Introduction

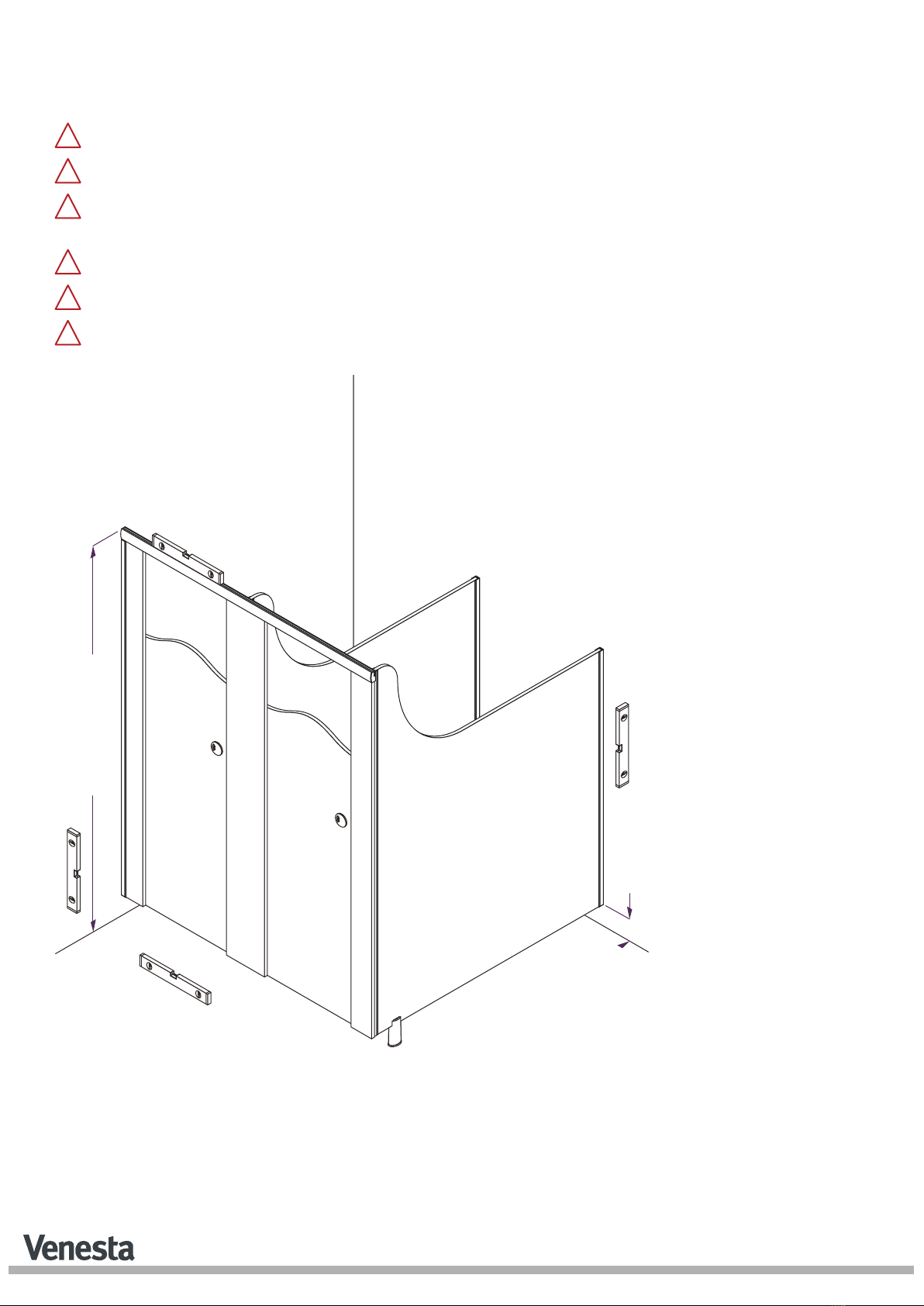

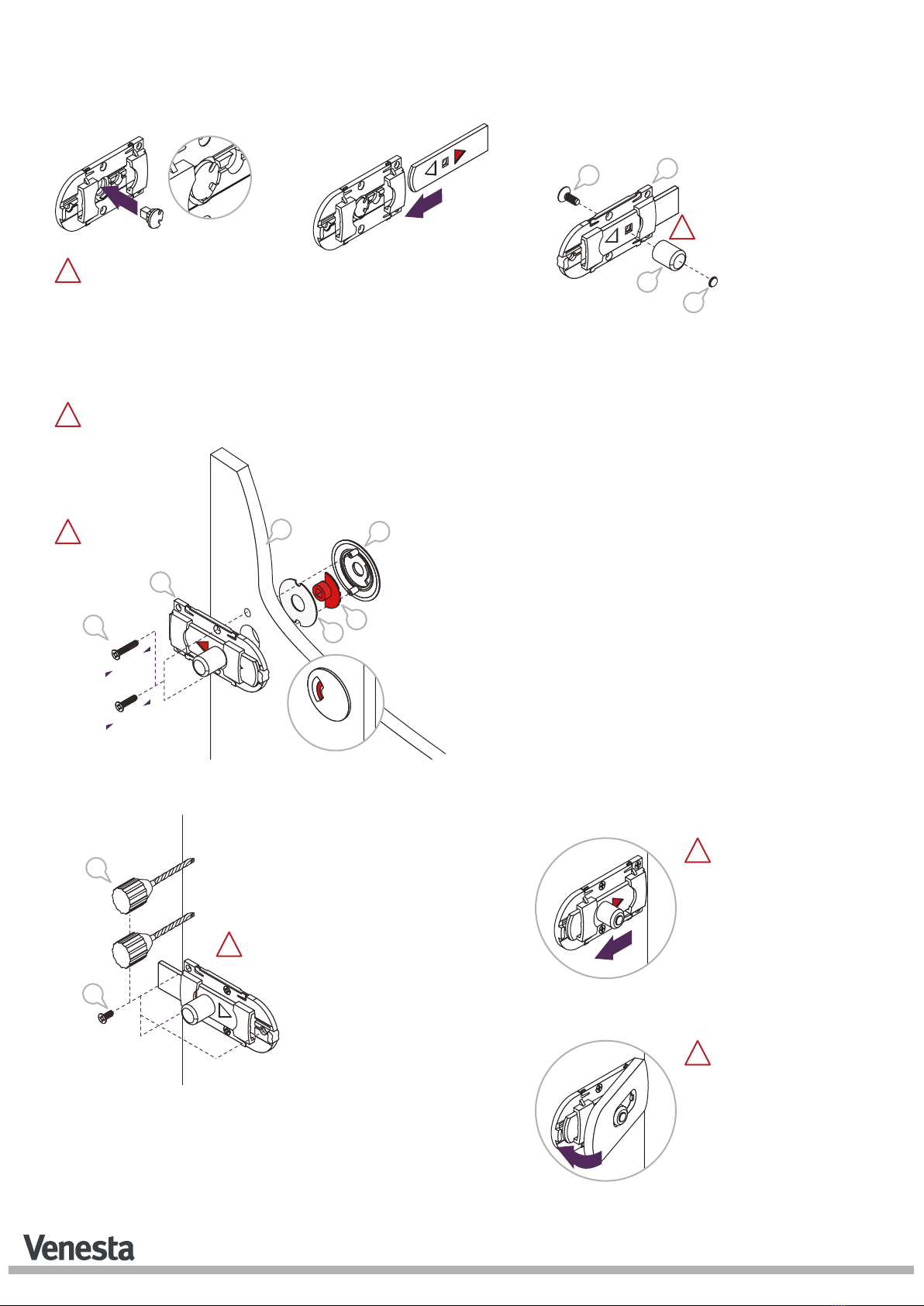

Secure Fixing

It is vital that the structural integrity of walls, ceilings

and floors is capable of taking the dynamic and static

loads imposed by the fixings to support the product.

Insufficient structural integrity will invalidate

guarantees.

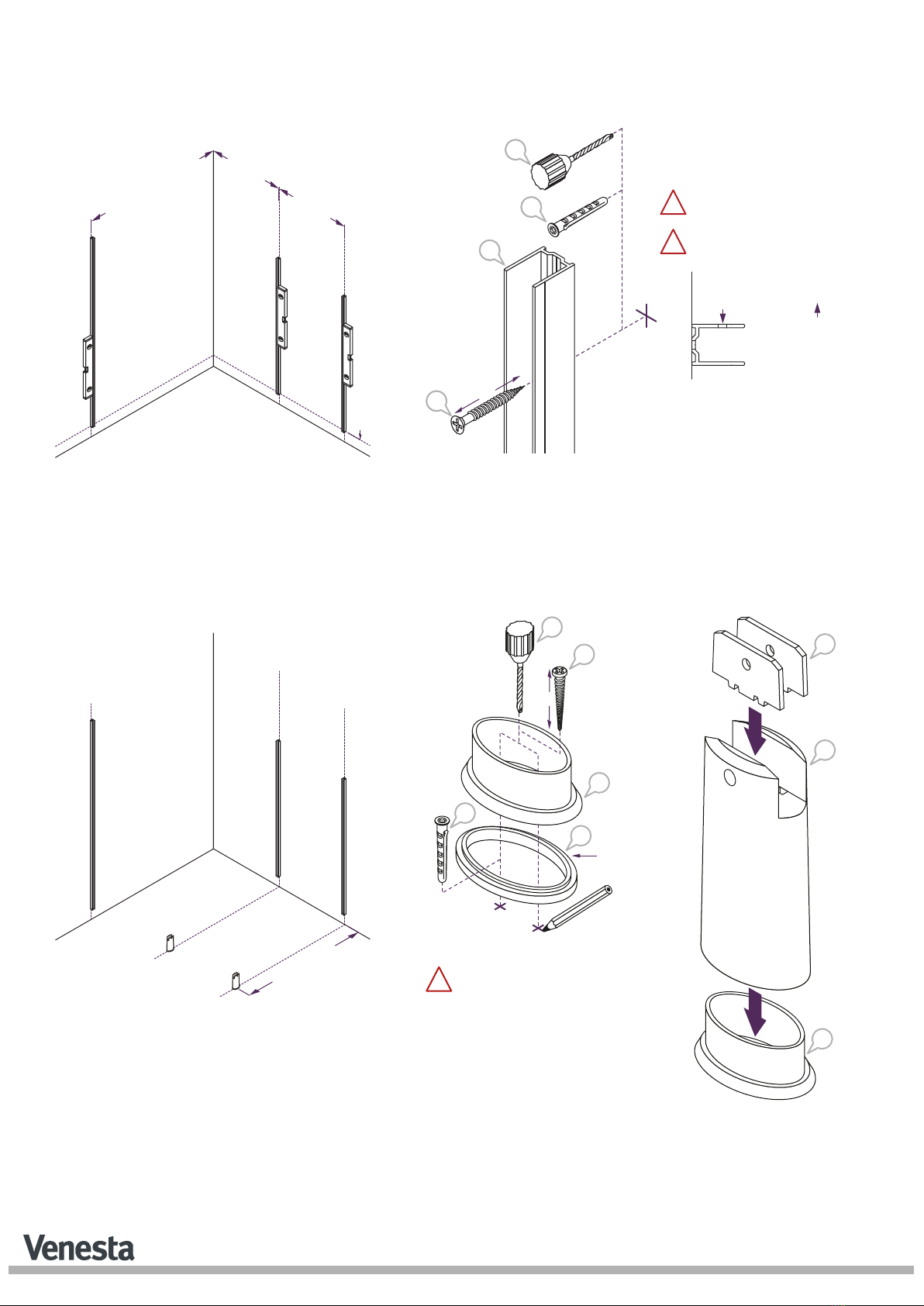

The surfaces being fixed into should be firm and

stable, without deflection and have good fixing

retention properties over the length and width of the

bearing surface.

Particular care should be taken with studwork walls

and suspended ceilings which will usually require the

inclusion of a pattress to sufficiently strengthen the

structure.

Poor security of fixings will compromise performance

and could lead to failure of the vanity units, cubicle or

duct systems.

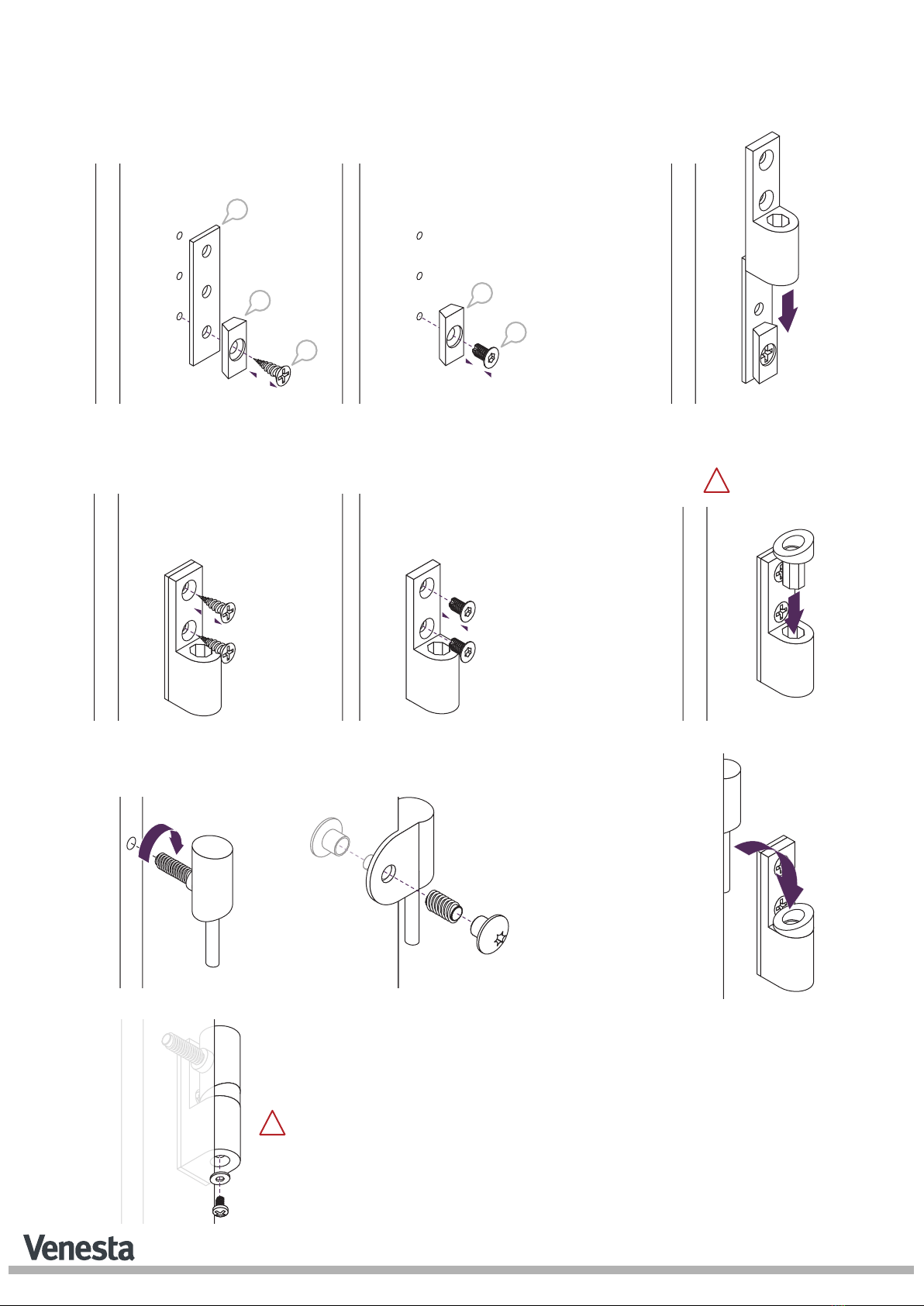

Screws and Fixings supplied to fix components to the

floor or wall structural material should be tested to

ensure they are suited and have sufficient holding

power to accept the static and dynamic loads

required to support our products. Due to the

multitude of floor and wall constructions, it should not

be assumed that the fixings supplied are suitable for

all installations. If you are uncertain contact your

local specialist fastening supplier.

Do NOT overtighten fasteners, if using power drivers

make sure that the torque settings are correct.

Cleaning & Maintenance

Please consult our cleaning & maintenance guide.

Panel Storage & Conditioning

• To ensure panels and doors remain flat ambient

site conditions must be stable prior to delivery.

Variable temperature and humidity can cause panels

to bow and twist irreversibly.

• Before, during and after installation, temperature

and humidity must be maintained between 18 - 25˚C.

• Panels should not be stored outside or in areas

where they may be exposed to water or humidity.

• Wet trades and forced-drying procedures should be

complete and the building fully dried out.

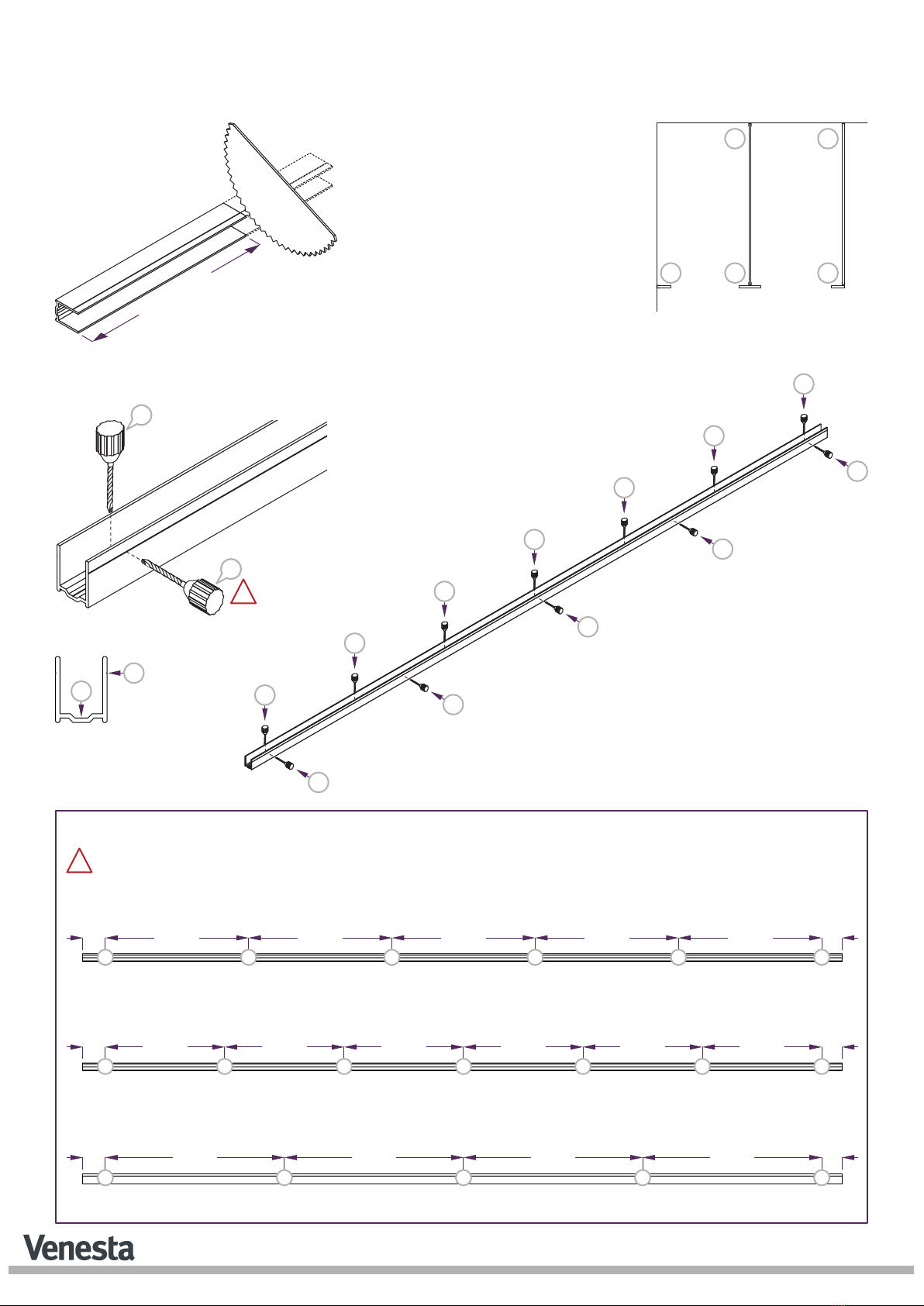

• Use supports and spacers to elevate panels off the

floor and keep space between panels; air must be

able to circulate around each panel evenly.

• The ideal base is a slatted pallet with base board;

however, if these are not available, panels should be

carefully stacked on bearers suitably spaced to

maintain flatness. Spacing of bearers should not

exceed 400mm.

• Avoid storage conditions where extremes of

temperature and humidity can occur.

• Panels must be allowed to equalise to levels

approximating to those that will prevail during

building use.

• BS EN438 recommendations should be adhered to:

Temperature – 18 to 25˚C

Air humidity – 40 to 60%

BS 4965 Flatness: Flatness to BS 4965 can only be

guaranteed at the time of delivery.

PrerequisitesSafety

3

627-124-14 (11/22)

Toolbox