Main Unit

Main unit connector

Main unit connector is used for Dash7 power supply, ECU communication and for connecting analog and digital

inputs to the Dash7. To disconnect main unit connector pull the violet plastic part to the side and at the same time

pull the connector out from the socket. Connector consists of 3 rows of pins (A, B, C), 8 pins in a row (total of 24

pins)

DO NOT FOLLOW THE POSITION OF A VIOLET PLASTIC PART ON THE PICTURE WHEN INSTALLING PINS,

BECAUSE THIS PART CAN BE MOUNTED IN BOTH DIRECTIONS!

Row A

Pin A1: Sensors +5V supply (load max. 700mA) (NOTE: Pin not connected for Sn2106 or less)

Pin A2: PWR connector of display unit - Pin 2

Pin A3: Sensors GND - Ground supply for sensors (NOTE: Pin not connected for Sn2106 or less)

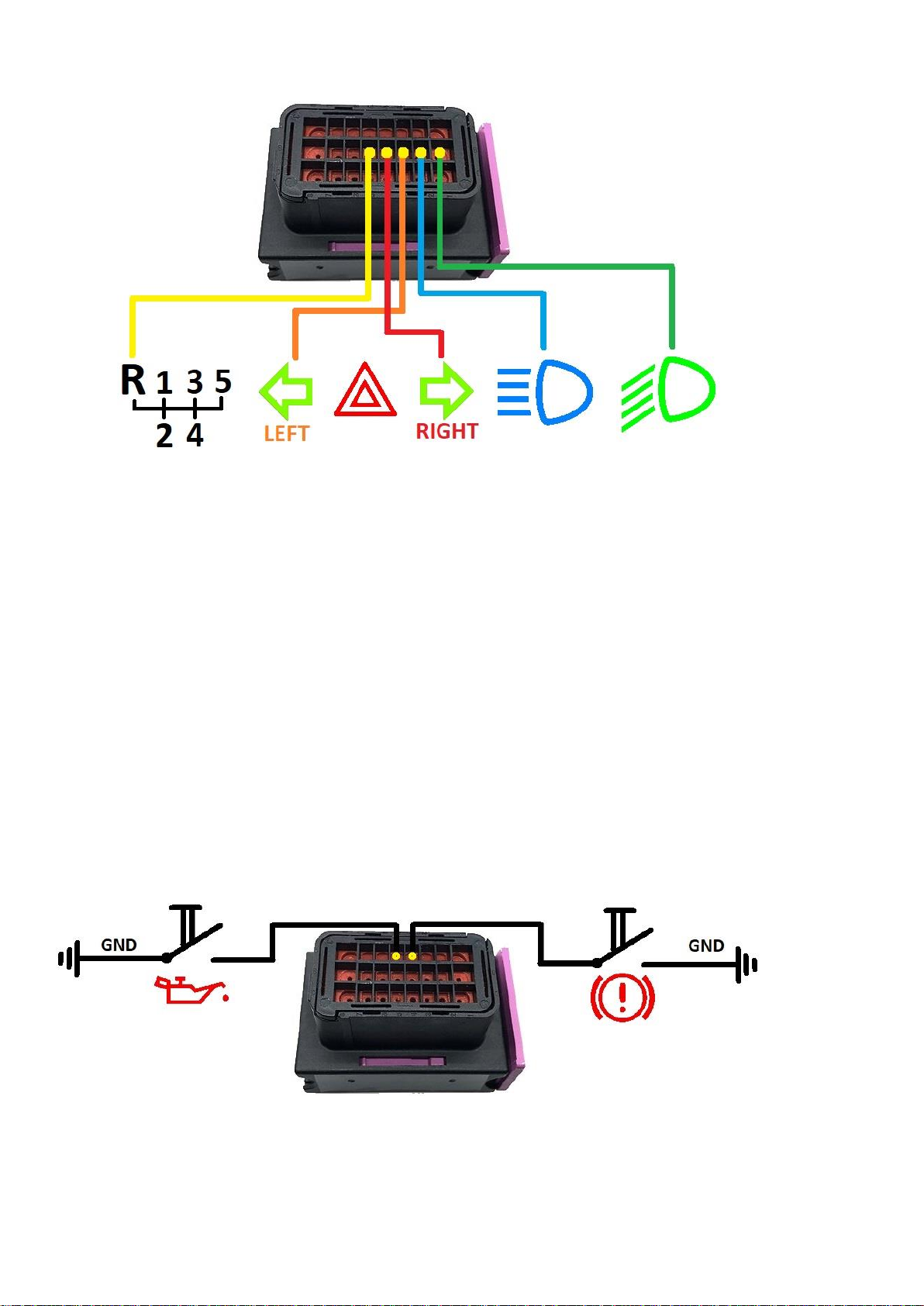

Pin A4: Input 9 (Handbrake - GND) –switch ONLY to GND ! (not protected input)

Pin A5: Input 10 (Oil Press Switch - GND) –switch ONLY to GND ! (not protected input)

Pin A6: PWR connector of display unit - Pin 5

Pin A7: PWR connector of display unit - Pin 4

Pin A8: PWR connector of display unit –Pin 1 (+5V display unit power supply)

Row B

Pin B1: Input 4 (Low Beam Lights +12V) –connect to the +12V of low beam light bulb

Pin B2: Input 5 (High Beam Lights +12V) –connect to the +12V of high beam light bulb

Pin B3: Input 6 (Turn Indicator LEFT +12V) –connect to the +12V of left turn ind. bulb

Pin B4: Input 7 (Turn Indicator RIGHT +12V) –connect to the +12V of right turn ind. bulb

Pin B5: Input 8 (Reverse Gear +12V) –connect to the +12V of reverse light bulb

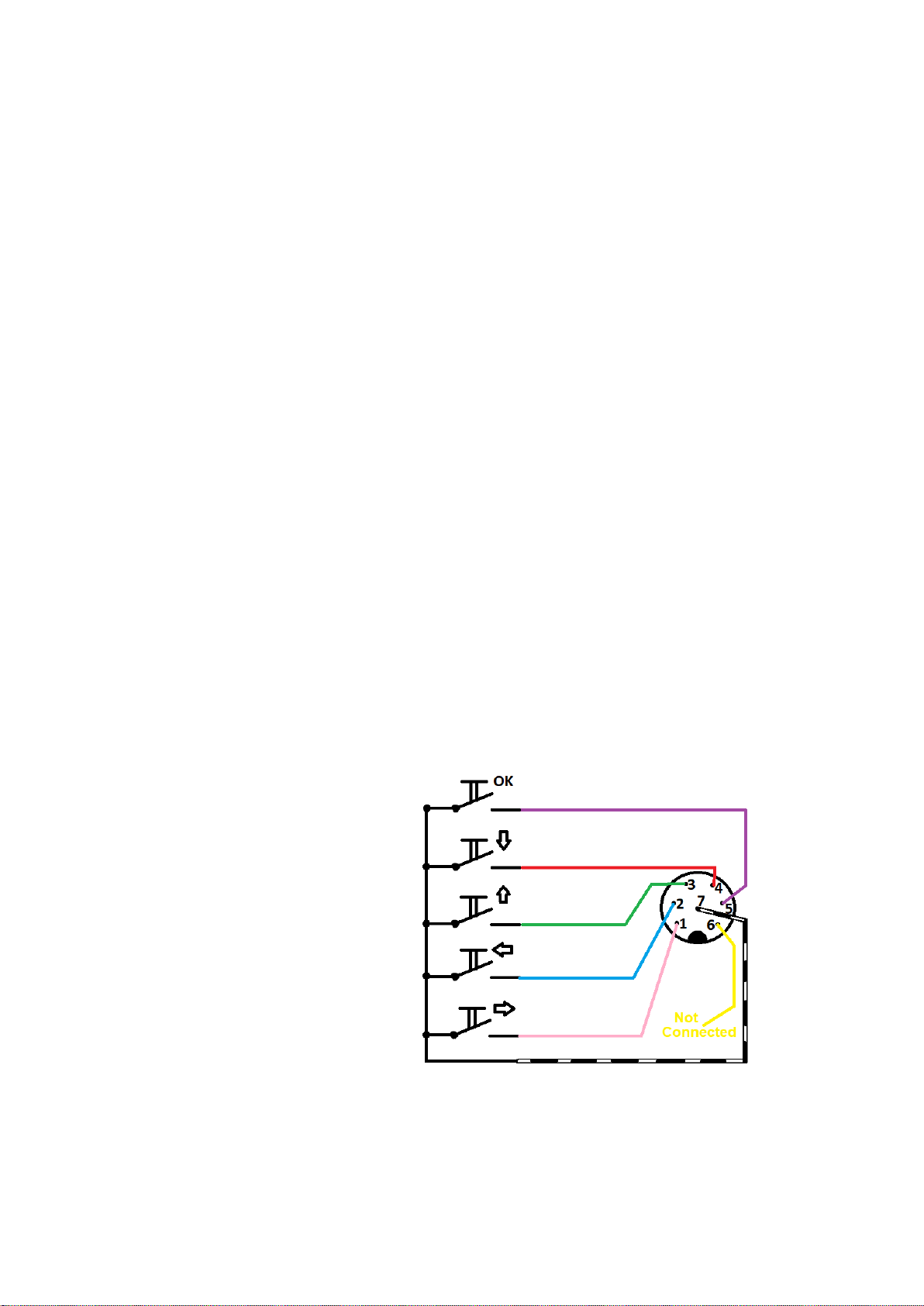

Pin B6: VEMS Serial RS232 (GND)

Pin B7: PWR connector of display unit - Pin 3

Pin B8: Main Power Supply +12V –connect this pin to the main switch or ignition switch in your car

Row C

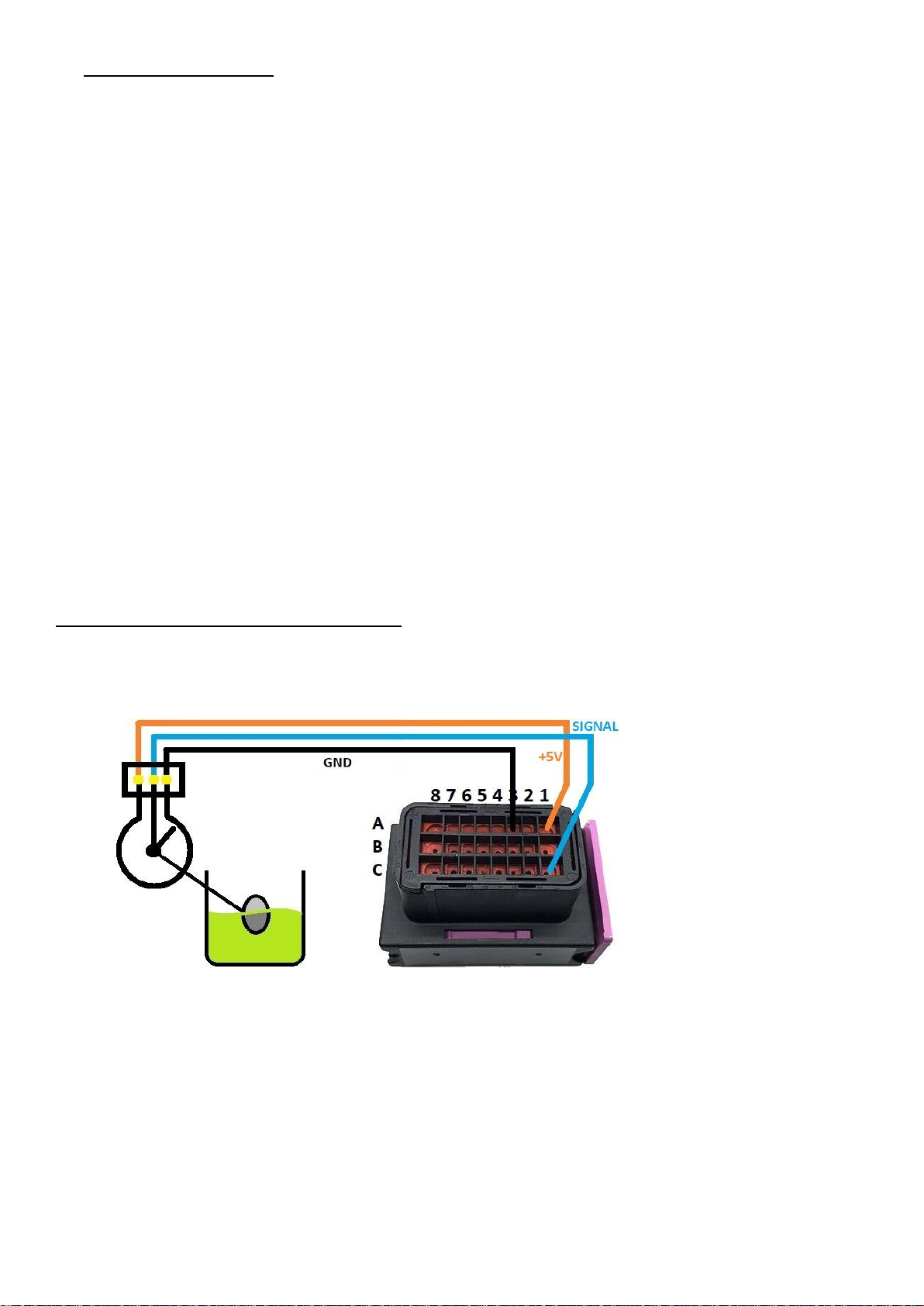

Pin C1: Analog Input 0 (Fuel Level Sensor) –MAX INPUT VOLTAGE 5V ! (unprotected)

Pin C2: Analog Input 1 (Pressure Sensor) –MAX INPUT VOLTAGE 5V ! (unprotected)

Pin C3: Analog Input 2 (Temperature Sensor) –NTC or PTC, MAX INPUT VOLTAGE 5V ! (unprotected)

Pin C4: Analog Input 3 (Configurable Input/Neutral) –any type of sensor, MAX INPUT VOLTAGE 5V ! (unprotected)

Since firmware V7.3.3 and GUI V3.6.2KN Configurable input can be used as Digital Input for Neutral switch

(in this case, connecting to GND means >> Neutral is selected)

Pin C5: VEMS Serial RS232 data (ECU pin EC18/14)

Pin C6: VEMS Serial RS232 data (ECU pin EC18/15)

Pin C7: PWR connector of display unit –Pin 6 (GND of display unit power supply)

Pin C8: Main Power Supply GND –connect to the battery negative terminal or vehicle ground