Ventmatika EKA Series Instruction manual

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

Technical data

Mounting

Maintenance

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

1

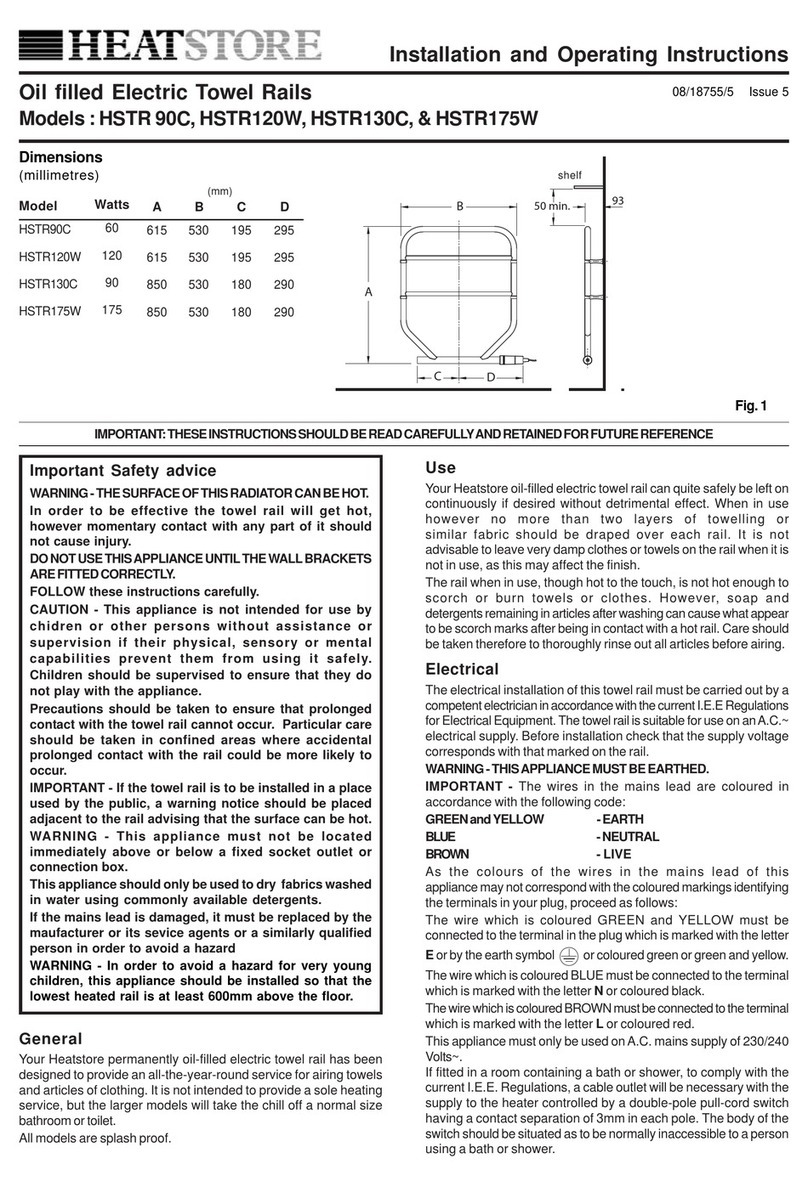

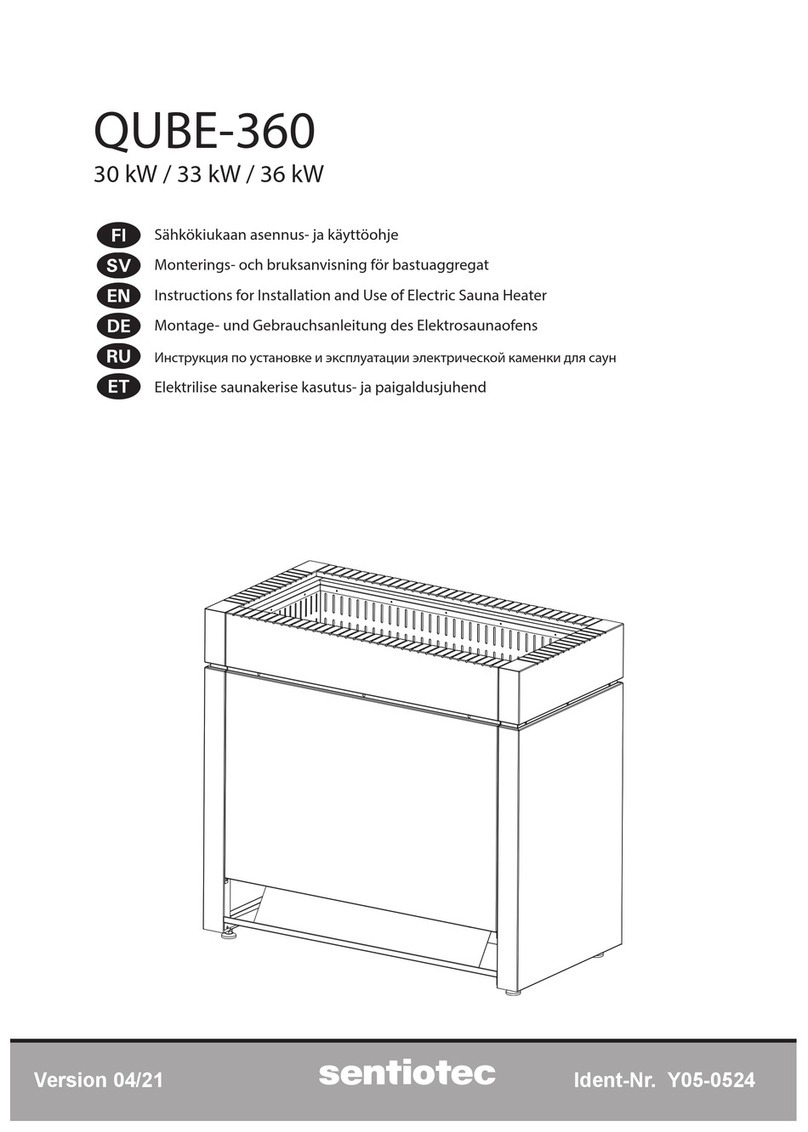

Electrical duct heaters EKA are designed to heat fresh air in ventilation systems. Casing (EKA

protection class IP 44, except EKA Type NV which protection class IP 30) is made from Aluzinc coated

steel which is high temperature proof and with rubber seals for duct connection. Heating elements

tube is made from stainless steel AISI 304. There are 2 protection thermostats and screw terminals

for easy connection installed in the heaters.

Heaters can be installed horizontally with the electrical connection box facing upwards or

sideways and vertically (only if the air flow direction upwards). The air velocity in the duct of the

heater must be 1,5 m/s minimum. The maximum temperature of the output is 50 °C.

k

DB

C

D

50 50

A

D+63 B

PS PS C

D

50 50

A

≤1,5 kW (1~230V)

<3,0 kW (2~400V); ≤3,0 kW (3~400V)

Description

Dimensions

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

2

D+25 B

C

D

50 50

A

D+25+63 B

PS PS C

D

50 50

A

>1,5 kW (1~230V)

≥3,0 kW (2~400V); >3,0 kW (3~400V)

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

3

Heater type

A(mm)

B(mm)

C(mm)

D(mm)

EKA 100

370

276

71

100

EKA 125

370

276

71

125

EKA 160

370

276

71

160

EKA 200

370

276

71

200

EKA 250

370

276

71

250

EKA 250-12kW

500

402

71

250

EKA 250-15kW

630

532

71

250

EKA 315

373

276

71

315

EKA 315-12kW

500

402

71

315

EKA 315-15kW

630

532

71

315

EKA 315-18kW

630

532

71

315

EKA 355

373

276

71

355

EKA 355-12kW

500

402

71

355

EKA 355-15kW

630

532

71

355

EKA 355-18kW

630

532

71

355

EKA 400

373

276

81

400

EKA 400-12kW

500

402

81

400

EKA 400-15kW

630

532

81

400

EKA 400-18kW

630

532

81

400

EKA 400-21kW

770

672

81

400

EKA 400-24kW

880

782

81

400

EKA 450

373

276

81

450

EKA 450-12kW

500

402

81

450

EKA 450-15kW

630

532

81

450

EKA 450-18kW

630

532

81

450

EKA 450-21kW

770

672

81

450

EKA 450-24kW

880

782

81

450

EKA 500

373

276

81

500

EKA 500-12kW

500

402

81

500

EKA 500-15kW

630

532

81

500

EKA 500-18kW

630

532

81

500

EKA 500-21kW

770

672

81

500

EKA 500-24kW

880

782

81

500

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

4

Heater type

Diameter

(mm)

Min. airflow

(m³/h)

Power supply

(VAC/50Hz)

Power

(kW)

Available

heating

elements (kW)

EKA 100

100

45

1~230

0,3...1,8

0,3

EKA 125

125

70

1~230

0,3...3,6

0,3/0,6

EKA 160

160

110

1~230

0,3...7,2

0,3/0,6/1,0/1,2

2~400

1,0...6,0

1,0

3~400

3,0...6,0

1,0

EKA 200

200

170

1~230

0,3...7,2

0,3/0,6/1,0/1,2

2~400

1,0...6,0

1,0

3~400

3,0...9,0

1,0/1,5

EKA 250

250

265

1~230

0,3...7,2

0,3/0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 250-12kW

250

265

3~400

12,0

1,0/1,5

EKA 250-15kW

250

265

3~400

15,0

1,0/1,5

EKA 315

315

425

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 315-12kW

315

425

2~400

12

1,0/1,5

3~400

12

1,0/1,5

EKA 315-15kW

315

425

2~400

15

1,0/1,5

3~400

15

1,0/1,5

EKA 315-18kW

315

425

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 355

355

535

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 355-12kW

355

535

2~400

12

1,0/1,5

3~400

12

1,0/1,5

EKA 355-15kW

355

535

2~400

15

1,0/1,5

3~400

15

1,0/1,5

EKA 355-18kW

355

535

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 400

400

680

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 400-12kW

400

680

1~230

9

1,0

2~400

12

1,0/1,5

3~400

12

1,0/1,5

EKA 400-15kW

400

680

1~230

12

1,0

2~400

15

1,0/1,5

3~400

15

1,0/1,5

Technical data

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

5

EKA 400-18kW

400

680

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 400-21kW

400

680

3~400

21

1,0/1,5

EKA 400-24kW

400

680

3~400

24

1,0/1,5

EKA 450

450

860

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 450-12kW

450

860

1~230

9

1,0

2~400

12

1,0/1,5

3~400

12

1,0/1,5

EKA 450-15kW

450

860

1~230

12

1,0

2~400

15

1,0/1,5

3~400

15

1,0/1,5

EKA 450-18kW

450

860

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 450-21kW

450

860

3~400

21

1,0/1,5

EKA 450-24kW

450

860

3~400

24

1,0/1,5

EKA 500

500

1060

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 500-12kW

500

1060

1~230

9

1,0

2~400

12

1,0/1,5

3~400

12

1,0/1,5

EKA 500-15kW

500

1060

1~230

12

1,0

2~400

15

1,0/1,5

3~400

15

1,0/1,5

EKA 500-18kW

500

1060

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 500-21kW

500

1060

3~400

21

1,0/1,5

EKA 500-24kW

500

1060

3~400

24

1,0/1,5

Heaters conforms to requirements of standards:

LST EN 60335-2-30:2003+A1:2005+A2:2007

LST EN 60335-2-30:2010+AC:2010+A11:2012 (EN 60335-2-30:2009+AC:2010+A11:2012)

and therefore complies with the essential requirements and provisions of the 2006/95/EC

and 2004/108/EC Directives.

The CE mark is affixed.

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

6

EKA 100-0.3-1f PS without integrated control

1 2 3 4

1 –Duct diameter (mm)

100 –100 mm 200 –200 mm 355–355 mm 500 –500 mm

125 –125 mm 250 –250 mm 400 –400 mm

160–160 mm 315 –315 mm 450 –450 mm

2 –Heating power (kW)

0.3 –0,3 kW ... 24.0 –24,0 kW

3 –Input voltage:

1f –Single phase 230V

2f –2-phase 400V

3f –3-phase 400V

3f –3-phase 230V (on request)

4 –Additional accessories:

PS –Differential pressure switch for air flow detection

EKA NV 100-0.3-1f PTC/2NTC with integrated controller

1 2 3 4 5

1 –Control type:

NV –Potentiometer on the top of the heater casing for temperature control

NI –External wired remote setpoint knob (TR5K) for temperature control

NIS –External wired remote (0…10) VDC signal for temperature control (analog input)

ESKM –External wired remote PWM (ON/OFF: ON (6…24) VDC)signal for temperature control

MB –External wired remote temperature control via Modbus RTU protocol (RS485)

2 –Duct diameter (mm)

100 –100 mm 200 –200 mm 355 –355 mm 500 –500 mm

125 –125 mm 250 –250 mm 400 –400 mm

160–160 mm 315 –315 mm 450 –450 mm

3 –Heating power (kW)

0.3 –0,3 kW ... 24.0 –24,0 kW (NV, NI, NIS,MB)

0.3 –0,3 kW ... 15.0 –15,0 kW (ESKM)

4 –Input voltage:

1f –Single phase 230V

2f –2-phase 400V

3f –3-phase 400V

3f –3-phase 230V (on request)

Model marking

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

7

5 –Additional accessories:

PS –Differential pressure switch for air flow detection

PTC –Sensor for minimum air velocity detection

PTC/PS –Sensor for minimum air velocity detection and diff. pressure switch for air flow detection

PTC/K –Sensor for minimum air velocity detection and contactor for overheating protection

PH –Sensor for minimum air velocity detection and diff. pressure switch for air flow detection

2NTC –2 sensors for the air temperature measuring

PTC/2NTC –Sensor for min. air velocity detection and 2 sensors for the air temperature measuring

In the electrical duct heaters EKA are installed two thermostats for overheating protection. The

first one with automatic reset, turns off the heating when the temperature reaches 50 °C and turns

on when the temperature drops below 50 °C. The second with manual reset, turns off the heating

when the temperature reaches 100 °C. Only way to reset it, push the reset button on the top of the

casing (see mounting examples) when the temperature drops below 100 °C.

In the heaters EKA ESKM are installed additional thermostat (with automatic reset) for

controller ESKM overheating protection. This thermostat turns off the heating when the temperature

reaches 70 °C and turns on when the temperature drops below 70 °C.

Electrical duct heaters EKA can be installed horizontally in any position except electrical

connection box downward and vertically (only if the air flow direction upwards)(see Fig. 1).

Fig. 1. Heaters installation positions

Heaters can’t be installed in explosive and aggressive substances environment. Heaters can be

used only for the clean air heating or preheating. Heaters intended only for inside installation. If

heater is installed in such way that can be accidental contact with heating elements, protective grill

must be installed. The air velocity in the duct of the heater must be 1,5 m/s minimum.

Overheating protection

Installation and electrical connection

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

8

IMPORTANT:

The installation to the mains power supply may only be wired by a competent electrician. The

power supply cable must be selected in the ratio with power of the heater. When installing these

heaters, the standards and regulations in force in your country must be followed strictly adhered to.

Within the installation an electrical isolation automatic circuit breaker (not included) must be present,

to enable the installer to cut all power supply lines. Automatic circuit breaker must be selected

regarding power and nominal current (see the electrical rating plate on the heater casing top) of the

heater and should have characteristic B. Connect the heater to the mains power supply, check that

the voltage, frequency, power and current are the same as those indicated on the electrical rating

plate. The heater must be earthed.

We recommend install supply air temperature sensor in distance multiplied by the heater’s

diameter (3xD). For example: heater EKA diameter 200 mm, sensor’s installation distance will be:

3x200=600 mm.

Fig. 2. Mounting example EKA NV…

Fig. 3. Mounting example EKA NI…

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

9

Fig. 3. Mounting example EKA NIS…

Fig. 4. Mounting example EKA ESKM…

Fig. 5. Mounting example EKA NV…2NTC…

Fig. 6. Mounting example EKA NI…2NTC…

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

10

AHU –Air handling unit

Fig. 7. Mounting example EKA NV… (Preheater)

AHU –Air handling unit

Fig. 8. Mounting example EKA NI… (Preheater)

AHU –Air handling unit

Fig. 9. Mounting example EKA NIS… (Preheater)

AHU –Air handling unit

Fig. 10. Mounting example EKA ESKM… (Preheater)

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

11

Heaters EKA with integrated temperature controller EKR-KN… (See Fig. 11) can be controlled in

five different ways depending on control type:

Type EKA NV –potentiometer on the top of the heater casing for temperature control

Type EKA NI –external wired remote setpoint knob (TR5K) for temperature control

Type EKA NIS –external wired remote 0…10V signal for temperature control

Type EKA ESKM –external wired remote PWM (ON/OFF: ON(6…24)VDC) signal for temp. control

Type EKA MB –external wired remote temperature control via Modbus RTU protocol (RS485)

Electrical duct heaters EKA with integrated temperature controller EKR-KN… works by PID

regulator. That enable fine temperature control. Controller EKR-KN… controls load by Triacs without

moving parts, which causes no-noise commutation.

Table 1. Technical characteristics of controller EKR-KN...

Power supply depending on model

single phase 230V / 2 - phase 400V / 3 - phase 400V

Power consumption in standby mode

0,1VA

Ambient temperature

0...50 °C

Relative humidity

Max. 90 % RH (non-condensing)

Fig. 11. Print circuit board (PCB) of temperature controller EKR-KN…

(View may vary depending on type EKR-KN)

Heaters EKA with integrated controller

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

12

Heaters EKA without integrated control can be controlled with external controllers (listed

below) with one or two air temperature sensors (ordered separately), depending on operating mode.

Type

Voltage

Input/Output

Controlled

Max. load

(kW)

Additional

Steps*/Max. load

(kW)

Total load

(kW)

Controlled

Max.

current (A)

EKR 6.1

1~230/1~230

3,2

-

3,2

16

2~400/2~400

6,4

-

6,4

EKR 15.1

3~230/3~230

9

1/9

18

25

3~400/3~400

15

1/15

30

EKR 15.1P

3~230/3~230

9

4/135

144

25

3~400/3~400

15

4/225

240

EKR 30.1

3~230/3~230

15

1/15

30

45

3~400/3~400

30

1/30

60

EKR 30.1P

3~230/3~230

15

4/225

240

45

3~400/3~400

30

4/450

480

* –relay outputs (5A/230V) intended for contactors control. For more information read

controllers user guide.

External controllers for the heaters EKA

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

13

Additional accessories (ordered separately) intended for use with external and integrated

controllers are listed below:

Type

Description

Measurement range

(°C)

Setpoint range

(°C)

TJ-K10K

Duct temperature

sensor

-30...105

-

TR NTC10

Room temperature

sensor panel

-30...105

-

TR5K NTC10

Room temperature

sensor panel with

setpoint knob

-30...105

0...30

TR5K

External remote

panel with

setpoint knob

-

0...30

For more information read accessories user guide.

Additional accessories for the controllers

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

14

Heater type

Temperature control type

Setpoint range

EKA NV...

Potentiometer on the top of the heater casing

(0...30) °C*

EKA NI...

External wired remote panel with setpoint knob (TR5K)

(0...30) °C

EKA NIS...

External wired remote (0...10) VDC signal (analog input)

P**×(0...100) %

EKA ESKM...

External wired remote PWM (ON/OFF: ON (6…24) VDC) signal

P**×(0...100) %

EKA MB...

External wired remote control via Modbus RTU protocol (RS485)

(0...30) °C or

P**×(0...100) %

* –other setpoint range on request

** –power of the heater (kW)

Electrical duct heaters EKA NV …are designed with integrated temperature control, one

temperature sensor, potentiometer on the top of the heater casing for temperature setpoint.

When the heater power supply is switched on, LED 6 on the controller (EKR-KN…) PCB (see Fig.

11) flashes once every 8 seconds if setpoint is 0 °C and every second if setpoint is higher than 0 °C. If

controller turns on the heating depending on the demand, LED 5 lights (see Fig. 11).

Heaters EKA NV … operates by the supply (TJ-K10K) air temperature sensor. Setpoint

temperature (0…30) °C.

There can be set the different desired (setpoint) air temperature by potentiometer on the top

of the heater casing.

If LED 6 lights continuously it means that there is a failure of: supply (TJ-K10K) air temperature

sensor or potentiometer on the top of the heater casing.

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NI …are designed with integrated temperature control, one

temperature sensor, wired remote control panel (TR5K) for temperature setpoint.

When the heater power supply is switched on, LED 6 on the controller (EKR-KN…) PCB (see Fig.

11) flashes once every 8 seconds if setpoint is 0 °C and every second if setpoint is higher than 0 °C. If

controller turns on the heating depending on the demand, LED 5 lights (see Fig. 11).

Heaters EKA NI … operates by the supply (TJ-K10K) air temperature sensor. Setpoint

temperature (0…30) °C.

There can be set the different desired (setpoint) air temperature by wired remote control panel.

If LED 6 lights continuously it means that there is a failure of: supply (TJ-K10K) air temperature

sensor or wired remote control panel TR5K.

Description of control type

Description of operating EKA NV …

2

Description of operating EKA NI …

2

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

15

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NIS …are designed for the heaters power (0…100) % control by

analog signal input (0…10) VDC.

When the heater power supply is switched on, LED 6 on the controller (EKR-KN…) PCB (see Fig.

11) flashes every second. If controller turns on the heating depending on analog signal, LED 5 lights

(see Fig. 11).

Electrical duct heaters EKA NV … PTC … are designed with integrated temperature control, PTC

(air velocity) and temperature sensors, potentiometer on the top of the heater casing for

temperature setpoint.

When the heater power supply is switched on, controller (EKR-KN…) is in preparing mode for 30

seconds, LED 1 flashes once every 5 seconds. If there is air velocity (Min. 1,5 m/s) in the duct heater

after preparing mode, LED 1 flashes once per second and controller turns on the heating depending

on the demand, LED 2 lights. If there is no air velocity, controller don’t turns on the heating till air

velocity appears.

Heaters EKA NV … PTC … (PH) operates by the supply (TJ-K10K) air temperature sensor. Setpoint

temperature (0…30) °C.

There can be set the different desired (setpoint) air temperature by potentiometer on the top

of the heater casing.

If LED 1 lights continuously it means that there is a failure of: PTC (air velocity) sensor, supply

(TJ-K10K) air temperature sensor, potentiometer on the top of the heater casing.

When the heater power supply is switched on, after power supply interruption or after any

failure, controller is in preparing mode for 30 seconds.

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NI … PTC … (PH) are designed with integrated temperature control,

PTC (air velocity) and temperature sensors, wired remote control panel (TR5K) for temperature

setpoint.

When the heater power supply is switched on, controller (EKR-KN…) is in preparing mode for 30

seconds, LED 1 flashes once every 5 seconds. If there is air velocity (Min. 1,5 m/s) in the duct heater

after preparing mode, LED 1 flashes once per second and controller turns on the heating depending

on the demand, LED 2 lights. If there is no air velocity, controller don’t turns on the heating till air

velocity appears.

Description of operating EKA NIS …

2

Description of operating EKA NV … PTC … (PH)

2

Description of operating EKA NI … PTC … (PH)

2

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

16

Heaters EKA NI …PTC … (PH) operates by the supply (TJ-K10K) air temperature sensor. Setpoint

temperature (0…30) °C.

There can be set the different desired (setpoint) air temperature by wired remote control panel.

If LED 1 lights continuously it means that there is a failure of: PTC (air velocity) sensor, supply

(TJ-K10K) air temperature sensor, wired remote control panel TR5K.

When the heater power supply is switched on, after power supply interruption or after any

failure, controller in preparing mode for 30 seconds.

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NIS … PTC … (PH) are designed for the heaters power (0…100) %

control by analog signal input (0…10) VDC and with integrated PTC (air velocity) sensor.

When the heater power supply is switched on, controller (EKR-KN…) is in preparing mode for 30

seconds, LED 1 flashes once every 5 seconds. If there is air velocity (Min. 1,5 m/s) in the duct heater

after preparing mode, LED 1 flashes once per second and controller turns on the heating depending

on analog signal, LED 2 lights. If there is no air velocity, controller don’t turns on the heating till air

velocity appears.

If LED 1 lights continuously it means that there is a failure of PTC (air velocity) sensor.

When the heater power supply is switched on, after power supply interruption or after any

failure, controller is in preparing mode for 30 seconds.

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NV … 2NTC are designed with integrated temperature control, two

temperature sensors, potentiometer on the top of the heater casing for temperature setpoint.

When the heater power supply is switched on, LED 6 on the controller (EKR-KN…) PCB (see Fig.

11) flashes once every 8 seconds if setpoint is 0 °C and every second if setpoint is higher than 0 °C. If

controller turns on the heating depending on the demand, LED 5 lights (see Fig. 11).

Heaters EKA NV … 2NTC operates by the supply (TJ-K10K) and by the room (NTC10) air

temperature sensor. Setpoint temperature (15…30) °C. In this mode is preprogrammed the minimum

(15°C) and the maximum (45°C) temperatures of supply air. The room air temperature sensor is

mounted in the wired panel TR NTC10.

There can be set the different desired (setpoint) air temperature by potentiometer on the top

of the heater casing.

If LED 6 lights continuously it means that there is a failure of: supply (TJ-K10K) or room (NTC10)

air temperature sensor, potentiometer on the top of the heater casing.

Description of operating EKA NV … 2NTC

2

Description of operating EKA NIS … PTC … (PH)

2

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

17

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NI … 2NTC are designed with integrated temperature control, two

temperature sensors, wired remote control panel (TR5K NTC10) for temperature setpoint.

When the heater power supply is switched on, LED 6 on the controller (EKR-KN…) PCB (see Fig.

11) flashes once every 8 seconds if setpoint is 0 °C and every second if setpoint is higher than 0 °C. If

controller turns on the heating depending on the demand, LED 5 lights (see Fig. 11).

Heaters EKA NI … 2NTC operates by the supply (TJ-K10K) and by the room (NTC10) air

temperature sensor. Setpoint temperature (15…30) °C. In this mode is preprogrammed the minimum

(15°C) and the maximum (45°C) temperatures of supply air. The room air temperature sensor is

mounted in the wired remote control panel TR5K NTC10.

There can be set the different desired (setpoint) air temperature by wired remote control panel

TR5K NTC10.

If LED 6 lights continuously it means that there is a failure of: supply (TJ-K10K) or room (NTC10)

air temperature sensor, wired remote control panel TR5K NTC10.

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NV … PTC/2NTC are designed with integrated temperature control,

PTC (air velocity) and two temperature sensors, potentiometer on the top of the heater casing for

temperature setpoint.

When the heater power supply is switched on, controller (EKR-KN…) is in preparing mode for 30

seconds, LED 1 flashes once every 5 seconds. If there is air velocity (Min. 1,5 m/s) in the duct heater

after preparing mode, controller turns on the heating depending on the demand, LED 2 lights. If there

is no air velocity, controller don’t turns on the heating till air velocity appears.

Heaters EKA NV … PTC/2NTC can operate in two modes:

1. Control by the supply air temperature sensor (TJ-K10K), when the first (1) switch of JP1 (see

Fig. 11) is in position OFF. LED 1 flashes once per second. Setpoint temperature (0…30) °C.

2. Control by the supply (TJ-K10K) and by the room (NTC10) air temperature sensor, when the

first (1) switch of JP1 (see Fig. 11) is in position ON. LED 1 flashes twice per second. Setpoint

temperature (15…30) °C. In this mode is preprogrammed the minimum (15°C) and the

maximum (40°C) temperatures of supply air. The room air temperature sensor is mounted

in the wired panel TR NTC10.

Depending on the operating mode there can be set the different desired (setpoint) air

temperature by potentiometer on the top of the heater casing.

Description of operating EKA NV … PTC/2NTC

2

Description of operating EKA NI … 2NTC

2

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

18

If LED 1 lights continuously it means that there is a failure of: PTC (air velocity) sensor, supply

(TJ-K10K) or room (NTC10) air temperature sensor, potentiometer on the top of the heater casing.

When the heater power supply is switched on, after power supply interruption or after any

failure, controller is in preparing mode for 30 seconds.

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Electrical duct heaters EKA NI … PTC/2NTC are designed with integrated temperature control,

PTC (air velocity) and two temperature sensors, wired remote control panel (TR5K NTC10) for

temperature setpoint.

When the heater power supply is switched on, controller (EKR-KN…) is in preparing mode for 30

seconds, LED 1 flashes once every 5 seconds. If there is air velocity (Min. 1,5 m/s) in the duct heater

after preparing mode, controller turns on the heating depending on the demand, LED 2 lights. If there

is no air velocity, controller don’t turns on the heating till air velocity appears.

Heaters EKA NI … PTC/2NTC can operate in two modes:

1. Control by the supply air temperature sensor (TJ-K10K), when the first (1) switch of JP1 (see

Fig. 11) is in position OFF. LED 1 flashes once per second. Set point temperature (0…30) °C.

2. Control by the supply (TJ-K10K) and by the room (NTC10) air temperature sensor, when the

first (1) switch of JP1 (see Fig. 11) is in position ON. LED 1 flashes twice per second. Setpoint

temperature (15…30) °C. In this mode is preprogrammed the minimum (15°C) and the

maximum (40°C) temperatures of supply air. The room air temperature sensor is mounted

in the wired remote control panel TR5K NTC10.

Depending on the operating mode there can be set the different desired (setpoint) air

temperature by wired remote control panel TR5K NTC10.

If LED 1 lights continuously it means that there is a failure of: PTC (air velocity) sensor, supply

(TJ-K10K) or room (NTC10) air temperature sensor, wired remote control panel TR5K NTC10.

When the heater power supply is switched on, after power supply interruption or after any

failure, controller is in preparing mode for 30 seconds.

IMPORTANT: If failure appears, power supply must be switched off and only then performed

fault elimination works.

Description of operating EKA NI … PTC/2NTC

2

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

19

Electrical duct heaters EKA MB … can communicate via Modbus RTU. Connected to the system

EKA MB … is a Slave device. Modbus settings are shown in table 2.

Table 2. Modbus settings

Setting

Possible values

Default value

Device address

1...247

10

Baud rate

2400, 4800, 9600, 19200, 38400

9600

Parity

None, Even, Odd

None

Stop bit

None, 1, 2

1

There is connection provided on the PCB for Modbus (see Fig. 11). Connector pin layout and

meanings are shown in Fig. 12.

Fig. 12. Connector for Modbus control

+12VDC

B-

A+

GND

For detailed information about control via Modbus please contact manufacturer.

Description of operating EKA MB …

2

This manual suits for next models

33

Table of contents

Popular Electric Heater manuals by other brands

Reznor

Reznor EWHB owner's manual

Fahrenheat

Fahrenheat FLCH4R Installation, operation & maintenance instructions

Strend Pro

Strend Pro EXO1-33 instruction manual

Trox

Trox TVZ manual

Orbegozo

Orbegozo BB 4000 instruction manual

Electric Radiators Direct

Electric Radiators Direct Haverland RC Wave Instructions for making settings