World Class Products World

lass Value World Class Product s World Class Value World Class Product s World Class Value World Class Product s

Venom Air Corps www.venom-aircorps.com Venom Air Corps www.venom-aircorps.com Venom Air Corps

World Class Products World

lass Value World Class Product s World Class Value World Class Product s World Class Value World Class Product s

Venom Air Corps www.venom-aircorps.com Venom Air Corps www.venom-aircorps.com Venom Air Corps

Throttle

Up

Throttle

Down

Pitch

Adjustment

Throttle

Adjustment

3D

Mode

Switch

23

14

Throttle

Up

Throttle

Down

Pitch

Adjustment

Throttle

Adjustment

3D

Mode

Switch

23

14

7

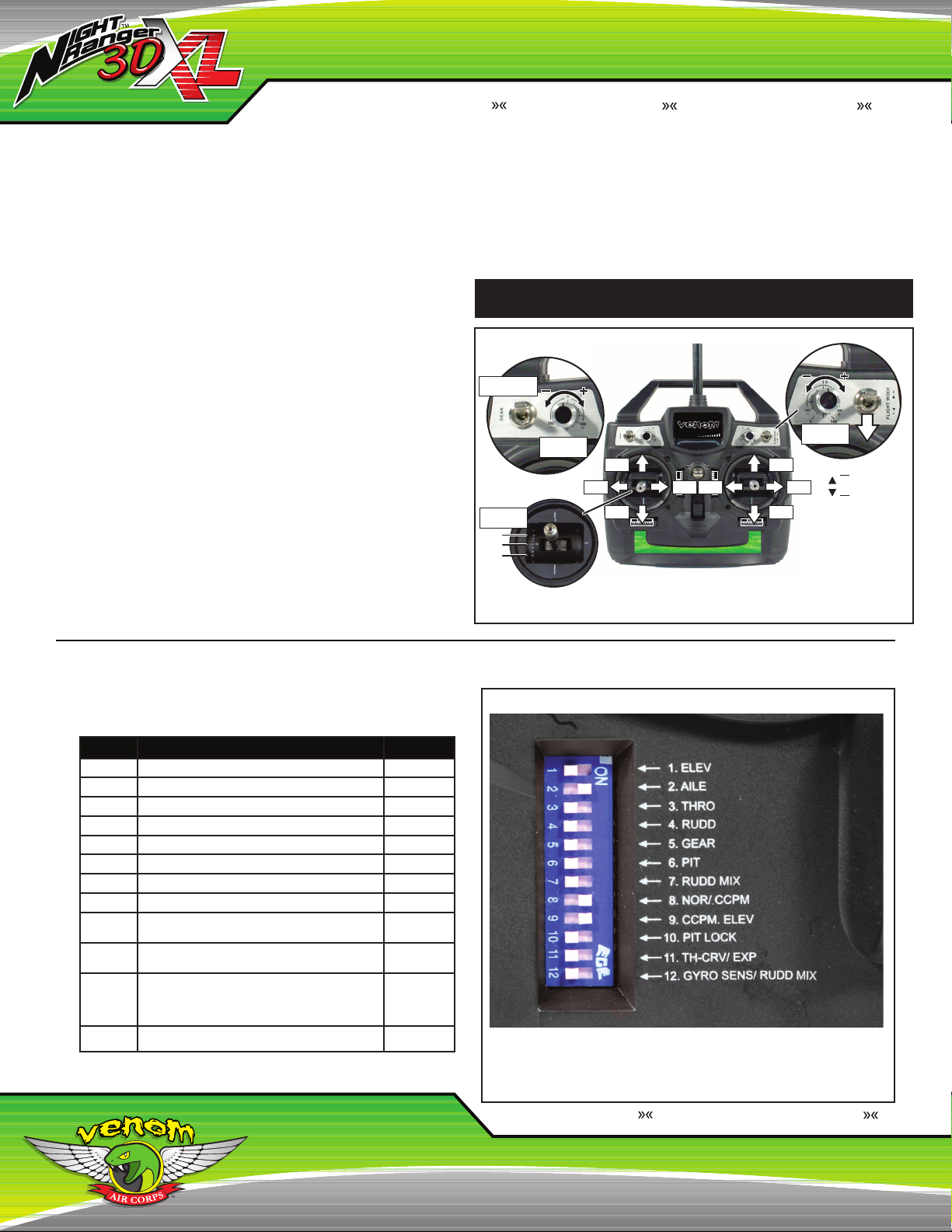

RADIO TRIM ADJUSTMENTS

(FINE TUNING):

MODE I - EUROPE & AUSTRALIA MODE II - NORTH AMERICA

ATTENTION: BEFORE CONNECTING THE BATTERY TO THE ESC, YOU MUST CONFIRM

THE FOLLOWING SETTINGS. MAKE SURE THE VNR 3DXL™ IS TURNED OFF DURING

THIS PROCESS!

1. The crystals on the radio and the receiver must match each other.

2. Antenna is screwed in and extended, batteries are fully charged and radio has been turned

on.

3. The throttle stick must be located in the throttle off position, otherwise serious damage to the

VNR 3DXL™ and personal injury may occur.

4. Make sure the Flight Mode switch is in the Normal Flight Mode.

If all of the above settings are confirmed, connect the battery to the ESC.

After the battery is connected, wait for the gyro to initialize (as described on page 5) before

flying. If the LED does not blink after the battery is connected, please check that you have

switched on the radio and that the battery is fully charged.

NOTE: If the throttle stick is not in the throttle off position when the battery is connected, the

gyro will still initialize but the throttle stick will not be active until it is returned to the throttle off

position. If the radio is working properly and the helicopter suddenly seems to shut off, that

condition is the result of a loss of signal or interference. The radio system has a built in fail safe

to prevent a run away helicopter. In the event of signal loss, the receiver is designed to stop its

activity and neutralize the helicopter to minimize damage to it and any property it may come in

contact with.

If the main rotor blades start rotating, and

the right control stick has not been pushed

forward, slowly adjust the radio trim 3until

they stop rotating.

If the main rotor blades start rotating, and

the left control stick has not been pushed

forward, slowly adjust the radio trim 2until

they stop rotating.

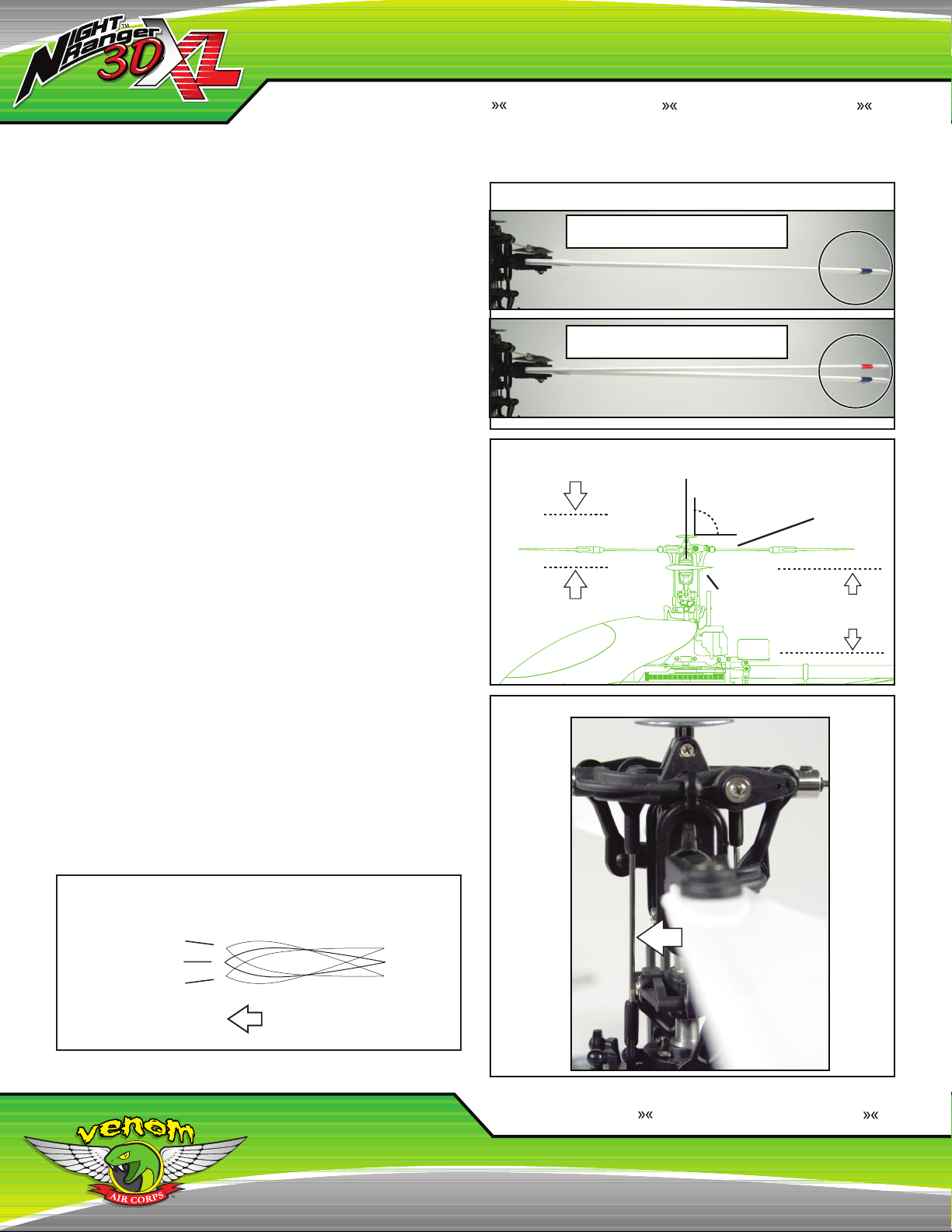

Make sure the swashplate is horizontal to the

ground. If the swashplate is not horizontal

from front to back, adjust the radio trim 2

until it is level to the ground (Fig. O). If the

swashplate is not horizontal from side to side,

adjust the radio trim 4until it is level to the

ground (Fig. O). Test the flight controls to

make sure they are operating properly and

the swashplate moves in the direction you

want to fly.

Make sure the swashplate is horizontal to the

ground. If the swashplate is not horizontal

from front to back, adjust the radio trim 3

until it is level to the ground (Fig. P). If the

swashplate is not horizontal from side to side,

adjust the radio trim 4until it is level to the

ground (Fig. P). Test the flight controls to

make sure they are operating properly and

the swashplate moves in the direction you

want to fly.

Push the right control stick slightly forward

to start the blade rotation. Keep your fingers,

eyes and other objects clear of the rotating

parts. When the main rotor blades start

rotating, the tail blades should start rotating

simultaneously.

Push the left control stick slightly forward to

start the blade rotation. Keep your fingers,

eyes and other objects clear of the rotating

parts. When the main rotor blades start

rotating, the tail blades should start rotating

simultaneously.

Slowly push the right control stick forward

to increase rotor speed. The VNR 3DXL™

may not take off vertically; it may go forward

or backwards, left or right. Continue to push

the right control stick forward and bring the

helicopter to a hovering height of waist high.

While hovering, use trim sliders 2 & 4to

fine tune the VNR 3DXL™ while hovering.

You may also find the helicopter’s nose

will swing to the left or right side when you

increase throttle. In this case, you need to

adjust the radio trim 1.

Slowly push the left control stick forward to

increase rotor speed. The VNR 3DXL™ may

not take off vertically; it may go forward or

backwards, left or right. Continue to push

the left control stick forward and bring the

helicopter to a hovering height of waist high.

While hovering use trim sliders 3 & 4to fine

tune the VNR 3DXL™ while hovering. You

may also find the helicopter’s nose will swing

to the left or right side when you increase

throttle. In this case, you need to adjust the

radio trim 1.

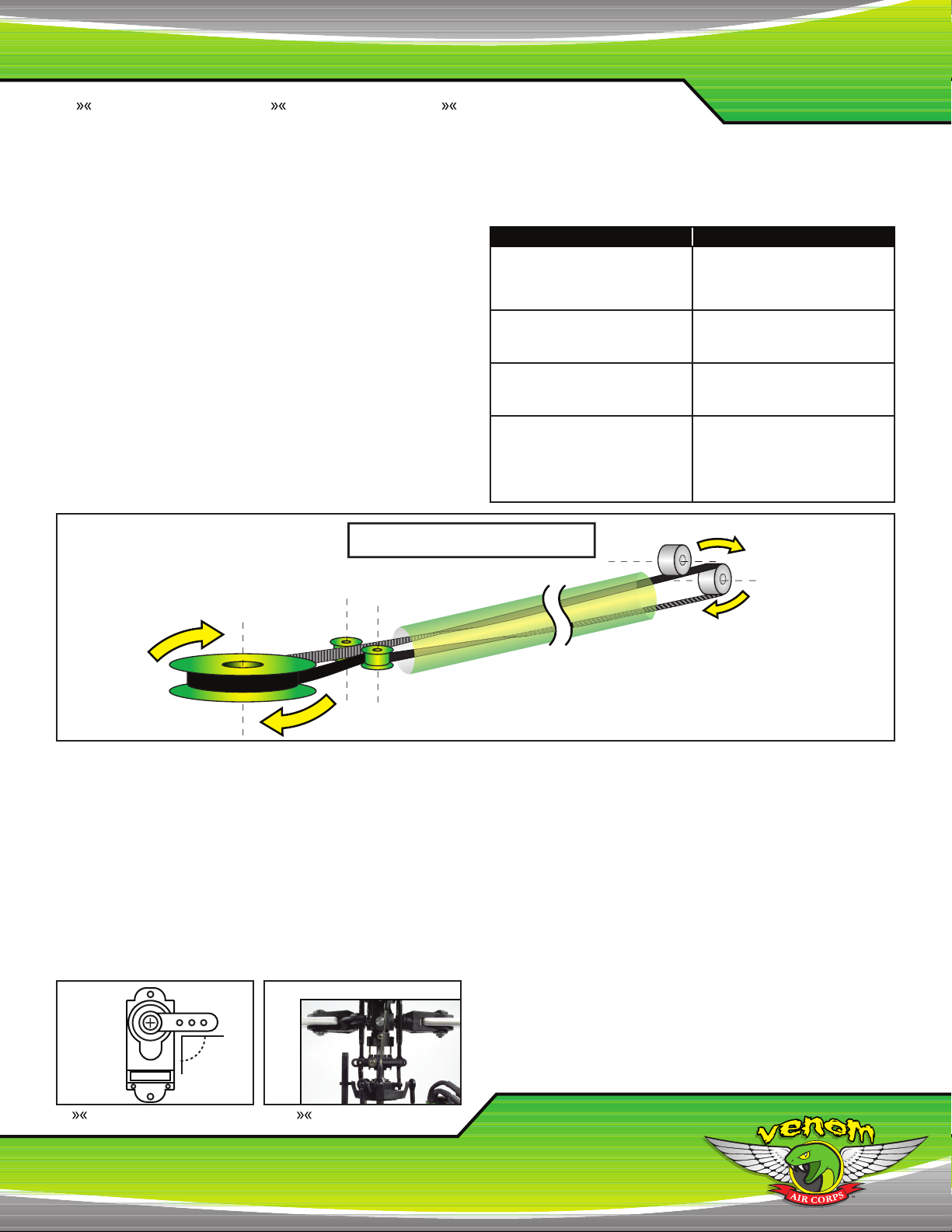

V. TUNING THE VNR 3DXL™

LESS RESPONSIVE:

- Reducing the throw of the Aileron and Elevator Cyclic will help make

the helicopter less sensitive. To do this move the pivot balls on the

servo arm to the inner most holes.

- With the head speed function selected (DIP switch #11) you can turn

down the head speed, which allows for a longer flight and makes

the helicopter less sensitive to control inputs. Do note that in windy

conditions, it is better to run a little bit higher head speed.

MORE RESPONSIVE:

- Increase the head speed, this will give you a faster response time,

but less flight time. Refer to the Pitch Range & Curve Adjustment

section on changing the head speed. Changing the head speed is

not only more effective than adding more cyclic throw, but has a

more positive response. Increasing the cyclic travel only binds the

head mechanics causing a loss of power and control.

NOTE: MODE I - EUROPE & AUSTRALIA

NOTE: MODE II - NORTH AMERICA

Fig. O

Fig. P