Velleman K8046 User manual

Total solder points: 274

Difficulty level:

beginner 1o2o3o4o5þadvanced

K8046

Touch screen keyboard

ILLUSTRATED ASSEMBLY MANUAL H8046IP-1

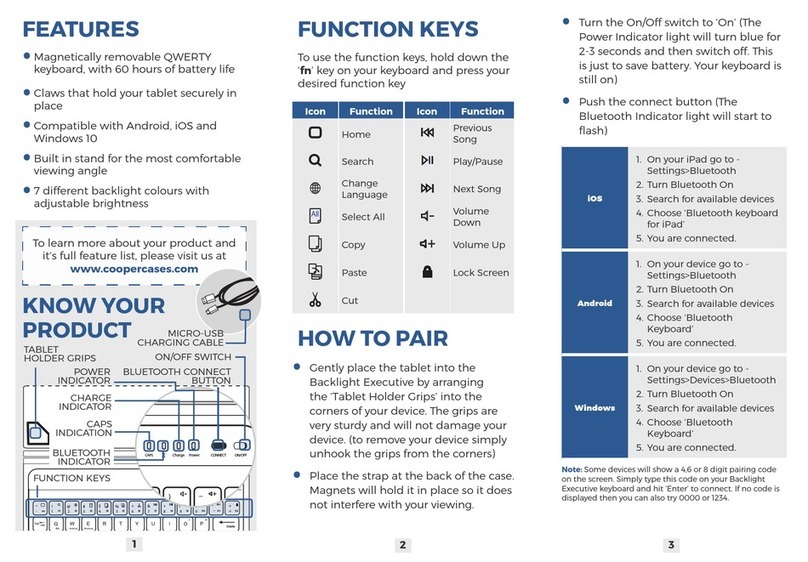

Features:

þLED status indication for each key/output

þEach key can be defined as toggle or momentary

þSoft touch, see-through touch panel with 8 keys

þBacklight with dim function

þUnique key-click feedback

þOptional infrared receiver module: IR38DM

þOptional BLUE BACKLIGHT: L-934MBC (8pcs required)

þ4 different functions (jumper selectable) :

•Eight independent keys (toggle or momentary selectable)

•Eight radio (rotary simulation) buttons

•Four radio buttons and 4 independent keys

•One key serves as a memory for 7 other keys or “clear all” key

Specifications:

•8 open collector switches: max 50 Volt / 50mA (all outputs)

•Board to wire connectors: 20cm wire.

•Dimensions (including frame): 165x90x35 (depth)

•Usable temperature range: -5°C to +40°C

•Keyboard operating force: 40g. (with R0.8mm test point)

•Keyboard lifetime: 1.000.000 operations with R3mm rubber

•Power supply: 2 x 9VAC or 12VDC / 250mA max.

VELLEMAN KIT NV

Legen Heirweg 33

9890 Gavere

Belgium

www.velleman.be

www.velleman-kit.com

CAUTION:

This kit is supplied with a GLASS type keyboard.

BE VERY GENTLE WITH THIS TYPE OF

KEYBOARD, THE SLIGHTEST BENDING WILL BREAK THE

GLASS AND COULD CAUSE

INJURY.

A BROKEN KEYBOARD IS NOT COVERED BY THE

WARRANTY, A NEW KEYBOARD CAN BE ORDERED AT YOUR DEALER.

ORDER CODE: KB020501

IMPORTANT: Since this is a complex assembly with a lot of

possibilities, it is advisable to read through the complete in-

structions BEFORE starting the actual assembly.

BE WARNED !

!

3

Assembly hints

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project

successful. Read them carefully.

1.1 Make sure you have the right tools:

•A good quality soldering iron (25-40W) with a

small tip.

•Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to

the tip, to give it a wet look. This is called ‘thinning’ and will protect

the tip, and enables you to make good connections. When solder

rolls off the tip, it needs cleaning.

•Thin raisin-core solder. Do not use any flux or grease.

•A diagonal cutter to trim excess wires. To avoid injury when cutting

excess leads, hold the lead so they cannot fly towards the eyes.

•Needle nose pliers, for bending leads, or to hold compo-

nents in place.

•Small blade and phillips screwdrivers. A basic range

is fine.

For some projects, a basic multi-meter is required, or might

be handy

1.2 Assembly Hints :

⇒Make sure the skill level matches your experience, to avoid disappointments.

⇒Follow the instructions carefully. Read and understand the entire step before

you perform each operation.

⇒Perform the assembly in the correct order as stated in this manual

⇒Position all parts on the PCB (Printed Circuit Board) as shown on the draw-

ings.

⇒Values on the circuit diagram are subject to changes.

⇒Values in this assembly guide are correct*

0.000

4

⇒Use the check-boxes to mark your progress.

⇒Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute

manual updates, indicated as ‘NOTE’ on a separate leaflet.

1.3 Soldering Hints :

1-Mount the component against the PCB sur-

face and carefully solder the leads

2-Make sure the solder joints are cone-

shaped and shiny

3-Trim excess leads as close as possible to the

solder joint

REMOVE THEM FROM THE TAPE ONE AT A

TIME !

Assembly hints

AXIAL COMPONENTS ARE TAPED IN

THE CORRECT MOUNTING SEQUENCE !

5

6

Construction

qR1 : 680E (6-8-1-B)

qR2 : 680E (6-8-1-B)

qR3 : 680E (6-8-1-B)

qR4 : 680E (6-8-1-B)

qR5 : 680E (6-8-1-B)

qR6 : 680E (6-8-1-B)

qR7 : 680E (6-8-1-B)

qR8 : 680E (6-8-1-B)

qR9 : 10K (1-0-3-B)

qR10 : 10K (1-0-3-B)

qR11 : 10K (1-0-2-B)

qR12 : 1K5 (1-5-2-B)

qR13 : 10K (1-0-3-B)

qR14 : 1K5 (1-5-2-B)

qR15 : 100K (1-0-4-B)

qR16 : 100K (1-0-4-B)

qR17 : 100K (1-0-4-B)

qR18 : 100K (1-0-4-B)

qR19 : 120E (1-2-1-B)

qR20 : 1K5 (1-5-2-B)

1. Resistors

R...

The unit consist out of two PCB’s, one is the main PCB, P8046B and the other is

the backlight PCB P8046L.

GTip : The pictures on the packaging can be used as a guideline. However due

to possible changes it is not 100% reliable.

First we will assemble the P8046B.

CONSTRUCTION

qD9 : 1N4148

qD10 : 1N4007

qD11 : 1N4007

Remark:

D1 to D8 are not mounted at this time.

2. Diodes, check the polarity

D...

CATHODE

qZD1 :5V6 -500mW

qZD2 :5V6 -500mW

qZD3 :5V6 -500mW

qZD4 :5V6 -500mW

qZD5 :5V6 -500mW

qZD6 :5V6 -500mW

3. Zenerdiodes

ZD...

CATHODE

7

Construction

qC1 : 22pF (22)

qC2 : 22pF (22)

qC3 : 100nF (104, u1)

qC4 : 100nF(104, u1)

qC5 : 100nF(104, u1)

4. Ceramic Capacitors

C...

qIC1 : 28p

qIC2 : 18p

5. IC sockets. Watch the posi-

tion of the notch!

qSW1 : RESET

qSW2 : BACKLIGHT

Type : KRS1273

6. Push buttons

SW...

7. Voltage regulator

M2.5 SPACER

M2.5 BOLT

M2.5 6mm SPACER

qSK3 : 3p

qSK5 : 10p

CUT BETWEEN PIN 11 & 12

qSK8 : 10p

8. Connectors

qSK4 : 6p

9. Conn. Printed cable

WATCH THE POSITION OF THE CONNECTOR !

8

Construction

qT1 : BC557

qT2 : BC547

10. Transistors

Power indication, make your choice

as you prefer:

qLD17 : 3mm green clear

OR 3mm red

11. LED. Watch the polarity!

LD1

CATHODE

27mm

qX1 : 4MHz

12. Quartz crystal

X...

qC6 : 10µF

qC7 : 100µF

13. Electrolytic capacitors.

Watch the polarity !

C...

qRY1: VR15M121C

14. Relays

qIC1: VK8046 Programmed

PIC16C55A-04 or equivalent

15. IC’s. Watch the position of

the notch!

PIN1

1

qSK1 -SK2 : 4p

16. Header

9

Each key is function definable (moment or toggle) and backlit. It is even possible

to simulate old fashioned “radio buttons” (only one output can be ON, just like a

rotary switch).

One key can be defined as a pre-set memory or serve as “all clear”.

The K8046 features 4 operating modes, selectable with shunt SK1 or SK2.

1. Eight independent keys (toggle or momentary selectable).

2. Eight radio (Rotary simulation) buttons.

3. Four radio buttons and 4 independent keys.

4. One key is reserved as memory or “clear all” function.

Momentary (push button-) function : Hold the key to activate the output and

release the key to deactivate it.

Toggle function : Operates according to the principle of a classic switch, i.e.

you have to press the key once to switch and press again to deactivate it.

For each output :

If a momentary output is needed, DO NOTmount a diode for the corresponding

output D1 to D8.

If a toggle output is needed, MOUNT a diode for the corresponding output D1 to D8.

D...

CATHODE

17. Keyboard set–up

Diode type: 1N4148

Check the polarity !

Keyboard set-up

MODE SK1 SK2

1OFF OFF

2OFF ON

3ON OFF

4ON ON

SHUNT SELECTION

10

Keyboard set-up

JUMPER SELECTION

Different possibilities in conjunction with diode setup:

1-Eight indepent keys(no jumper is mounted) toggle or

momentary selectable see previous page.

2-Eight radio ( Rotary simulation) buttons, only one button (output) at a

time can be ON. Again with possibility of momentary or toggle.

FNormally a toggle function will be used for this type of output.

3-Four radio buttons and 4 independent keys.

This is a combination of above. The first row (1 to4). Are independent

buttons, the second row (5 to 8) have a rotary simulation.

4-Key 8 is reserved as memory or ‘Clear all’ Function.

If D8 is mounted this key will switch between all clear and mem-

ory of the previous keyboard setting.

If D8 is NOT mounted, this key will serve as all clear.

SK2

SK1

SK1

SK2

SK1

SK2

SK1

SK2

HINT: the separate CLEAR button can also be used as keyboard

clear function. This key will actually reset the processor.

11

It is possible to use the keyboard together with a remote control (e.g. our K8049

& K8051). In this case an optional receiver module type IR38DM is available.

Position the module like in the drawing. Use some hot glue to hold the receiver

in place on the relay (Fig 1.0)

Make the connections:

-Connect 1 with right side of R13

-Connect 2 with COM connection of the output connector

-Connect 3 with left connection of R20. See picture.

1

2

3

IR detector

18. Optional IR detector

a special cut-out

in the front panel

has to be made.

Fig 1.0

Fig 2.0

12

Construction

P8046L Backlight PCB assembly

qR21 : 180E (1-8-1-B)

qR22 : 180E (1-8-1-B)

qR23 : 180E (1-8-1-B)

qR24 : 180E (1-8-1-B)

qR25 : 180E (1-8-1-B)

qR26 : 180E (1-8-1-B)

qR27 : 180E (1-8-1-B)

qR28 : 180E (1-8-1-B)

1. Resistors

R...

qMount six 8mm M2,5 spacers at the indicated positions using six 6mm M2,5

screws (Fig 3.0).

2. Spacers for keyboard support

Fig 3.0

13

Output status indication

qLD1 : 3mm Red

qLD2 : 3mm Red

qLD3 : 3mm Red

qLD4 : 3mm Red

qLD5 : 3mm Red

qLD6 : 3mm Red

qLD7 : 3mm Red

qLD8 : 3mm Red

3. Output status indications

Max. 7mm

•Cut of a piece of shrinking tube with a length

equal to 7mm.

•Slide the shrinking tube over each LED. (Fig 4.0)

GHINT: if not all keys/outputs are used, do not mount a LED for the not

used key/output.

Fig 4.0

14

LED’s for backlight

Anode

First: Bend the leads exactly like the drawing (Fig 5.0).

Next: Solder one lead, and check the position, if necessary correct by heating

the soldering (Fig 6.0).

Last: Solder the second connection.

qLD9 :3mm Green clear

qLD10 :3mm Green clear

qLD11 :3mm Green clear

qLD12 :3mm Green clear

qLD13 :3mm Green clear

qLD14 :3mm Green clear

qLD15 :3mm Green clear

qLD16 :3mm Green clear

IMPORTANT

Mount these LED’s exactly

like in the drawings.

LD...

TIP

Blue backlight is possible using

special LED’s (8pcs required).

Ordernr. : L-934MBC

4. LED’s for backlight

Fig 6.0

Fig 5.0

MAX.7mm

15

Backlight connection

First cut the header into two headers with each 10

contacts (Fig 7.0)

Thenplace one 10p at position SK9 (Fig 8.0).

Last solder the header (see fig 9.0)

qSK9 : Pin header

5. Header for backlight PCB connection

10p 10p

Solderside

10!

10!

Fig 7.0

Fig 8.0

Fig 9.0

16

Test assembly

qMount the four 15mm spacers as shown in the drawing Using four 6mm bolts

(Fig 10).

6. Assembling (for testing)

Fig 10

17

qFit the touch screen pcb at the component side of the base PCB (Fig 11)

FDo not fix yet !

Test assembly

GMake sure that the connector is correctly inserted when

you mount the backlight onto the spacers.

Fig 11

18

Testing the circuit

Before making a final assembly we will test the circuit:

Supply the power to the circuit (use the supplied wired connector, brown (-) and

red (+) wire).

Normally the relay should “click” and the backlight should lit. If not; try “reset”

SW1.

Now test the keyboard input (keyboard connector SK4):

Using a small piece of wire, make a shunt between point A and point 1, one of

the output LED’s should lit.

Now test the other points A+2, A+3 and A+4.

All the top row output LED’s should have lit one by one.

Perform the same test using point B as common, all the bottom row output

LED’s should lit one by one.

The circuit is now ready for final assembly.

REMOVE THE BACKLIGHT PCB !

7. Testing the circuit

A

B

1

2

3

4

Connect 9 to 12Vdc / 300mA, between GND (-) and VA or VB

19

Creating your printed keyboard

The big advantage of this kit is that it is possible to create your own keyboard

lay-out using a computer and printer.

Use transparent foil suitable for your printer

As an example a few standard lay-outs are supplied, these can be used as a

guide to create your own. Please cut-out the desired layout before use.

On our web site a template can be downloaded to start making you own design,

your imagination is the limit, just keep in mind the position of the keys and posi-

tion of the output indications LED’s. (see drawing 12)

* Measurements are in mm !

8. Creating your printed keyboard

Fig 12

20

Mounting order

Printed lay-out

Housing

PCB’s

Support

Touch screen

Buttons

Top cover

Front label

9. Mounting order overview

FOLLOW THE ASSEMBLY STEPS EXACTLY

LIKE ON THE NEXT PAGES !!

Other manuals for K8046

1

Table of contents