Installation and Operation Manual PEL - 6 © Vega Industries Ltd, April 2008

3

1.0 General Description.......................................................................................................................... 4

1.1 Introduction......................................................................................................................... 4

1.2 Lamps Used in PEL Sector Lights...................................................................................... 4

1.21 Power Supplies for PEL Sector Lights ............................................................................... 5

1.5 Colour Filter Assembly....................................................................................................... 5

1.6 Intensity Reduction Filter ................................................................................................... 6

1.7 Projection System ............................................................................................................... 7

1.8 Aperture Stop...................................................................................................................... 7

1.9 Air Cooling System ............................................................................................................ 7

1.10 Electric Motors ................................................................................................................... 7

1.11 Electronic Controller........................................................................................................... 7

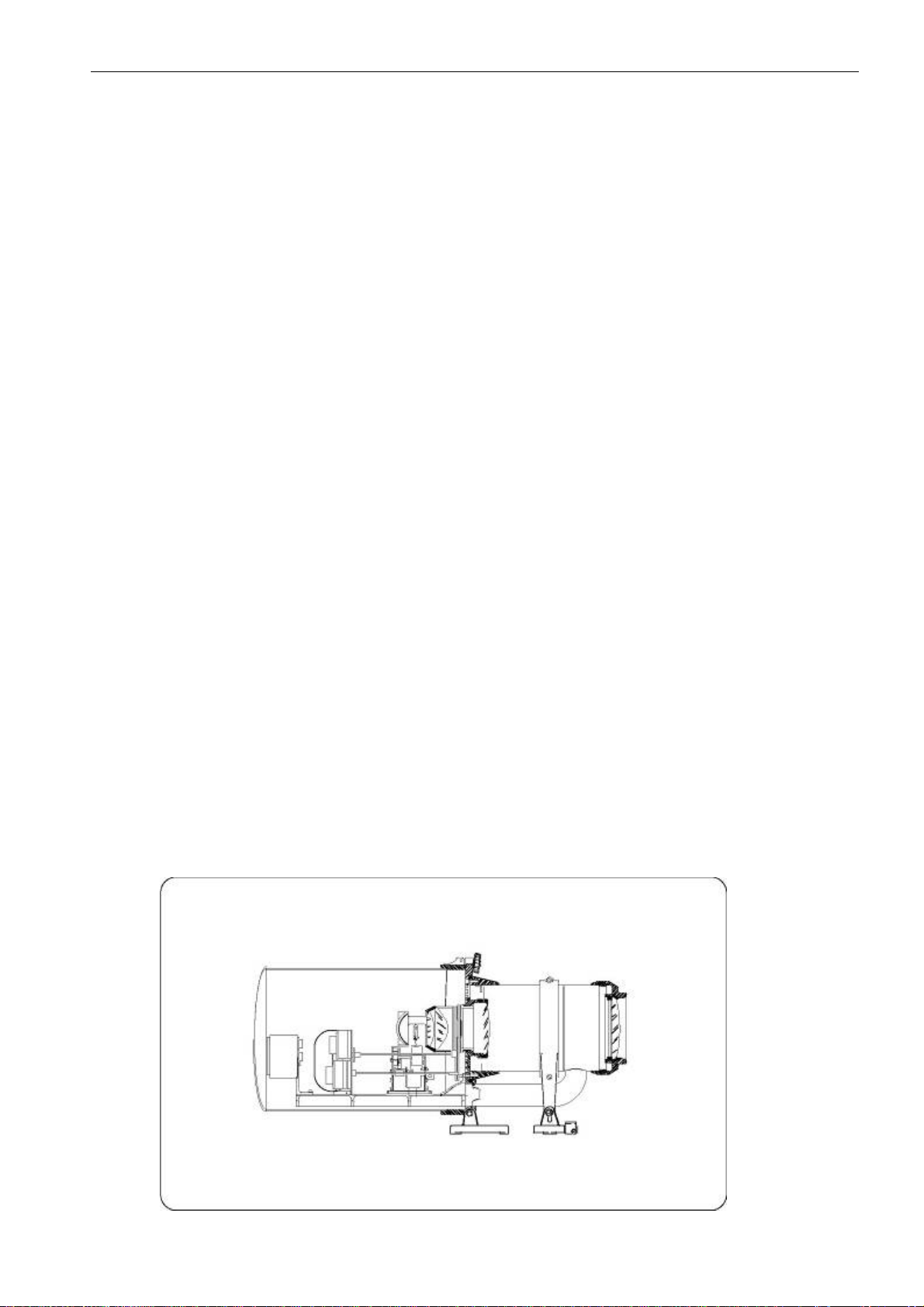

2.0 Mounting and Installation................................................................................................................. 8

2.1 Acceptance Inspection........................................................................................................ 8

2.2 Exclusion of Moisture......................................................................................................... 8

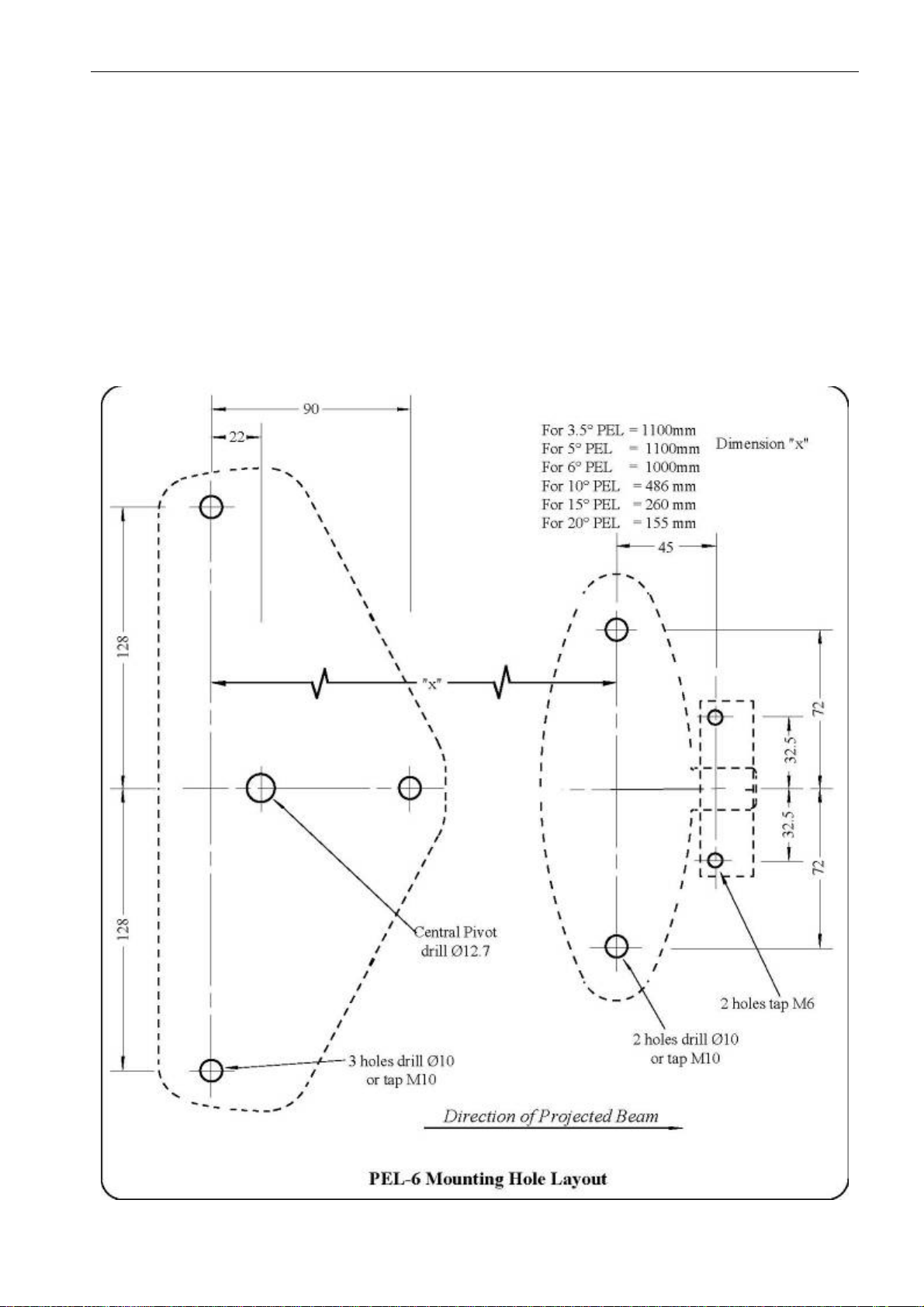

2.3 Physical Mounting.............................................................................................................. 8

2.4 Alignment of Sector Light.................................................................................................. 9

2.5 Masking Stray Light ......................................................................................................... 10

3.1 Input Power Connections.................................................................................................. 10

3.2 CALC (Electronic Controller) Connections ..................................................................... 11

3.3 Stepping Motor Inverters.................................................................................................. 11

4.0 Lampchanger Operation ................................................................................................................. 12

4.1 Fitting of Lamps................................................................................................................ 12

4.2 Lamp Alignment on Lampchanger................................................................................... 13

4.3 Lamp Changer Alignment ................................................................................................ 13

5.3 Parts Listing: Intensity Reduction Filter Assembly.......................................................... 17

6.0 Air Cooling System ........................................................................................................................ 17

7.0 Oscillating Boundary Device (optional extra)................................................................................ 18

7.1 General Description.......................................................................................................... 18

7.2 Mechanical Arrangement.................................................................................................. 18

7.3 Servicing the Oscillating Boundary Device...................................................................... 18

7.5 Reassembly of the Oscillating Boundary Device and Colour Filters............................... 19

7.6 Exploded View ................................................................................................................. 21

7.7 Parts Listing: Intensity Reduction Filter and Oscillating Boundary Device .................... 22

8.0 Maintenance Procedures................................................................................................................. 23

8.1 Objective Lens.................................................................................................................. 23

8.2 Oscillating Boundary........................................................................................................ 23

8.3 Internal Optical Surfaces .................................................................................................. 23

8.4 Aluminised Mirror............................................................................................................ 23

8.5 Filter Glasses..................................................................................................................... 23

8.6 Seals.................................................................................................................................. 24

9.0 Trouble Shooting List..................................................................................................................... 24

9.1 Loss of Intensity or Change in Intensity Profile............................................................... 24

9.2 Poor Sector Resolution ..................................................................................................... 24

9.3 Oscillating Boundary Fails to Oscillate............................................................................ 24

9.4 Lamp Inoperative / Lampchanger Faults.......................................................................... 24

9.5 Electronic Controls ........................................................................................................... 24