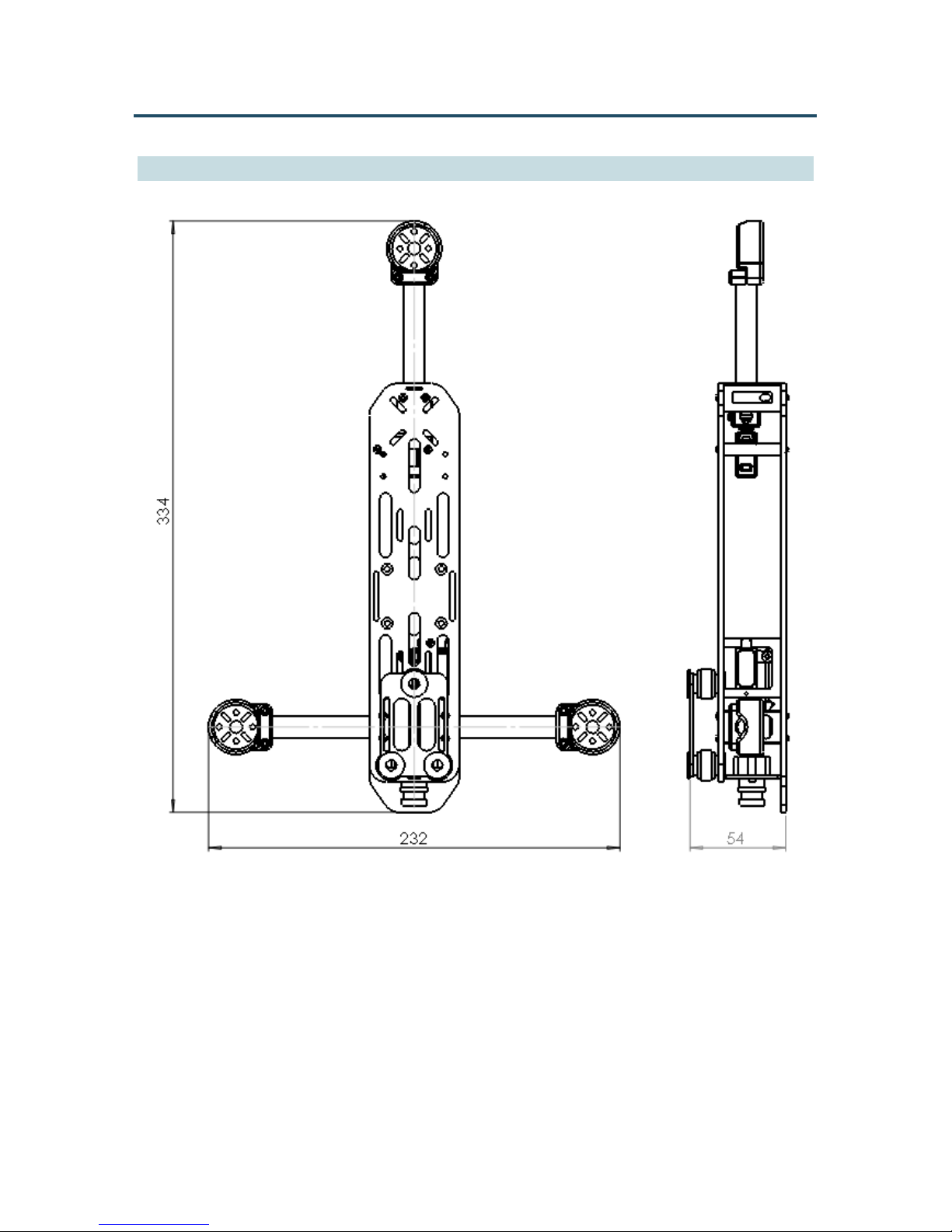

VECTORQUADS

6. Mount the Servo Mount Frame onto the

base plate using two Flat Head Phillips

Screw 9mm Length. Do not over tighten

screws.

7. Mount the tail Servo Mount Frame onto

the base plate using two Pan Head

Phillips Screw 9mm Length. Do not

over tighten screws.

8. Assemble the Motor Mount onto the ends of the tubes using a Motor

Mount Clamp and two Socket Head Cap Screw M2.5x0.45x16. Align

the locating pins on the clamp and mount to the guide holes on the tube.

IMPORTANT: Do not completely tighten one screw, then the other.

Tighten each screw a little at a time to avoid putting too much stress on

one side of the tube. Tighten screws just enough to remove any play on

the motor mount.

Note that due to the tube length and frame size, 5 inch props are the

max size that can be used with this frame.

Do not install motors at this time. Simply choose the orientation of the

motor mounts based on the intended motor size you plan to use.

For 1806 18mm diameter motors, install

inside the motor mount. Use supplied

washers with screws to mount the motors.

For a stator diameter larger than 18mm,

rotate the motor mount upside down and

install motors on the bottom side.