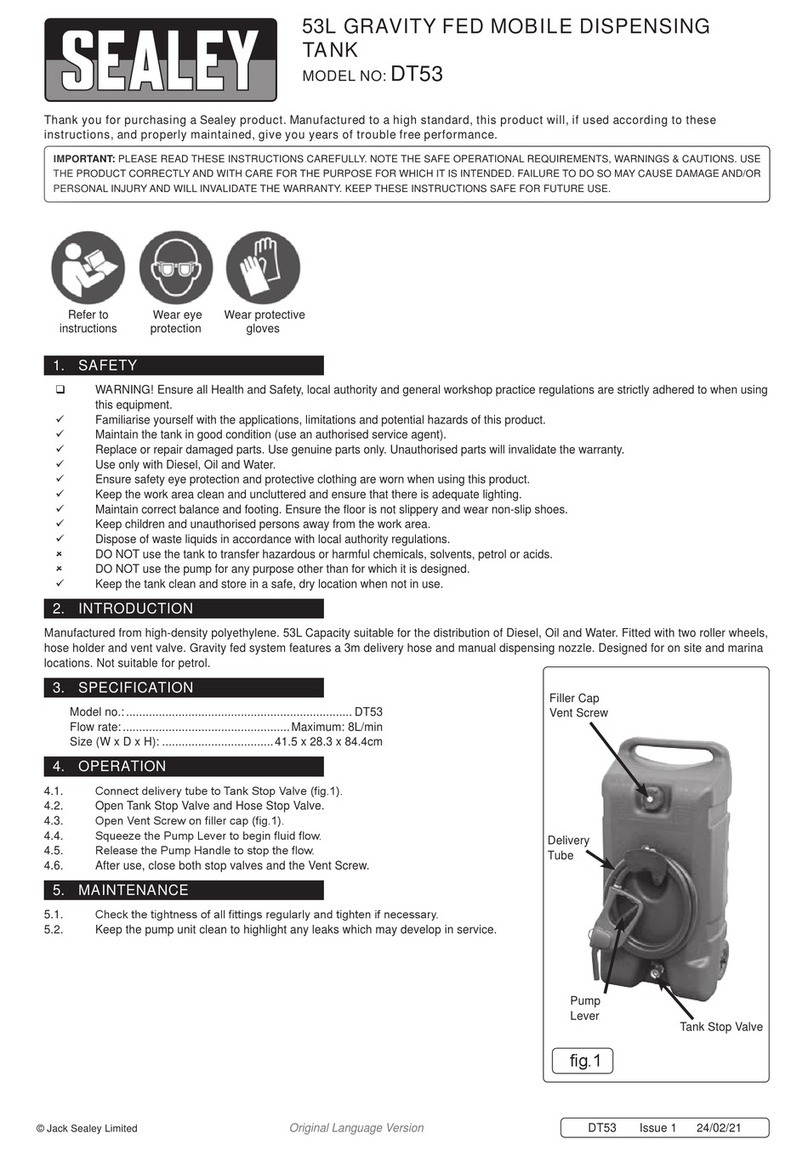

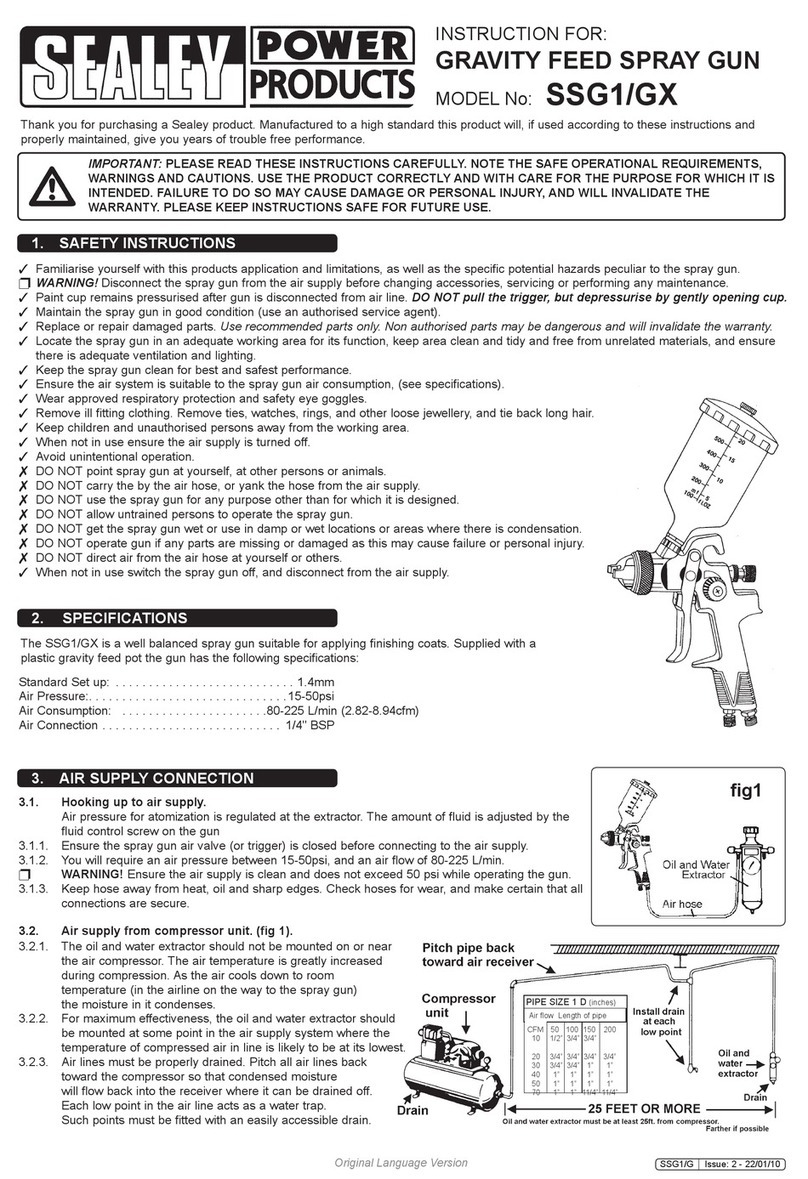

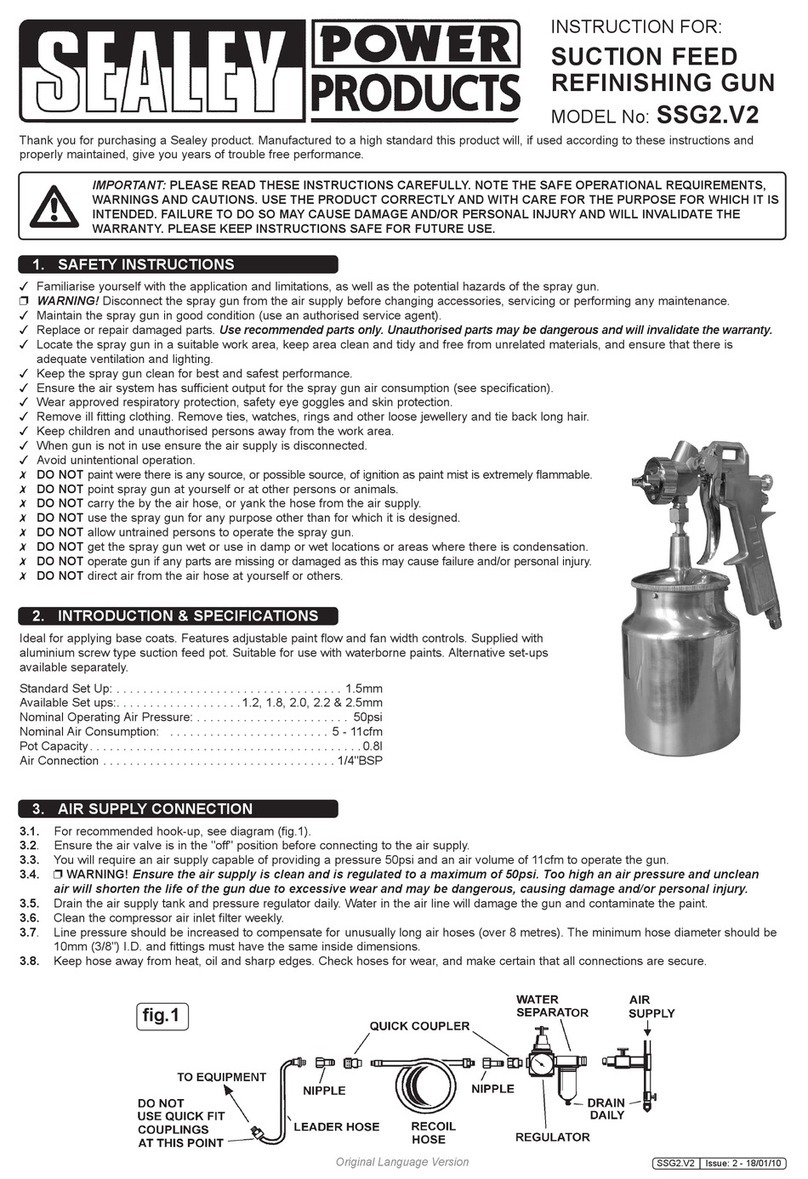

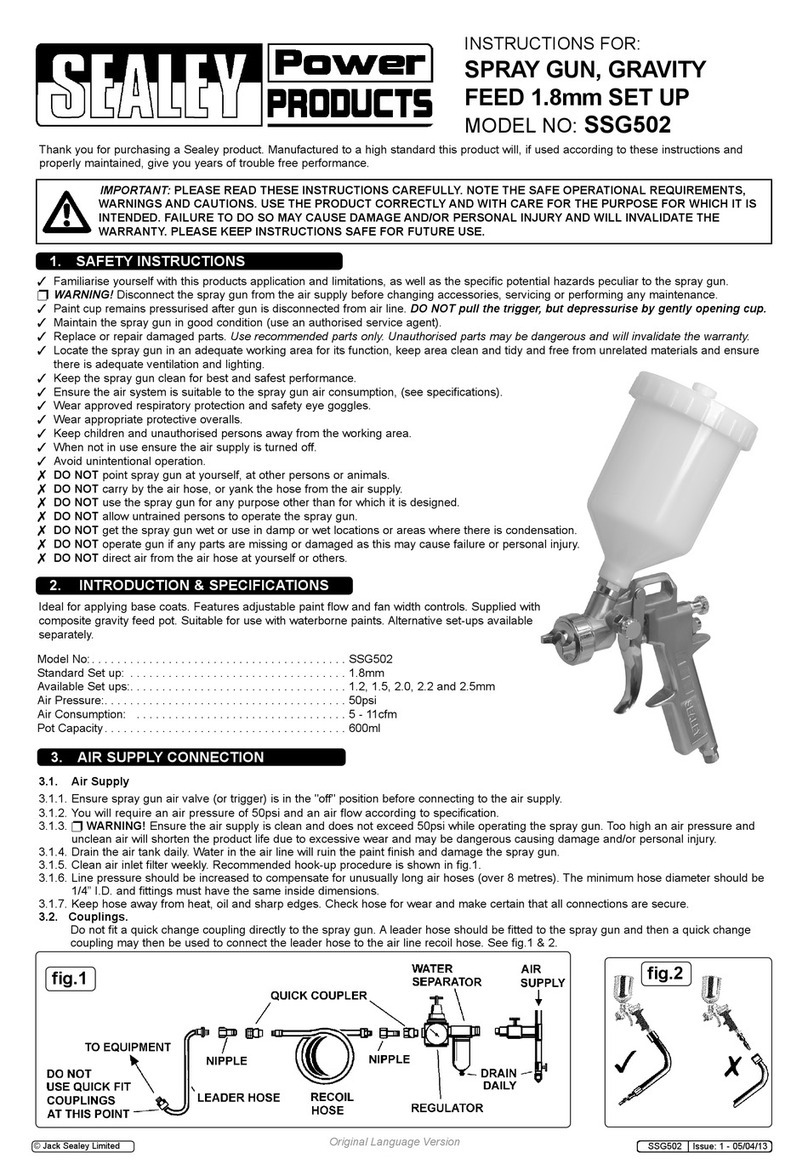

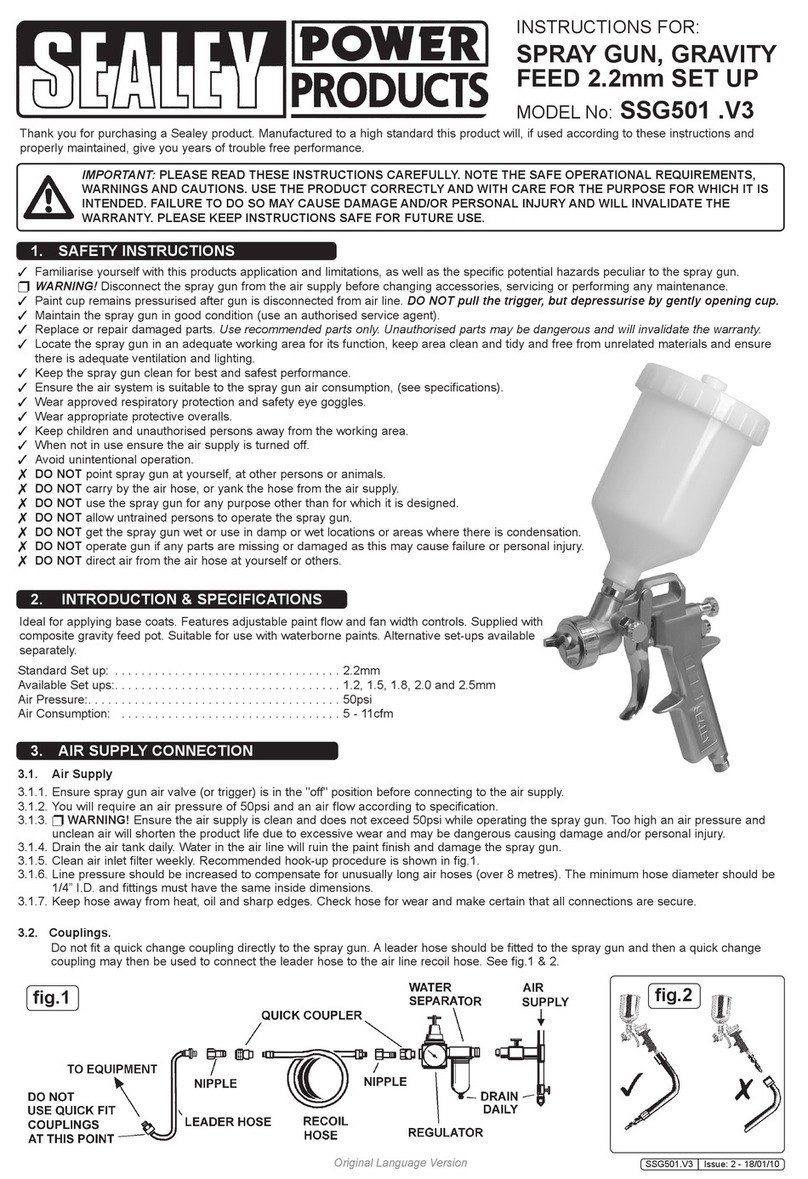

4.1.3. Clean air inlet filter weekly. Recommended hook-up procedure is shown in (fig.1).

4.1.4. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should be

1/4” I.D. and fittings must have the same inside dimensions.

4.1.5. Keep hose away from heat, oil and sharp edges. Check hose for wear and make certain that all connections are secure.

4.2. COUPLINGS

Do not fit a quick change coupling directly to the spray gun. A leader hose should be fitted to the spray gun and then a quick change

coupling may then be used to connect the leader hose to the air line recoil hose (fig.1 & 2).

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear safety

footwear

Wear protective

clothing

Wear

respiratory

protection

Model No:.....................SSG501.V4 ..............................SSG502.V2

Standard Set Up:................2.2mm ......................................1.8mm

Available Set Ups:...............1.5, 1.8mm............................... 1.5, 2.2mm

Air Pressure: ...................50psi ........................................50psi

Air Consumption:................4.5-8cfm................................... 4.5-8cfm

Pot Capacity:...................600ml....................................... 600ml

SSG501.V4, SSG502. V2 Issue 2 30/4/19

Original Language Version

© Jack Sealey Limited