VEGASWING 61, 63 - N 3

25470-EN-030707

Product description

1 Product description

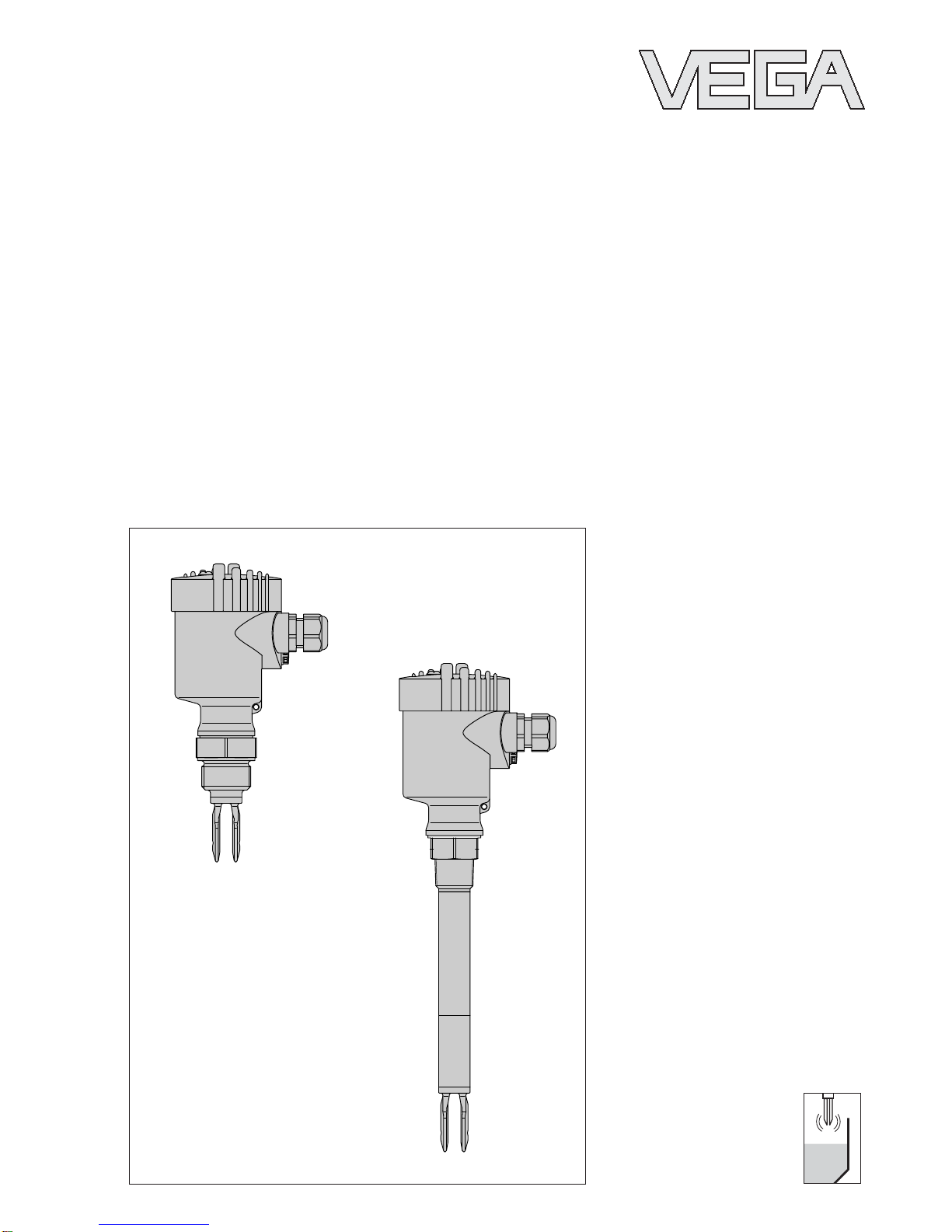

VEGASWING 61 and 63

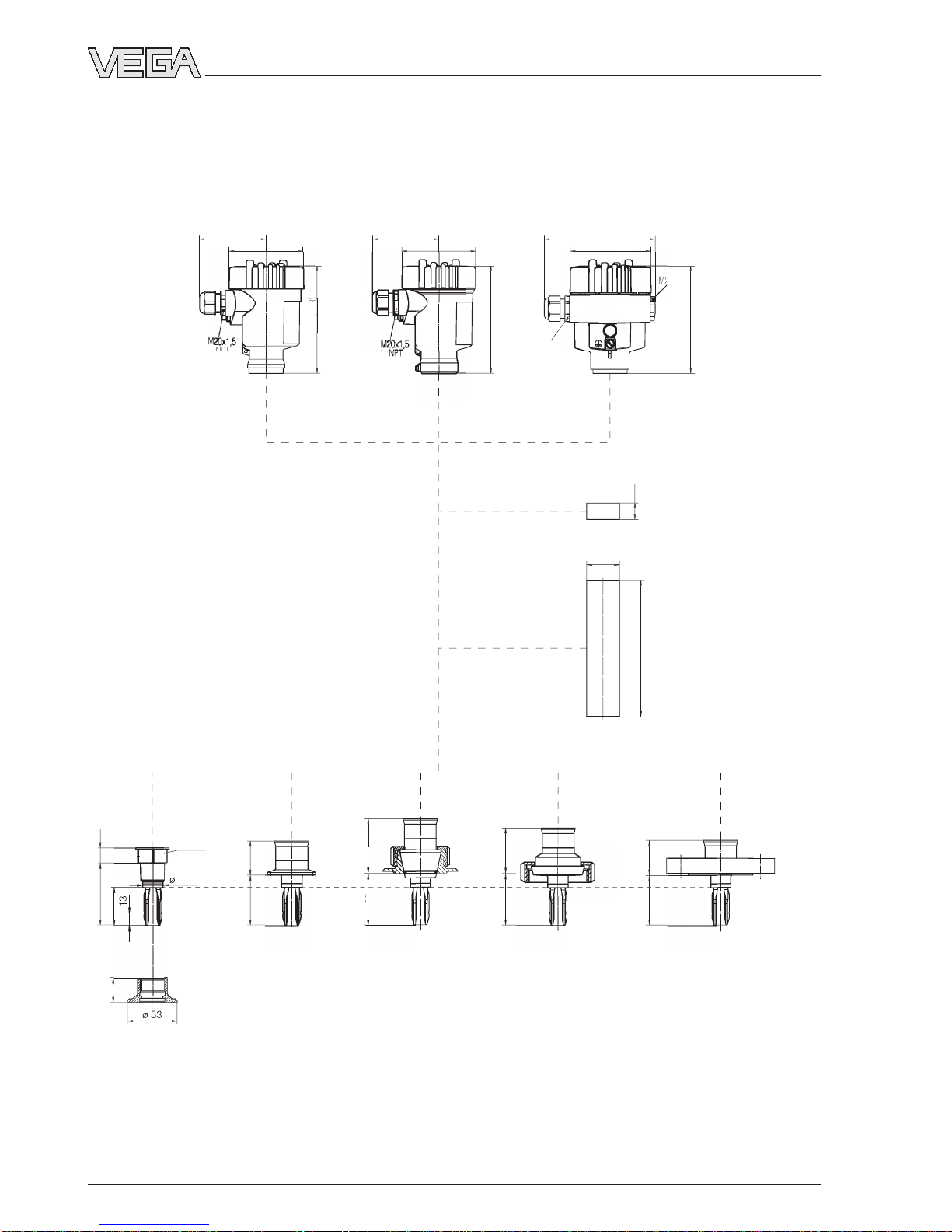

VEGASWING 61/63 vibrating level switches

are used for level detection of liquids.

Typical applications are overfill and dry run

protection. Using a tuning fork with a length

of only 40 mm, VEGASWING 61 opens up

new areas of application, e.g. in pipelines

from DN 25. Power supply and output signal

correspond to the Namur interface acc. to

IEC 60947-5-6 (EN 50227).

VEGASWING series 60 vibrating level

switches detect levels of liquids with a vis-

cosity of 0.1 … 10.000 mPa s and a density

of ≥0.5 g/cm3. Modular construction enables

their use in vessels, tanks and pipelines.

Thanks to its simple and rugged measuring

system, VEGASWING is virtually unaffected

by the chemical and physical properties of

the liquid. It does its job even under unfa-

vourable conditions such as turbulences, air

bubbles, foam generation, buildup, strong

external vibration or constantly changing

products.

• Tuning fork with only 40 mm length.

• Thread from ¾ and flanges from DN 25

(ANSI 1").

• Process temperature -50°C ... +250°C

without shock limitation.

• Insensitive to external vibration.

• Process pressure up to 64 bar.

• Also ECTFE or PFA coated or enamelled.

• Viscosity 0.1 ... 10000 mPa s.

• Density range 0.5 g/cm3… 2.5 g/cm3.

• NAMUR output.

• Ex-Zone 0/1

ATEX II 1G or 1/2G EEx ia IIC T6

ATEX II 1/2G or 2G EEx d IIC T6

• Overfill protection acc. to WHG.

• Integrated fault monitoring.

• Fixed, exactly reproducible switching

point.

• Switching point visible with closed instru-

ment (LED).

• Set-up without adjustment.

• Installation in any position.

• Min. or max. mode.