2

Table of Contents

Initial Information ........................................................................................................................................ 4

Legal isclaimer ....................................................................................................................................... 4

Planning Guide ......................................................................................................................................... 4

Getting Started ............................................................................................................................................ 5

Power up on the bench ............................................................................................................................ 5

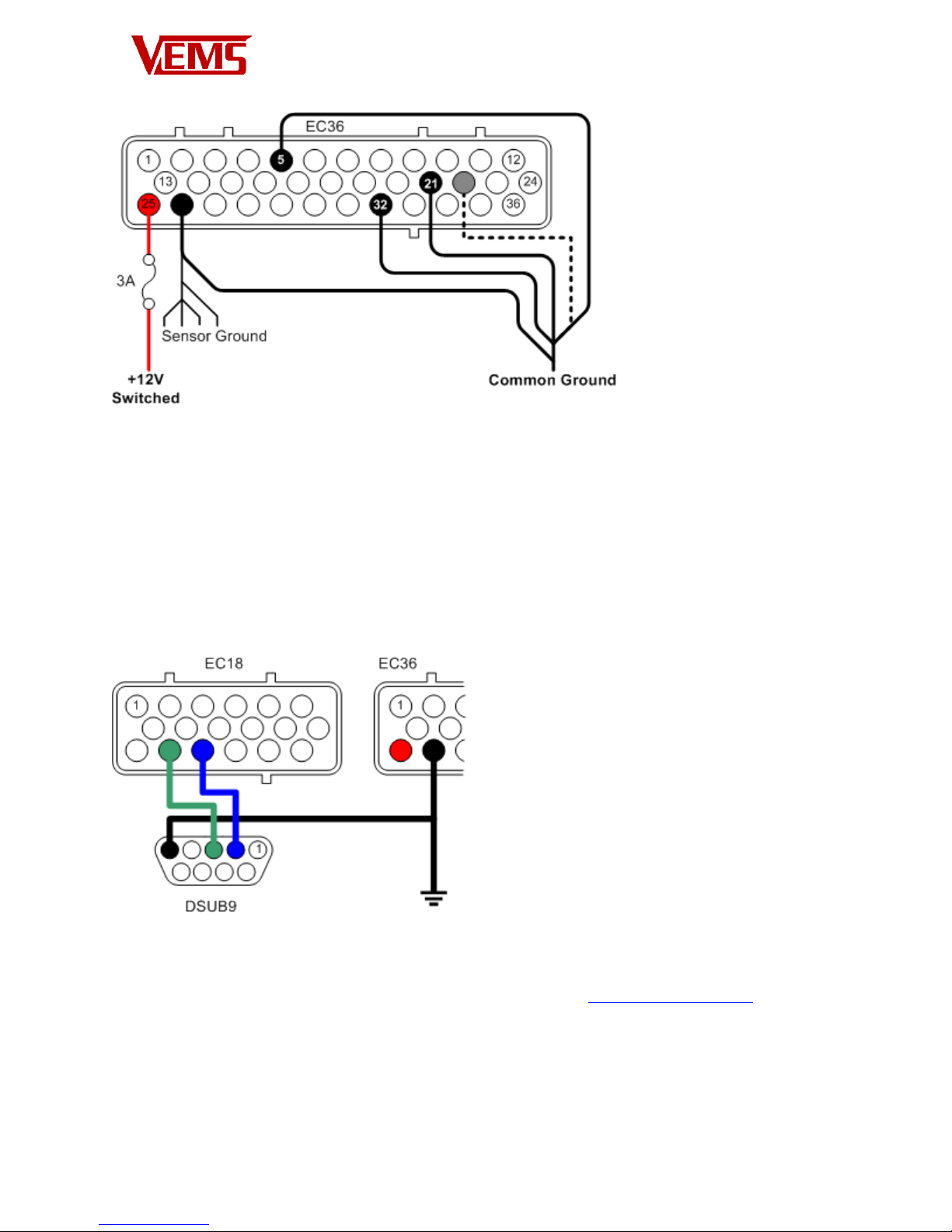

Grounds ................................................................................................................................................... 5

Power Grounds .................................................................................................................................. 5

Sensor Ground ................................................................................................................................... 6

+12V Supply ............................................................................................................................................. 6

Connecting serial port .............................................................................................................................. 7

Connect essential sensors ............................................................................................................................ 8

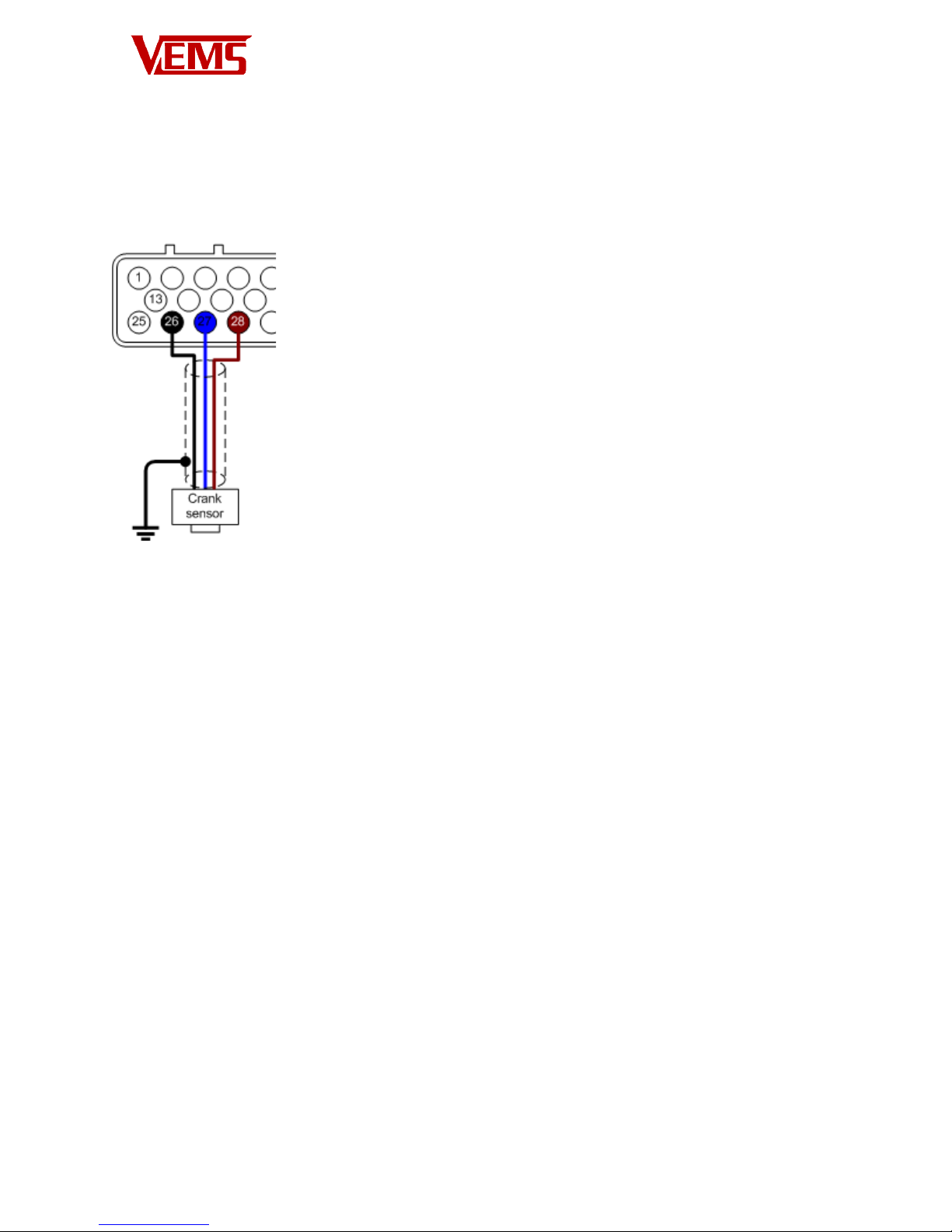

Crank Trigger ............................................................................................................................................ 8

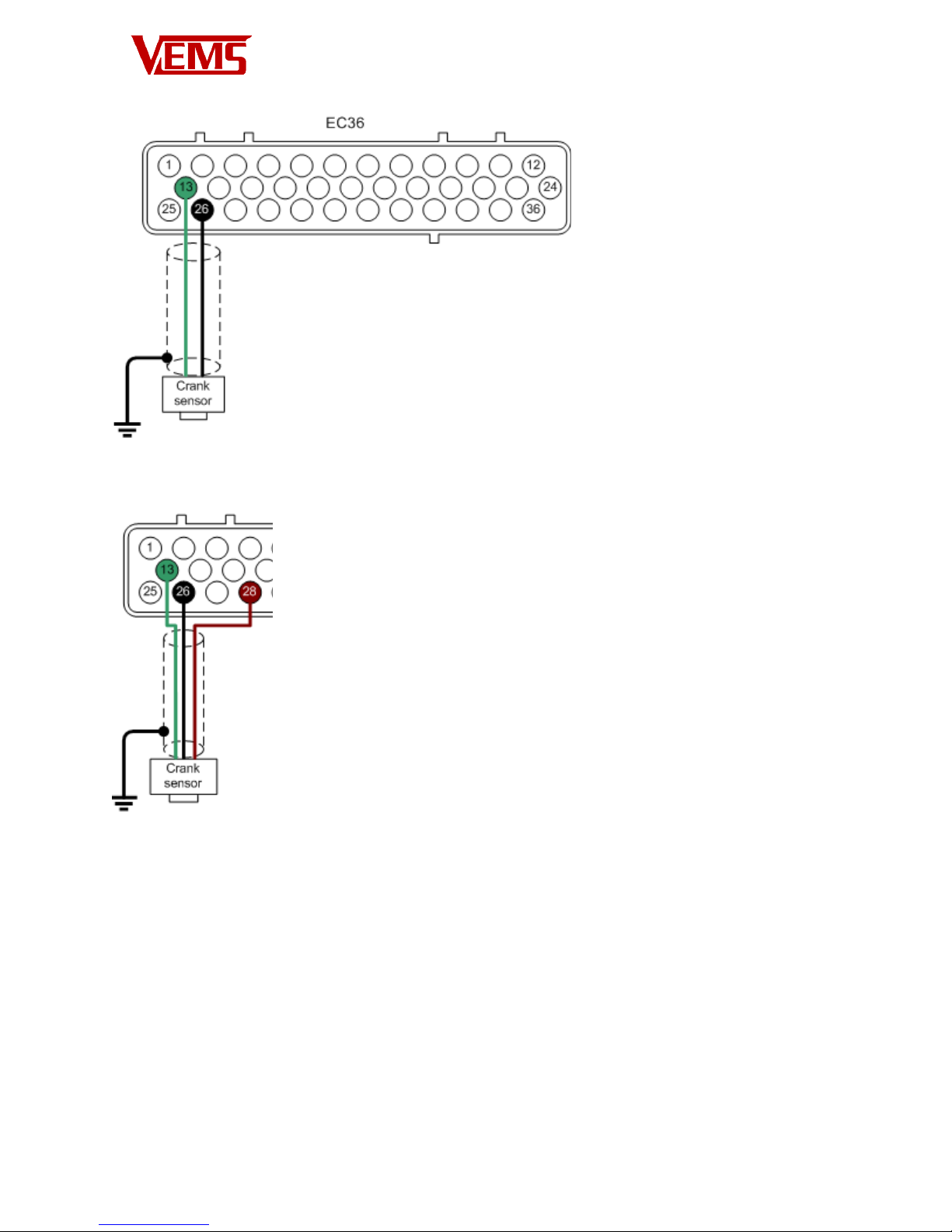

Connecting the primary trigger (Crank) ................................................................................................... 8

Configuring the crank trigger ................................................................................................................... 9

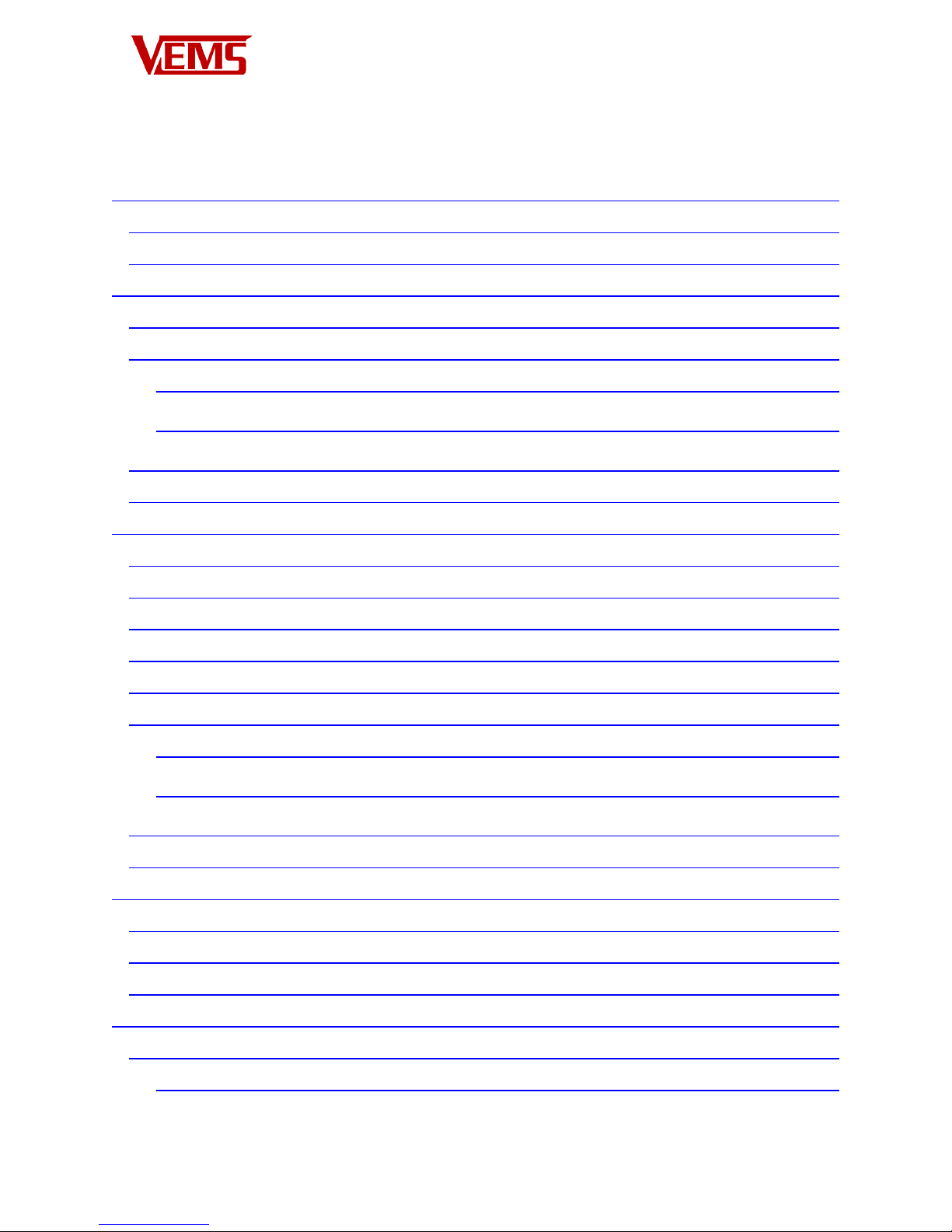

Connecting the Secondary Trigger (Cam) ................................................................................................. 9

Configuring the Secondary Trigger (Cam) .............................................................................................. 10

Temperature Sensors ............................................................................................................................. 10

IAT – Inlet Air Temperature .............................................................................................................. 10

CLT – Coolant Temperature .............................................................................................................. 10

TPS – Throttle Position Sensor ............................................................................................................... 11

Configuring the TPS sensor ................................................................................................................... 11

Secondary Sensors ..................................................................................................................................... 12

WBO2 ..................................................................................................................................................... 12

EGT ........................................................................................................................................................ 12

Knock .................................................................................................................................................... 13

Primary Outputs ........................................................................................................................................ 14

Connecting Ignition Components .......................................................................................................... 14

Example coil connections ................................................................................................................ 16