VEGASON 51K …53K 5

Product description

1.2 Application features

Applications

•Level measurement of all liquids

•Level measurement of solids

(only short measuring distances) such as

e.g.:

coal, ore, stones, stone dust, cement,

gravel, crushed stones, sand, sugar, salt,

cereals, flour, granules, powder, dusts,

saw dust, wood chips

•Flow measurement on different flumes

•Gauge measurement, distance measure-

ment, object monitoring and conveyor belt

monitoring

Two-wire technology

•Supply and output signal on one two-wire

line (Loop powered)

•4 …20 mA-output signal

Rugged and precise

•Unaffected by product features such as

density, conductivity, dielectric constant …

•Suitable for aggressive substances

•Measuring ranges 0,25 m …15 m

Adjustment choice

•With adjustment software VEGA Visual

Operating (VVO) on PC

•With detachable adjustment module

MINICOM

•With the HART®-Handheld

•Measured value indication integrated in the

sensor

•Optional indication separate from the sen-

sor

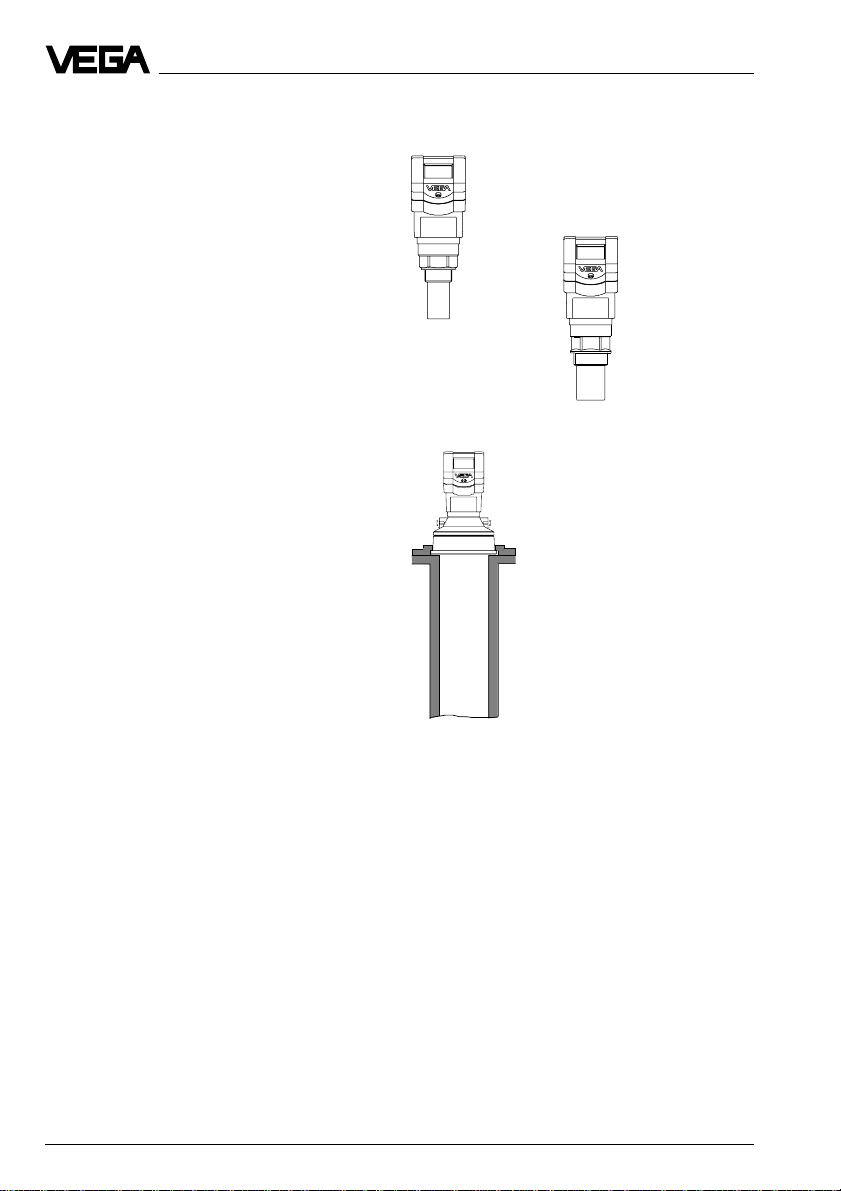

Connection for each process

•G 11/2 A, 11/2" NPT

•G 2 A, 2" NPT

•Compression flange DN 100, ANSI 4"

Approvals

•CENELEC, ATEX, PTB, FM, CSA, ABS,

LRS, GL, LR, FCC

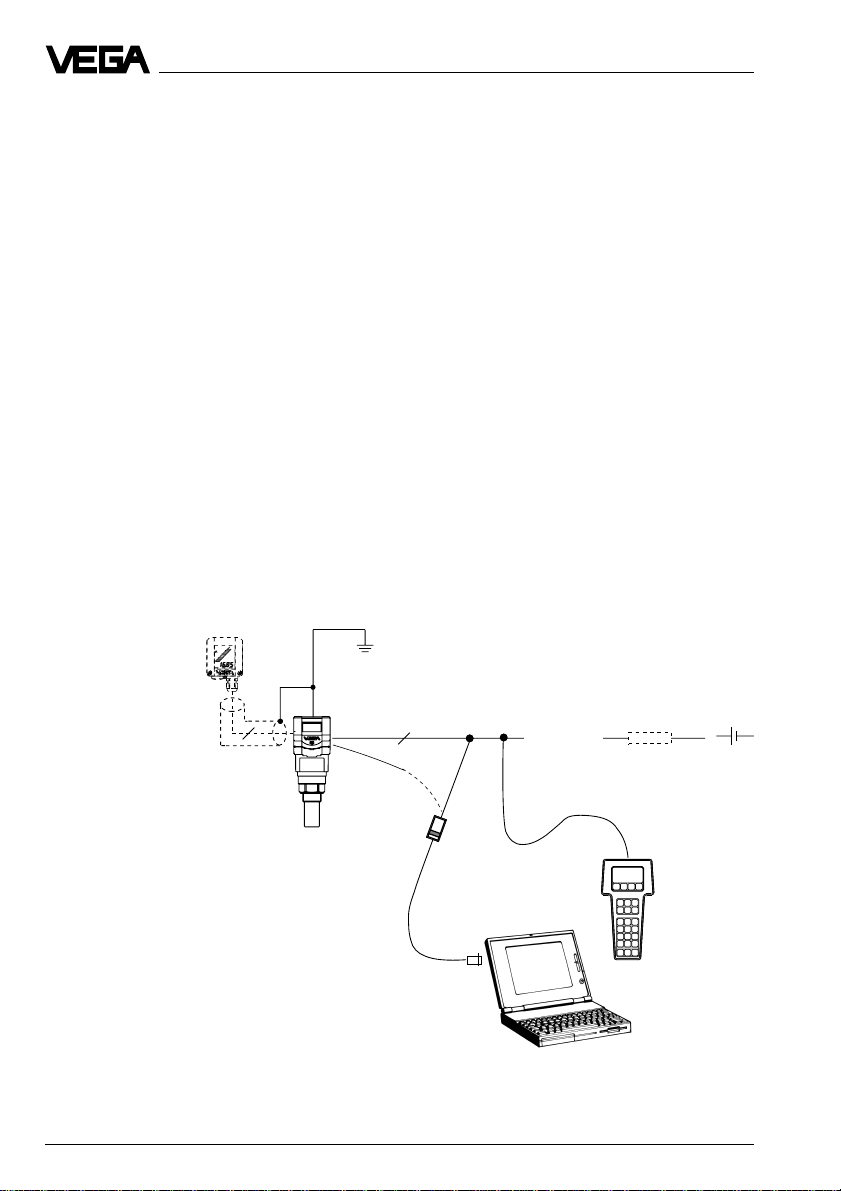

1.3 Adjustment

Each measuring distance is different, there-

fore each ultrasonic sensor must be given

some basic information on the application

and the environment, e.g. you need to inform

the sensor which level means “empty“and

which level “full“. Apart from this “empty and

full adjustment“, a number of other adjust-

ments can also be carried out with

VEGASON ultrasonic sensors.

The adjustment and parameter adjustment of

the ultrasonic sensors are carried out with

- the PC

- the detachable adjustment module MINI-

COM

- the HART®--Handheld

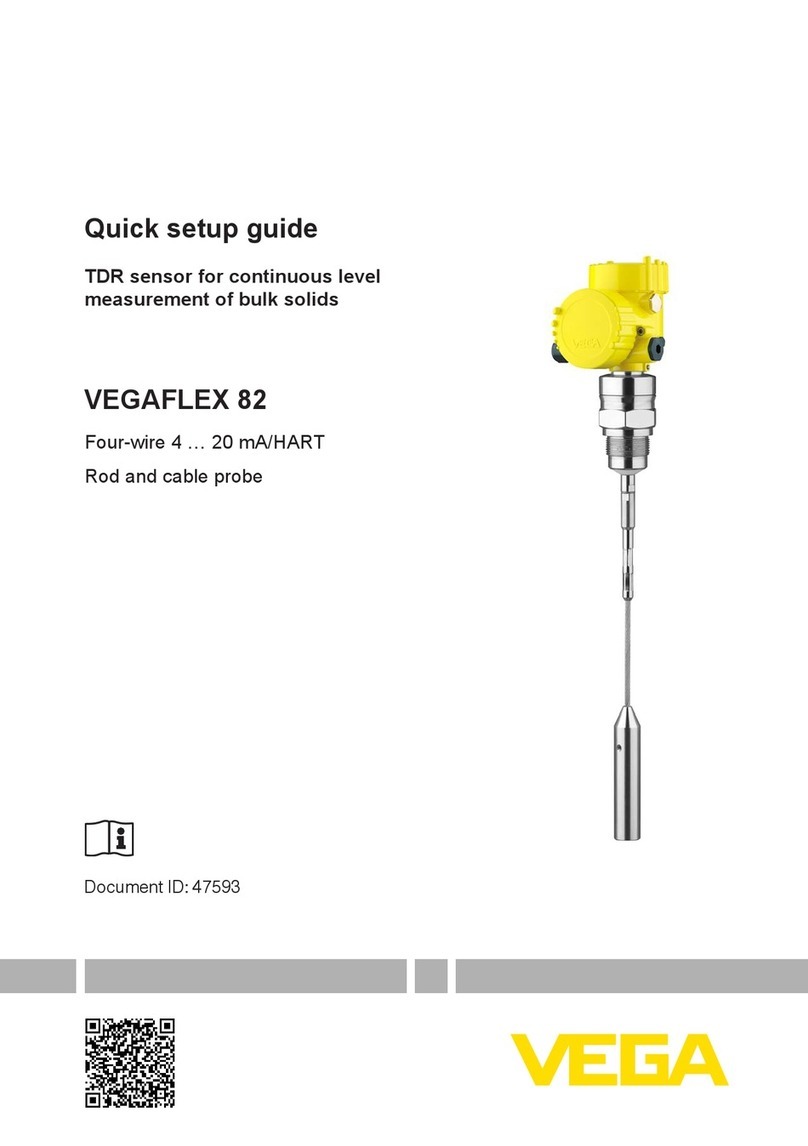

Adjustment with PC

The set-up and adjustment of the ultrasonic

sensors is generally made on the PC with the

adjustment program VEGA Visual Operating

(VVO) under Windows®.

The program leads quickly through the ad-

justment and parameter adjustment via pic-

tures, graphics and process visualisations.

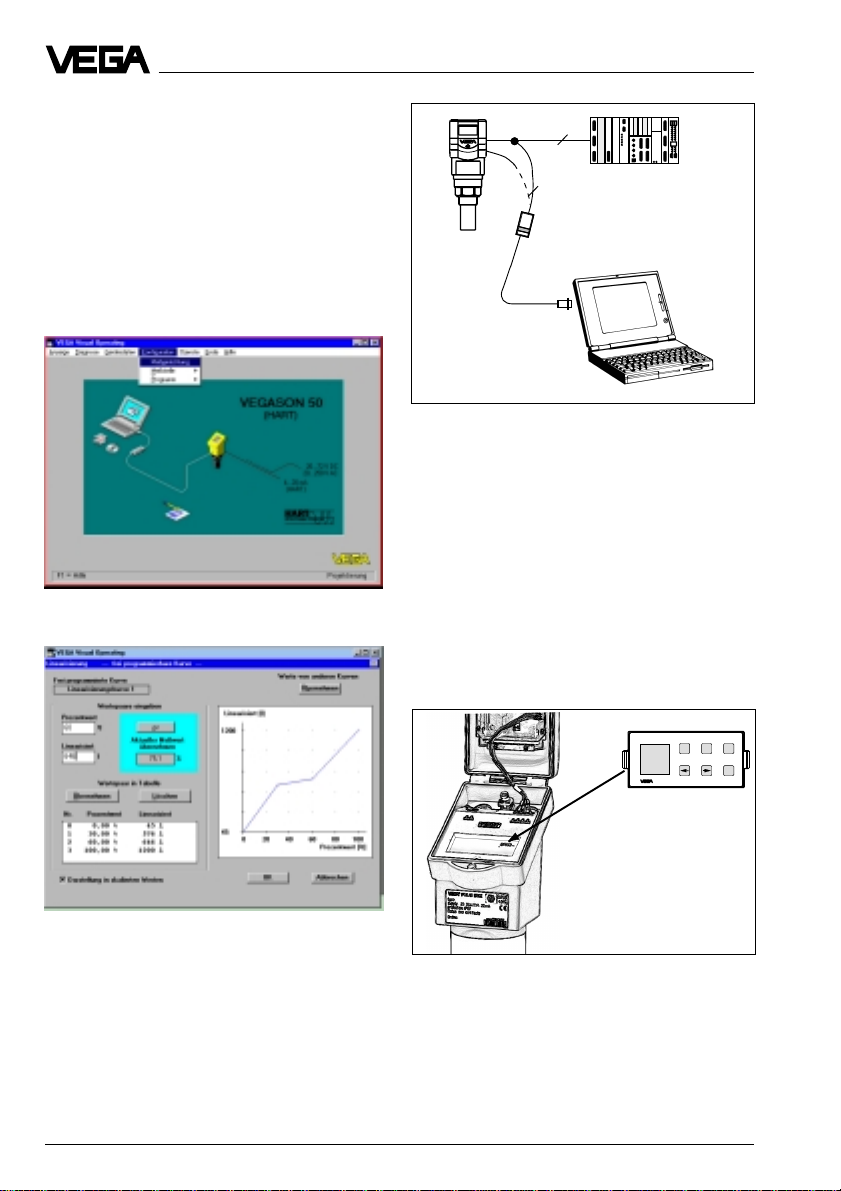

Adjustment with the PC on the analogue 4 …20 mA-

signal and supply line or directly on the sensor (four-

wire sensor)

2

2

4 ...20 mA