T-33 SHOOTING STAR PAGE 10 OF 17

PREPARING THE FUSELAGE

First assemble the WM400 Fan

accor ing the WM400 Instruction

manual

Place the WM400 fan through the fan

access oor into its position at the en

of the intake tube. Cut out the nee e

place for the motor cables or copper

stripes into the intake uct. Check for

the correct position of the fan mounts

to the flange at the en of the intake

uct. Be sure the fan housing is well

inserte into the ucting; it shoul be

slotte into the uct snugly.

In the kit, there are two semi roun e

woo formers that serving both

purposes – servo elevator mounting

an fan support.

The formers are being installe into the

fuselage by having one si e of the

formers epoxy first then follow by the

next former ue to the limite space

opening hatch esign on the fuselage

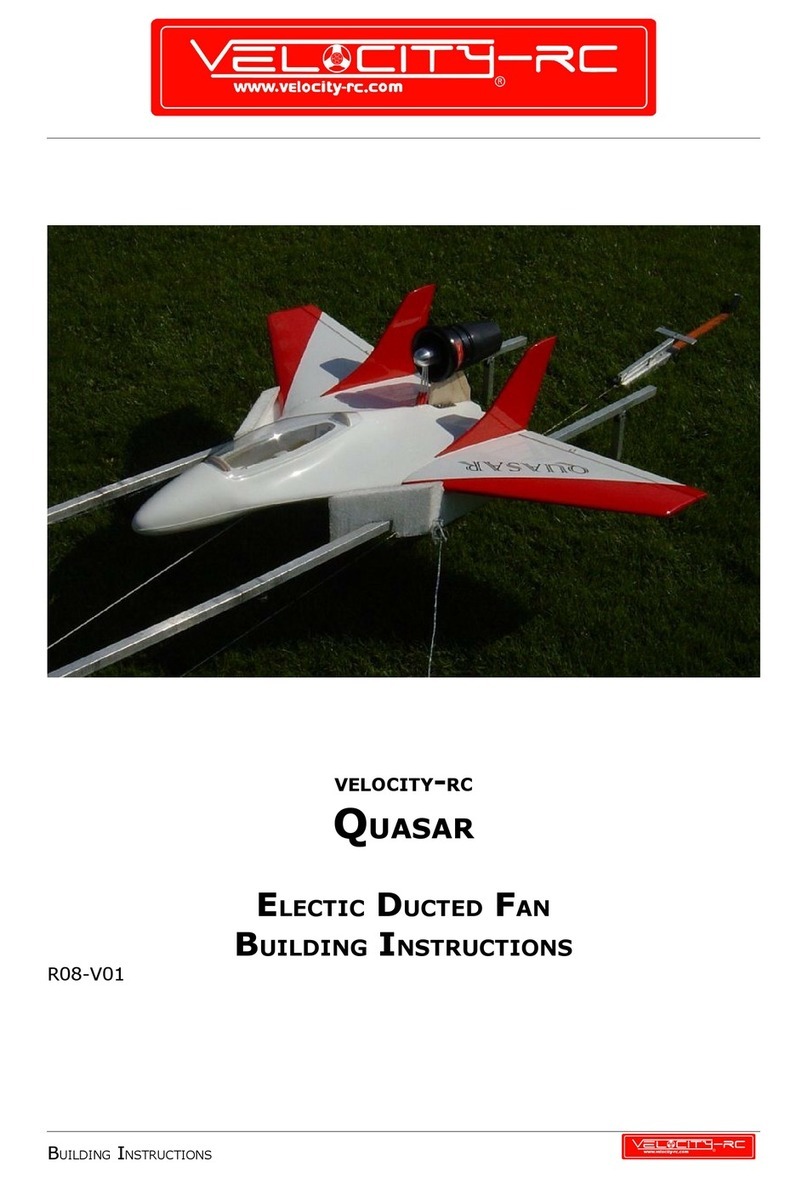

Picture shows the fully assemble

formers for WM400 Fan an elevator

servo insi e the fuselage.

Just sli e this preassemble formers

more to the front so they will act as

support for the fan. Glue in the former

to its final position.

Once epoxy is cure , rill four holes for

the screws to allow fan housing to be

mounte .

Buil a thrust tube from a thin A3 foil.

A template at the en of the manual is

provi e for making a thrust tube

mounte at the back of the wm 400.

Print out the 3 pages from this template

an tape them together. On the foil, let

an overlap of 10mm an use 3M tape to

fully seal up gap to form up a tube.

BUILDING INSTRUCTION