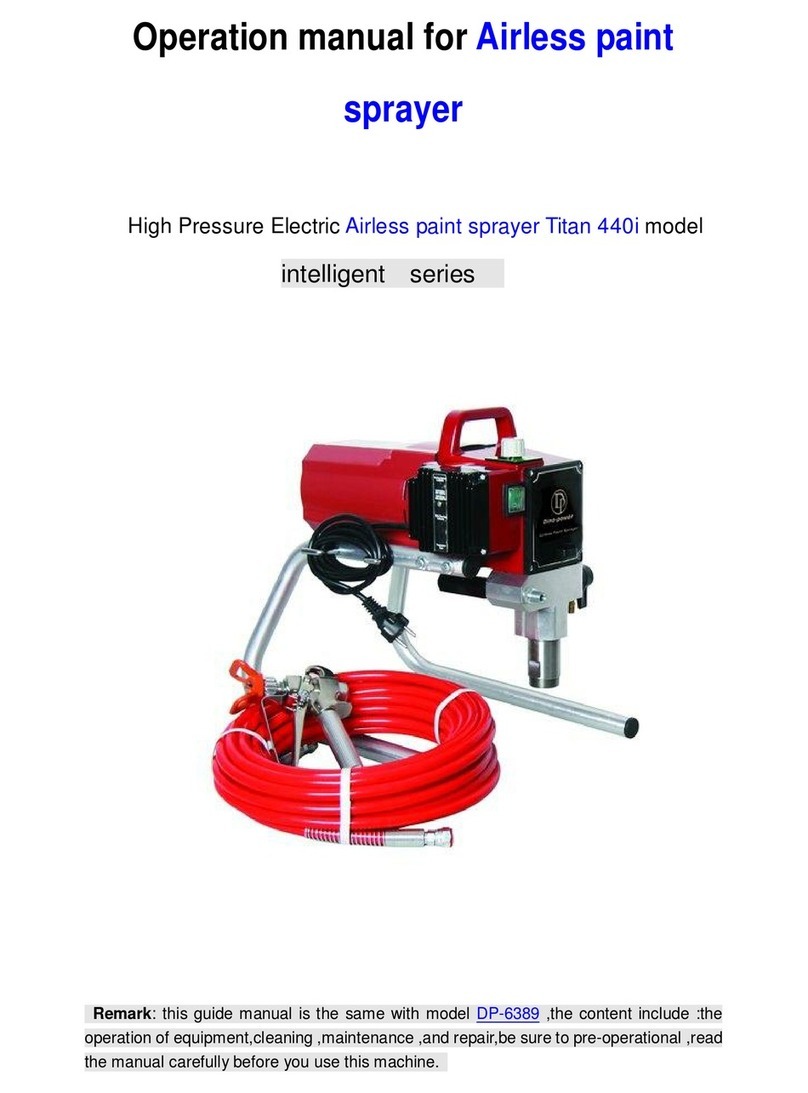

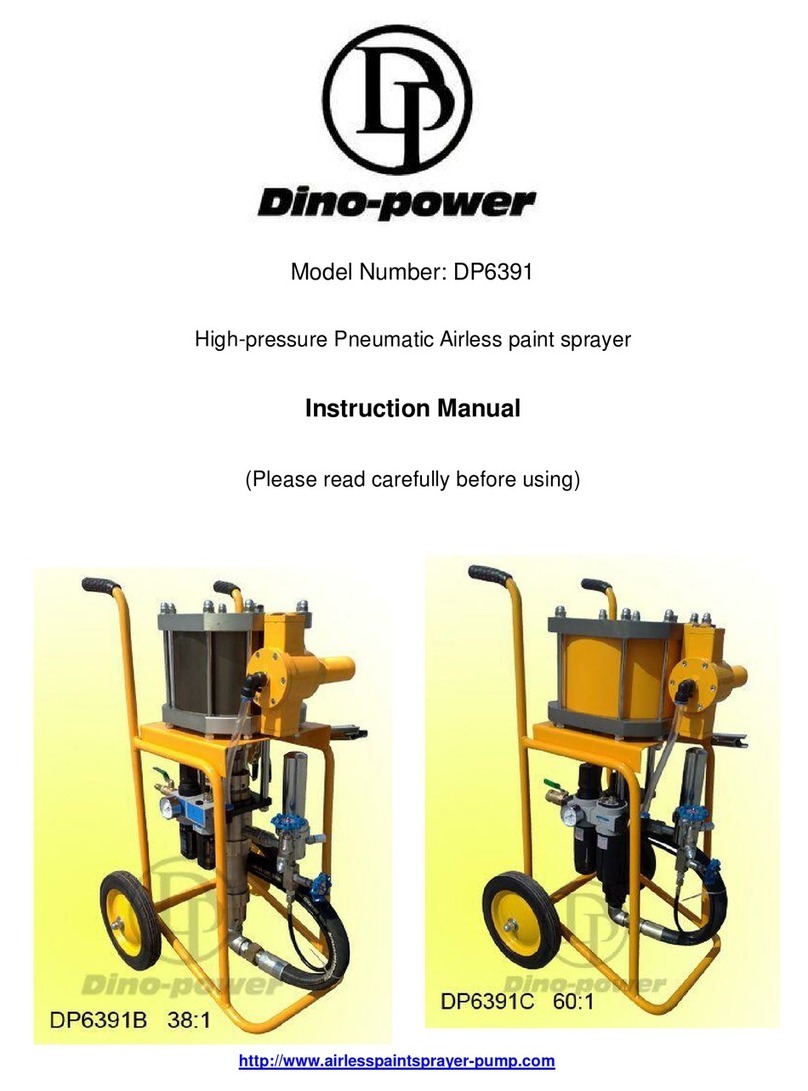

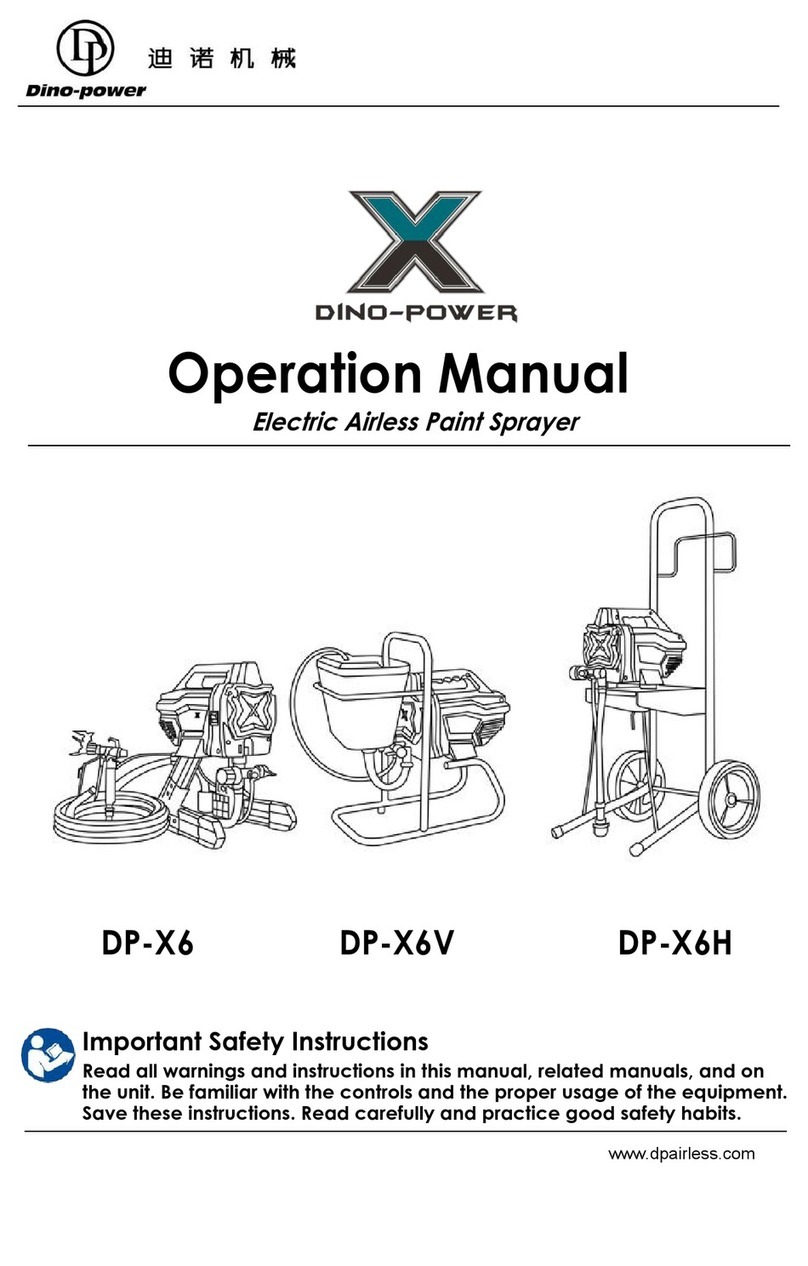

Dino-Power DP-X Series User manual

Operating Instruction

DP- X series

X20 X24 X28 X45 X52

Please read and keep this manual, Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instruction for future reference.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

●Do not spray flammable or combustible materials near an open flame or sources of ignition such as

cigarettes, motors, and electrical equipment.

●Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity

creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray

system, including the pump, hose assembly, spray gun, and objects in and around the spray area shall

be properly grounded to protect against static discharge and sparks. Use DINO-POWER conductive or

grounded high-pressure airless paint sprayer hoses.

●Verify that all containers and collection systems are grounded to prevent static discharge.

●Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

●Do not use a paint or a solvent containing halogenated hydrocarbons.

●Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump

assembly in a well ventilated area. Do not spray pump assembly.

●Do not smoke in the spray area.

●Do not operate light switches, engines, or similar spark producing products in the spray area.

●Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

●Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets

(MSDS) and container labels provided with the paints and solvents. Follow the paint and solvents

Manufacturer's safety instructions.

●Fire extinguisher equipment shall be present and working

Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or

●Keep sprayer at least 20 feet (6 m) away from explosive vapors.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, set up, or usage of the system can cause electric

shock.

●Turn off and disconnect power cord before servicing equipment.

●Use only grounded electrical outlets.

●Use only 3-wire extension cords.

●Ensure ground prongs are intact on power and extension cords.

●Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

●Do not aim the gun at, or spray any person or animal.

●Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with

any part of the body.

●Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

●Use DP nozzle tips.

●Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while

spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure

before removing the nozzle tip to clean.

●Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure for turning off the unit

●Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

●This system is capable of producing 3630 psi. Use DP replacement parts or accessories that

are rated a minimum of 3000 psi

WARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

●Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

● Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

●Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

●Do not operate or spray near children. Keep children away from equipment at all times.

●Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

●Stay alert and watch what you are doing.

●Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure for turning off the unit.

●Do not operate the unit when fatigued or under the influence of drugs or alcohol.

●Do not kink or over-bend the hose.

●Do not expose the hose to temperatures or to pressures in excess of those specified by us.

●Do not use the hose as a strength member to pull or lift the equipment.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

●Keep clear of moving parts.

●Do not operate equipment with protective guards or covers removed.

●Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

BURN HAZARD

Equipment surfaces can become very hot during operation. To avoid severe burns, do not touch

hot qui hot equipment. Wait until equipment has cooled completely.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

●Please pay attention to know the specific hazards of the fluids before spraying.

●Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

●Protective eyewear, and hearing protection.

●Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

WARNING

Maintenance Tips:

1.There are two sides for the ball seat, both are chamfered, for one side worn, change to another side.

2.While changing the V-packings(both the upper and lower ones) for piston rod, please note that the convexity side shall be towards the piston rod,

then using rubber hammer to hit the flat side of the V-packings to fit the piston rod.

3. While fastening the screws for the pump block, please do not fasten one screw to maximum and then fasten the other one, the correct action is to

fasten one screw to 90% depth first and then fasten the other screw to maximum and later fasten the first screw to maximum.

4.There is one washing piece inside the pressure sensor, normally the washer won’t be broken, but it can not be left out.

5. After changing the upper V-packings, the nut shall be fully tightened by using a bench clamp.

6. Before starting up a new airless piston pump, please double check the two screws for the pump block and make sure that they are fully fastened.

Same checking after changing new V-packings.As the V-packings are made of high polymer material,after being stocked or used for some time, they

could somehow expand.

7. It’s critically important to turn on the PRIME VALVE before spraying or after changing the paint bucket, if air happens to enter into the piston pump

system and you forget turn on the PRIME VALVE before spraying, it will do big damage to the machine system itself, as the compression ratio for paint

coatings and for air are different.

8.The positive pole and negative pole for the motor can not be connected reversely via the carbon brush,if connected reversely, then the motor will turn

reversely,if the machine runs this way for some time, the motor be become demagnetized. (*For model X20 only)

9. If the V-packings are broken, then there will be paint coatings leakage, please change V-packings immediately, otherwise, the paint coatings may

enter into the gear box to damage the whole gear box.

10. While turning the pressure knob to adjust pressure,please do not turn the knob too hard,as the electric parts inside the knob could be damaged

due to too hard turning.

11.There is micro switch in every airless pump with mechanical pressure control system, and the fixing screw of the micro switch is set properly

before shipment, please do not try to change the position of the fixing screw, otherwise, the micro switch may not work properly.(For X20 model only)

12. One quick tip to identify if the ball seat is good or not, after turning the PRIME VALVE back to spraying position, please open the front cover, if the

connection rod stays on the upper position, then the ball inside the piston rod is somehow damaged, if the connection rod stays on the lower position,

then the ball seat is somehow damaged.

13. If the airless piston pump is not fully cleaned after spraying, the drywall coatings may stop the pressure sensor from working properly, so the airless

piston pump shall be fully cleaned after spraying.

14. If the fuse is burned due to over voltage, please check the capacitor first to see if it’s in good condition, if yes, then please further check the bridge

rectifier with a universal meter.

15.One quick tip to check the pressure control board for airless piston pumps with mechanical pressure control system, first step is to turn on the

PRIME VALVE, then stick to the micro switch with a screw driver, if the machine could stop, means no problem for the pressure control board.

16.If the airless pump is equipped with manifold filter, then the filter shall be often cleaned after spraying,once per day is recommended, or at least

once per week, if the filter is totally stuck by drywall coatings, then the electric board and pressure sensor could be burned, under this situation, fuse

could not protect the electronical board and pressure sensor.

17. As a reminder, for big airless piston pump with big flow rate(mainly refers to X45 and X52/X52L), please do not use short high pressure hose like

3m or 5m, as it might cause serious motor damage. Cleaning the machine, parts every time after finished the paint work.

18.Tips need to replace after 4000 – 5000 m2 depending on abrasiveness of paint.

19.The Piston rod/V-packing and sintered carbide ball need to replace after about 200 hours spraying, Especially when the pressure goes down,

or difficult to draw in paint.

20.For the permanent magnet DC motor, the carbon brush need to replace after 1500 hours, otherwise, the motor will be damaged.

21.Please check every parts had been screwed on the machine very tightly before using machine.

22.If the machine need to be storage over 10 days, Do run the machine with lubricating oil thoroughly, for rust protection or any stuck inside the

pump .(check the details in CLEAN UP)

23.For the maintenance of the fluid pump, do strictly in accordance with the instructions, and screw tightly.(check the details in Service)

24.Please read the manual or contact the distributor if any problems with the machine, DO NOT take the machine to pieces without professional staff.

Component Identification FOR X52L

1

Cart/ Hose with wrap rack

Carry machine and Stows paint hose. (DP637H)

2

Filter Housing

(Manifold filter inside**)

Manifold filter will reduce the tip clogs and ensure you nice finish.

3

Digital pressure display

(Under the cover)

X20 With Pressure Gauge Only

X24 X28 X45 X52 With digital pressure display

4

Pressure regulator

Adjust the pressure for different applications.

5

Prime/Spray valve.

●In PRIME position (pointing down) directs fluid to prime

tube.

●In SPRAY position (pointing parallel) directs pressurized

fluid to paint hose.

●Automatically relieves pressure system in overpressure

situations

6

Fluid pump

(piston rod&v-packing** inside)

Drains fluid in system during priming and pressure relief.

7

Suction tube

Draws fluid from paint pail into pump. (the tube must be screwed

tightly otherwise air enter inside, so the pressure can’t be reached

your desired high pressure.)

7

Suction hose*

The pics is X52L lower suction type, For X45/X52, it will be the

suction tube, and X20/24/28 will be the suction hose instead.

8

Suction filter

Suction filter reduce the tip clogs and ensure you nice finish.

9

Prime hose

10

Power Plugs

It will be suitable for countries.

11

Wheel

Easy for machine to stand/move on the ground.

12

Airless spray gun

Dispenses fluid.

13

High pressure hose

Transports high-pressure fluid from pump to spray gun.

(The parts marked with ** are easily worn parts.)

Technical Data

Operation

Item No.

X20

X24

X28

X45

X52

Pressure controlling

Mechanical

Electronic

Motor power

1100W

PMDC

1500W

Brushless Motor

1700W

Brushless Motor

2000W

Brushless Motor

2400W

Brushless Motor

Flow rate

2.0L/MIN

2.4L/MIN

2.8L/MIN

4.5L/MIN

5.2L/MIN

Max. tip size

0.021''

0.023''

0.025''

0.033''

0.035''

Max.Working

pressure

200bar/2900psi

Net/Gross weight

14.9/20.1kgs

15.1/20.3kgs

16.4/21.6kgs

45.5/61.2kgs

50.5/66.5kgs

Package

Carton box(49*42*53)

Woden Box(61*65*87)

Trigger Lock

Always engage the trigger lock when you stop spraying

to prevent the gun from being triggered accidentally by

hand or if dropped or bumped.

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever you

stop spraying and before cleaning, checking, servicing,

or transporting equipment.

1. Turn power switch OFF and unplug

power cord.

2. Turn Prime/Spray valve to PRIME

to relieve pressure.

3. Hold gun firmly to side of pail.

Trigger the gun to relieve

pressure.

4. Engage trigger lock.

NOTE: Leave Prime/Spray valve in the PRIME position

until you are ready to spray again.

If you suspect the spray tip or hose is clogged or that

pressure has not been fully relieved after following the

steps above, VERY SLOWLY loosen tip guard retaining

nut or hose end coupling to relieve pressure gradually,

then loosen completely. Clear hose or tip obstruction.

Read Unclogging Spray Tip instructions in the Sprayer

or Gun Operation manual.

Setup

1. Prepare the paint according to

the manufacturer’s recommendations

This is probably one of the most important steps

toward trouble-free spraying!

Remove any skin that may have formed on the top of

the paint. If necessary, thin the paint. Finally, strain

the paint through a fine nylon mesh filter bag

(available at most paint dealers) to remove particles

that could clog the spray tip

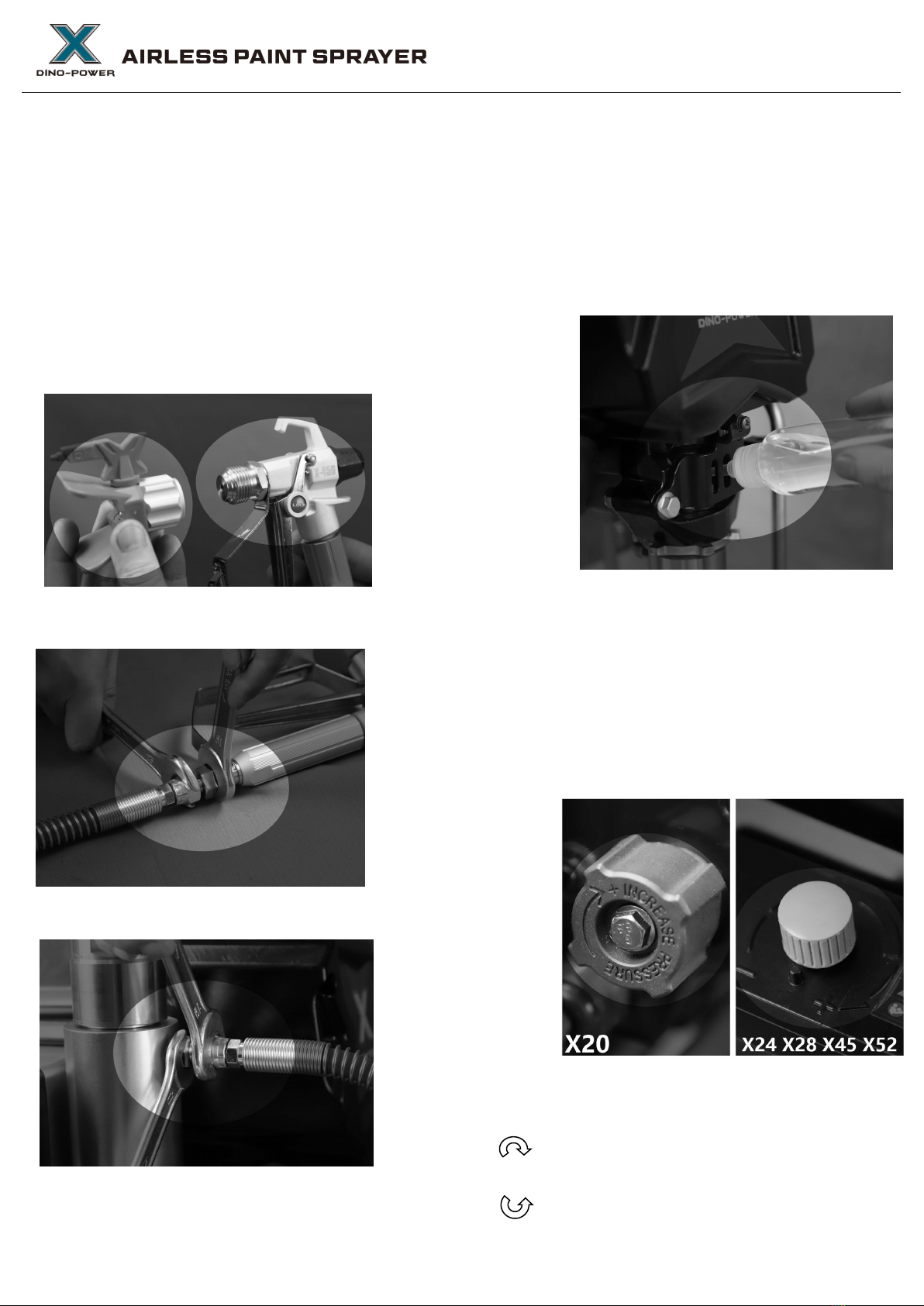

3. Unscrew tip and guard assembly from gun.

4. Uncoil hose and connect one end to gun. Use two

wrenches to tighten securely and tightly.

5. Connect other end of hose sprayer.

6. Oiling

Fill throat packing nut with lubricating oil(3~5 drops) to

prevent premature packing wear, Do this every time

when you spray.

7. Check the electrical service Be sure the electrical

outlet is properly grounded. Longer extension cords

may affect the sprayer performance. Use more spray

hose, not longer extension cords.

8.Plug in the sprayer. First be sure the ON/OFF

switch is OFF and the pressure control is turned

fully

counterclockwise. Plug the

sprayer

into a grounded

outlet that is at least 3 m away from the spray area to

reduce the chance of a spark igniting, spray vapors or

dust particles.

Pressure regulator valve

Clockwise: stronger / Higher pressure

Counter clockwise: weaker / Lower pressure

Startup

1. First be sure the ON/OFF switch is OFF.

2. Adjust Pressure Control counter clockwise to

lowest pressure.

3. Place the suction hose into the coating barrel.

4. Pull up the Prime/Spray Valve to Prime

position.

5. Plug sprayer in a grounded cable socket.

6. Switch ON the machine。

7. Turn the Pressure Control clockwise, till the

fluid is circulating in the prime tube

8. Turn power switch OFF.

9. Transfer suction tube to paint pail and

submerge suction tube in

paint.

10.Turn power switch ON.

11. When you see paint coming out of prime

tube:

(1). Point gun into waste pail.

(2). Unlock gun trigger lock.

(3). Pull and hold gun trigger.

(4). Turn Prime/Spray valve to SPRAY position.

12.Continue to trigger gun into waste pail until

you see only paint coming out of gun.

13. Release trigger. Engage trigger lock.

14.Transfer prime tube to paint pail and clip

prime tube to suction tube.

SPRAYING

SPRAYING TECHNIQUE

1. The key to a good paint job is an even coating over the entire surface. With spray painting, this is

done by using even strokes, with your arm moving at a constant speed and keeping the spray gun a

constant distance from the surface.

2. As much as possible, keep the spray gun at right angles to the surface. This means moving your

entire arm back and forth rather than just flexing your wrist.

30cm

3. Keep the spray gun perpendicular to the surface, otherwise one end of the pattern will be thicker

than the other.

Right way to spray

Approximately

10 to 12 Inches

Right way

Wrong

4. In most cases, the best spraying distance is 10 to 12 inches (25-30cm) between the spray tip and

the surface.

5. The spray gun should be triggered off at the end of each stroke and on again at the beginning of the

next. This avoids paint buildup at the end of the stroke which may result in runs and sags. Triggering

at the end of the stroke also saves paint and results in a better looking job. (See picture below)

Approximate

Work

10 to 12 Inches

E ven

Steady

Stroke

Start stroke End stroke

6. The

correct speed

for

moving

the gun will allow a full, wet coating to be

applied without runs or sags.

Lapping

each stroke about 40% over the

previous

stroke

produces

uniform paint thickness. Spraying in a uniform

pattern alternately from right to left and then left to right, provides a

professional finish. (See picture on the right)

One way to do this is to point the spray tip at the edge of the last stroke

before triggering the gun on.

7. When taking a short break from painting (up to 1 hr.), lock the spray gun trigger OFF, reduce pressure

to its minimum (zero) setting and set the unit to Prime position . Turn sprayer off and unplug. Refer

to Pressure Relief Procedure.

8. For interior corners, such as on a bookcase or inside a cabinet,

aim the gun toward the center of the corner to spray. By dividing the

spray pattern this way, the edges on both sides are sprayed evenly.

Install Tip & Guard on Spray Gun

1. Engage trigger lock.

2. Verify tip and guard parts are assembled in

order shown.

3. Use tip to align seat Tip must be pushed in

guard all the way into guard

4. Screw tip and guard assembly on

gun. Tighten retaining nut.

Gasket

Guard

Tip

Tip Selection

Selecting Tip Hole Size

Tips come in a variety of hole sizes for spraying a range of fluids. Your sprayer includes an 0.017 in

(0.43 mm) tip or maybe 0.019” (0.48mm) for use in most spraying applications. For narrow or smaller

surfaces(cabinet,fence,railings), pattern width of 6 inches is the best choice, it will provide sharper

definition and more control; For large surfaces(Ceilings/walls), a wider spray pattern width of 10 to 12

inches is your best choice to cover large areas more quickly.

Using a good-quality spray tip that is appropriately sized for your painting project is critical to achieving

good spraying results, the spray tip controls the amount of paint applied and the area the spray pattern

will cover. A range of tip sizes classified by both hole size and spray pattern width can be used, based

on 3 factors;

1;Coating/painting 2;Surface being sprayed 3;Sprayer's ability to support the tip hole size.

A key difference is sprayers is the maximum tip they can support. Choose your sprayer based on the

coating types you'll be spraying, and make sure the largest tip(hole size) you plan to use is within the

maximum tip size range the sprayer can support.

It is always best to have a machine with more capacity, Fox example, if you plan to use .017 tip

frequently, your sprayer's capacity should be one tip hole size larger(.019 tip), this allows for tip wear,

which causes the tip hose size to increase.

Choosing the Correct Tip

Consider coating and surface to be sprayed. Make sure you use best tip hole size for that coating and

best fan width for that surface.

Tip Hole Size

Tip hole size controls flow rate - the amount of paint that comes out of the gun.

HINTS:

• Use larger tip hole sizes with thicker coatings and smaller tip hole sizes with thinner coatings.

Fan Width Fan width is the size of the spray pattern, which determines the area covered with each

stroke. Narrower fans deliver a thicker coat, and wider fans deliver a thinner coat.

Understanding Tip Number

The last three digits of tip number contain information about

hole size and fan width on surface when gun is held 12 in.

(30.5 cm) from surface being sprayed.

Last two digits = tip hole size in thousands of an inch

Reversible Tip Selection Chart

Orifice Size

Fan Width - Inches

Flow Rate

Application

Filter

inch

4” – 6”

Fan

6” –

8” Fan

8” – 10”

Fan

10” – 12”

Fan

12” – 14”

Fan

gpm

L/min

0.011”

211

311

411

511

611

0.12

0.45

Stain or Lacquer

150mesh (red)

0.013”

213

313

413

513

613

0.18

0.68

0.015”

215

315

415

515

615

0.24

0.91

Oil Base Paint

100mesh (yellow)

0.017”

217

317

417

517

617

0.31

1.17

Latex Paint /

Acrylic / Enamel

100mesh

0.019”

219

319

419

519

619

0.38

1.44

60mesh (white)

0.021”

321

421

521

621

0.47

1.78

0.023”

323

423

523

623

0.57

2.16

Heavy latex

60mesh (white)

0.025”

325

425

525

625

0.67

2.54

0.027”

427

527

627

0.77

2.91

0.029”

329

429

529

629

0.90

3.41

Elastomeric /

Blockfiller /

Primer /

30mesh (green)

0.031”

331

431

531

631

1.03

3.90

0.033”

333

433

533

633

1.17

4.43

0.035”

335

535

1.31

4.98

0.043”

243

343

443

543

643

1.98

7.51

Important things to know about tip wear

It's important to replace a tip when it becomes worn, this ensures you''ll have a precise spray pattern,

maximum productivity and a quality finish. When tip wears, the hole (orifice) size increases and spray

pattern width decreases.

Tip life varies by coating, Extend tip life by spraying at the lowest

pressure that breaks up (atomizes)the coating into a complete

spray pattern.

Recommend tip replacement Latex: After 4000~5000 ㎡

CLEAN UP

As with all spray equipment, your sprayer must be cleaned properly or it will not operate properly.

Clogged are the most common causes of problems. If followed, these guidelines will insure trouble

free performance from your sprayer.

1. Do pressure relief procedure.

Remove siphon tube set from paint and place in

flushing fluid.

Note: Use water for water base paint and mineral spirits

for oil base paint

2. Turn power On, turn

prime/spray valve up to

close drain valve.

3. Increase the pressure to about to 1/2

maximum take the trigger safety OFF, trigger

gun until flushing fluid appears.

3. Move the gun to waste pail, hold gun against

pail, trigger gun to throughly flush system,

release trigger and put trigger safety ON.

4. Turn prime valve down to open drain valve

and allow flushing fluid to circulate for 15

seconds to clean drain tube.

5. Raise siphon tube above flushing fluid and

run sprayer for 15 or 30 seconds to drain fluid.

7. Turn up prime valve up to close drain valve,

Trigger gun into flushing pail to purge fluid from

hose, Turn Power OFF.

8. Turn prime valve down to open drain valve,

Unplug sprayer.

9. Remove filters from gun and sprayer, if

installed. Clean and inspect, install filters.

10. If flushing with water, flush again with

mineral spirits, or pump armor, to leave a

protective coating to prevent freezing or

corrosion.

11.If the machine will be storage for over 10 days,

after you cleaned the machine thoroughly,

please take off the suction tube, hose&gun, and

pour about 10ml WHITE lubricating oil into the

fluid pump, Then switch on the machine and let it

keep running (PRIME POSITION) for 5

seconds(once you can see the oil in the prime

tube), This will prevent the wet parts inside being

stuck, corrosive or rusted.

12. Wipe sprayer, hose and gun with a rag

soaked in water or mineral spirits.

Troubleshooting

Problem

Cause

Solution

Power switch is on and

sprayer is plugged in, but

motor does not run, and

pump does not cycle.

Pressure is set at

zero pressure.

Turn pressure control knob clockwise

to increase pressure setting.

Motor or control is damaged.

Please contact with your supplier or

DPAIRLESS directly.

Electric outlet is not providing

power.

• Try a different outlet or plug in

something that you know is working

to test outlet.

• Reset building circuit breaker or

replace fuse.

Extension cord is damaged.

Replace extension cord.

Sprayer electric cord

is damaged.

Check for broken insulation or wires.

Replace electric cord if damaged.

Paint and/or water is frozen or

hardened in pump.

Unplug sprayer from outlet. If frozen

do NOT try to start sprayer until it is

completely thawed or you may

damage the motor, control board

and/or drivetrain.

Make sure power switch is OFF.

Place sprayer in a warm area for

several hours. Then plug in power

cord and turn sprayer ON. Slowly

increase pressure setting to see if

motor will start.

If paint is hardened in sprayer, pump

packings, valves, drivetrain or

pressure switch may need to be

replaced. Please contact with your

supplier or contact with DP-AIRLESS

directly.

Problem

Cause

Solution

Sprayer starts up but does

not draw in paint.

Unit will not prime or has lost

prime

Replace prime Unit

No paint. Suction tube

not totally immersed in paint

Immerse suction tube in paint

Suction set filter clogged.

Clean filter.

Suction tube loose at inlet valve

Clean connection and tighten

Inlet valve is leaking

Clean inlet valve. Be sure the ball

seat is not nicked or worn and that

ball seats well, Reassemble valve.

Pump packing are worn

Replace pump packings.

Piston rod worn or damaged.

Clean or replace

Pump cycles but does not

build up pressure.

Pump is not primed.

Prime pump.

Inlet screen is clogged .

Clean debris off inlet screen and

make sure suction tube is immersed

in fluid.

Suction tube is not immersed in

paint.

Make sure suction tube is immersed

in paint.

Suction tube is leaking.

Tighten suction tube connection.

Inspect for cracks or vacuum leaks. If

cracked or damaged, replace suction

tube.

Prime/Spray Valve is worn or

obstructed with debris.

Clean the valve or replace a new one.

Pump cycles, but paint only

dribbles or spurts when

spray gun is triggered.

Pressure is set too low.

Slowly turn Pressure Control Knob

clockwise to increase pressure

setting which will turn motor on to

build pressure.

O-ring in pump is worn or

damaged

Replace O-rings

Inlet valve ball is packed with

material

Clean inlet valve,

Spray tip is clogged

Unclog spray tip

Fluid filter is clogged.

Clean or replace fluid filter

Spray gun fluid filter is clogged.

Clean or replace gun fluid filter,

Spray tip is too large or worn.

Replace tip.

Problem

Cause

Solution

Sprayer draws up paint but

drops away when gun is

opened

Worn spray tip

Replace with new tip.

Suction set filter clogged

Clean filter.

Gun or spray tip filter plugged.

Clean or replace filter. Keep extra

filters on hand

Paint too heavy or coarse.

Thin or strain paint

Worn V-packing

assembly.

Replace

Inlet valve worn or damaged.

Replace valve

Tip assembly leaks

Assembled incorrectly

Check assembly.

Worn seal.

Replace seal.

Spray gun won't spray

Spray tip, gun filter or

tip clogged

Clean spray tip

filter plugged

Clean or replace gun or filter.

Spray tip in Clean position

Put tip in Spray position

Paint tailing.

Pressure is set too low.

Increase pressure

Gun, tip, or suction

filter plugged.

Clean filters

Suction tube loose

Tighten suction tube fitting

Tip worn.

Replace tip

Paint too thick

Thin paint

Thermal overload tripped

Motor over heated.

Allow to cool 15 to 30 min.

Paint build up on motor.

Clean paint from motor.

Unit sitting in hot sun.

Move to a shady location

No display,

sprayer operates.

Display is damaged or had bad

connection.

Check connection, replace display

Display error code E02

Communication failure

Check the signal line

between pressure sensor and PCB

Display error code E03

Pressure sensor failure

check the pressure sensor

if poor contact or damaged

Display error code E04

Motor and

PCB communication failure

Or mechanical fault

Check the signal line between motor

and PCB or if mechanical

components stuck

Display error code E06

IPM alarm

Display error code E07

High pressure in

cleaning mode

Reduce the pressure when cleaning

Display error code E08

Low line voltage

Check the power supply

Paint leaks down outside of

pump..

Pump packings are worn

Replace pump packings.

Fan pattern varies

dramatically while spraying.

OR Sprayer does not turn

on promptly when resuming

spraying.

Pressure control switch is

worn and causing

excessive pressure variation.

Please contact with your supplier or

DP-AIRLESS.

Parts List

X20 Motor&Pressure control assembly

No.

Serial No.

Description

Qty

No.

Serial No.

Description

Qty

1

X20301

Carbon Brush

1

15

X20515

Stem

1

2

X20302

Baffle

1

16

X20516

Spring

1

3

X20303

Carbon Brush

1

17

X20517

Pressure Regulating Knob

1

4

X20304

Brush Holder

2

18

X20518

Wire

1

5

X20305

Washer

1

19

X20519

Circuit Board

1

6

X20506

Capacitor

1

20

X20520

Bridge

1

7

X20507

Screw

2

21

X20521

Screw

1

8

X20508

Wire

1

22

X20322

Rotor

1

9

X20509

Pressure Regulator Housing

1

23

X20323

Bearing

1

10

X20510

Wire

1

24

X20324

Washer

2

11

X20511

Connector

1

25

X20325

Long Screw

2

12

X20512

Switch

1

26

X20326

Fan

1

13

X20613

Power Cord

1

27

X20327

Screw

1

14

X20614

Plastic Cover

1

28

X20328

Stator

1

Other manuals for DP-X Series

1

This manual suits for next models

5

Table of contents

Other Dino-Power Paint Sprayer manuals

Dino-Power

Dino-Power DP-X Series User manual

Dino-Power

Dino-Power DP-X5 User manual

Dino-Power

Dino-Power DP-6336iB User manual

Dino-Power

Dino-Power Titan 440i User manual

Dino-Power

Dino-Power DP6388B Operation instructions

Dino-Power

Dino-Power DP-6840iB User manual

Dino-Power

Dino-Power DP6391C User manual

Dino-Power

Dino-Power DP-X6 User manual

Dino-Power

Dino-Power DP-X3 User manual