VentAHood Equipped with Magic Lung Blower Operating manual

Other VentAHood Ventilation Hood manuals

VentAHood

VentAHood ISLAND RANGE HOOD User manual

VentAHood

VentAHood K250 ARS User manual

VentAHood

VentAHood RM1000 Operating manual

VentAHood

VentAHood AH12 User manual

VentAHood

VentAHood K-SERIES User manual

VentAHood

VentAHood EUROLINE User manual

VentAHood

VentAHood K250 ARS User manual

VentAHood

VentAHood Ventilation Hood Models Equipped with K250... User manual

VentAHood

VentAHood K250 ARS User manual

VentAHood

VentAHood M600 User manual

VentAHood

VentAHood XLH12 User manual

VentAHood

VentAHood CWSH3 User manual

VentAHood

VentAHood T400 User manual

VentAHood

VentAHood EUROLINE User manual

VentAHood

VentAHood B100 User manual

VentAHood

VentAHood VP526 User manual

VentAHood

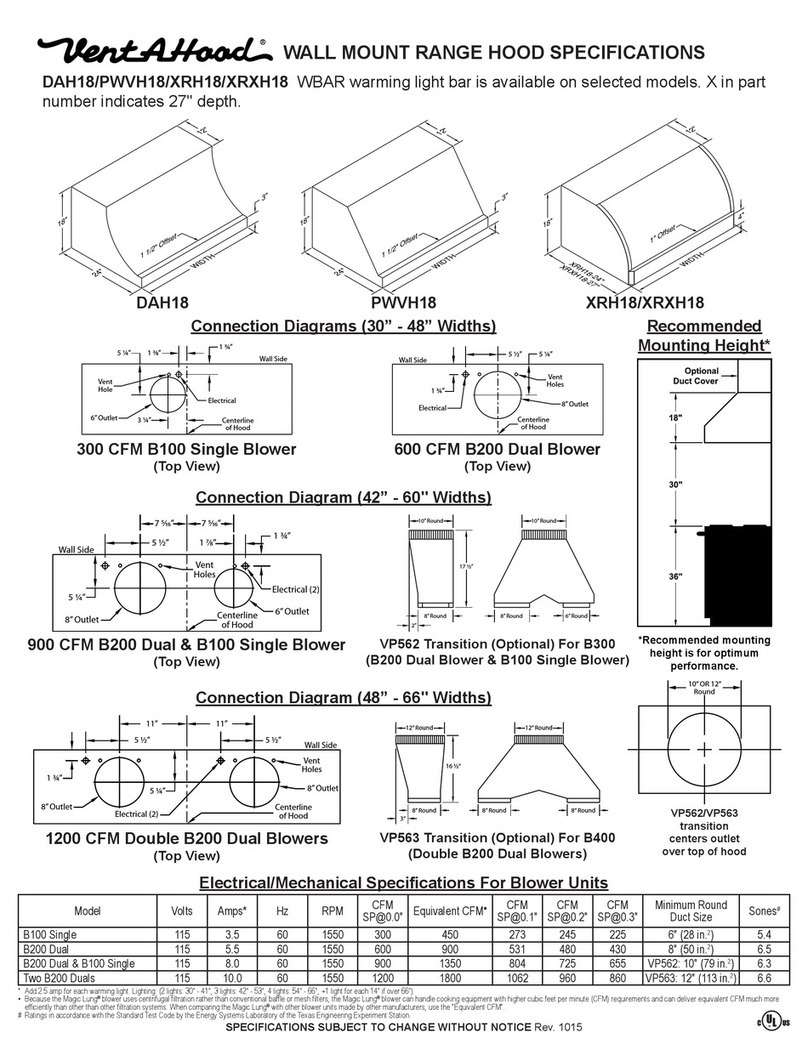

VentAHood DAH18 User manual

VentAHood

VentAHood B100 Single User manual

VentAHood

VentAHood CILH9 ISLAND RANGE HOOD User manual

VentAHood

VentAHood ISLAND RANGE User manual

Popular Ventilation Hood manuals by other brands

Gorenje

Gorenje S3 IHGC963S4X manual

KOBE

KOBE ISX2136SQB-1 Installation instructions and operation manual

U.S. Products

U.S. Products ADVANTAGE-100H Information & operating instructions

Kuppersberg

Kuppersberg DUDL 4 LX Technical Passport

Framtid

Framtid HW280 manual

Thermador

Thermador HGEW 36 FS installation manual