9

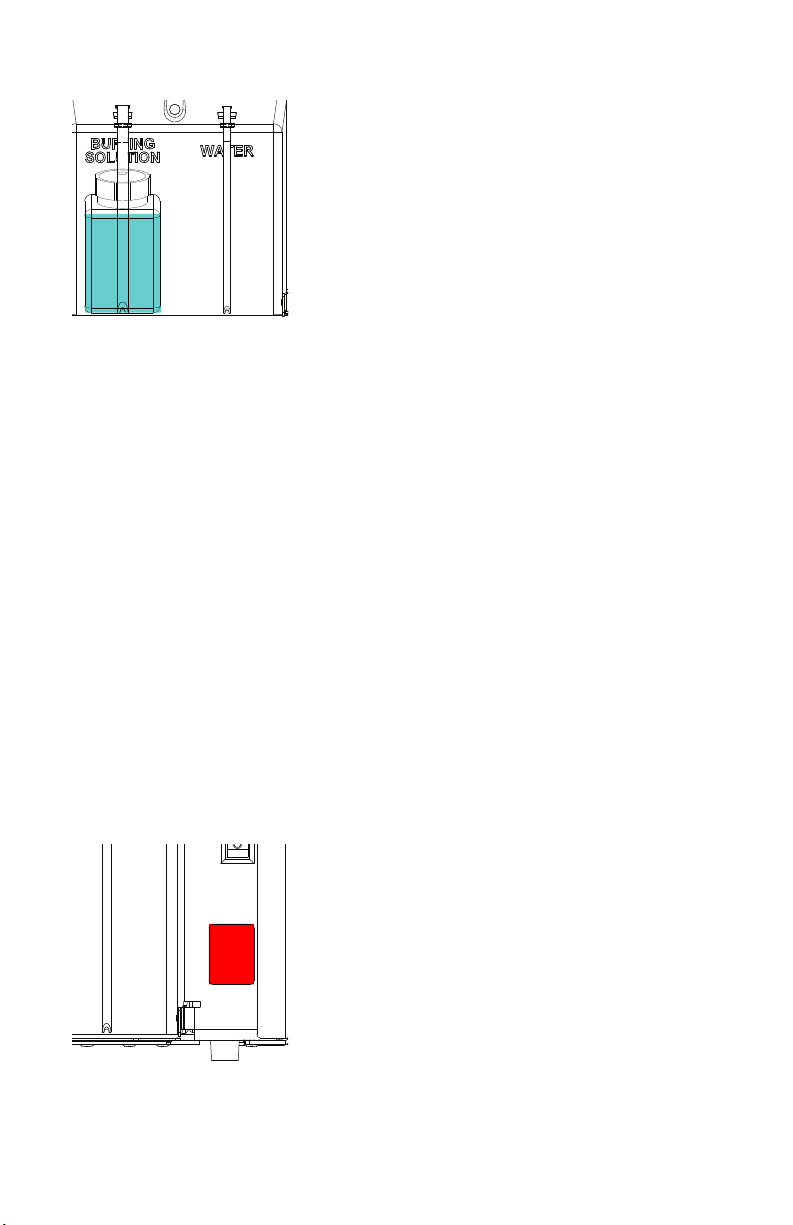

5. Prep Bung Solution and Water Lines:

Warning: Failure to prep the Bung Solution &

Water lines will cause damage to both the disc

and the Bung Pads!

The top cover must be in the open position to

perform these steps. Have a paper towel or small

container ready, in order to catch the Bung

Solution and the Water, which will come from the

tube nozzles.

Locate the two smaller buttons, labeled“C”& “W”, on the front User Keypad.

“C” = Bung Solution & “W”= Water.

To activate the prepping process, press either the “C” or the “W” button. Note:

Both lines can be prepped at the same time.

Once the prepping process has been activated, tilt the Top Cover down

toward you, at about a 45 degree angle. (Note: Make sure that the Platen

Assembly is installed, so that solution and water does not pour directly onto

the shaft of the main motor!) This will ensure that the solution and the water

drips out of the nozzles and onto the paper towel.

Once the Bung Solution and the Water comes out of the designated tube

nozzles and there is no more air left in the lines, press the“C” and the “W” button

to stop the prepping process. Leave the Top Cover in the Open position.

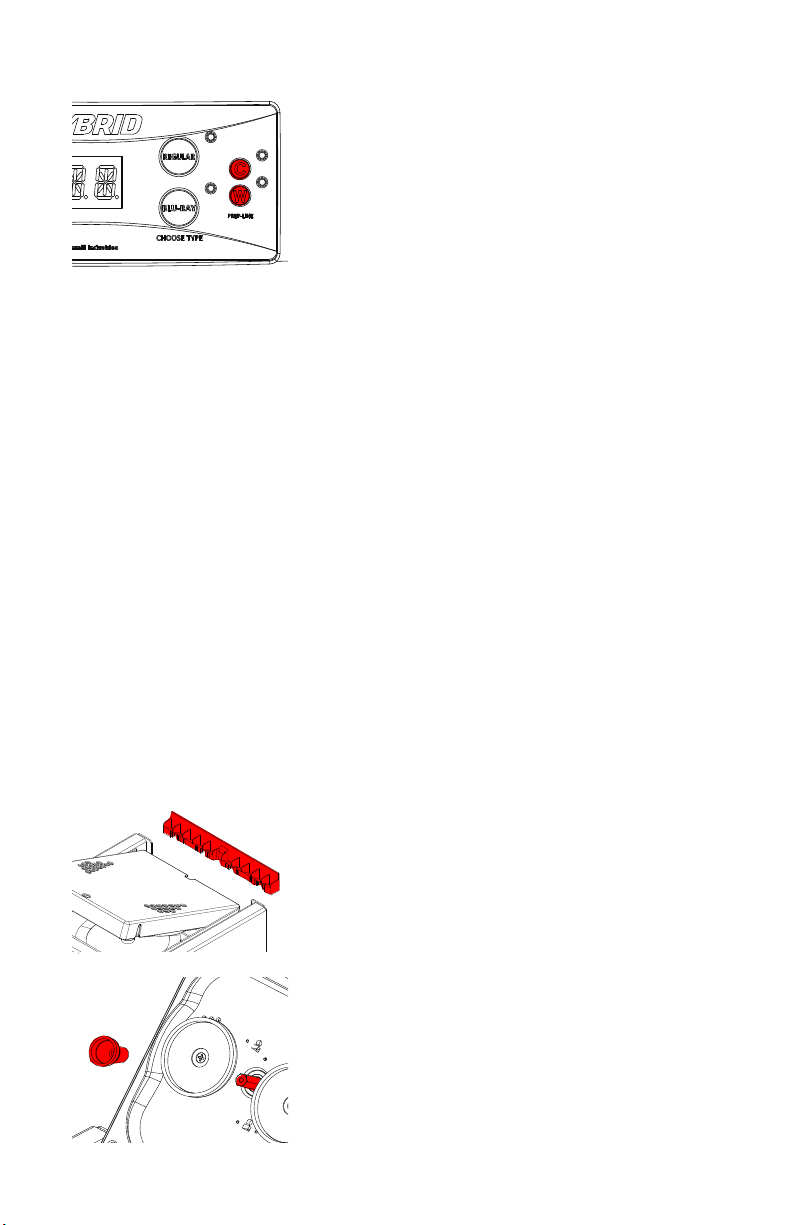

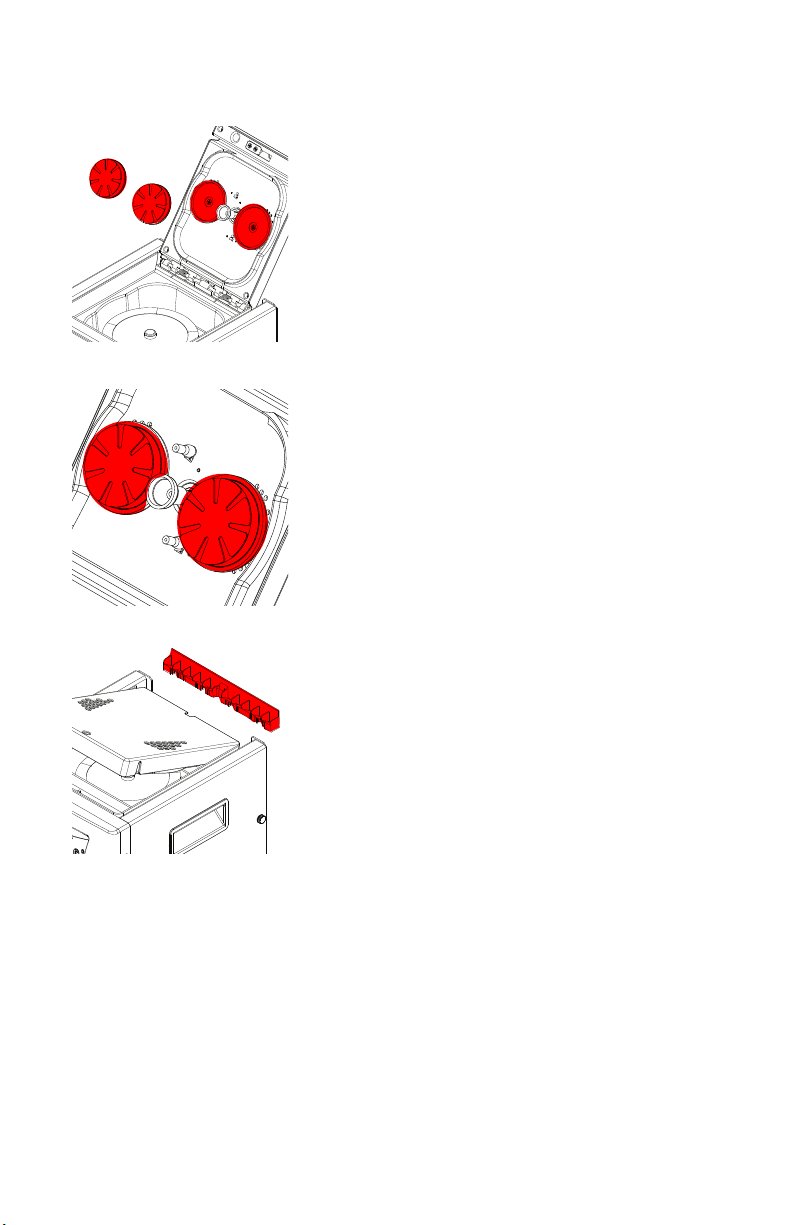

6. Install the Center Hub:

Locate and remove the Lid Stopper. Let the Top

Cover gently open to its farthest position. Locate

the Hex shaped post between the two Bung

Pad holders.

Take a Center Hub and line up the hex shaped

opening on the hub with the hex shaped

post. Push the Center Hub into place. Spin the

Center Hub by hand to make sure that the hub

is installed properly. The Center Hub should

not wobble when it spins. If needed, make an

adjustment. Leave the Top Cover in the Open

position.